Patents

Literature

87results about How to "The detection value is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

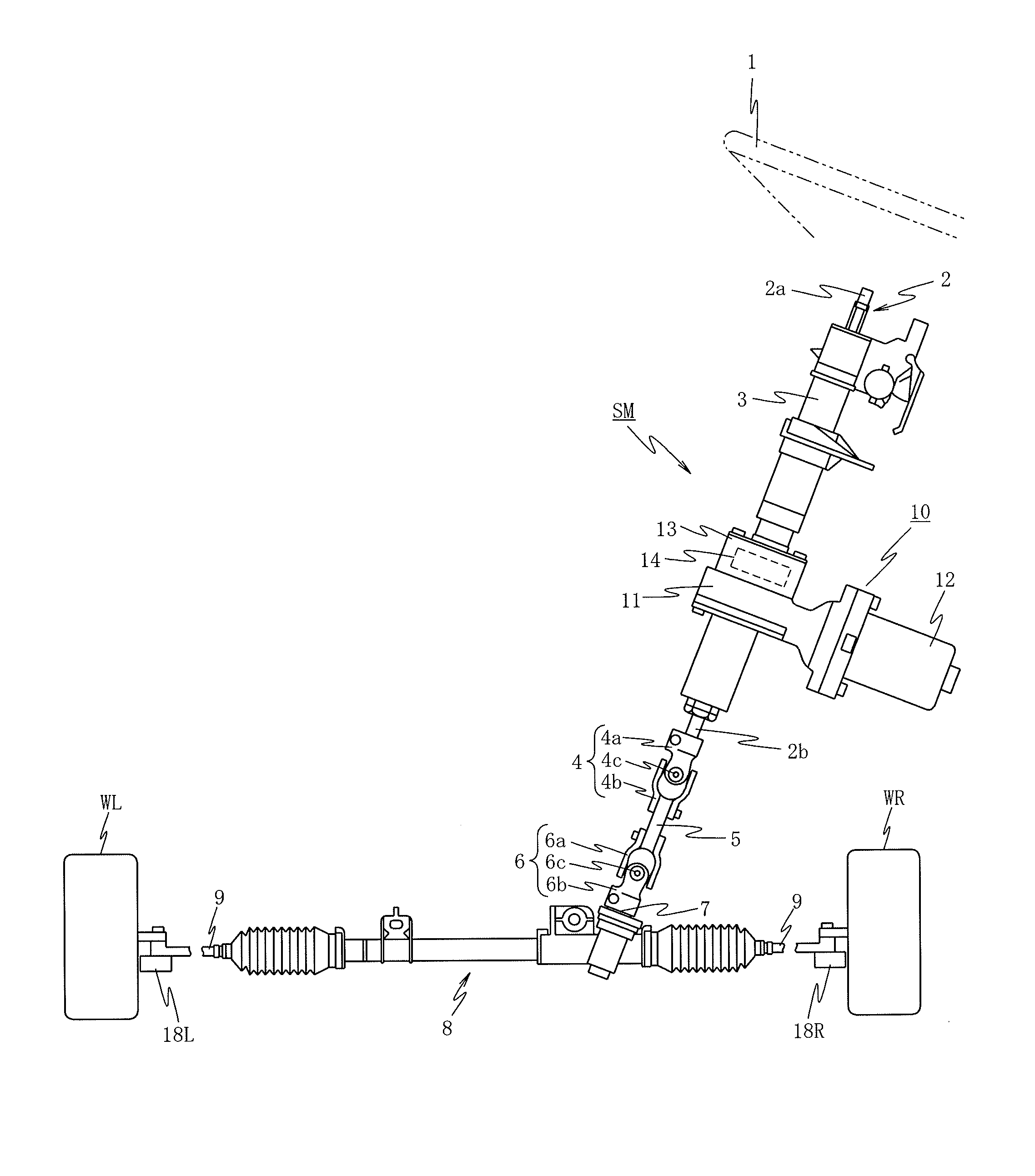

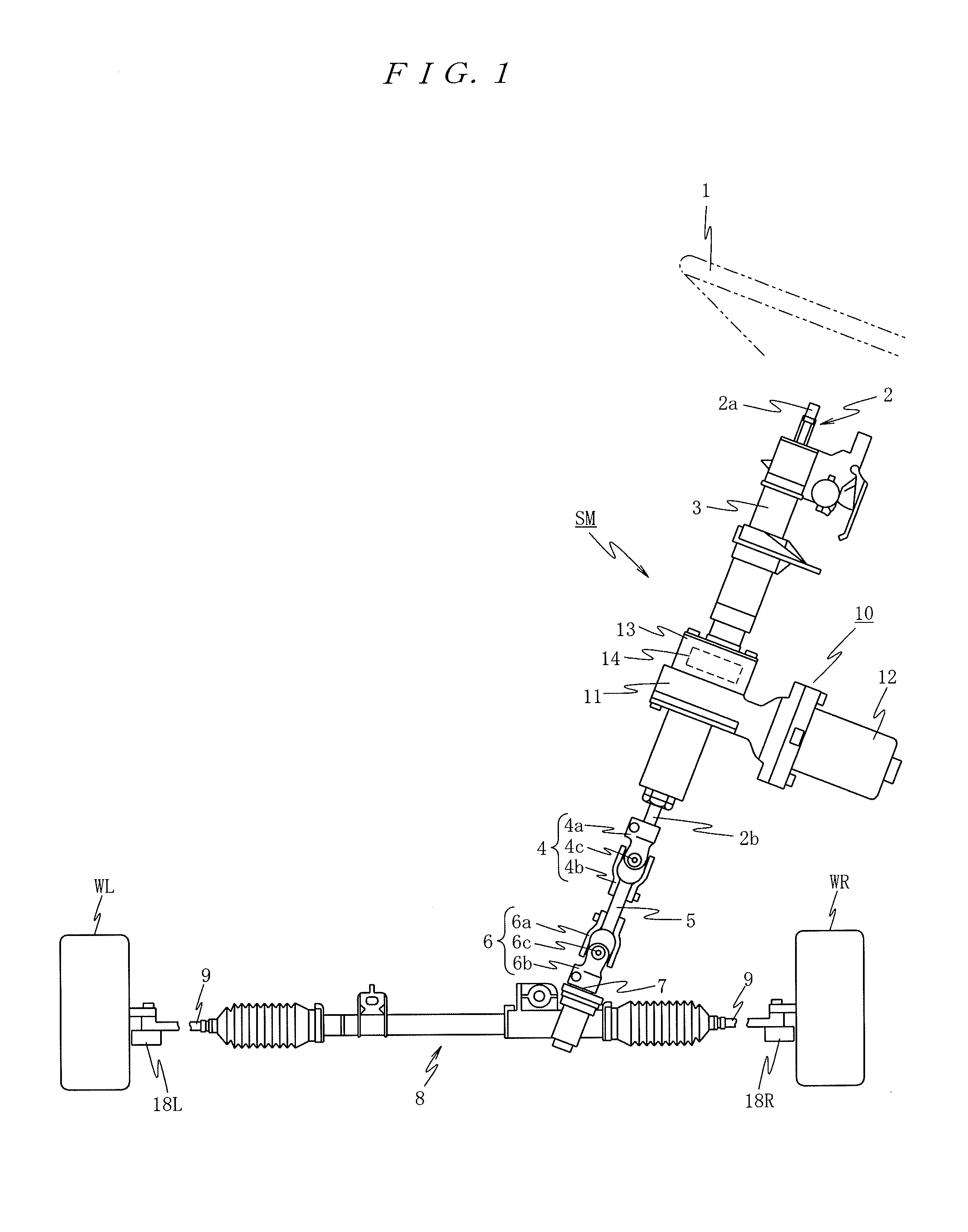

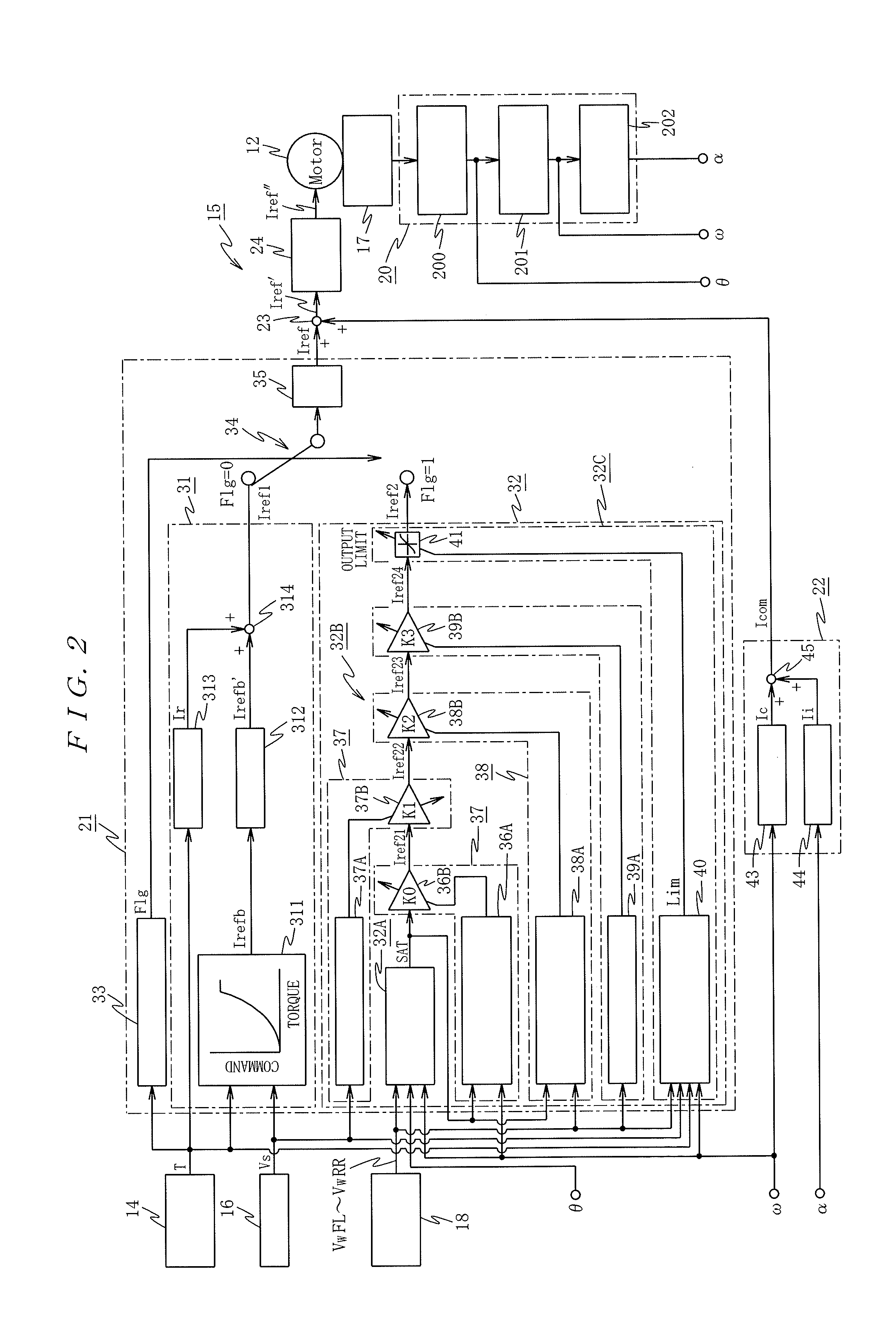

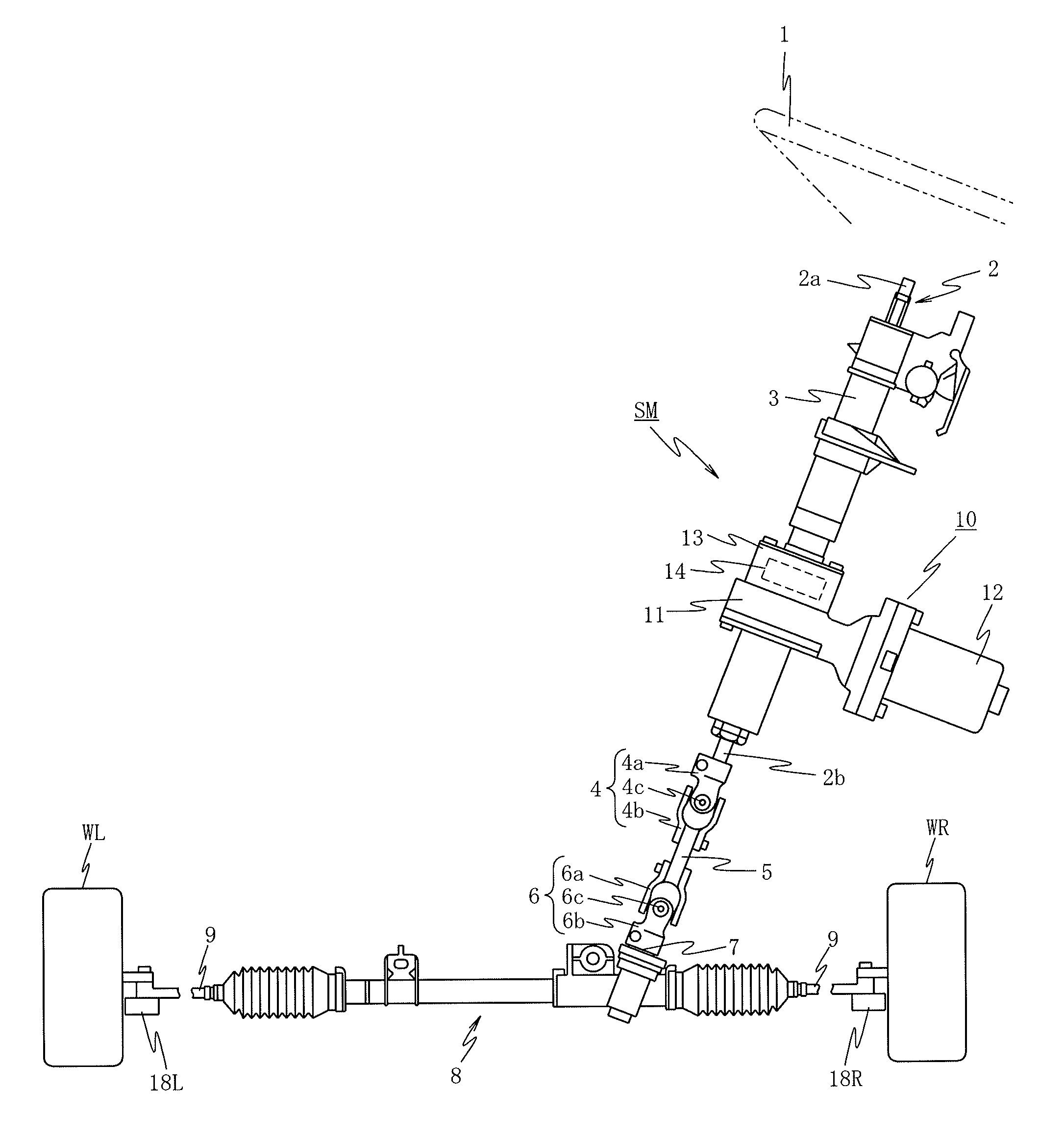

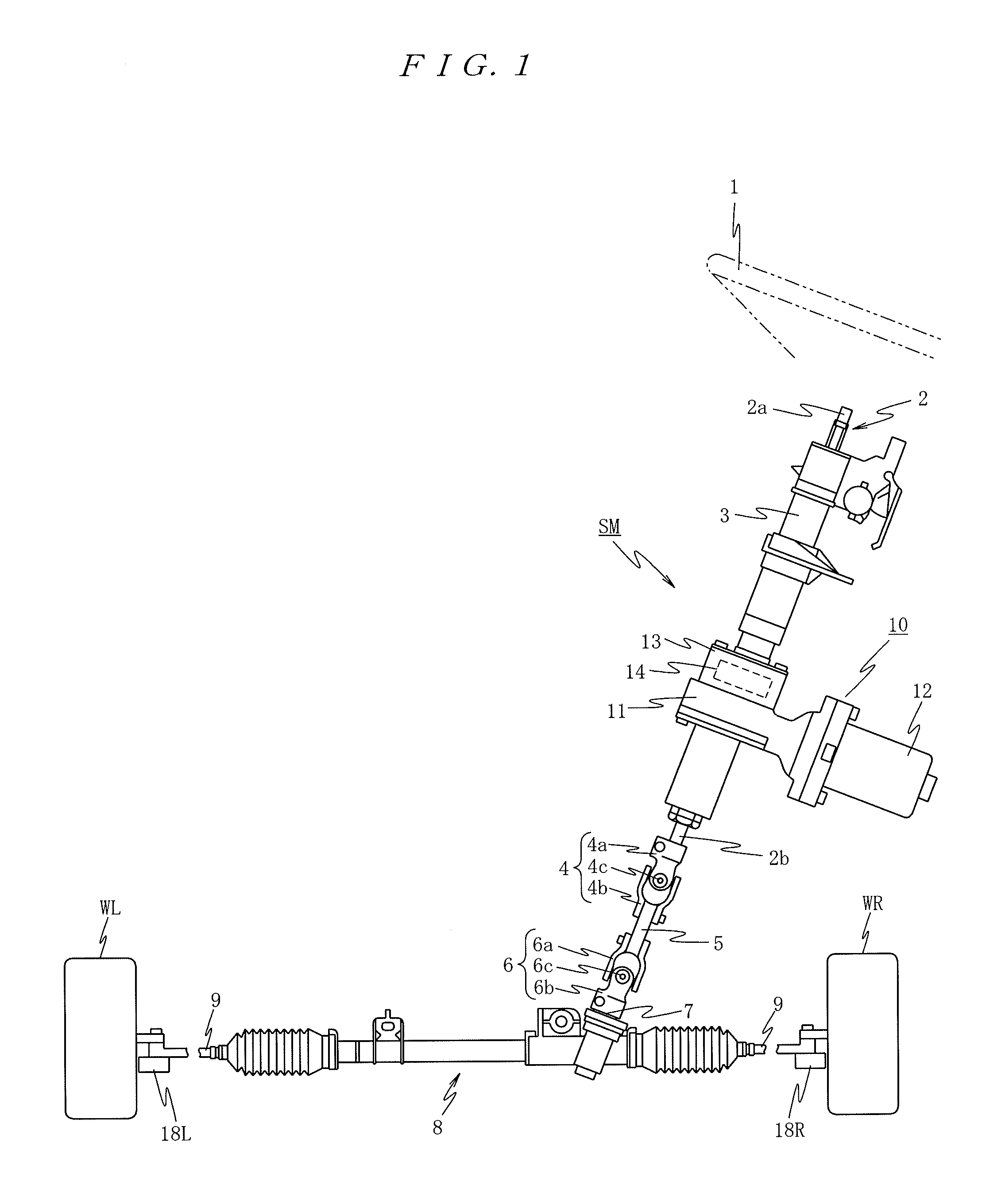

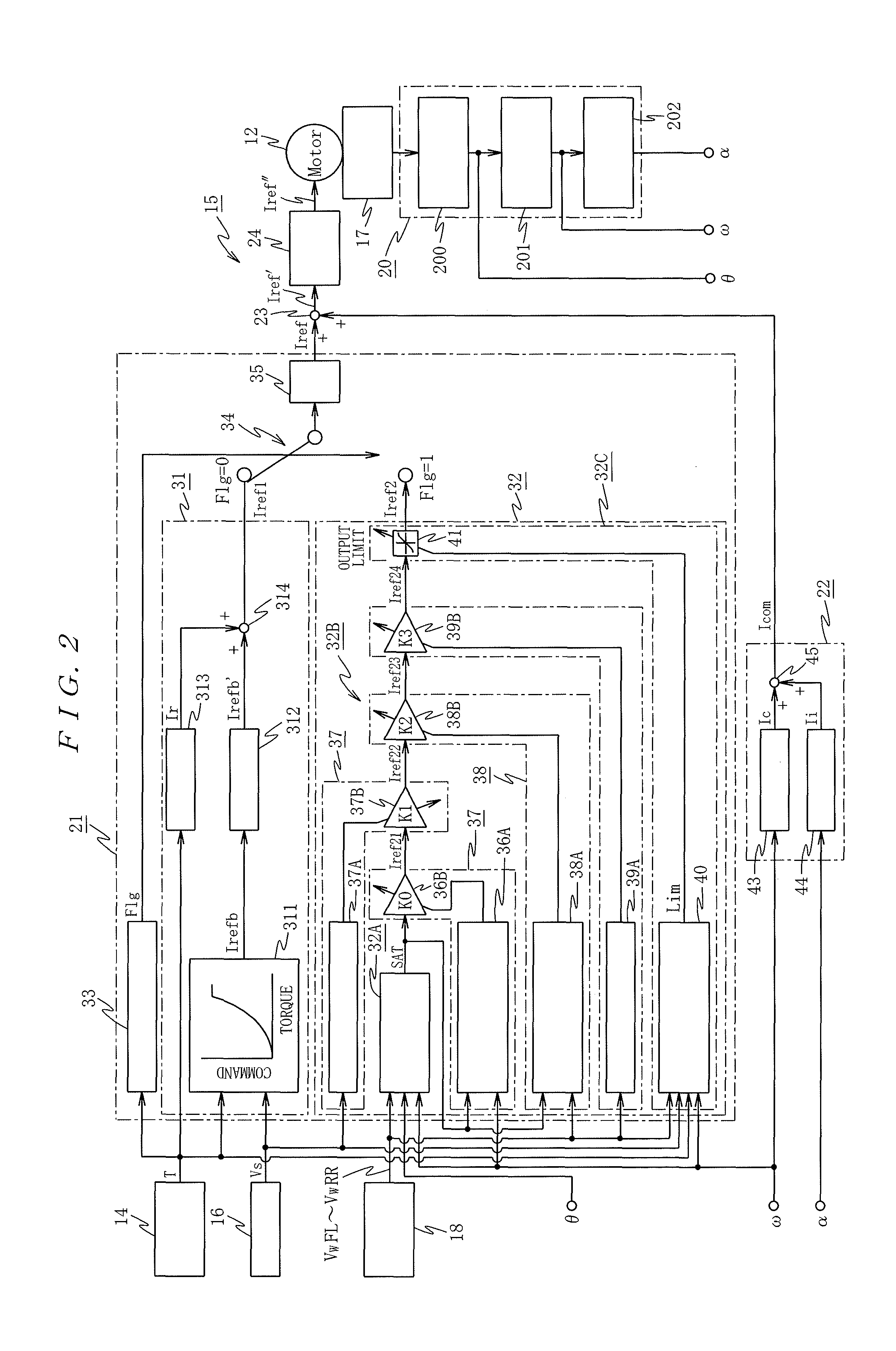

Electric Power Steering Apparatus

InactiveUS20130261894A1Accurate torque detecting valueThe detection value is accurateSteering initiationsDigital data processing detailsRotation velocityElectric power steering

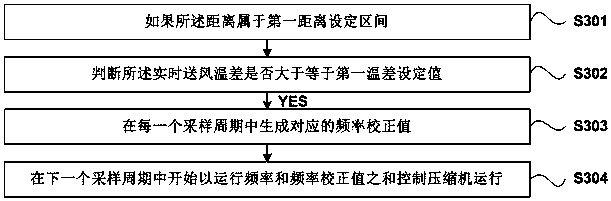

An electric power steering apparatus includes a first torque calculating unit for calculating a first torque command based on a steering torque detected by the steering torque detecting unit, a second torque command calculating unit for calculating a second torque command based on the wheel rotation speed, an emergency switching unit for outputting the second torque command instead of the first torque command when error of the rotation torque is detected, a wheel rotation speed error detecting unit for detecting an error of the wheel rotation speed based at least on the wheel rotation speed, the steering torque in a normal state and the motor rotation information, and an emergency command limiting unit for liming the second torque command when normal and the motor rotation information, and where error of the wheel rotation speed is detected, when the second torque command is selected by the emergency switching unit.

Owner:NSK LTD

Automobile fuel quantity signal indicating system and fuel quantity computing method

InactiveCN102980624AShield measurement deviationAccurate fuel remainingMachines/enginesLevel indicatorsAutomotive engineeringMemory module

The invention provides an accurate and highly reliable automobile fuel quantity signal indicating system and a fuel quantity computing method. According to the automobile fuel quantity signal indicating system and the fuel quantity computing method, the automobile fuel quantity signal indicating system comprises a fuel liquid level sensor, an engine control unit and an indicating unit which is provided with a memory module and a computation module. The indicating unit is respectively connected with the fuel liquid level sensor and the engine control unit. The automobile fuel quantity signal indicating system is formed merely by modifying the existing parts. The fuel quantity computing method can detect fuel liquid levels by using the fuel liquid level sensor in a static state, so that accurate detected values can be obtained, and moreover, actual fuel consumption can be acquired merely through an engine control system in the driving process, and thus the measured deviation of the fuel liquid level sensor under a bumping condition is removed to enable current residual fuel which is obtained finally through computation to be accurate as far as possible.

