cutting machine head

A technology of cutting machine and machine head, which is applied in the cutting of textile materials, textiles and papermaking, metal processing, etc. It can solve the problems of no vibration damping device, large noise, and no installation, so as to prolong life, reduce noise, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the utility model is described further.

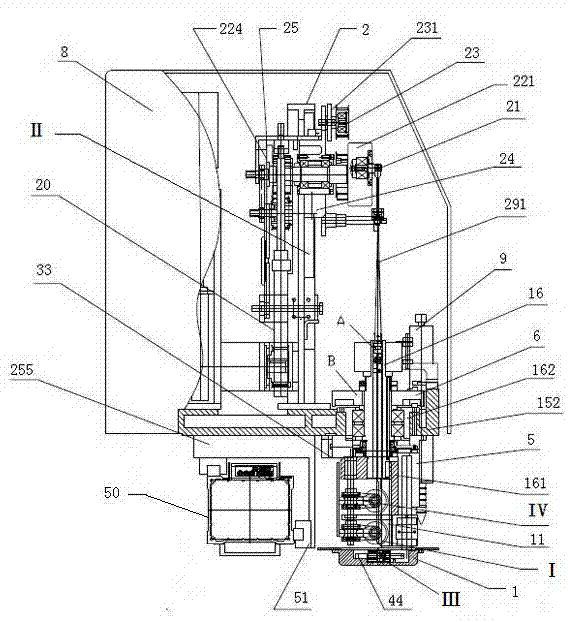

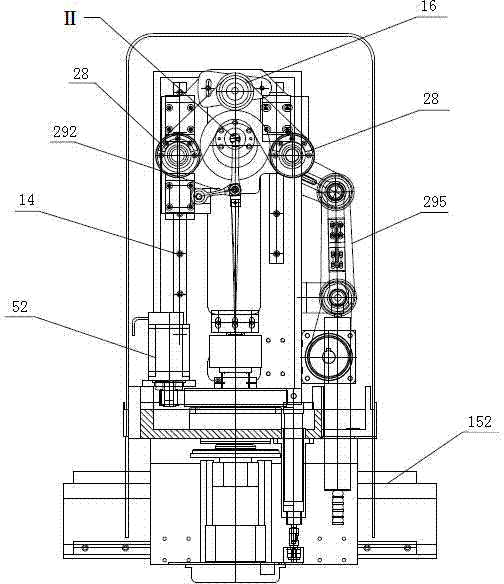

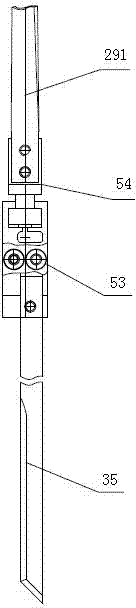

[0033] see Figure 1 to Figure 16 , The head of the cutting machine in this embodiment includes a material pressing and knife feeding device I, a vibration damping device II, a tool deviation correction device III and a knife sharpening device IV.

[0034] The sharpening device IV in this embodiment is located at the upper part of the machine head, the tool deviation correction device III, the sharpening device IV and the pressing and knife-feeding device I are located at the lower part of the whole machine, and the pressure plate 1 on the pressing and knife-feeding device I The elastic arm 34 is connected, and the tool deviation correction device III is arranged on the elastic arm 34. The material pressing and knife-feeding device I is connected with the machine head horizontal fixing frame 152 on the head of the whole machine through the rotating shaft, and the shar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com