Owner:CHERY AUTOMOBILE CO LTD

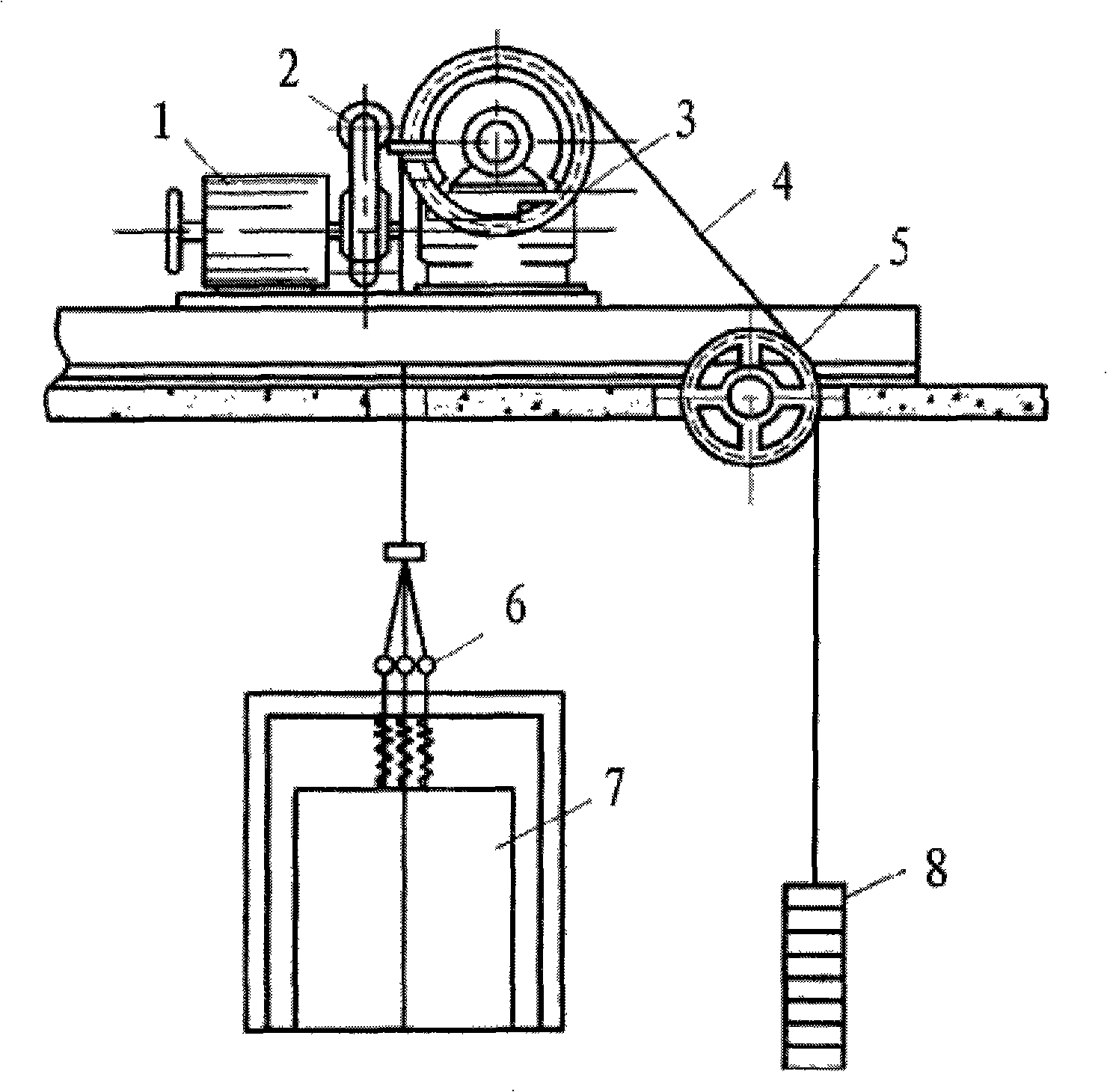

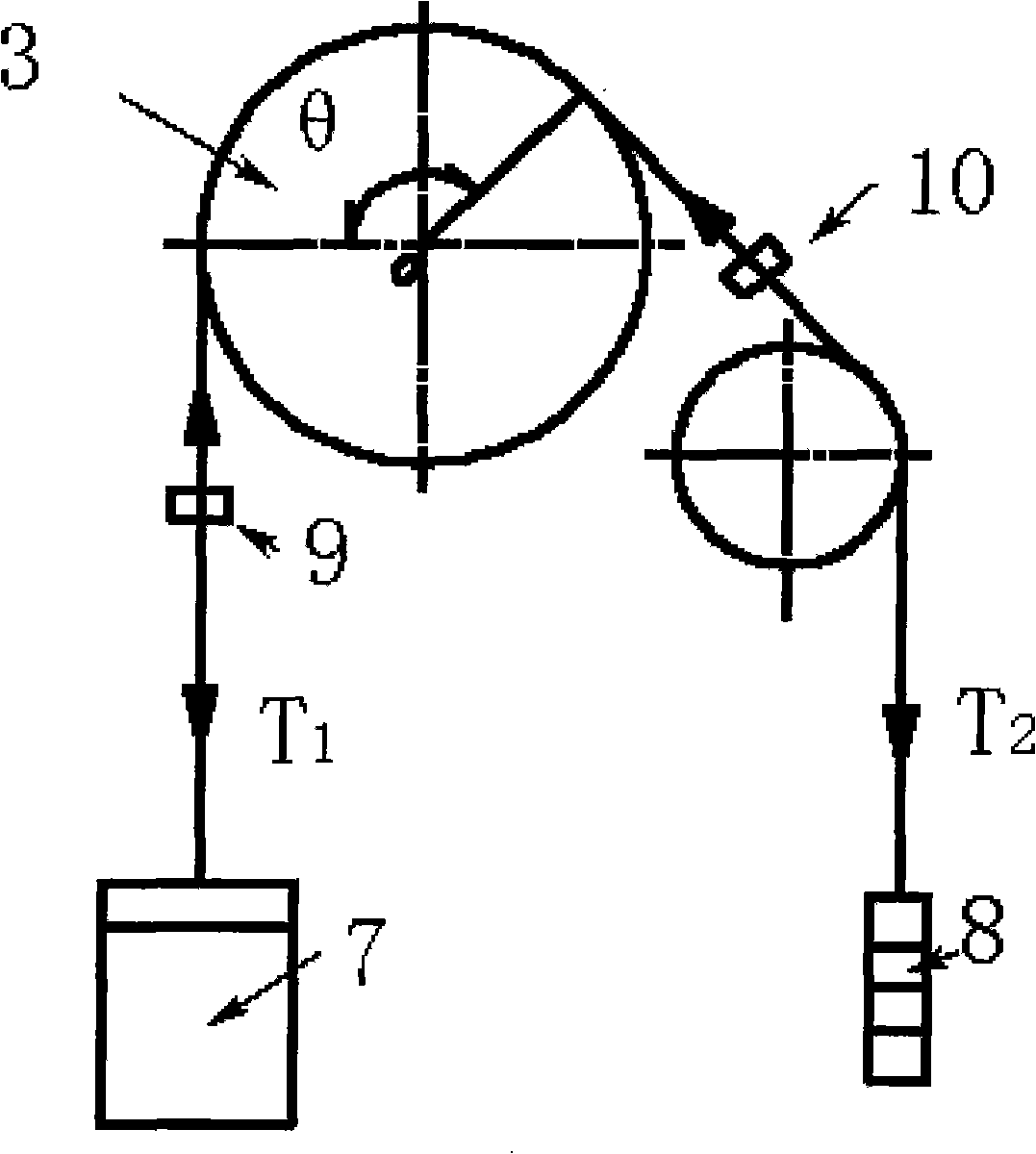

Elevator non-load traction capacity detecting method

InactiveCN101537955AThe detection value is accurateEffective detection dataElevatorsRelative displacementGear wheel

The invention relates to an elevator non-load traction capacity detecting method, belonging to the elevator detecting technical field. The method comprises the steps as follows: firstly, a carriage and a counter-weight side wire cable are fixed, thereby preventing relative displacement between wire cables at the two sides of a traction sheave; secondly, an elevator tractor brake is released so that a reducer gear is in free status and the value of a sensor fixed on a counter-weight side wire cable is read; the traction sheave rotates along clockwise direction until the relative sliding between the traction sheave and a traction cable occurs, and then the valve on a counter-weight side pressure sensor is read; and finally, a traction sheave rotates along counter clockwise direction until the relative sliding occurs between the clockwise direction and the traction cable and the value on the counter-weight side pressure sensor is recorded. The detected data are treated so as to finally obtain maximum carriage static load of an elevator tractor system. The method has the advantage that the practically detected value is used in computing formula to the maximum and the theoretical value or the guess value is reduced as much as possible, thereby obtaining a more precise detected value.

Owner:北京市朝阳区特种设备检测所

Electric power steering apparatus

InactiveUS8977433B2The detection value is accurateDigital data processing detailsSteering initiationsElectric power steeringElectric machine

An electric power steering apparatus includes a first torque calculating unit for calculating a first torque command based on a steering torque detected by the steering torque detecting unit, a second torque command calculating unit for calculating a second torque command based on the wheel rotation speed, an emergency switching unit for outputting the second torque command instead of the first torque command when error of the rotation torque is detected, a wheel rotation speed error detecting unit for detecting an error of the wheel rotation speed based at least on the wheel rotation speed, the steering torque in a normal state and the motor rotation information, and an emergency command limiting unit for liming the second torque command when normal and the motor rotation information, and where error of the wheel rotation speed is detected, when the second torque command is selected by the emergency switching unit.

Owner:NSK LTD

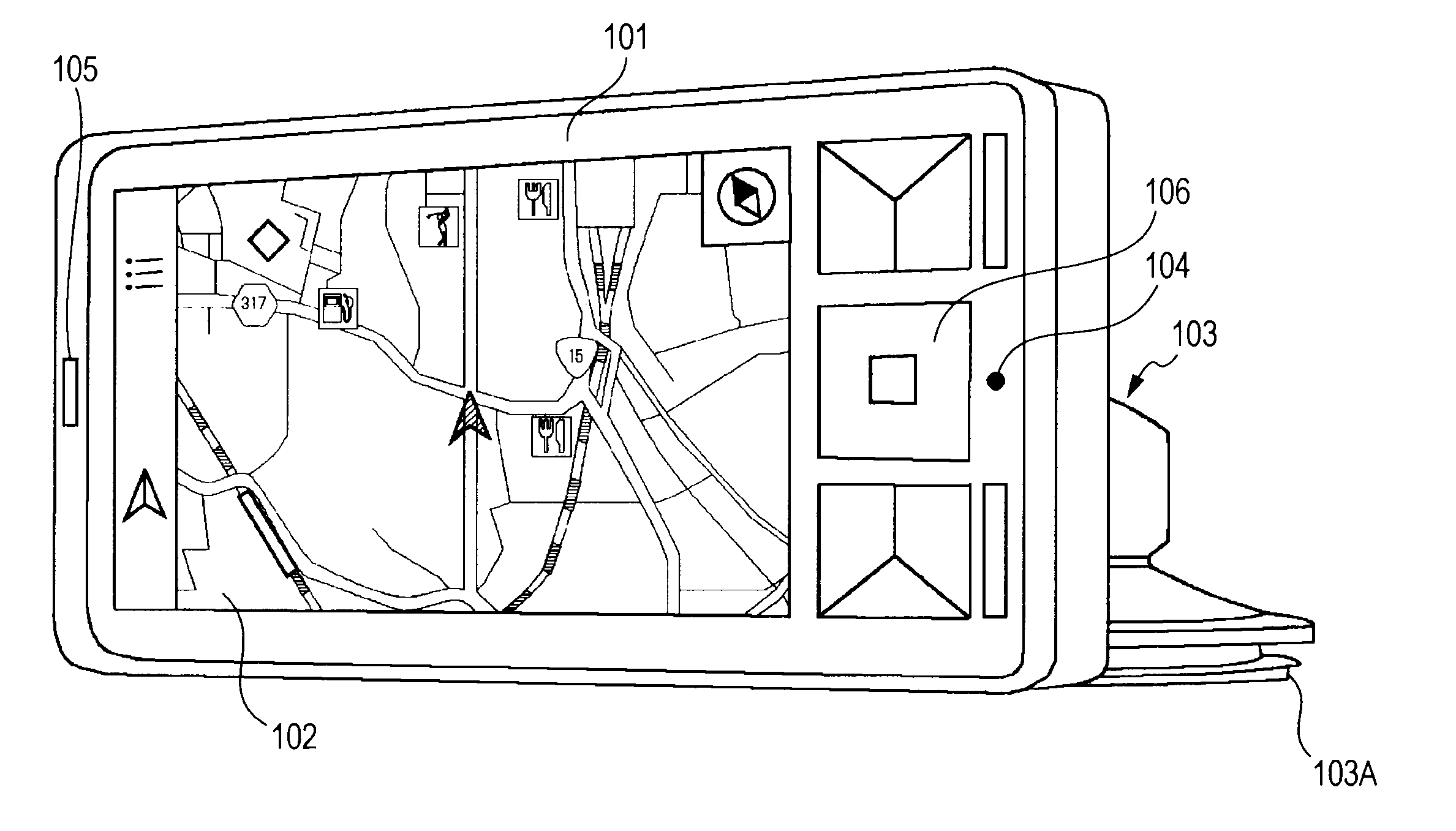

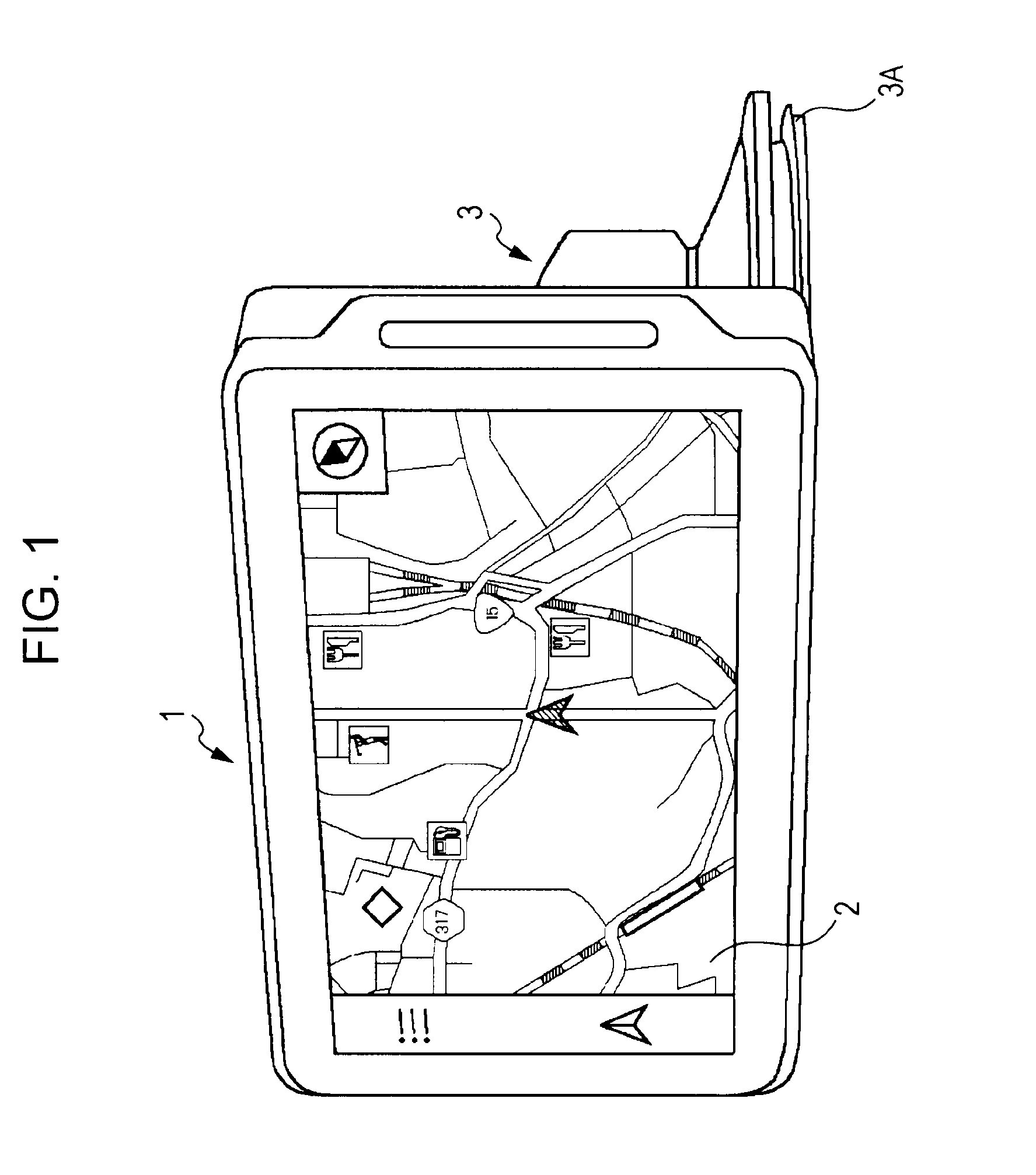

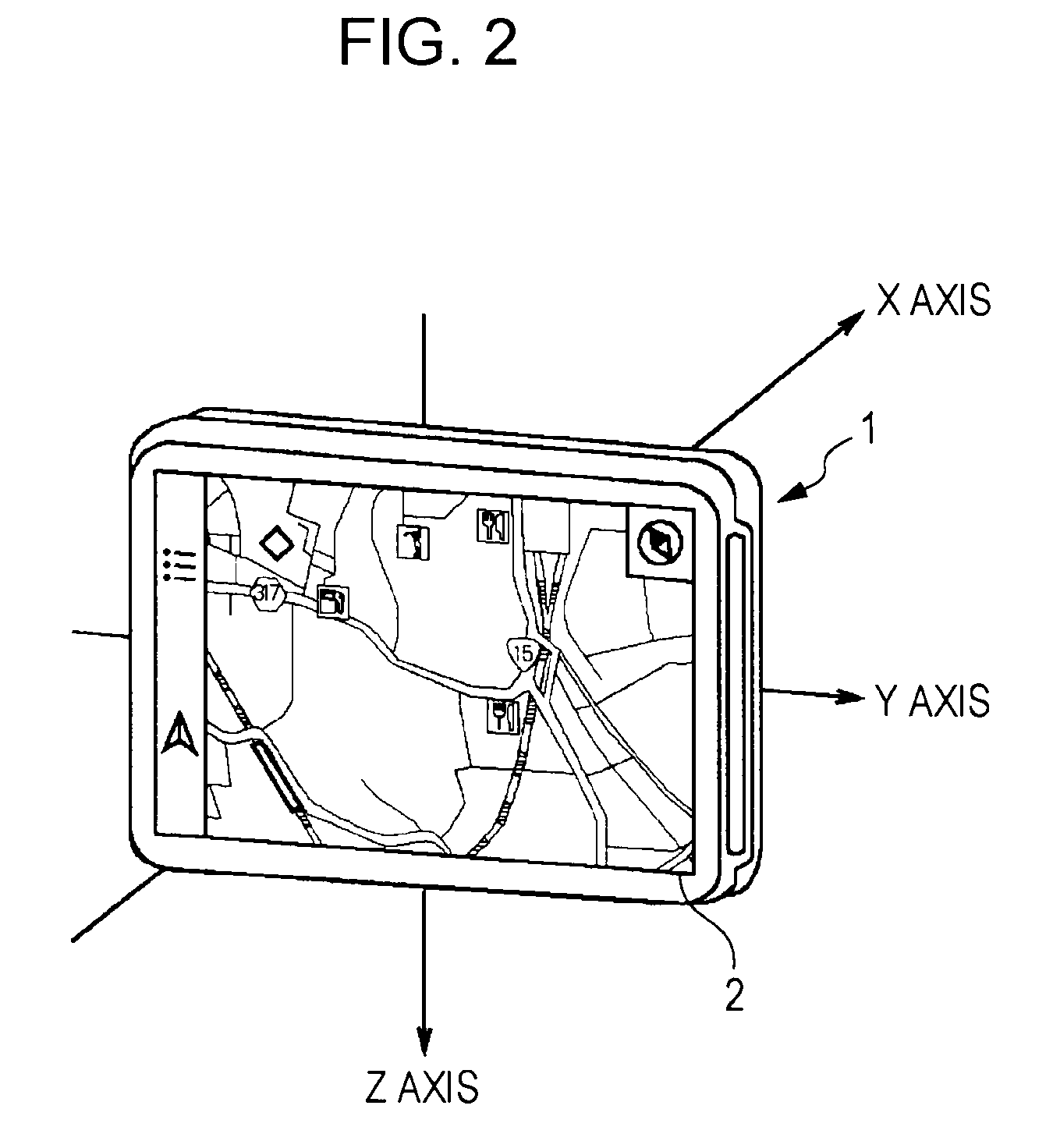

Angular velocity correction device, angular velocity correction method, navigation device, and cellular phone having navigation function

InactiveUS20110065473A1Accurate removalImprove accuracyRoad vehicles traffic controlNavigation by speed/acceleration measurementsAxis–angle representationHorizontal axis

An angular velocity correction device includes a horizontal angular velocity detection unit to detect horizontal axis angular velocity, that is mounted on a main unit attached to a moving object that moves along a predetermined movement surface, and that is made up of angular velocity around the horizontal axis which is orthogonal to the advancing direction of the moving object, occurring according to the inclination angle of the movement surface; a correction value generating unit to generate a correction value for correcting the horizontal axis angular velocity, based on the horizontal axis angular velocity that satisfies predetermined horizontal determining conditions of the horizontal axis angular velocity in the past; and a correction unit to correct the horizontal axis angular velocity using the correction value.

Owner:SONY CORP

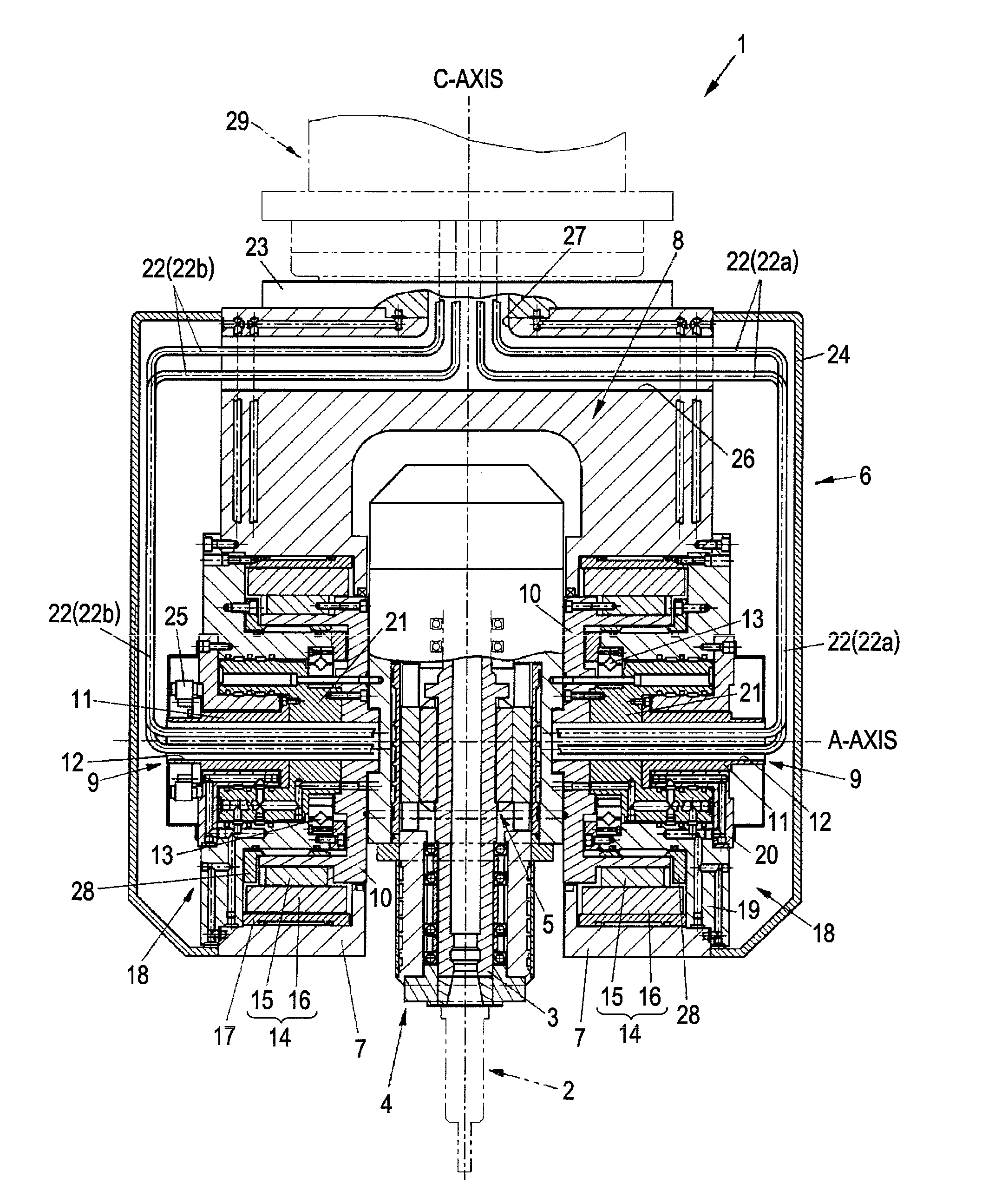

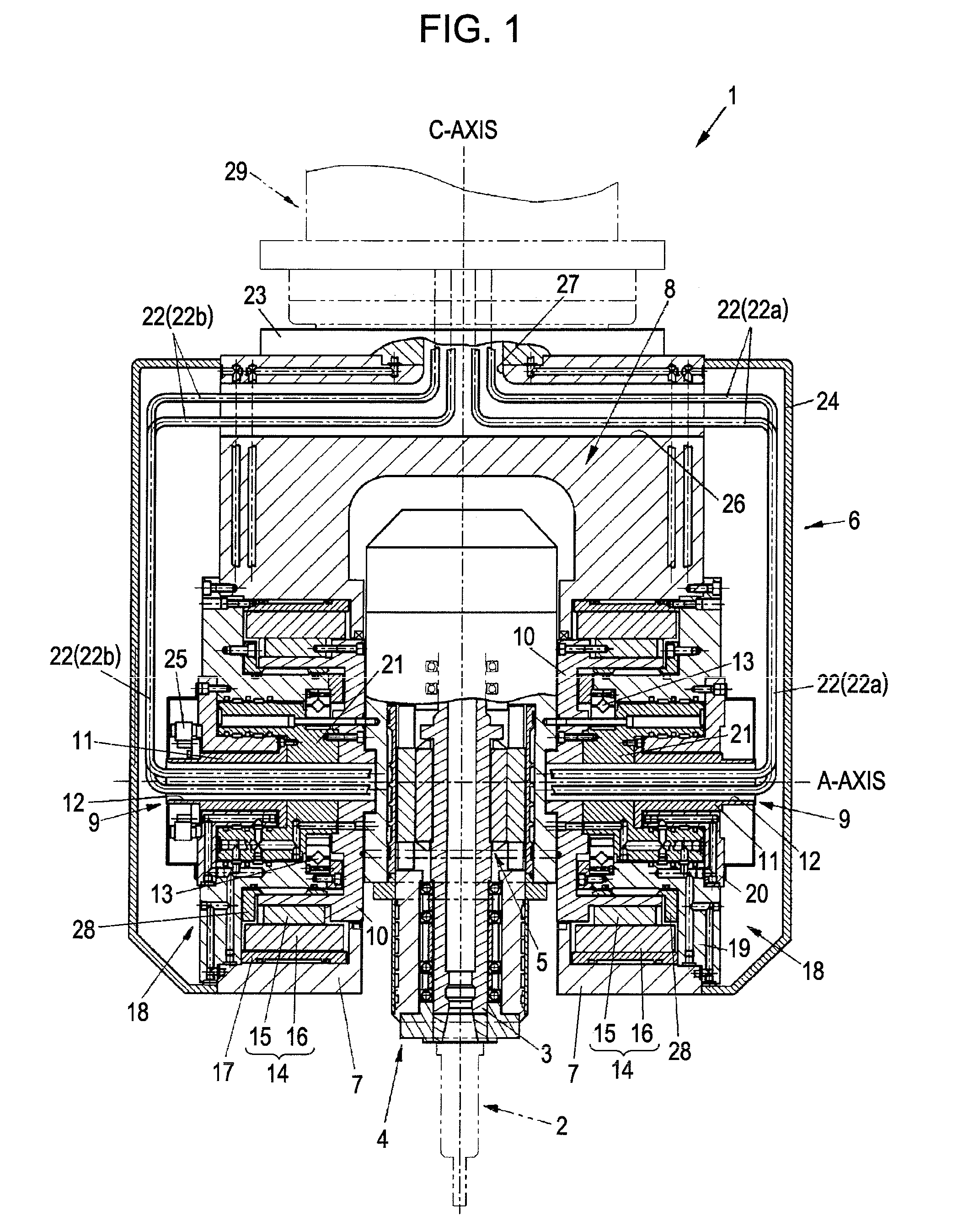

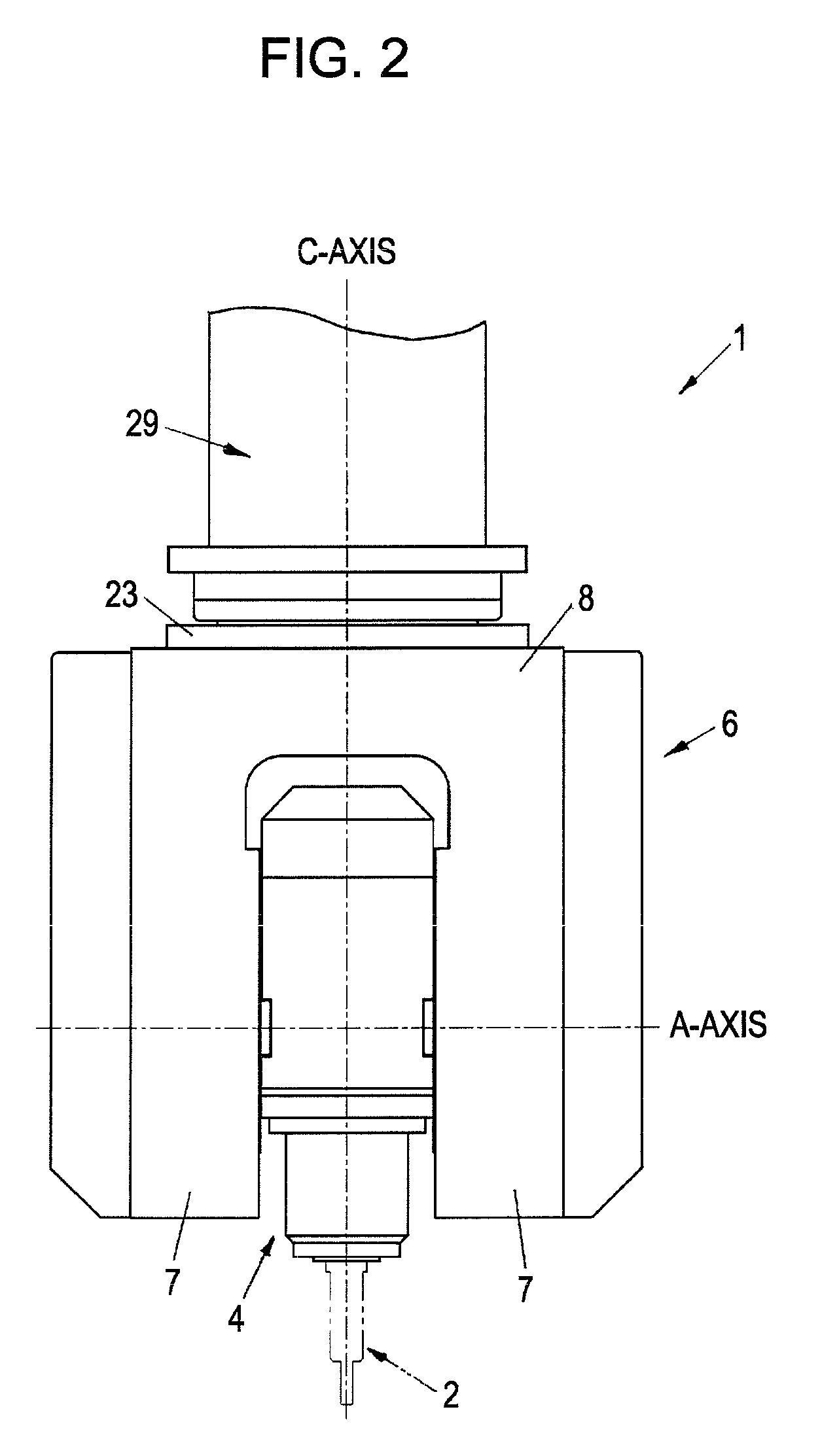

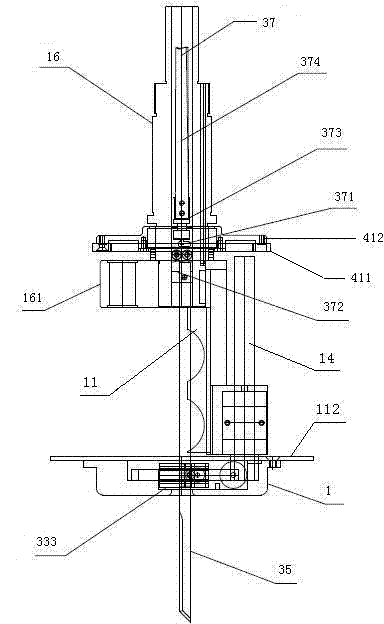

Spindle head for machine tool

InactiveUS7938603B2Large spatial roomMinimize occurrenceMachine tool componentsMilling machinesEngineeringMachine tool

Owner:TSUDAKOMA KOGYO KK

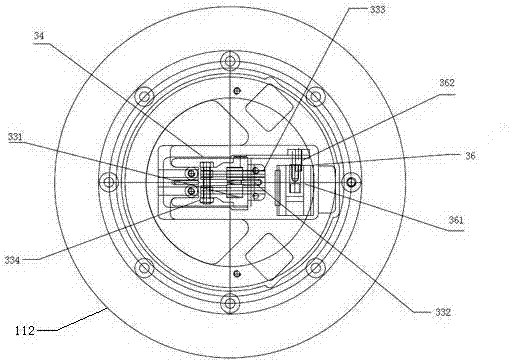

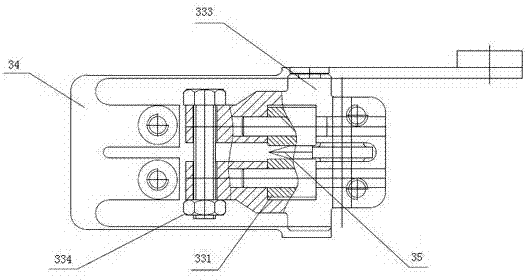

Tool deviation correcting device for cutting machine head

ActiveCN103112039ARealize synchronous rotationThe detection value is accurateMetal working apparatusEngineeringMechanical engineering

The invention relates to a cutter deviation correcting device for a cutting machine head and belongs to the field of cutting machines. The cutter deviation correcting device for the cutting machine head comprises a pressure plate and a cutter apron and further comprises a guide wheel support, pressure wheels and a position sensor arranged on an elastic arm. The guide wheel support is arranged on the pressure plate. The pressure wheel and a rear pressure wheel are arranged on the guide wheel support. The guide wheel support is connected with the pressure plate through the elastic arm. The guide wheel support, the elastic arm and the pressure plate are combined as a whole. The cutter apron comprises a pressure block, a cutter fixing square core, a rotary core and an elastic connecting rod. The rotary core is movably arranged between the pressure block and the cutter fixing square core. The rotary core is connected with the elastic connecting rod. The cutter deviation correcting device solves the problem of torsion of a cutter caused by extrusion of the cutter by a material in the process of cutting so that the cutter is prevented from being broken, deviation is reduced, a gap is adjusted in real time and quality of a product is guaranteed.

Owner:HANGZHOU ECHO SCI TECH

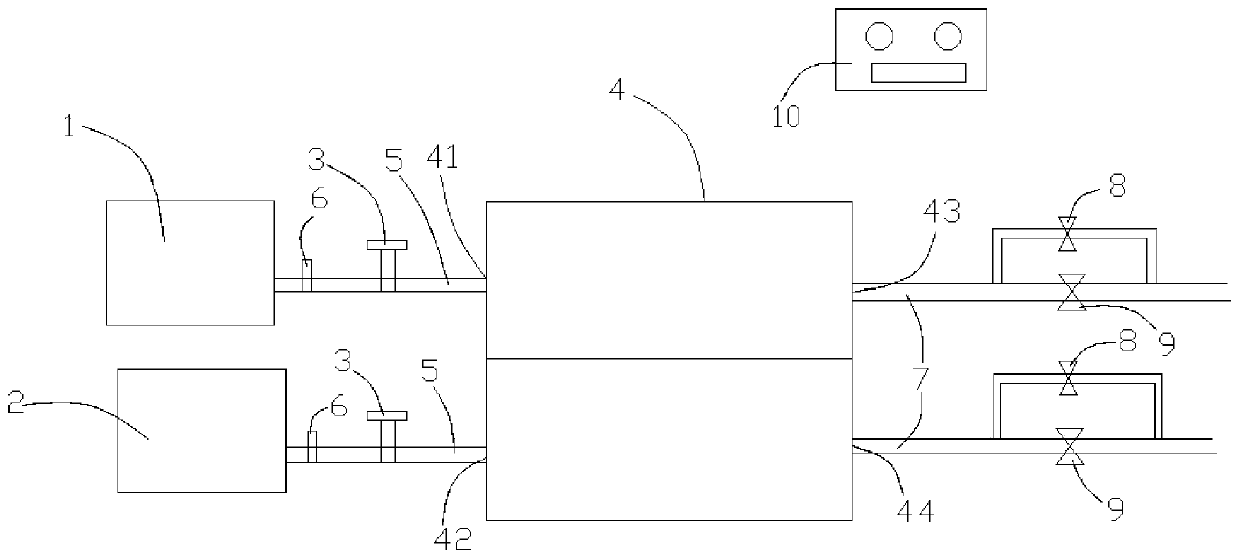

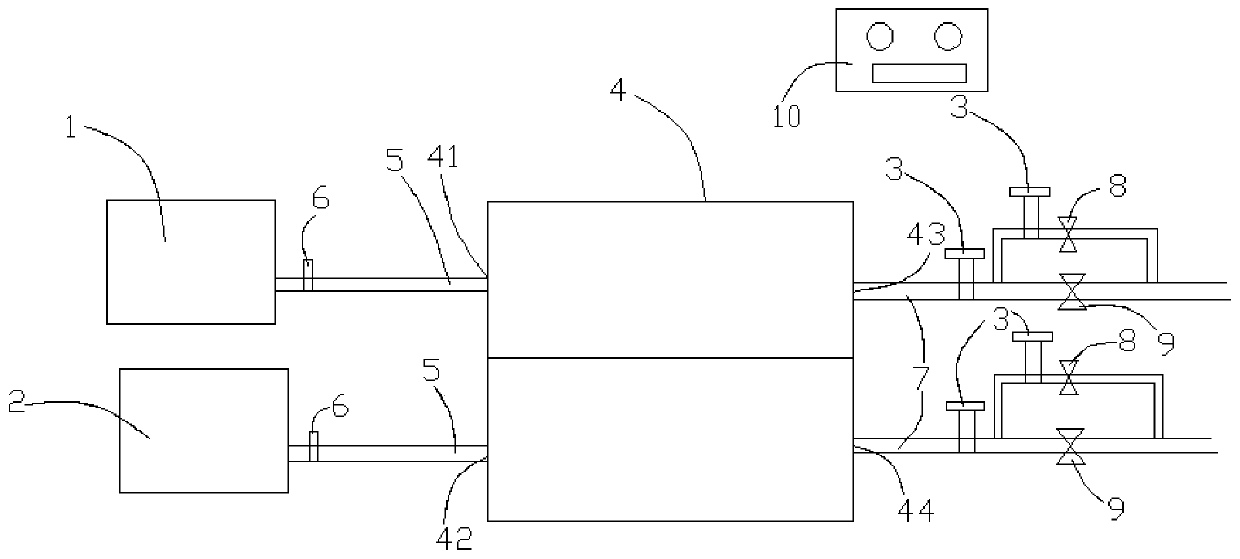

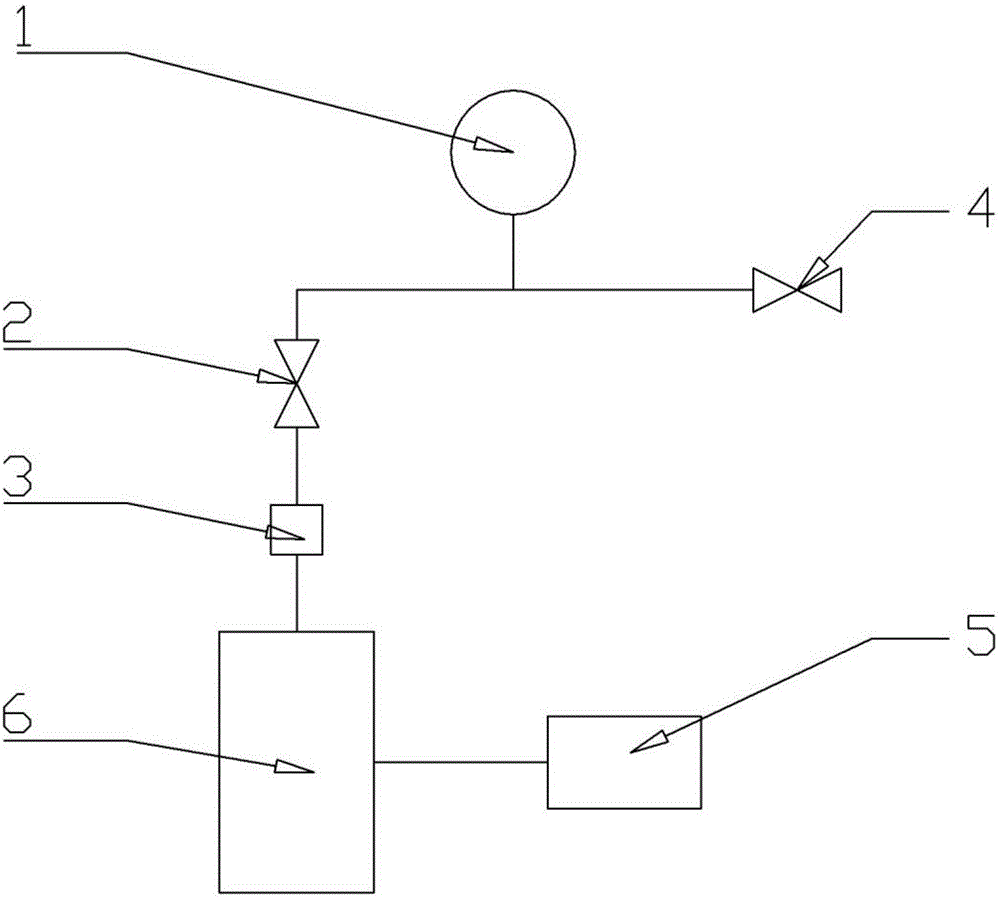

Fuel cell stack test board and back pressure control method thereof

The invention discloses a fuel cell stack test board and a back pressure control method thereof. The test board comprises a hydrogen system and an air system. The hydrogen system is communicated witha hydrogen inlet of a fuel cell stack through an air inlet pipeline; the air system is communicated with an air inlet of the fuel cell stack through an air inlet pipeline; flow meters for detecting the flow of the air inlet pipelines are arranged on the air inlet pipelines; a hydrogen outlet and an air outlet of the fuel cell stack are respectively provided with an air outlet pipeline; first backpressure valves and second back pressure valves are arranged on the air outlet pipelines in parallel; the back pressure range of the first back pressure valve is smaller than that of the second back pressure valve; and pressure sensors used for detecting the pressure are arranged on pipeline sections between the air inlet pipeline or / and the air outlet pipeline and the first back pressure valve and between the air inlet pipeline or / and the air outlet pipeline and the second back pressure valve. According to the back pressure control method, double back pressure valves and two-way control are utilized, and back pressure control is rapidly achieved through different flow, higher-precision control is realized, and meanwhile, the coverage of a larger power range is realized, and the cost of the test board of a client is saved.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

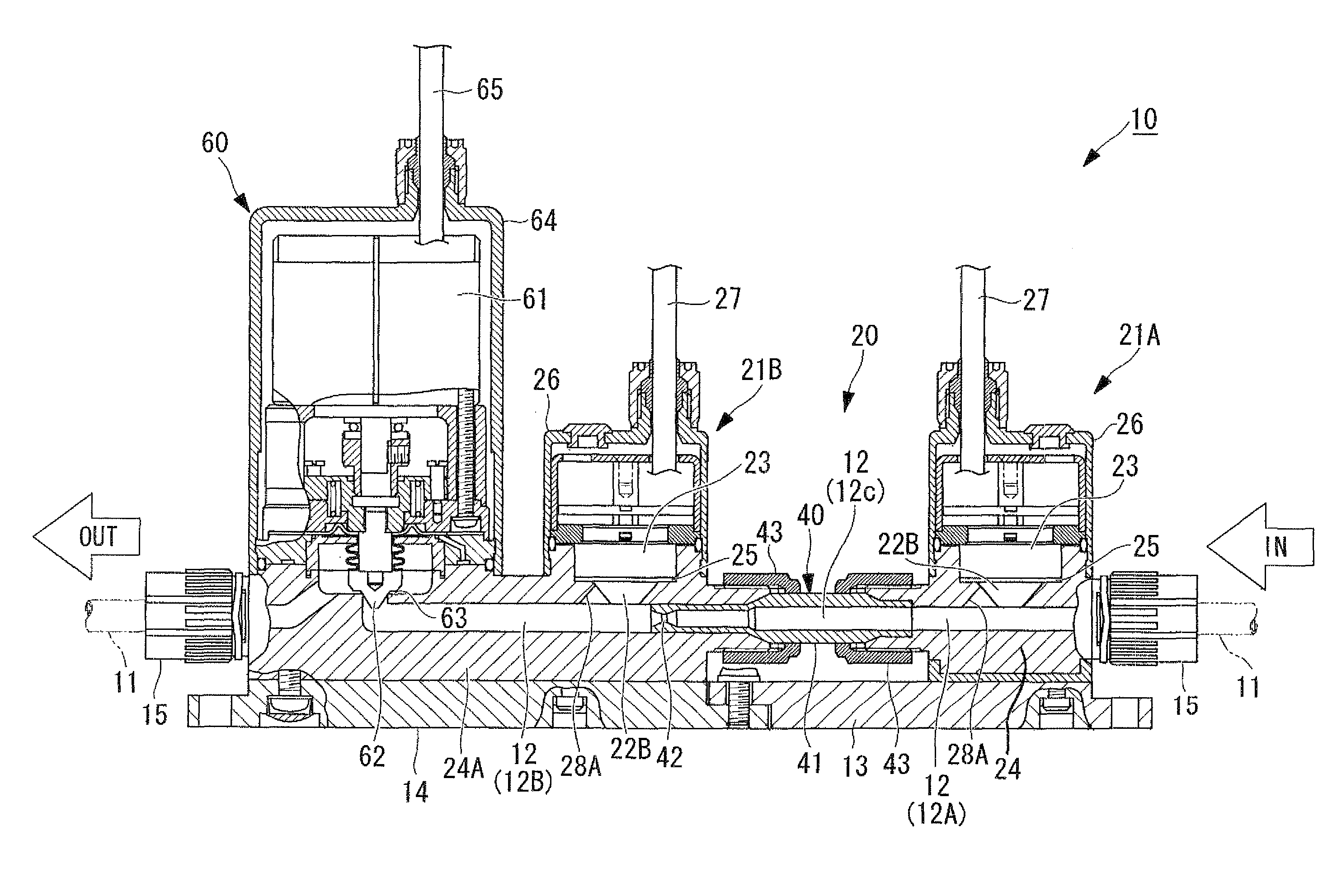

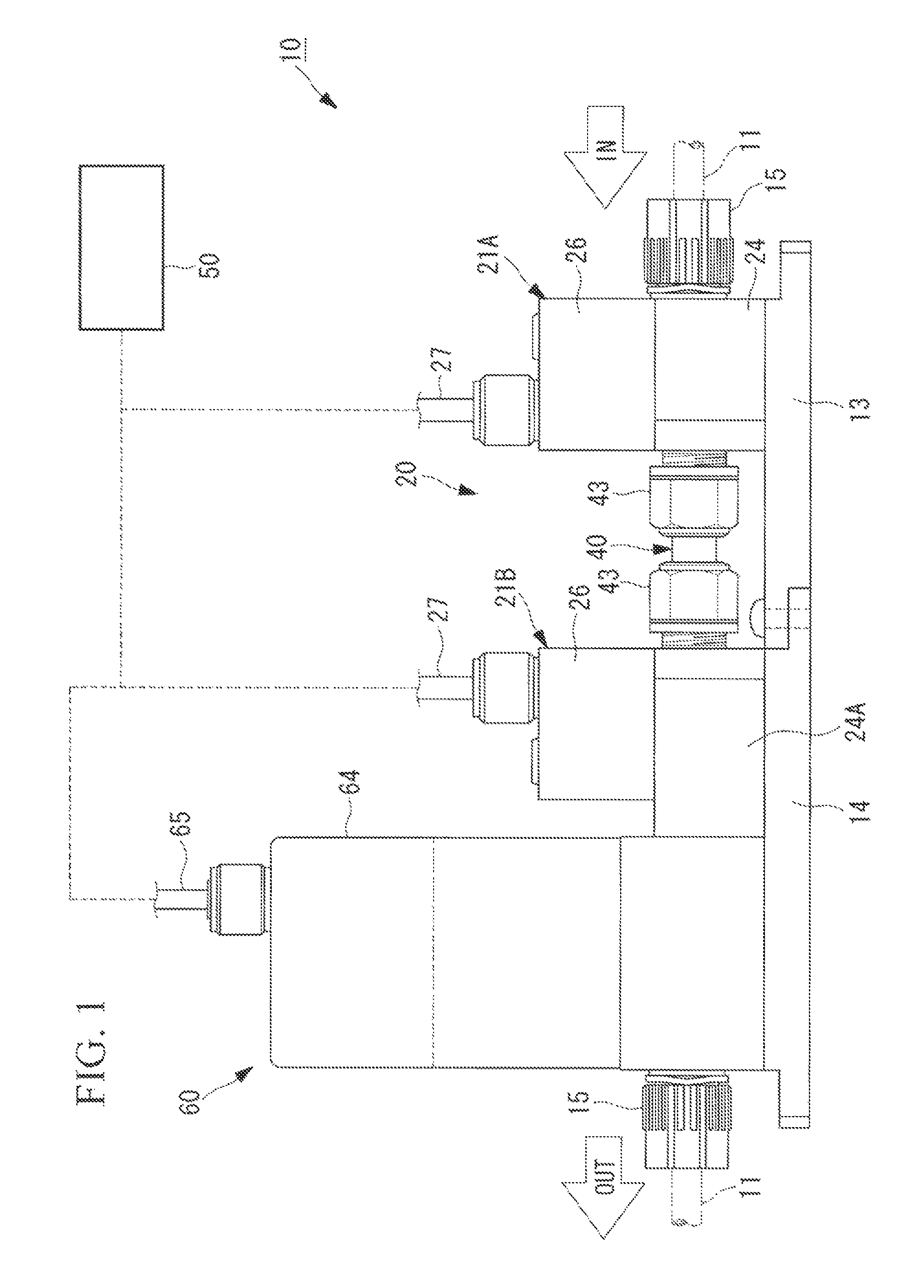

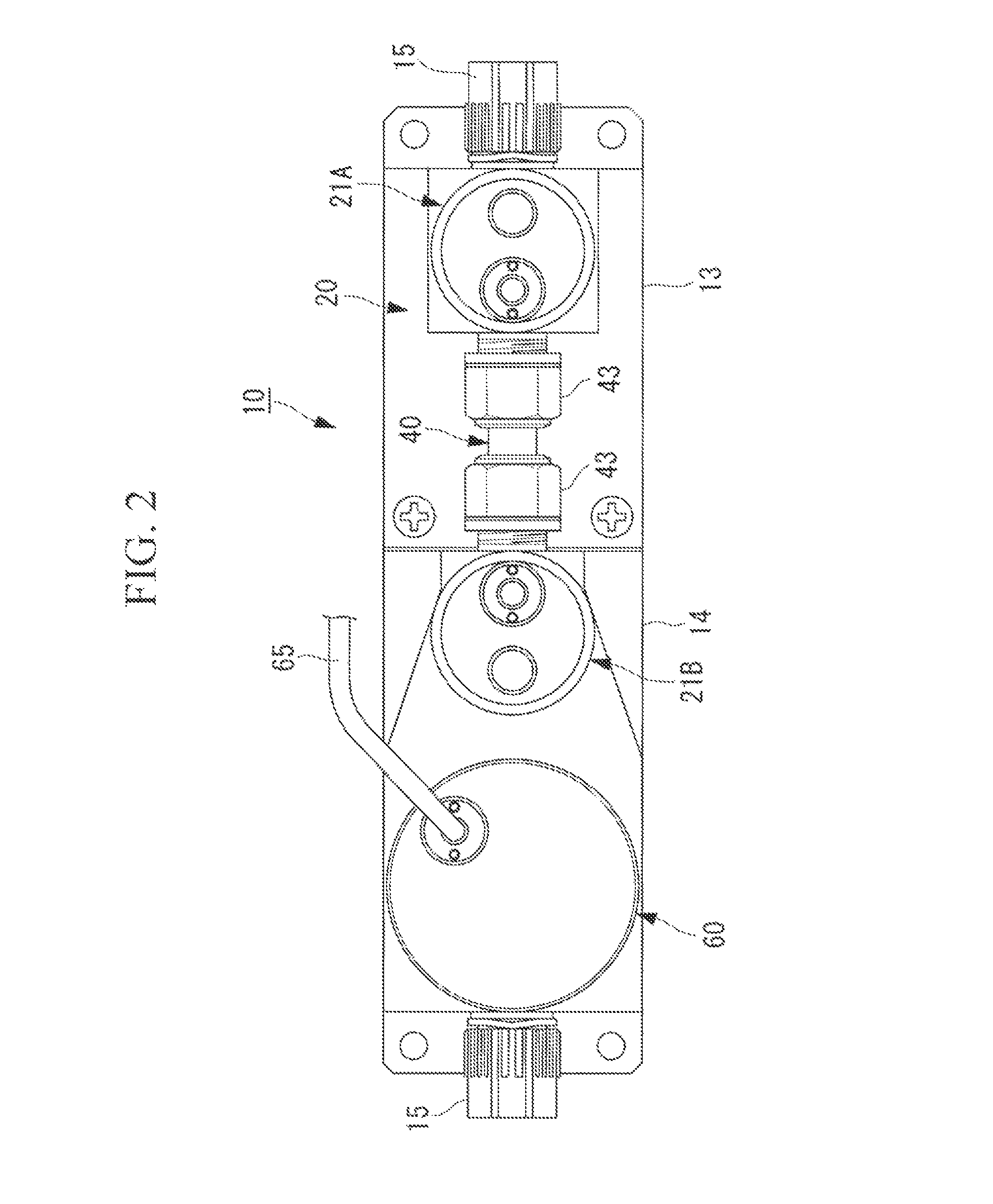

Pressure sensor, differential pressure type flow meter, and flow rate controller

ActiveUS8590561B2Avoid stagnationReduce measurement errorOperating means/releasing devices for valvesFluid pressure measurement by mechanical elementsDifferential pressureEngineering

A pressure sensor having a structure in which compressible fluid is prevented from stagnating in the vicinity of a pressure-receiving surface of the pressure sensor in the interior of a pressure introducing portion is provided. In a pressure sensor including a sensor body arranged in a pressure introduction flow channel branched in a T-shape upward from a primary fluid flow channel in which fluid to be subjected to pressure measurement flows, the pressure introduction flow channel includes an inclined surface extending in a direction to increase an opening area on the side of an inlet port of the fluid on a wall surface on the downstream side in terms of the direction of flow of the fluid.

Owner:SURPASS IND

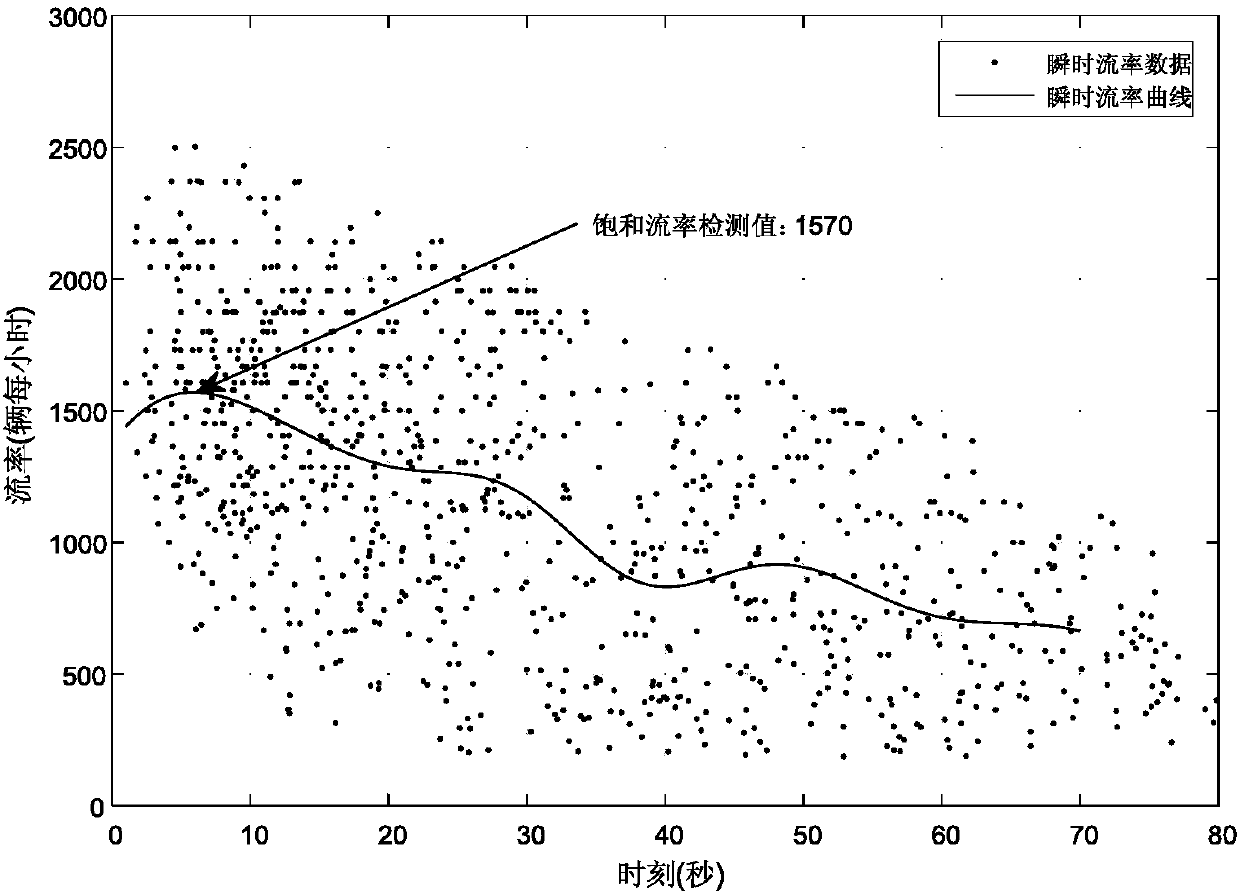

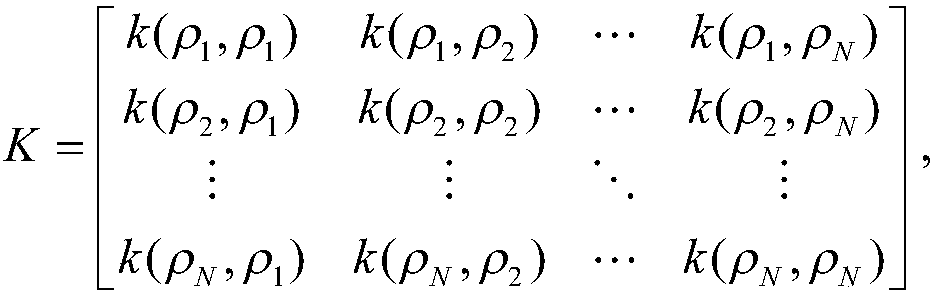

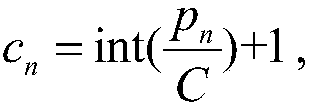

Gaussian process regression saturation flow rate detection method

ActiveCN107909825AFully excavatedThe detection value is accurateRoad vehicles traffic controlRate curveTime data

The invention provides a Gaussian process regression saturation flow rate detection method. The method comprises the steps that 1) original passing time data of a certain lane of an intersection at astop line during a period of interest are acquired; 2) the original passing time data are pre-processed to acquire passing time data; 3) instantaneous flow data and the passing time data in a cycle are calculated by using a timing scheme and the passing time data; 4) a Gaussian process regression method is used to fit an instantaneous flow rate curve based on the instantaneous flow rate data and the passing time data in the cycle; and 5) the maximum value of the instantaneous flow rate curve is solved and is used as the detection value of the saturation flow rate. Compared with the prior art,the method provided by the invention fully exploits intermittent traffic flow information contained in passing time big data at the stop line at the intersection, and acquires the saturation flow ratedetection value which is more accurate.

Owner:航天科工广信智能技术有限公司

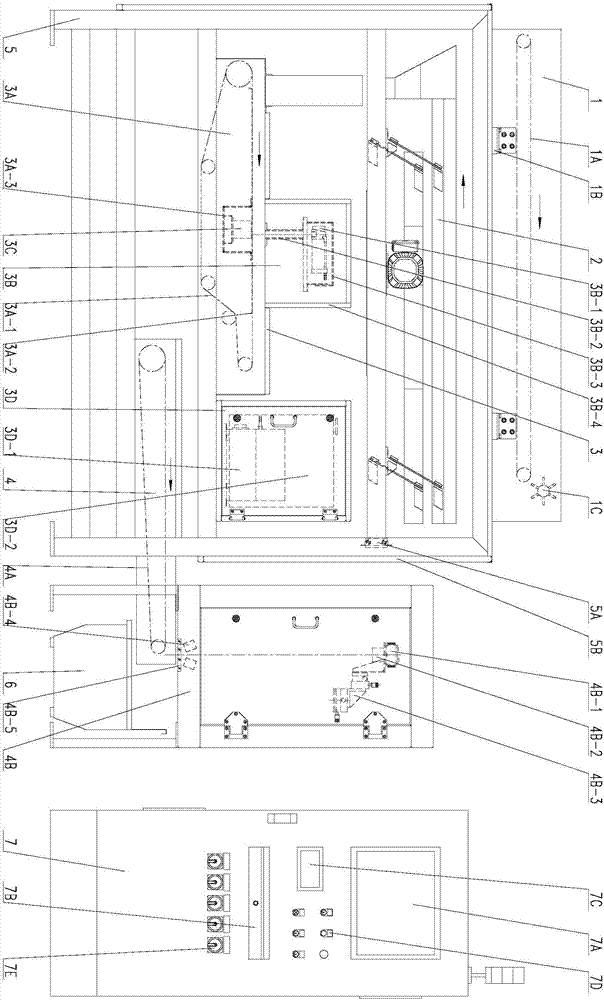

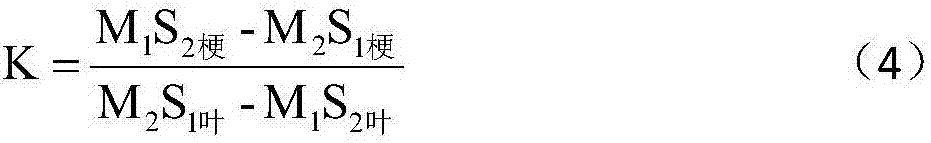

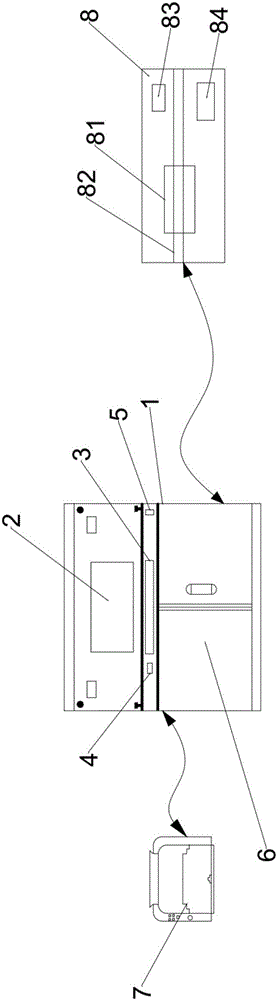

Dual spectrum technology based leaf and stalk separating and cutting quality detection device and detection method

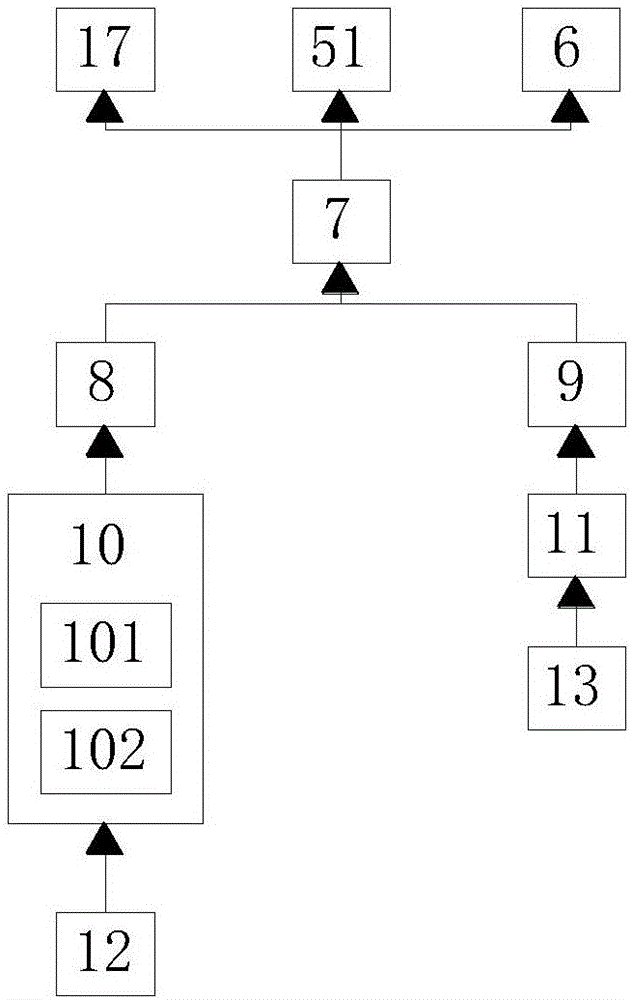

PendingCN107991303AImprove detection and recognition accuracyThe device is compactMaterial analysis using wave/particle radiationInvestigation of vegetal materialX ray imageTobacco leaf

The invention discloses a dual spectrum technology based leaf and stalk separating and cutting quality detection device and detection method. The detection device comprises a spreading device (1), a paving machine (2) arranged under the spreading device (1), an X ray detector (3) arranged under the paving machine (2), a visible light detector (4) arranged under the outlet of the X ray detector (3), a receiving device (6), a frame (5), and a control cabinet (7). The receiving device (6), the frame (5), and the control cabinet (7) are arranged under the outlet of the visible light detector (4).By adopting a visible light and X ray imaging technology and corresponding image algorithm, the tobacco leaf area, tobacco stalk area, and tobacco stalk length can be obtained; the leaves and stalks in a same image do not need to be separated, and the identification accuracy of image detection is improved. The leaf structure and long stalk rate can be detected, the stalk containing rate of leavesand leaf containing rate of stalks can be detected, the stalk density and leaf density are not needed during the index calculation process, and the leaf cutting quality indexes can be automatically calculated out.

Owner:QILIN REDRYING FACTORY YUNNAN TOBACCO REDRYING +1

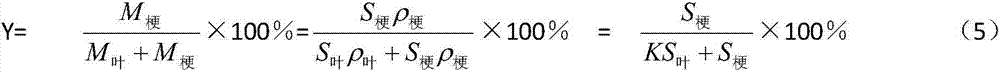

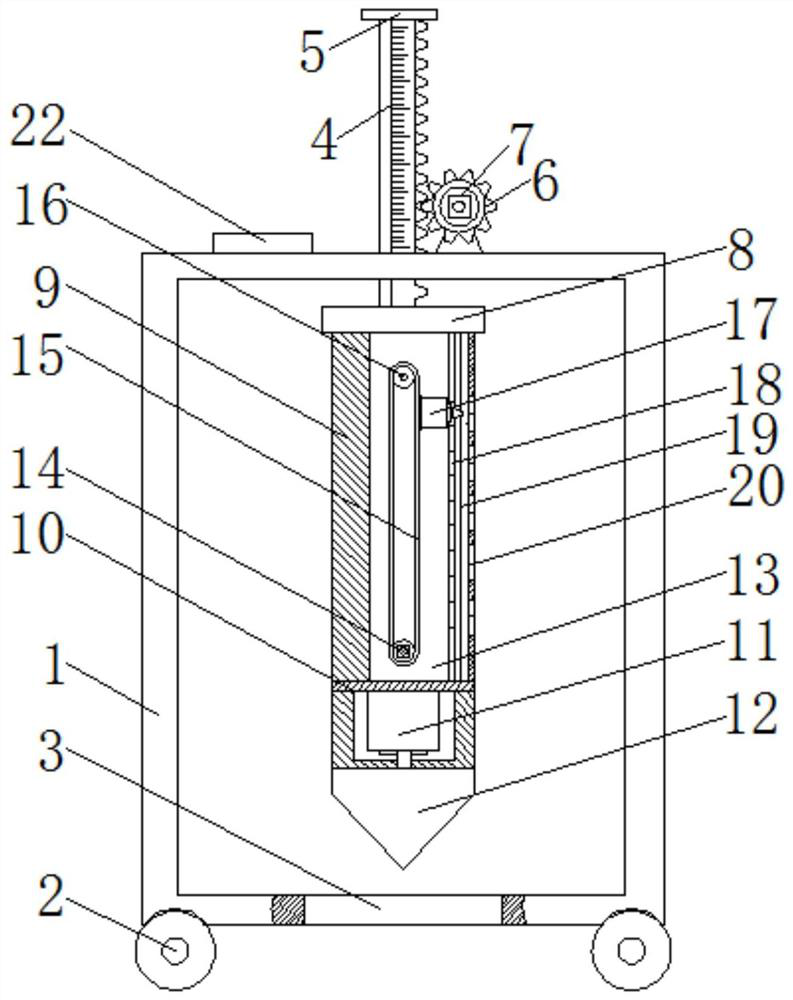

Black rice planting soil detection device

PendingCN112505300ACheck pHThe detection value is accurateEarth material testingThermometer applicationsAgricultural engineeringEdaphic

The invention relates to the technical field of soil detection, and discloses a black rice planting soil detection device which comprises an equipment box, rollers are fixedly mounted at the bottom ofthe equipment box, a through hole is formed in the middle of a bottom plate of the equipment box, the middle of the upper end of the equipment box is movably sleeved with a rack, and the upper end ofthe rack is fixedly connected with a limiting block. And one side of the rack is engaged with a gear. After the detection box drills into soil along with cooperation of a drill bit, the gear and therack, the detector can be located at soil positions of different depths through up-down transmission of a conveying belt, at the moment, a first telescopic rod and a second telescopic rod extend, a probe, a temperature sensor and a depth sensor are controlled to make direct contact with the soil for detection, and an accurate detection value is obtained; after the detection is finished, the detector is withdrawn, the detector is driven to ascend or descend along with the conveying belt, the detection operation is carried out again, and the pH value, the temperature and the humidity of the soilat any depth can be detected after one-time drilling.

Owner:福建省见知信息科技有限公司

Device for detecting water level in water tank

InactiveCN105509843AEasy to detectRealize detectionLevel indicators by floatsWireless dataComputer module

The invention discloses a device for detecting a water level in a water tank. The device is mounted on a body of a living water tank in a residential building or a large-scale production water tank in a factory and comprises a fixed support plate and a liquid level detection rod. A plurality of sensing elements equidistantly arranged from top to bottom are arranged on a face plate of the fixed support plate and are in circuit connection with an integrated control unit, and the integrated control unit is in wireless data connection with a terminal display module which is capable of receiving signals sent by the integrated control unit and displaying after processing the signals. The liquid level detection rod comprises a float rod and a float ball disposed at the lower end of the float rod, and a metal probe capable of sensing with the sensing elements is arranged at the top end of the float rod. The device for detecting the water level in the water tank has the advantages that a user can check actual water level conditions in the water tank conveniently, and accordingly, water level detection is achieved effectively; the device is convenient, practical, good in detection effect and precise in detecting numerical values.

Owner:SUZHOU SHANGKE PROD TEST CENT

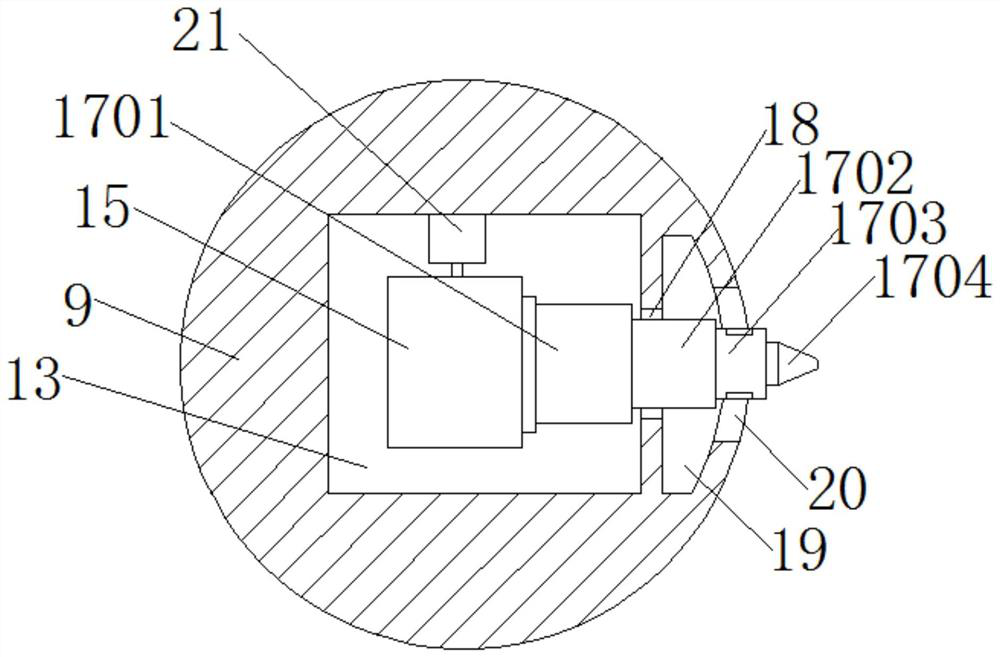

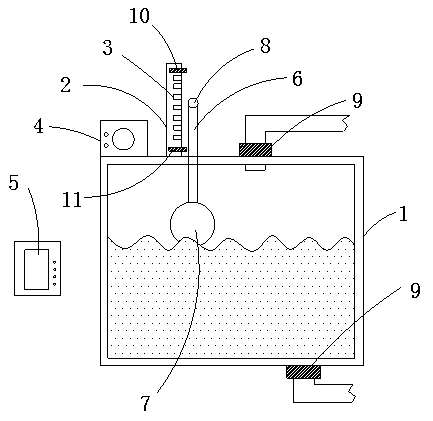

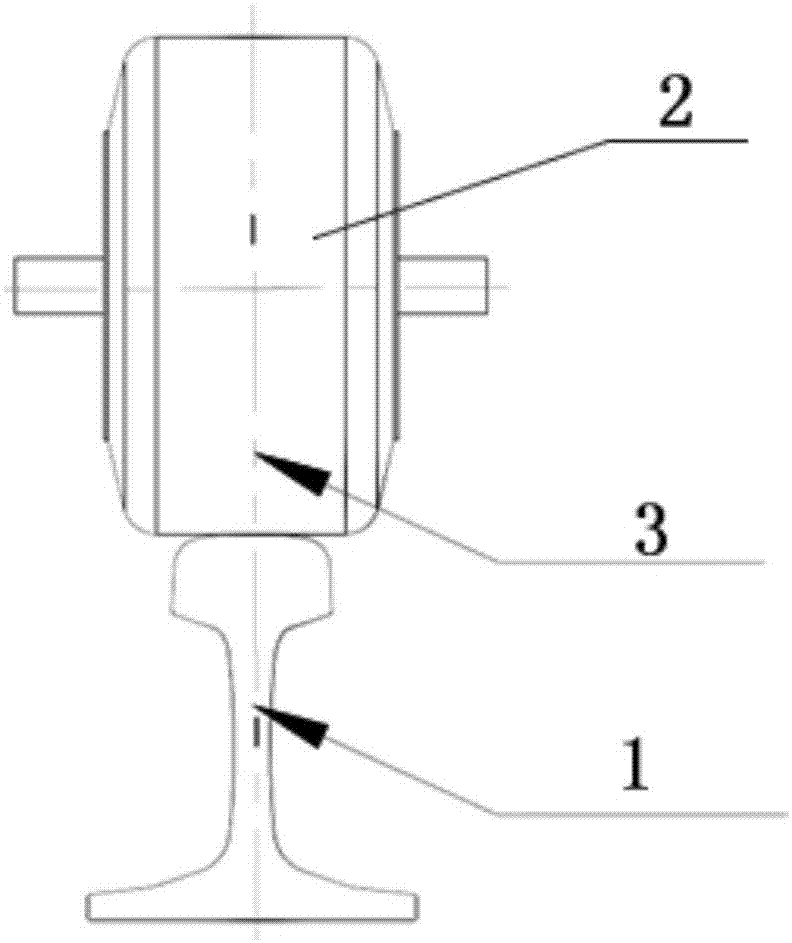

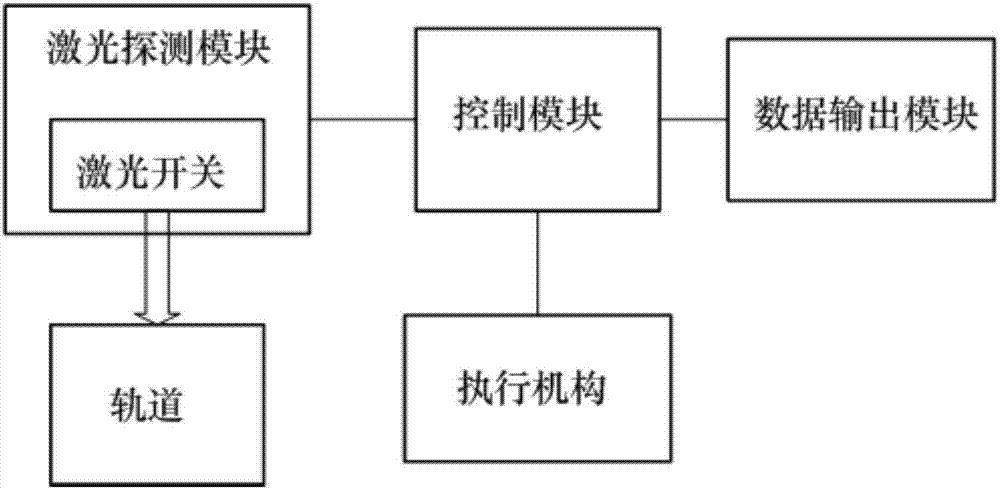

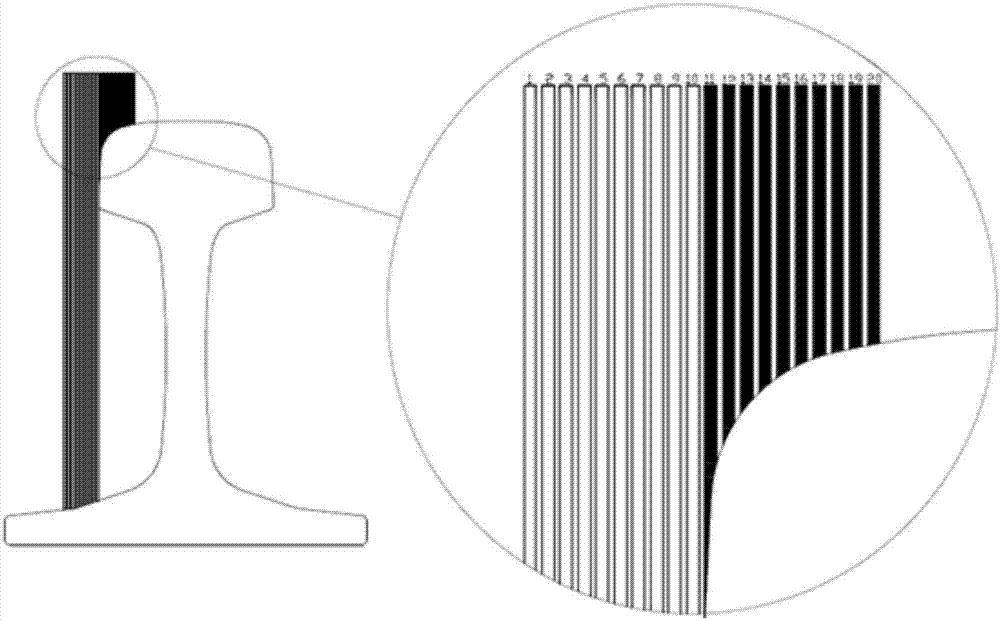

Automatic centering system used for track flaw detection and centering detection method thereof

ActiveCN107289861ACalculation method is simpleThe detection value is accurateUsing optical meansTotal factory controlTrackwayLight beam

The invention relates to the technical field of track flaw detection and displacement sensors, and particularly relates to an automatic centering system used for track flaw detection and a centering detection method thereof. The automatic centering system comprises a control module and a laser detection module which is arranged on a wheel detector. The laser detection module comprises multiple laser switches which are equidistantly arranged. Each laser switch irradiates laser beams to the track, and the laser beams are mutually parallel and perpendicular to the track. The laser switches which irradiate to the track and the laser switches which do not irradiate to the track transmit different state values to the control module. The control module calculates the transverse deviation value of the laser detection module relative to the edge of the track according to the state values of all the laser switches. The track is detected by using the laser switches arranged in a spaced way, and the transverse deviation value of the wheel detector relative to the edge of the track is calculated through different state values obtained by the laser switches which irradiate to the track and the laser switches which do not irradiate to the track so that the calculation method is simple, the detection value is accurate, the reliability is high, the stability is high and the real-time performance is great.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

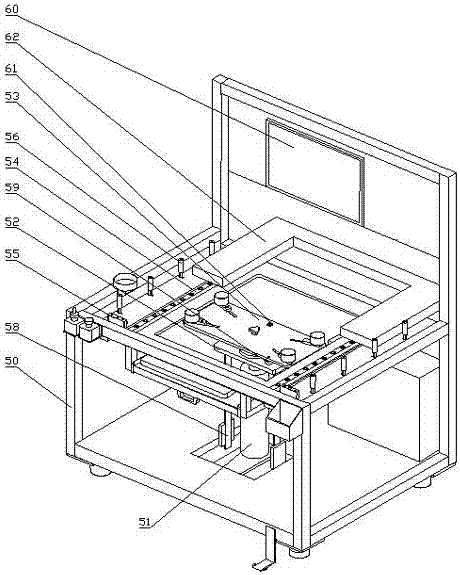

Vehicle skylight glass curvature detection platform

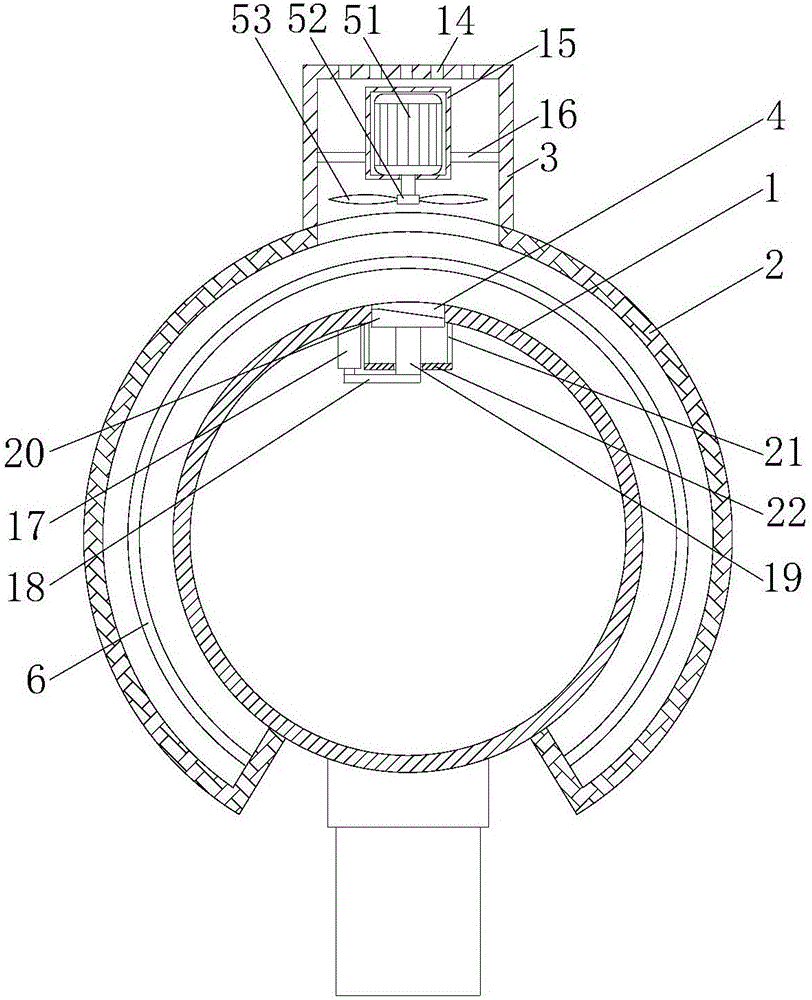

PendingCN107063164AQuick and easy accessPut in smoothlyMechanical measuring arrangementsEngineeringSkylight

A vehicle skylight glass curvature detection platform comprises a rack body (50), a glass support device and a detection tool location device. The glass support device comprises a support cylinder (51), a detection rotary table (52), a glass supporting plate (53) and a rotary locking cylinder (59). The detection tool location device comprises a pair of universal ball raceways (54), one ends of the universal ball raceways (54) are provided with stop blocks (55), the universal ball raceways (54) are installed on the rack body (50) and located at two sides of the glass support device, and one sides of the universal ball raceways (54) are respectively provided with a set of guide rollers (56). According to the vehicle skylight glass curvature detection platform, the detection tool can be stably put at the bottom portion of the glass, the detection value is accurate, the glass taking and putting are simple and rapid, and the vehicle skylight glass curvature detection platform has good practical values.

Owner:秀卓自动化设备(湖北)有限公司

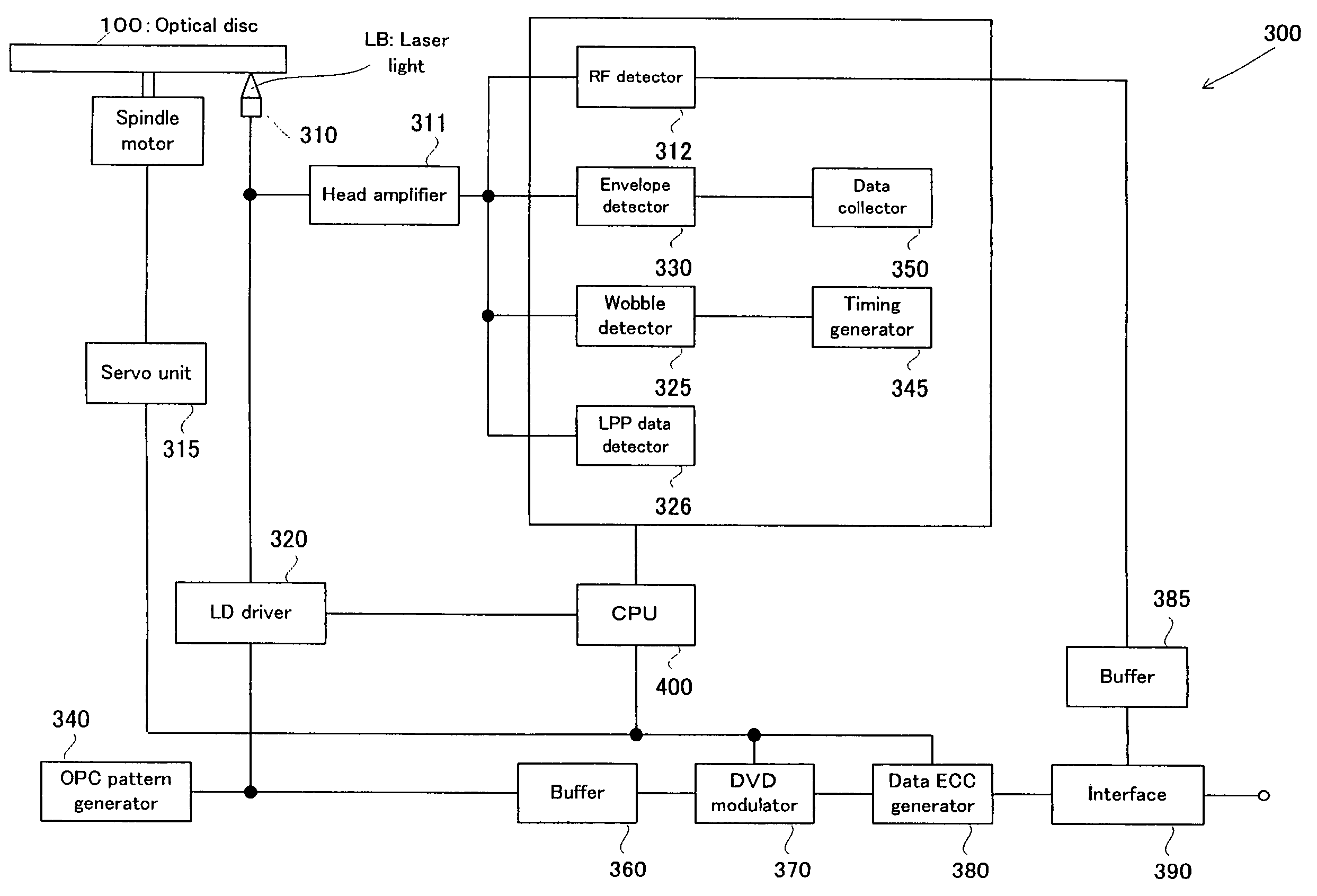

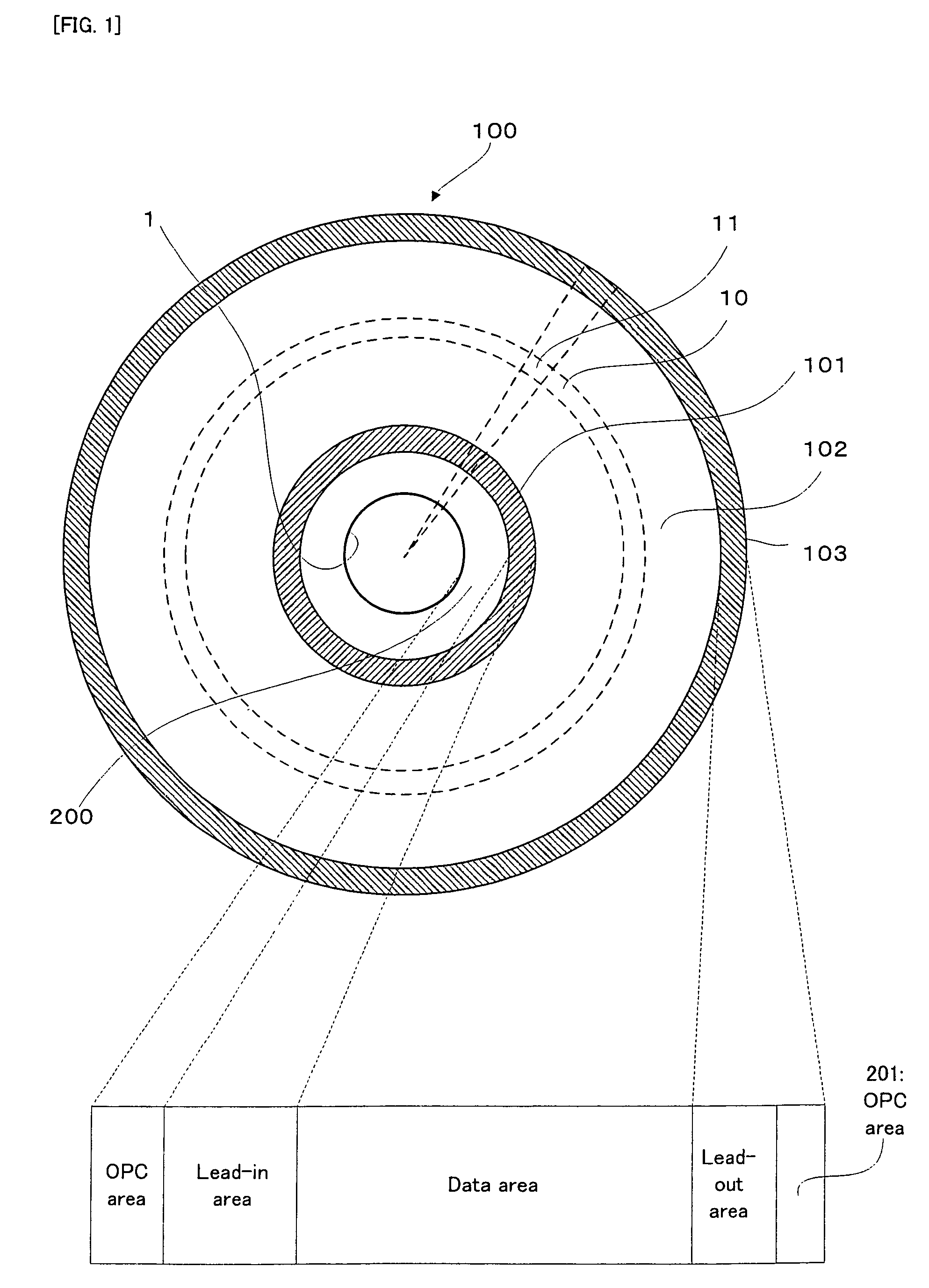

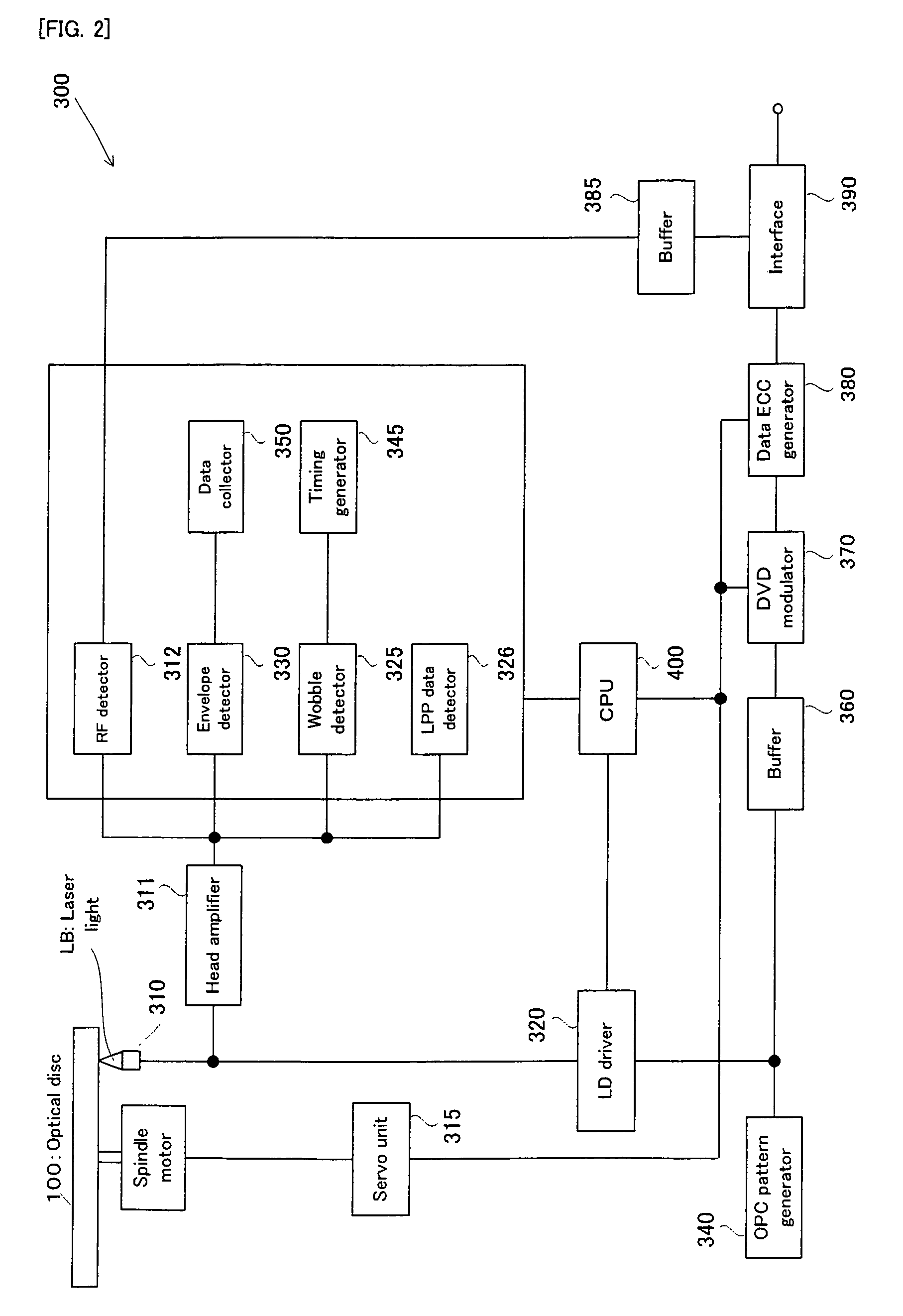

Information recording apparatus and method, information recording/reproducing apparatus and method and computer program

InactiveUS7602683B2Accurate detectionThe detection value is accurateCombination recordingFilamentary/web record carriersLaser lightData recording

An information recording apparatus includes:a recording device capable of recording information into a data area of an information recording medium, by irradiating laser light, in conformity with a predetermined error correction method; an optimum-recording-power detecting device for obtaining an optimum recording power of the laser light, by recording test writing data into a data area portion with a length which is equal to or less than an allowable defect length in the predetermined error correction method, within the data area, by using the recording device; and a controlling device for controlling the recording device to record the information into the data area with the obtained optimum recording power.

Owner:PIONEER CORP

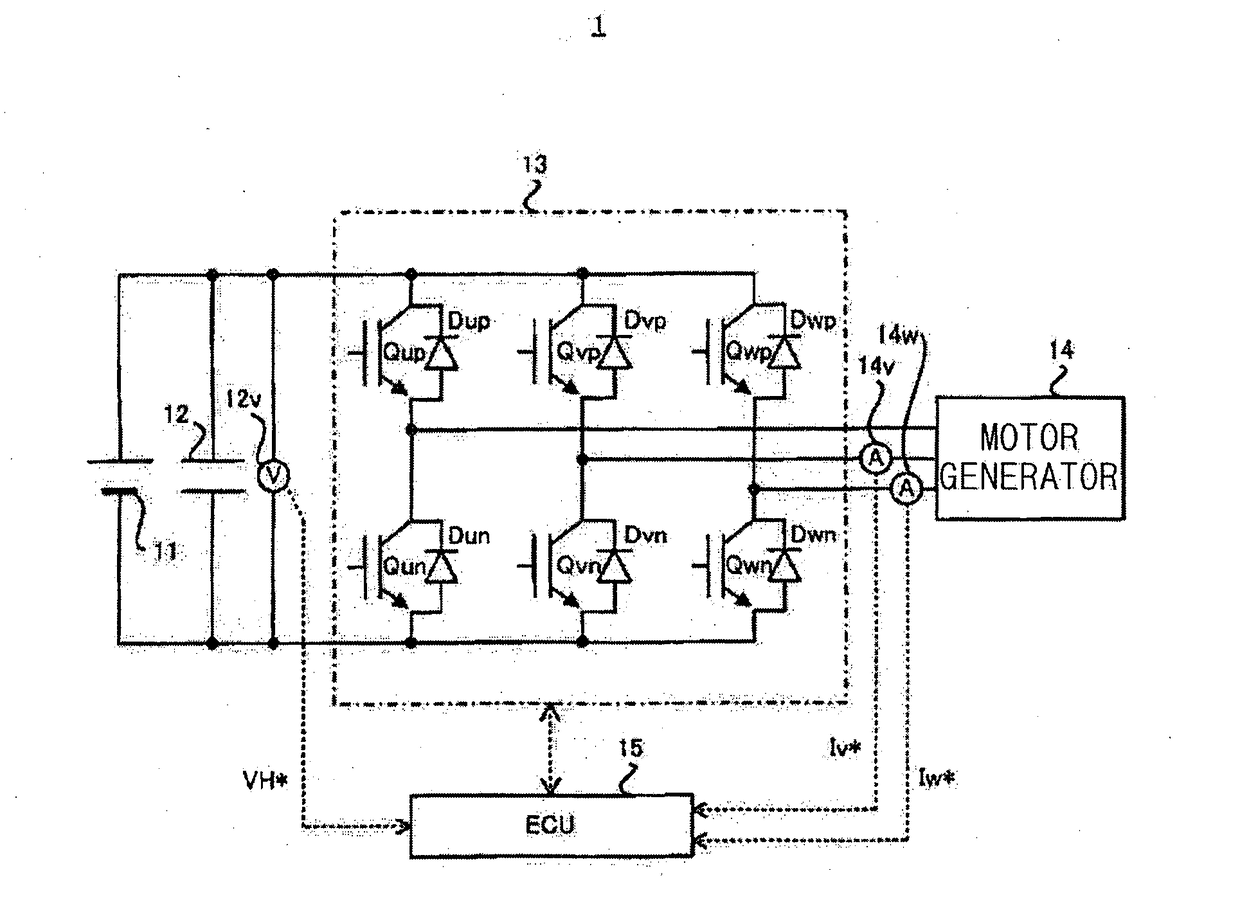

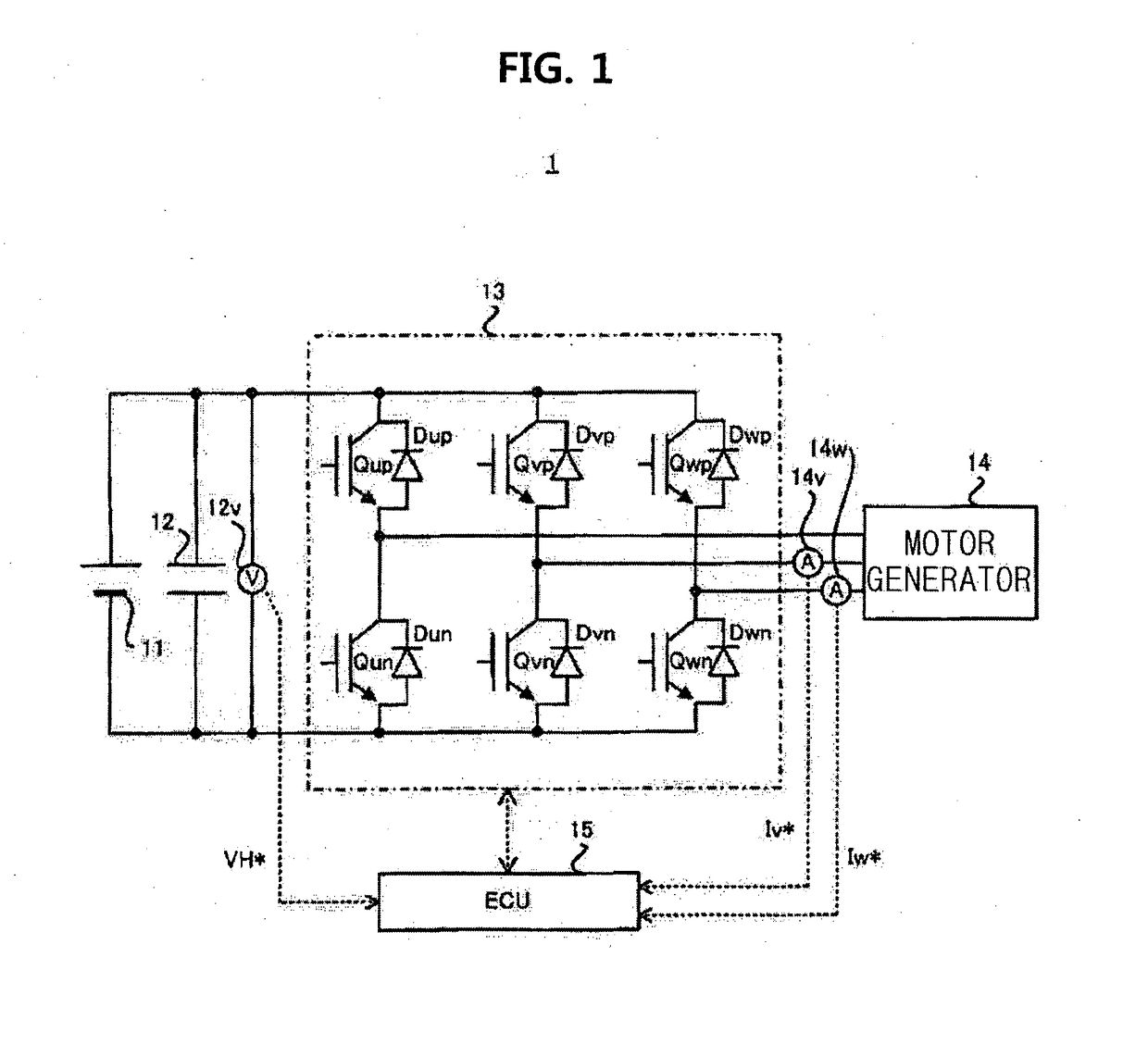

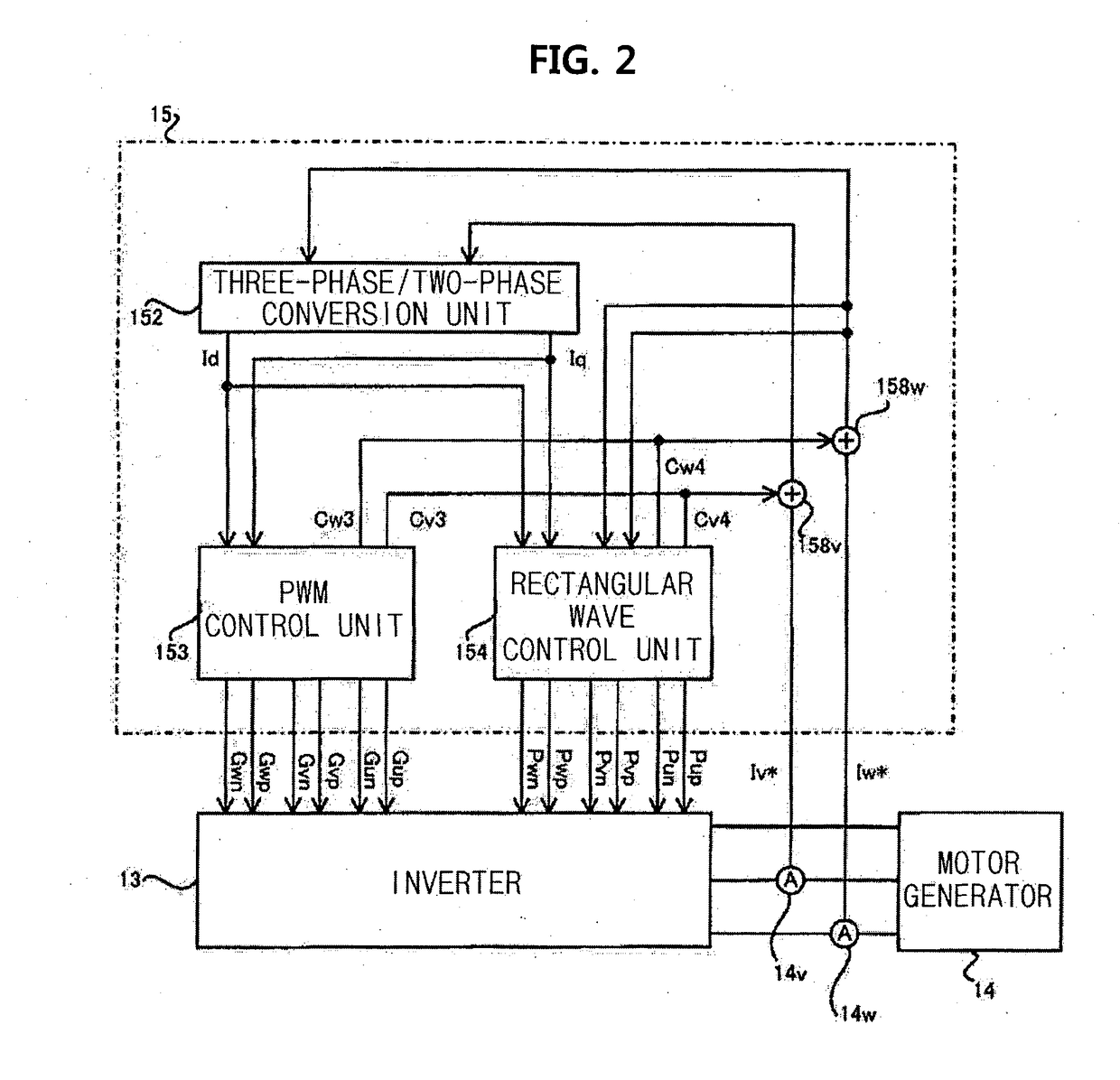

Controller for electric motor system

ActiveUS20170214355A1The detection value is accurateExclude influenceAC motor controlAc-dc conversionPhase currentsTerminal voltage

A controller for an electric motor system is provided. The electric motor system includes a DC power supply, a power converter, a smoothing capacitor, a three-phase AC motor, and a current sensor. The controller includes an electronic control unit. The electronic control unit is configured to control the power converter such that an inter-terminal voltage of the smoothing capacitor matches a first reference value. The first reference value is a value which is determined as the inter-terminal voltage of the smoothing capacitor when a phase current is equal to a second reference value. The electronic control unit is configured to correct a detection value of the current sensor so as to decrease a difference between the detection value and the second reference value when the inter-terminal voltage matches the first reference value and the detection value does not match the second reference value.

Owner:DENSO CORP

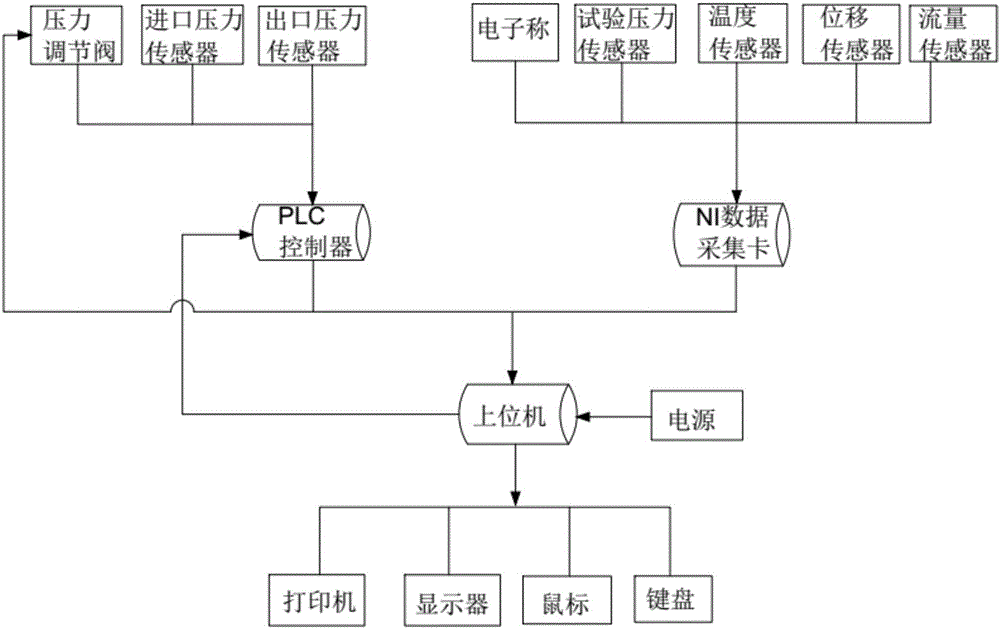

Safety valve performance online detection device

InactiveCN106404379AEnsure personal safetyEasy to operateMachine part testingElectricityPower switching

The invention provides a safety valve performance online detection device. The safety valve performance online detection device comprises an operation piano-type cabinet and a mechanical operation platform; the operation piano-type cabinet is provided with a display, a keyboard, a mouse and a power source switch; an electrical control system is arranged in the operation piano-type cabinet; the electrical control system comprises a host computer as well as a PLC and an NI data acquisition card which are both electrically connected with the host computer; the electrical control system further comprises a switching quantity unit, a pressure regulating valve, an inlet pressure sensor and an outlet pressure sensor which are all electrically connected with the PLC; and the electrical control system also comprises an electronic scale, a test pressure sensor, a temperature sensor, a displacement sensor and a flow sensor which are all electrically connected with the NI data acquisition card. With the safety valve performance online detection device of the invention adopted, various kinds of performance parameters of safety valves can be detected precisely and automatically.

Owner:ANHUI WANT AUTOMATION

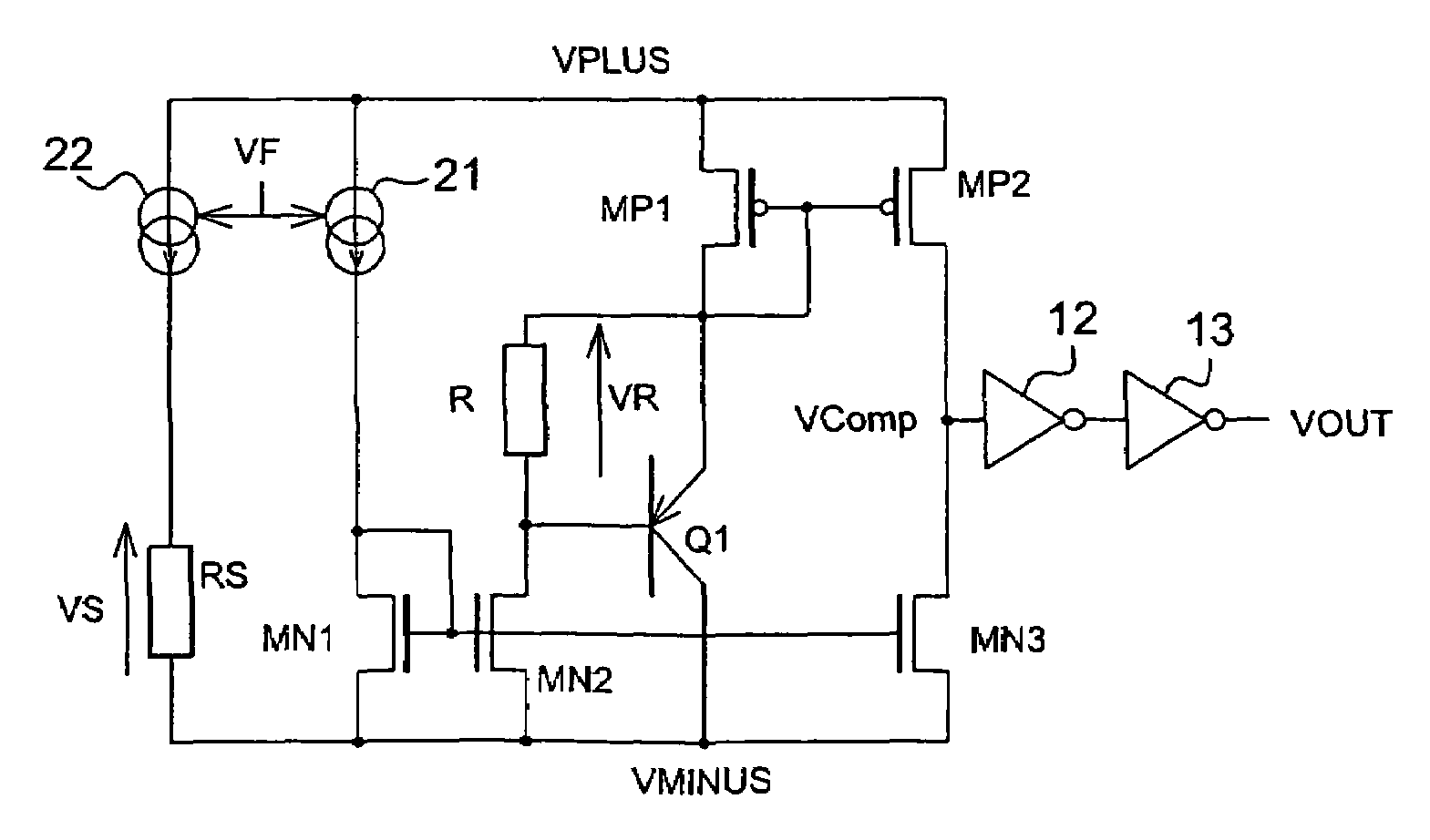

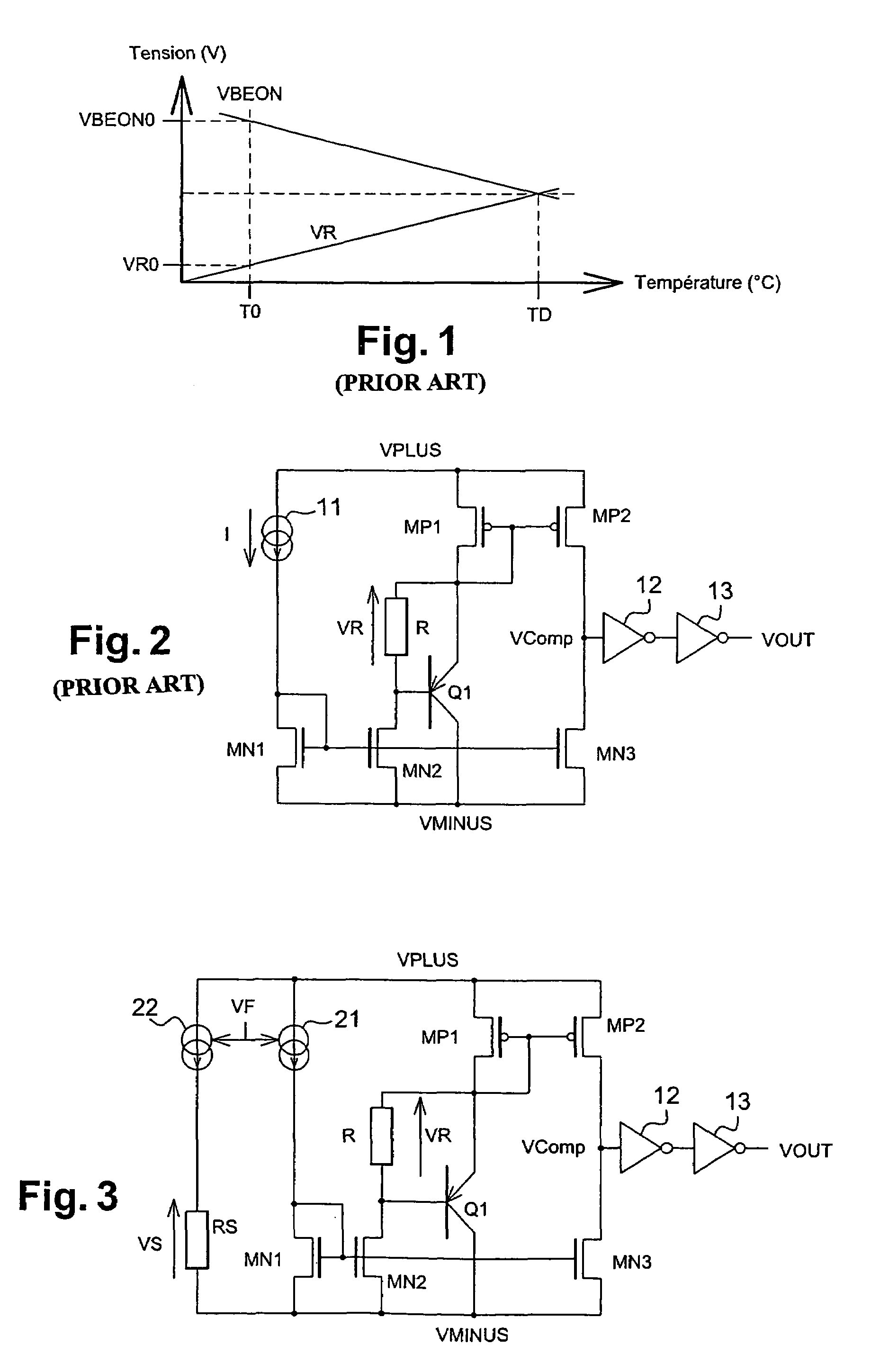

Temperature detection cell, and method to determine the detection threshold of such a cell

ActiveUS7003424B2Avoid insufficient temperatureLow costThermometer detailsThermometers using material expansion/contactionEngineeringDetection threshold

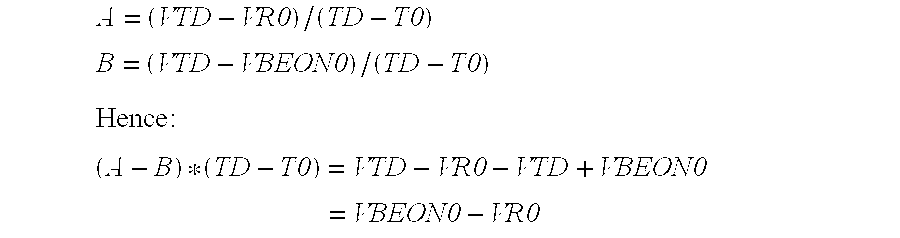

A temperature detection cell includes a circuit for producing a voltage that increases with temperature, a circuit producing a voltage that decreases with temperature, and a comparison circuit to compare the increasing voltage with the decreasing voltage. The comparison circuit produces a warning signal when the temperature reaches a detection threshold such that the decreasing voltage becomes lower than the increasing voltage. The cell also has a test circuit to determine the detection threshold of the cell. Also disclosed is a method for testing a temperature detection cell, during which the detection threshold of a cell is determined from measurements of the increasing voltage and the decreasing voltage at a reference temperature.

Owner:ST ERICSSON SA

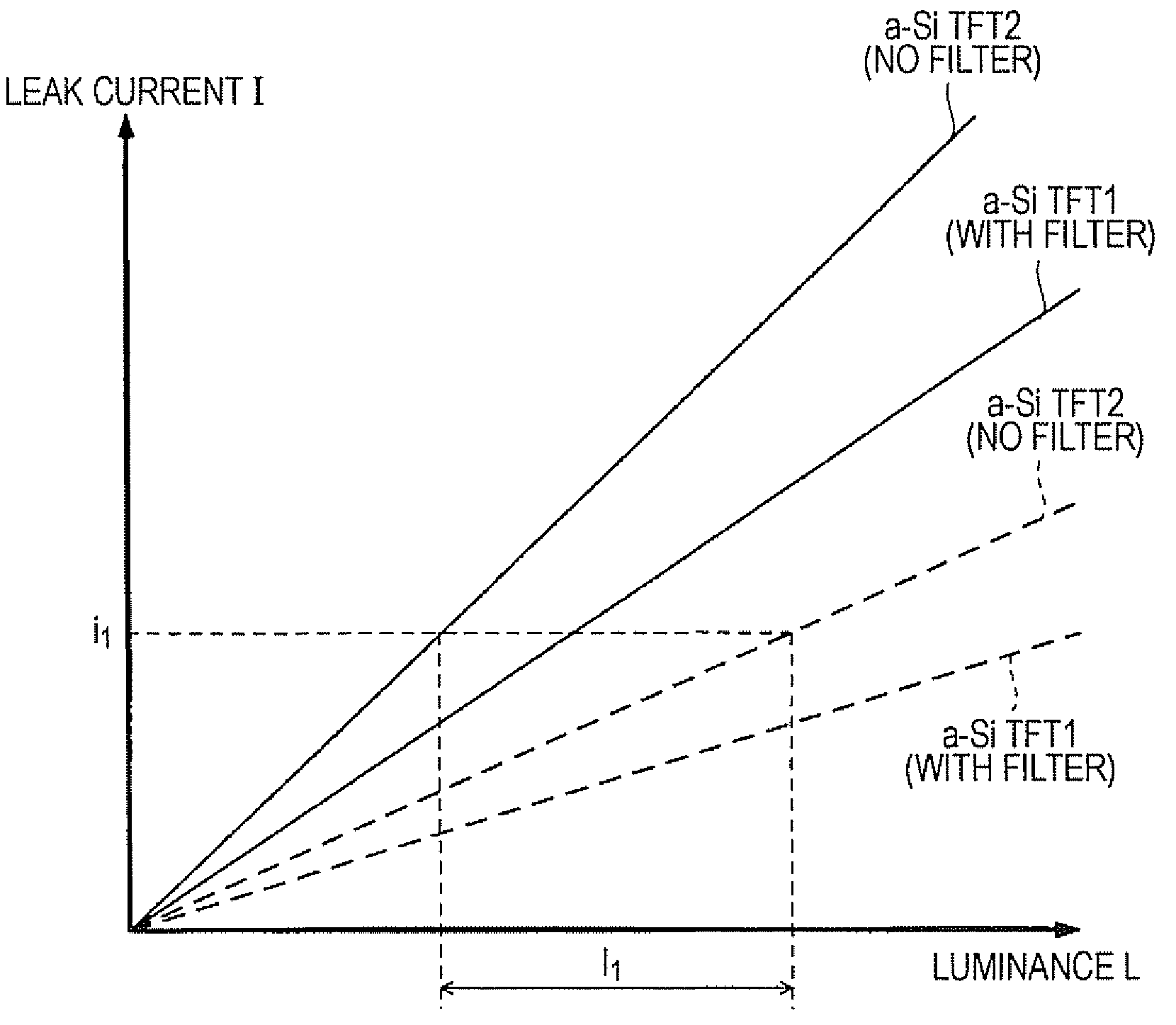

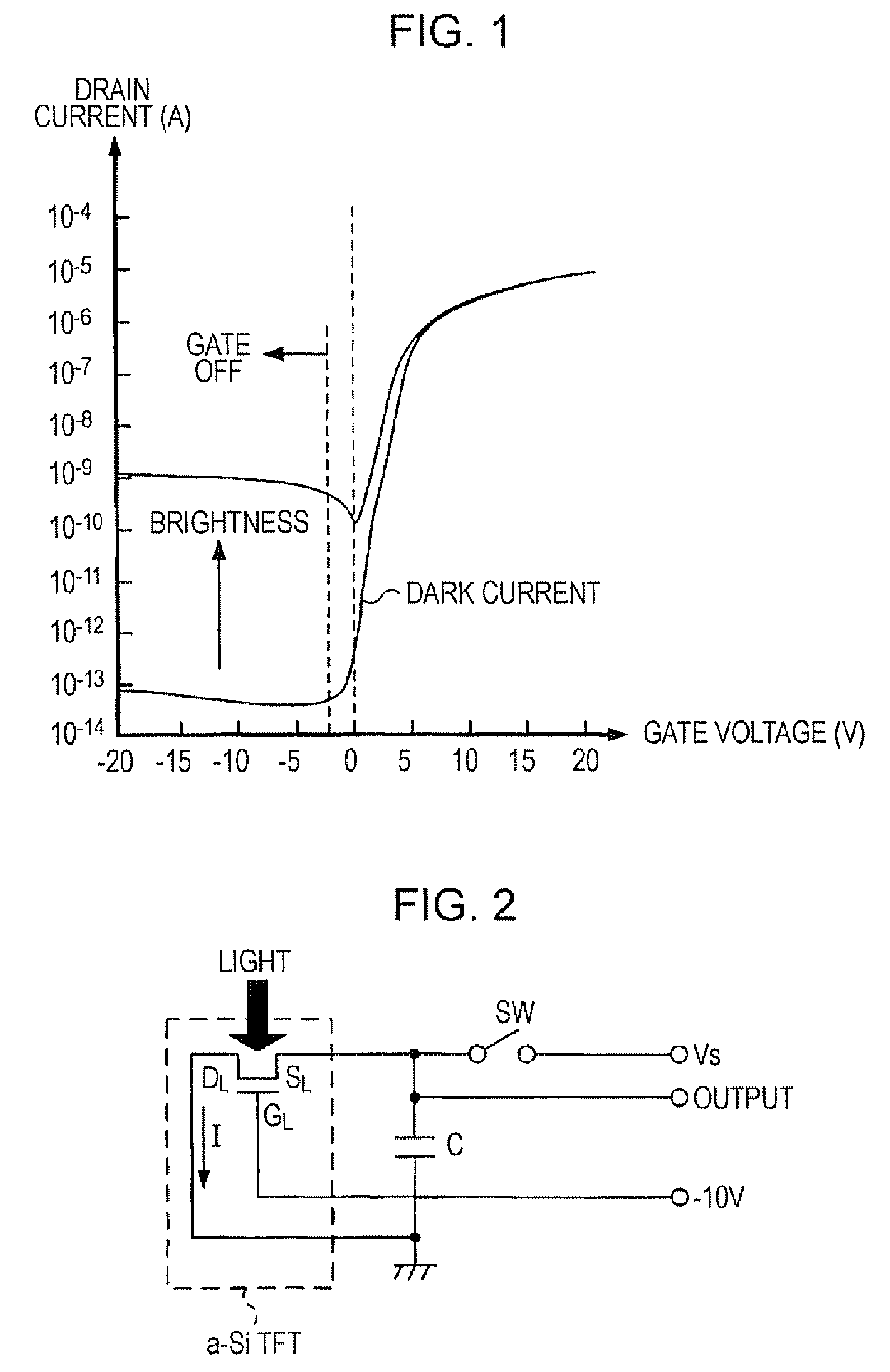

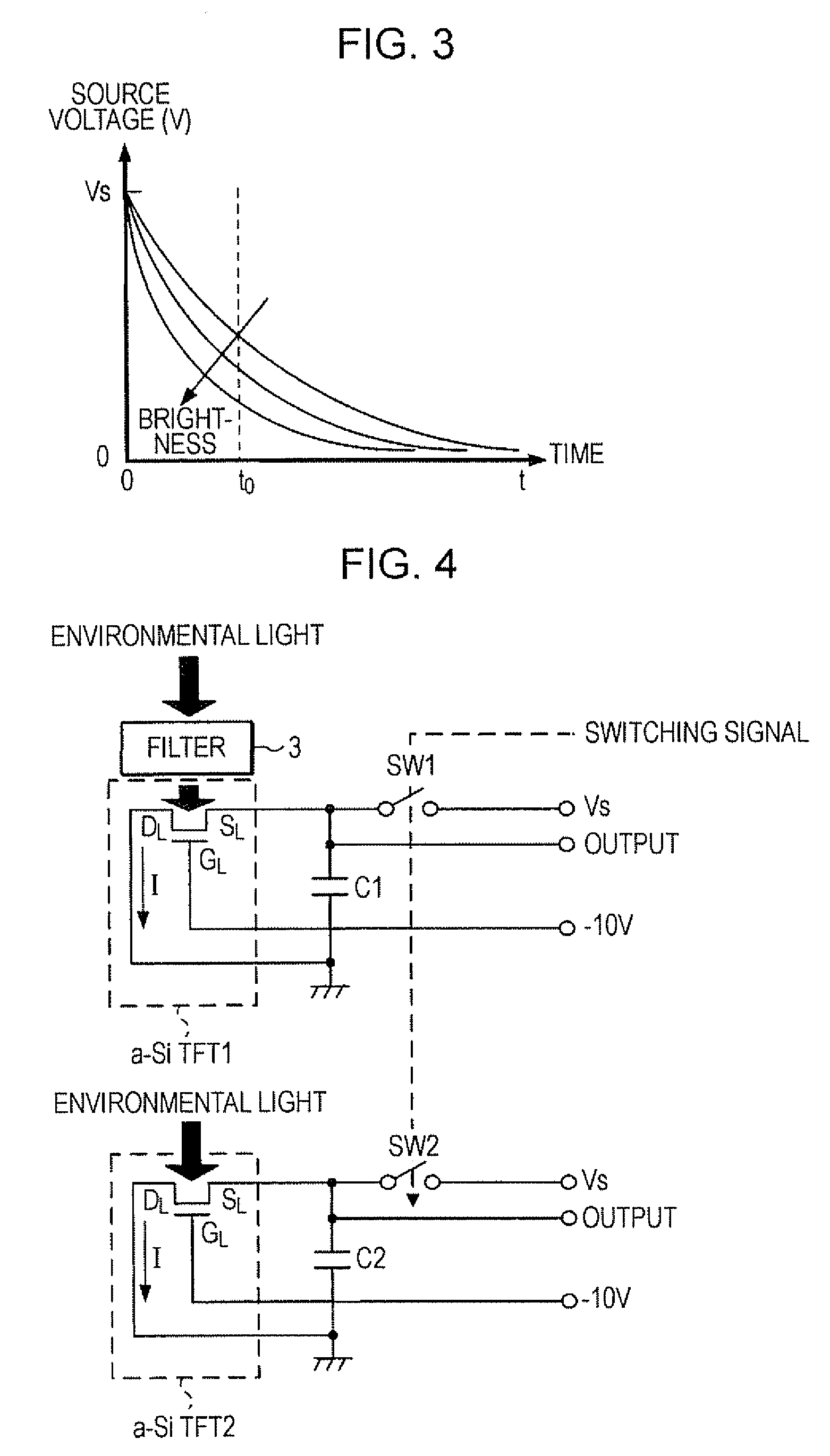

Sensing circuit, optical detection circuit, display device, and electronic apparatus

ActiveUS20080319695A1Accurate correctionCorrect deviationPhotometry using reference valueTesting/calibration apparatusDisplay deviceEngineering

Owner:BOE TECH GRP CO LTD

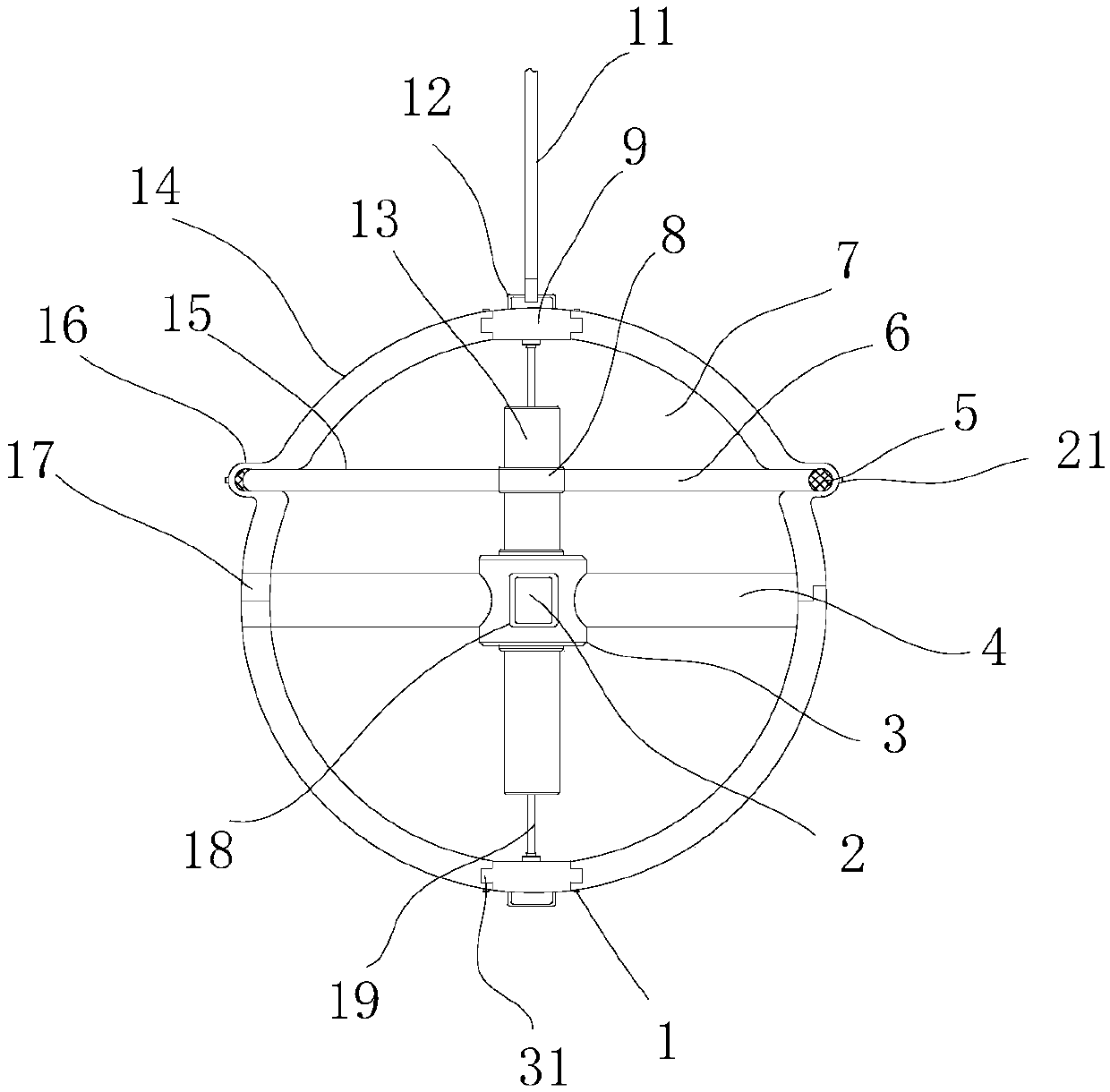

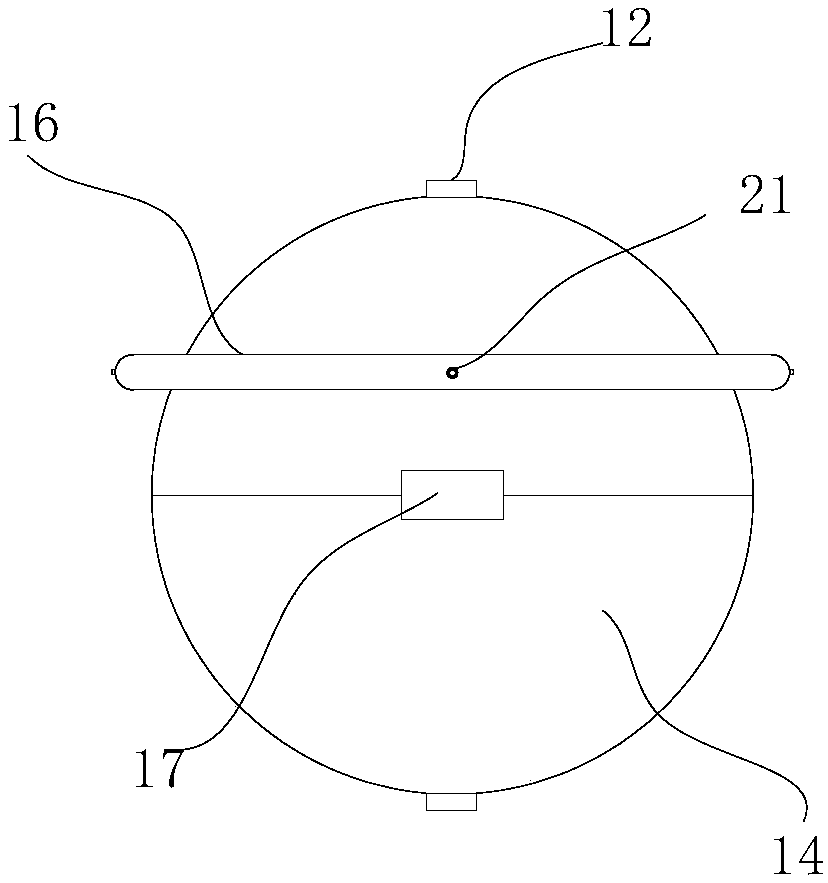

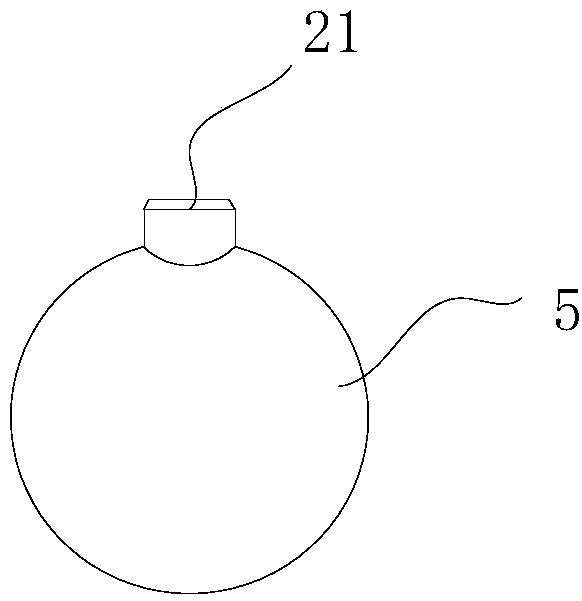

River sludge extraction device

ActiveCN109100177AThe detection value is accurateNice appearanceWithdrawing sample devicesSludgeEngineering

The invention discloses a river sludge extraction device which comprises a spliced sphere. A spherical cavity is arranged in the middle of the sphere; a convex ring is arranged on the upper end surface, close to the circle part, of the sphere; a limiting cavity communicated with the spherical cavity is arranged in the convex ring; four air bag balls are embedded in the front and back surfaces andthe left and right surfaces in the limiting cavity separately; one end of each air bag ball is provided with a convex air outlet; and the air outlet penetrates through the sphere and extends to the outside. According to the sludge extraction device, sludge in different positions can be automatically extracted in a free dragging process; area can be divided and extracted without electronic components; only one small sphere structure is needed; and the operation is simple, and detection values of extracts are more accurate.

Owner:义乌市丹航科技有限公司

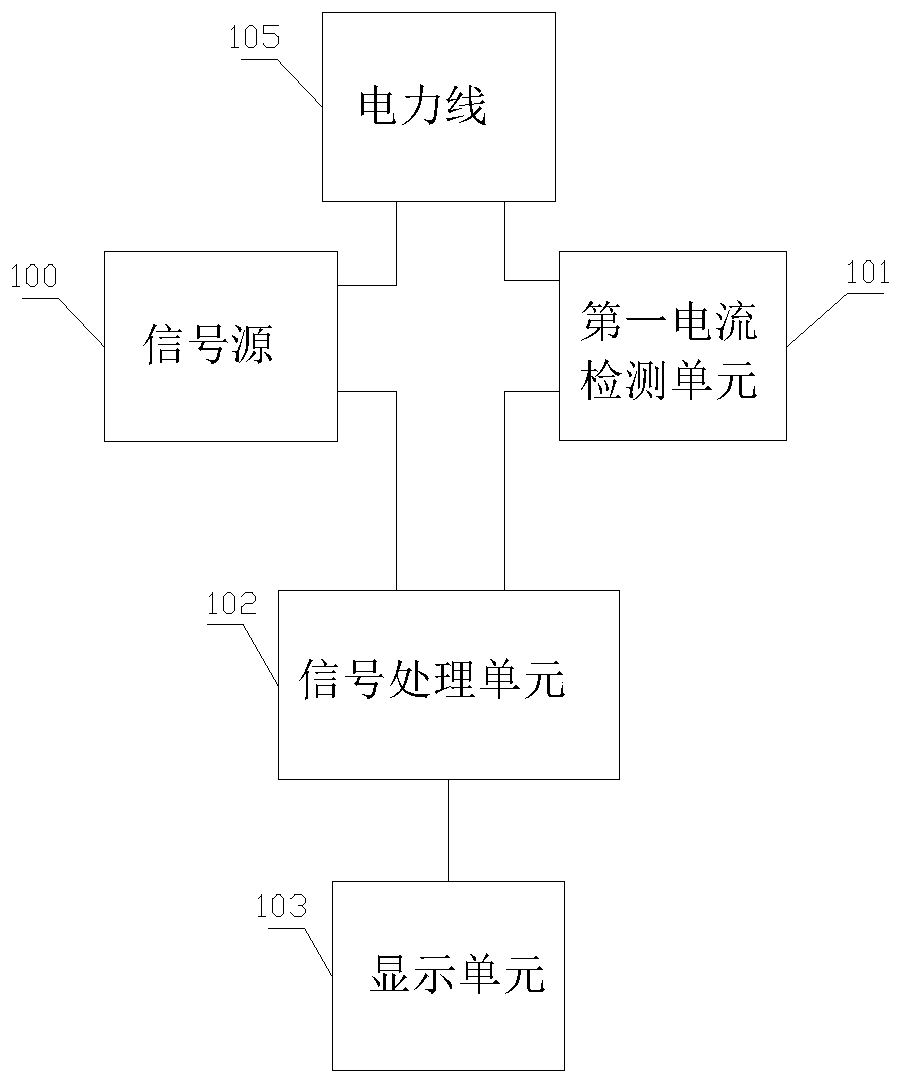

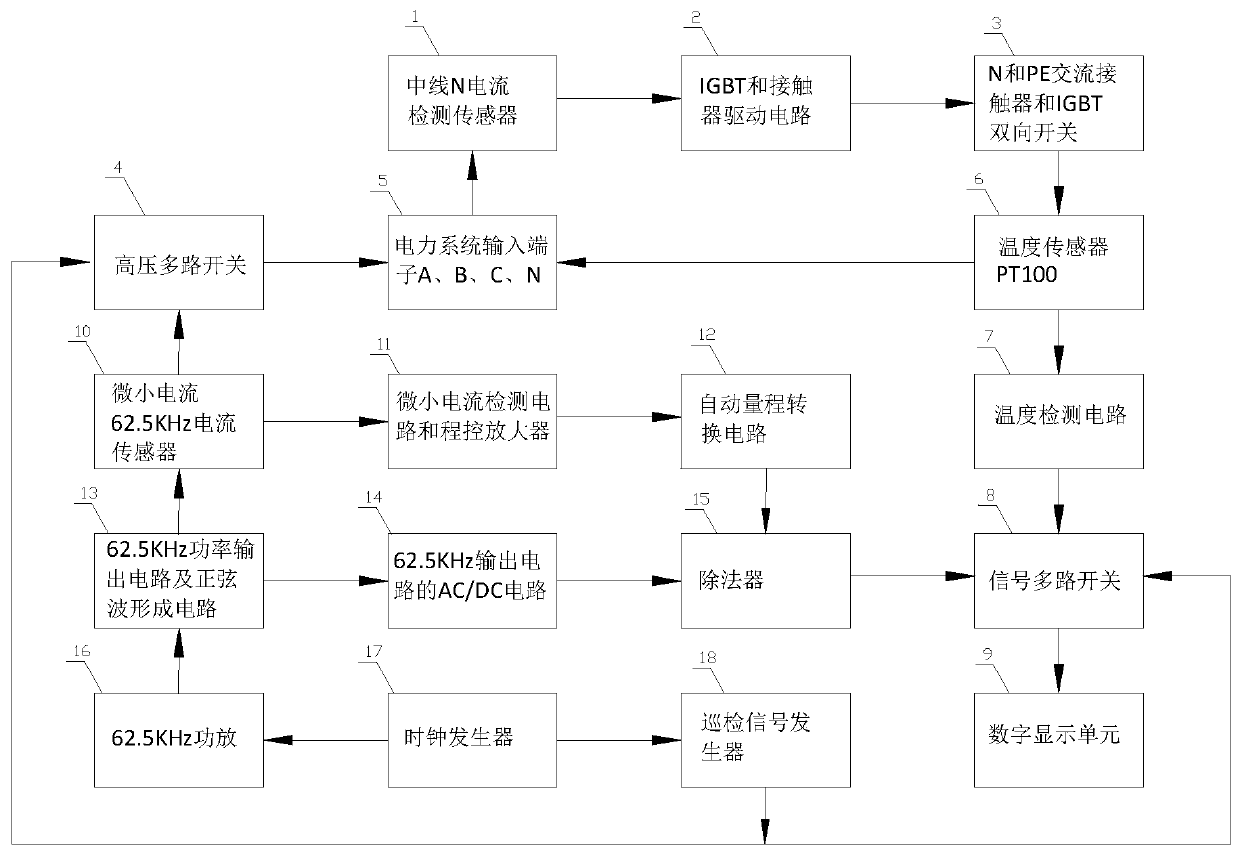

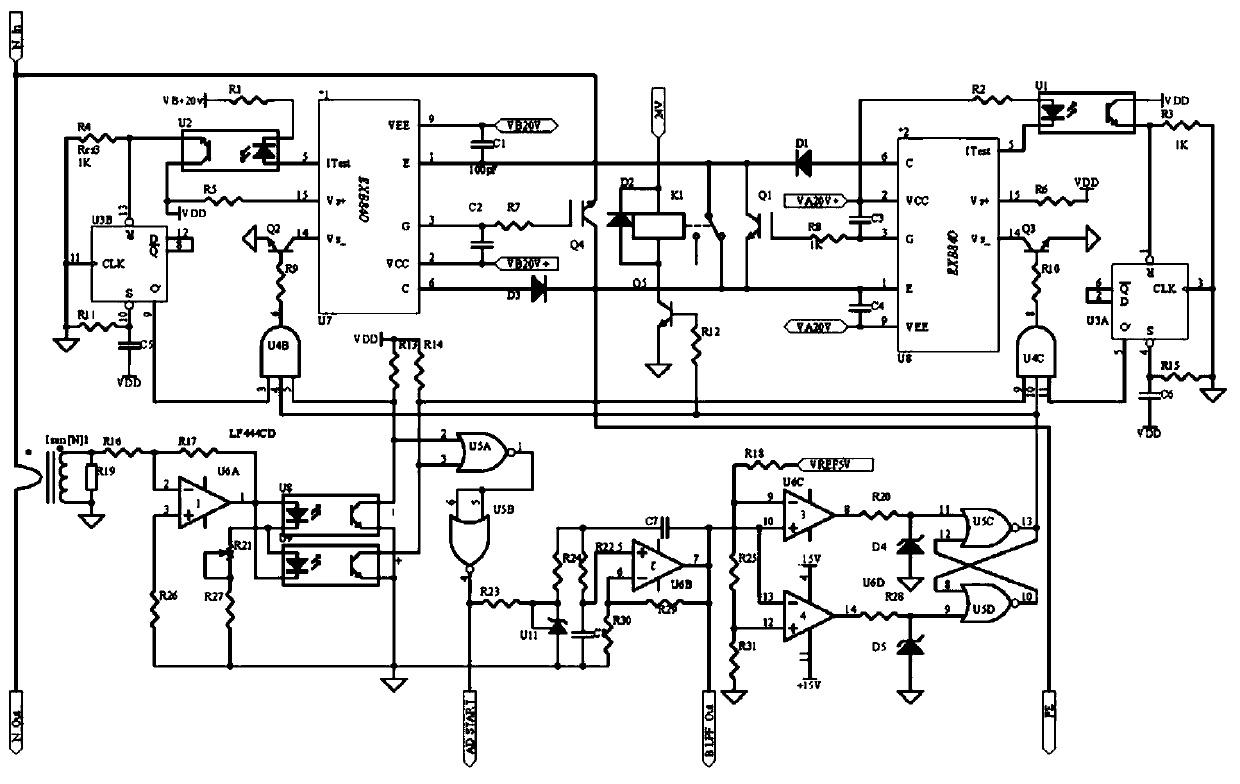

On-line testing device for insulation resistance

ActiveCN110554239AThe detection value is accurateRealize online detectionVery high resistance measurementsInsulation resistanceSignal processing

The invention discloses an on-line testing device for insulation resistance, and the device comprises a signal source which is used for applying an AC voltage signal to a power line; a first current detection unit which is used for detecting a current signal generated by the voltage applied by the signal source in the power line; a signal processing unit which is used for acquiring the current signal detected by the first current detection unit and the voltage signal of the signal source, and calculating the insulation resistance value of the power line according to the acquired current signaland voltage signal; and a display unit which is used for displaying the insulation resistance value of the power line. The device can detect the insulation resistance value of the power line on linein real time, is convenient to operate, is high in detection precision, and guarantees the normal operation of equipment.

Owner:天恩璐(大连)节能服务有限公司 +1

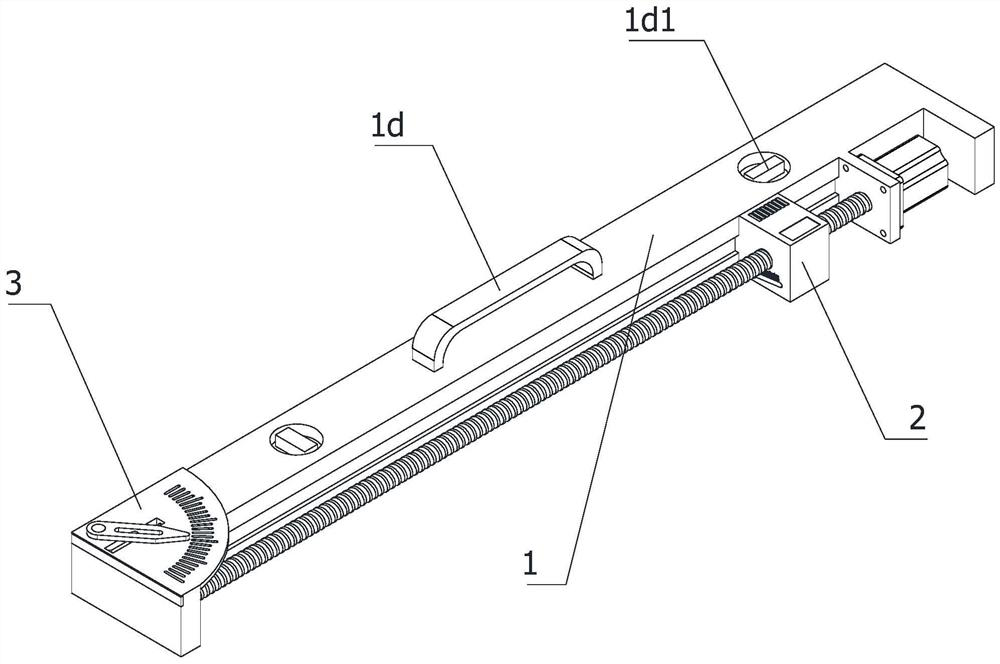

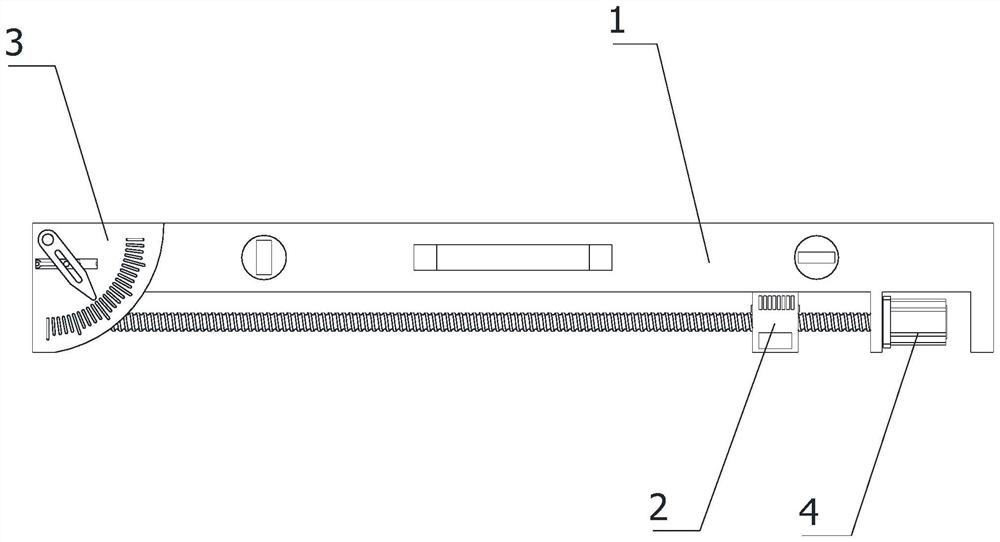

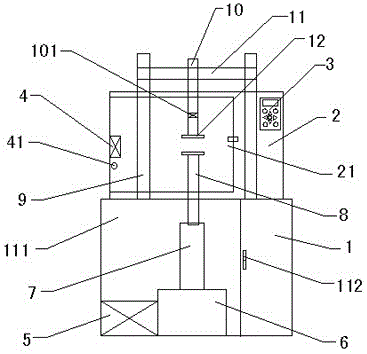

Flatness detection equipment for constructional engineering and use method of flatness detection equipment

InactiveCN114234895AReduce workloadImprove detection efficiencyMeasurement devicesStructural engineeringFeeler gauge

The invention relates to the technical field of flatness detection of constructional engineering, in particular to flatness detection equipment for constructional engineering and a use method thereof, and the flatness detection equipment comprises a measuring scale, and a first measuring head, a first detection surface, a second detection surface, a first sliding rail, a first sliding chute and a second measuring head which are arranged on the measuring scale, the first detection surface is located at the bottom of the measuring ruler, the second detection surface is located at one end of the measuring ruler in the width direction, the first sliding rail is arranged on the side wall of the measuring ruler, the first measuring head is slidably connected to the first sliding rail, the first sliding groove is located at one end of the top of the measuring ruler, and the second measuring head is slidably connected to the first sliding groove. The flatness of the wall surface or the ground is detected by sliding the first measuring head, a plurality of measuring points of the measuring scale do not need to be repeatedly measured through a feeler gauge, the detection efficiency is improved, the workload of workers is relieved, the second measuring head is convenient to read an angle more accurately, whether the angle is vertical or not is judged, and the detection precision is improved.

Owner:谢俊娥

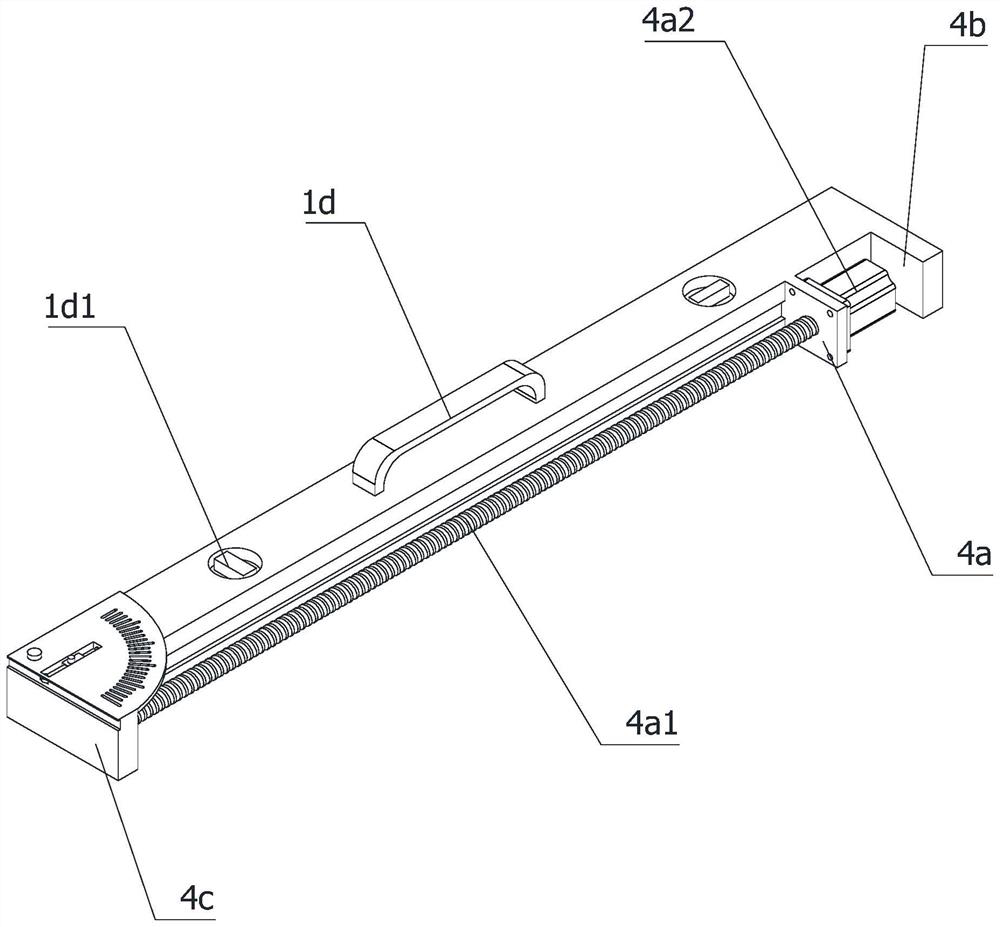

Elevator guide rail end detection device

The invention discloses an elevator guide rail end detection device. Elevator guide rail end detection devices are arranged on two end parts of a guide rail to be detected. Each elevator guide rail comprises a first detection mechanism, a second detection mechanism and a control and detection system. The first detection mechanism is located on a female tenon end of a guide rail, and comprises a first guide mechanism, a first follow-up device and a first measuring tool detection head fixedly connected with the first follow-up device; the first guide mechanism is fixedly connected with the first measuring tool detection head; the second detection mechanism is located on a male tenon end of the guide rail, and comprises a second guide mechanism, a second follow-up device and a second measuring tool detection head fixedly connected with the second follow-up device; and the second guide mechanism is fixedly connected with the second measuring tool detection head. The elevator guide rail end detection device effectively realizes high-precision scanning and detection of female and male tenons on the end parts of the guide rail, and is accurate in detection value, good in detection effect, high in automation degree, convenient to operate, and high in practicability.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

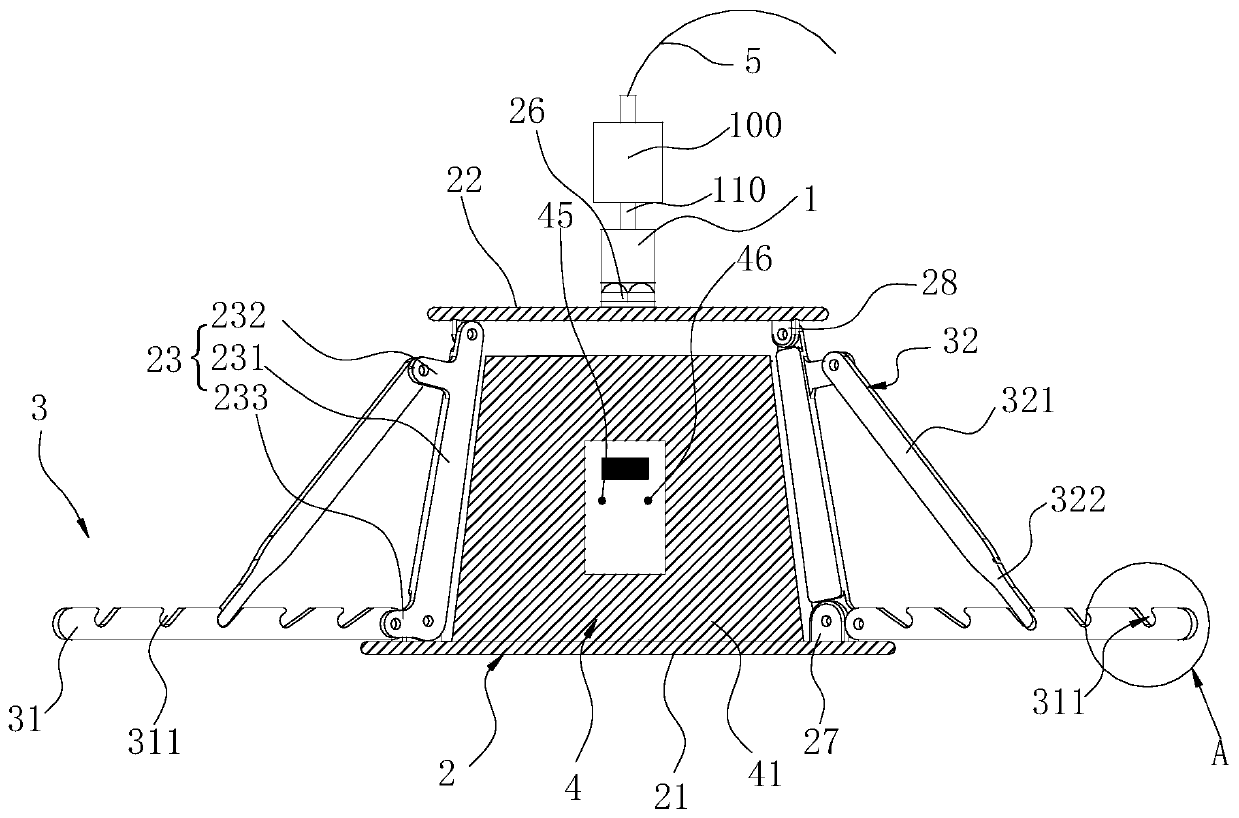

Integral supporting device

ActiveCN111308135AThe detection value is accurateImprove securityMeasurement instrument housingStructural engineeringElectric cables

The invention relates to an integrated supporting device. The device comprises a fixing part, a base, a leveling assembly and an inspection mechanism, the fixing part is used for fixing a cable protector. The fixing part is a metal piece and connected with an electric wire. one end, away from the fixing part, of the wire is connected with an external experimental instrument; the base comprises a substrate, a supporting plate and first connecting rods. The substrate is made of insulating material, the supporting plate is installed above the substrate through at least three first connecting rods. One end of each first connecting rod is hinged with the supporting plate; the fixing part is installed on the side face, deviating from the substrate, of the supporting plate. A leveling assembly isconnected with the base and used for adjusting the levelness of the supporting plate, the inspection mechanism is connected with the electric wire and used for preliminarily verifying whether the cable protector is good or not according to the current of the electric wire, and the inspection mechanism is arranged between the base plate and the supporting plate. The integrated supporting device issimple in structure, convenient to carry, high in detection precision and good in safety.

Owner:GUANGDONG POWER GRID CO LTD +1

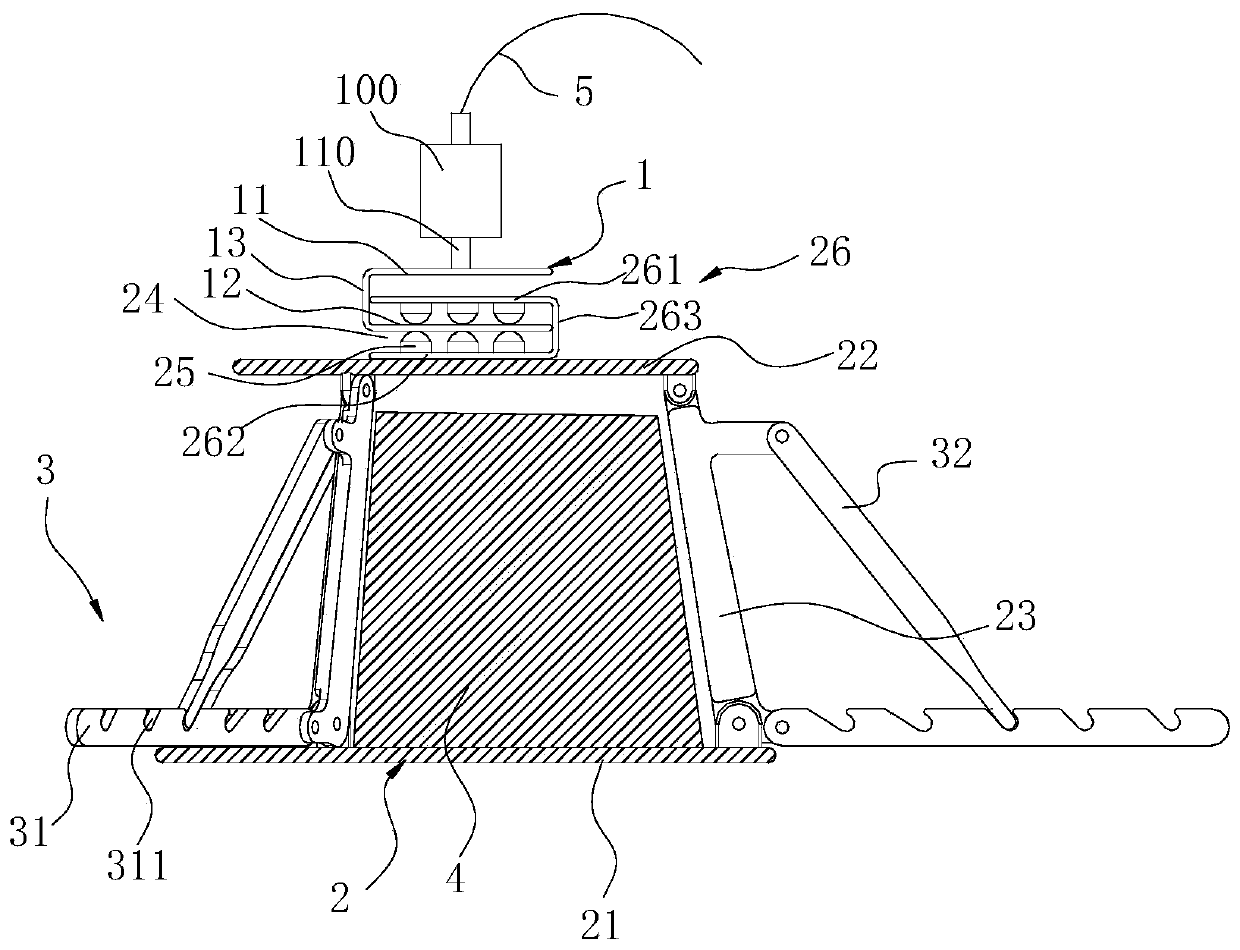

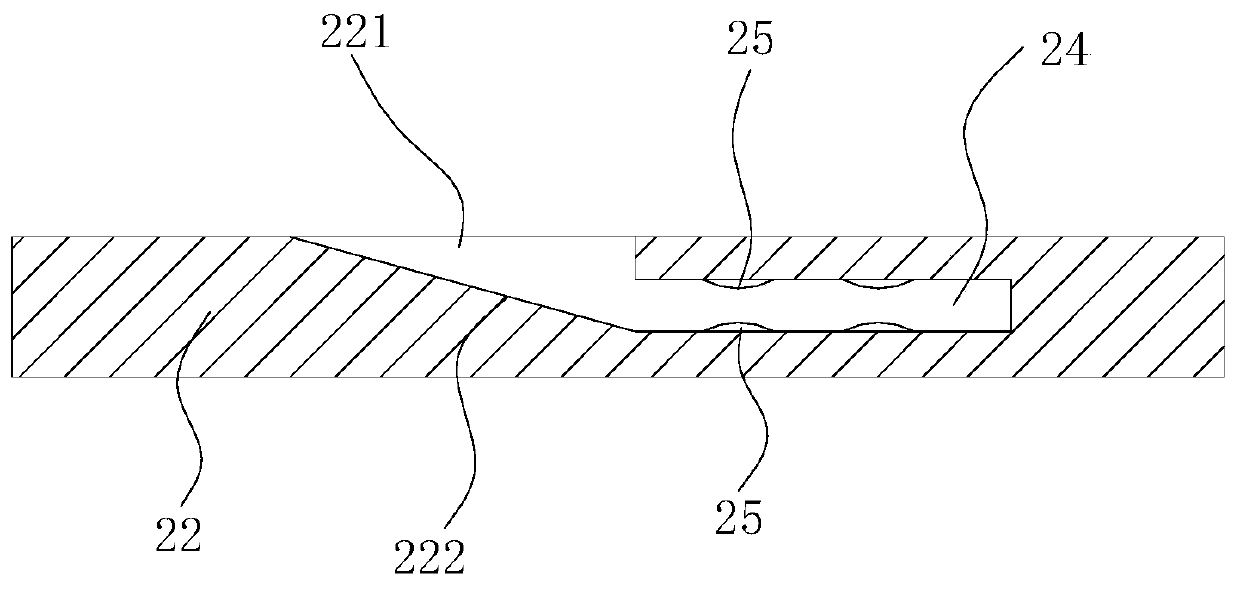

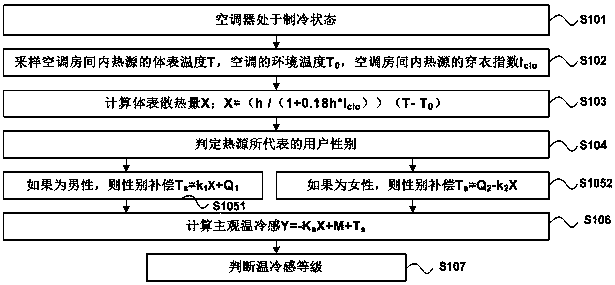

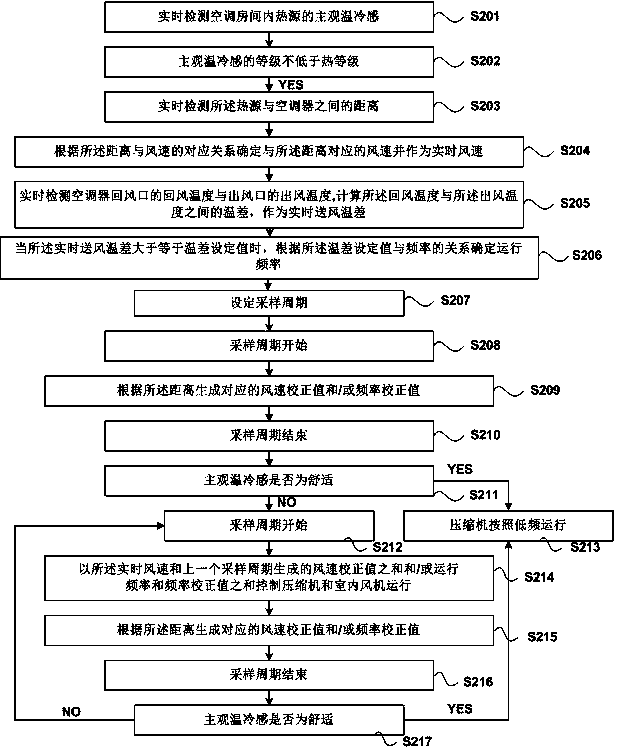

Temperature sense air conditioner control method based on gender compensation and air conditioner

ActiveCN108317691AThe detection value is accurateImprove comfortMechanical apparatusLighting and heating apparatusEngineeringBody surface

The invention discloses a temperature sense air conditioner control method based on gender compensation. Subjective temperature sense of heat sources in an air-conditioned room is detected in real time through the following methods: heat source surface temperatures, environmental temperatures and dressing indexes Iclo are sampled, and heat source surface heat dissipating quantities are calculated;user genders represented by the heat sources are judged: if users are males, the gender compensation is calculated according to the following formla: Ts=k1X+Q1; if the users are females, the gender compensation is calculated according to the following formla: Ts=Q2-k2x, wherein k1 is smaller than k2, and Q1 is smaller than Q2; the subjective temperature sense Y is calculated, Y=-KsX+M+Ts; and thesubjective temperature sense grade is judged according to the numerical value of the subjective temperature sense Y. Meanwhile, the invention discloses an air conditioner. The advantage of high intelligence degree is achieved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Double-surface indication pressure meter

PendingCN107436206AReduce mistakesThe detection value is accurateForce measurementFluid pressure measurementEngineeringPhysics

The invention discloses a double-surface indication pressure meter which comprises a pressure meter shell. A heat insulating shell is fixedly connected on the outer wall of the pressure meter shell, a containing shell is fixedly connected at the top of the heat insulating shell and communicated with the heat insulating shell, a communication opening is formed in the top of the pressure meter shell, the pressure meter shell is communicated with the heat insulating shell through the communication opening, an air inlet device is arranged in the containing shell, and a ventilation hole is formed in the top of the containing shell. The double-surface indication pressure meter is provided with the air inlet device, electric heating wires, a treatment device, a first feedback module, a second feedback module, a first comparison module, a second comparison module, a first temperature sensor and a second temperature sensor, so that the temperature in the pressure meter can be detected, heating treatment is performed when the temperature is lower, the pressure meter can work under suitable temperature, detection errors of the pressure meter can be reduced, numerical values can be accurately detected by the pressure meter, and use of people is facilitated.

Owner:WUXI CITY KAIFENG PRESSURE GAUGES CO LTD

Pavement material detector

InactiveCN105115829AEasy to operateThe detection value is accurateMaterial strength using tensile/compressive forcesTemperature controlBiochemical engineering

The invention discloses a pavement material detector. A temperature change box is fixed on a base, a supporting rod is fixedly connected with the base, a cross beam is arranged on the upper portion of a supporting frame, a clamping plate fixing rod is arranged in the middle of the cross beam, a pressure sensor is arranged on the clamping plate fixing rod, a temperature control device is arranged on the inner wall on the left side of the temperature change box, a temperature sensor is arranged below a temperature change control device, the temperature change control device and the temperature sensor are electrically connected with a controller, a motor is arranged at the bottom of the base, a compressor is arranged on the left side of the motor, an extensible device is arranged on the motor, the motor, the compressor and the the extensible device are electrically connected with the controller, and the controller is arranged on the right side of the temperature change box. The pavement material detector is simple to operate, accurate in detection value and wide in application range.

Owner:江苏建研建设工程质量安全鉴定有限公司

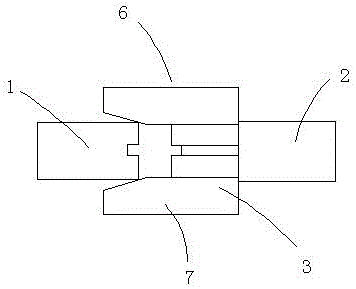

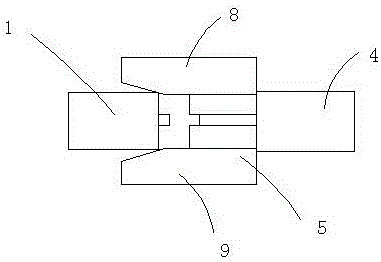

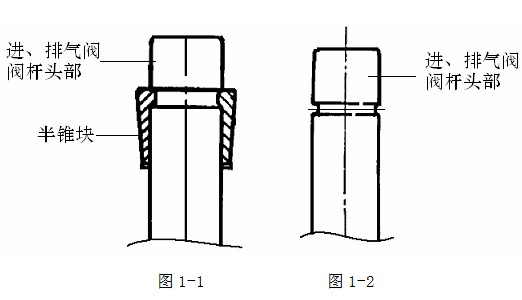

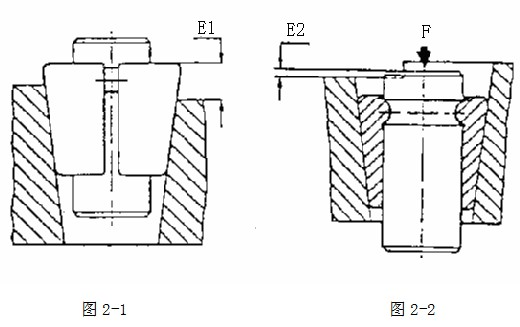

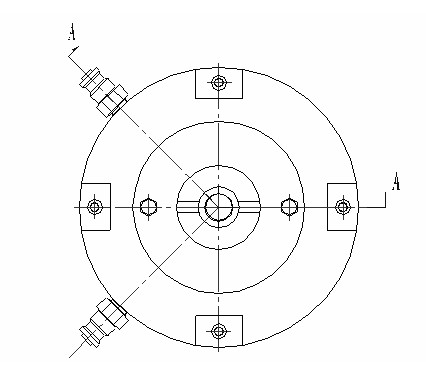

Device for testing material property of hemiconical block of air valve

ActiveCN102410959ASimple structureCompact structureMaterial strength using tensile/compressive forcesHydraulic cylinderEngineering

The invention discloses a device for testing material property of a hemiconical block of an air valve. In structure, the device comprises a stretcher, a valve rod and a conical block seat, wherein the stretcher comprises a cylindrical hydraulic cylinder, which consists of an upper part of the hydraulic cylinder and a lower part of the hydraulic cylinder; the upper part of the hydraulic cylinder and the lower part of the hydraulic cylinder are respectively provided with a quick joint; the conical block seat is in a convex shape, and an obconical through hole is formed at the centre of the conical block seat; the conical block seat is connected with the top of the hydraulic cylinder; and a hemiconical block is mounted at the upper part of the valve rod, and the lower part of the valve rod is connected with a piston in the hydraulic cylinder. Hydraulic oil is injected through the upper and lower quick joints, so as to control the stretcher to ascend or descend, and further control the valve rod to ascend or descend.

Owner:HUDONG HEAVY MACHINERY

Quick qualitative detection method for heptafluoropropane fire extinguishing agent and implementation device of method

The invention discloses a quick qualitative detection method for a heptafluoropropane fire extinguishing agent and an implementation device of the method, and relates to the field of gaseous fire extinguishing agents. The method mainly comprises the steps that the medium pressure in a heptafluoropropane standard sample bottle and the medium pressure in a sampling bottle at the same temperature are measured according to the principle that at the same temperature, heptafluoropropane and other fire extinguishing agents have the different saturated vapor pressures; if the medium pressure in the standard sample bottle and the medium pressure in the sampling bottle are same, a sample to be detected is heptafluoropropane; if the medium pressure in the standard sample bottle and the medium pressure in the sampling bottle are different, the sample to be detected is not heptafluoropropane. Therefore, the function of quickly and conveniently detecting the heptafluoropropane fire extinguishing agent is achieved.

Owner:CHONGQING RISING GAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com