Automatic centering system used for track flaw detection and centering detection method thereof

An automatic centering and track technology, which is applied in the field of track flaw detection and displacement sensor, can solve the problems that cannot satisfy the lateral offset detection of track flaw detection, large error of electromagnetic displacement sensor, etc., and achieve high reliability, adjustable detection accuracy, real-time good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

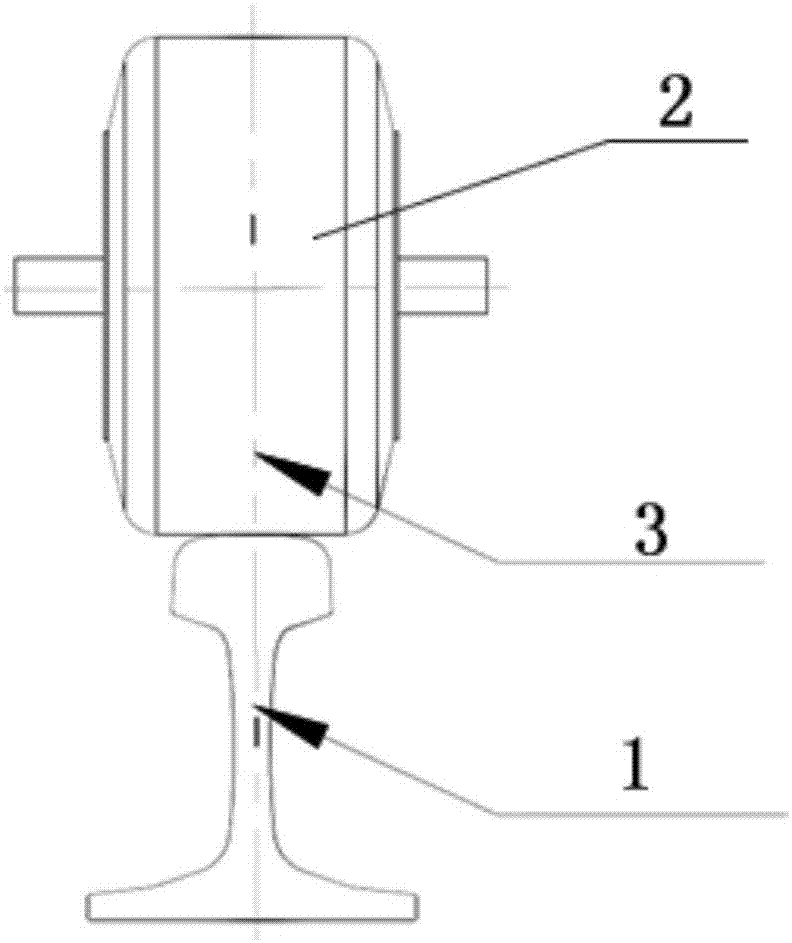

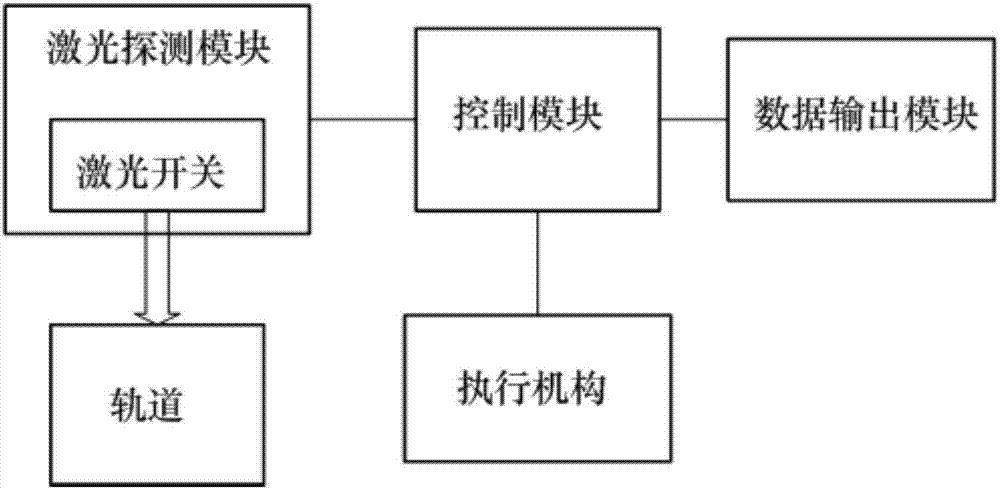

[0036] The invention provides an automatic centering system for rail flaw detection, such as figure 2 As shown, the automatic centering system mainly includes a control module and a laser detection module arranged on the probe wheel 2 . The laser detection module includes a plurality of laser switches 4 arranged at equal intervals, and the control module mainly receives signals from the laser detection module to calculate the horizontal line offset.

[0037] Specifically, since the laser switch 4 can emit a laser beam to detect whether there is an object in the irradiation place, the laser switches 4 in the laser detection module of the present invention are arranged at equal intervals, and each laser switch 4 can illuminate the tracks parallel to each other and perpendicular to each other. The laser beams of the track, that is, the laser beams emitted by the laser switches 4 are arranged at equal intervals, and the edge of the track is irradiated with parallel laser beams at...

Embodiment 2

[0052] On the basis of the above-mentioned embodiment 1, this embodiment provides the arrangement form of the laser switches 4. The laser switches 4 can be arranged horizontally or obliquely at a certain interval, but it should be noted that for the convenience of calculating the lateral offset No matter whether the laser switches 4 are arranged horizontally or obliquely, it is necessary to ensure that the distance between adjacent laser switches 4 in the horizontal direction is the diameter of the laser beam.

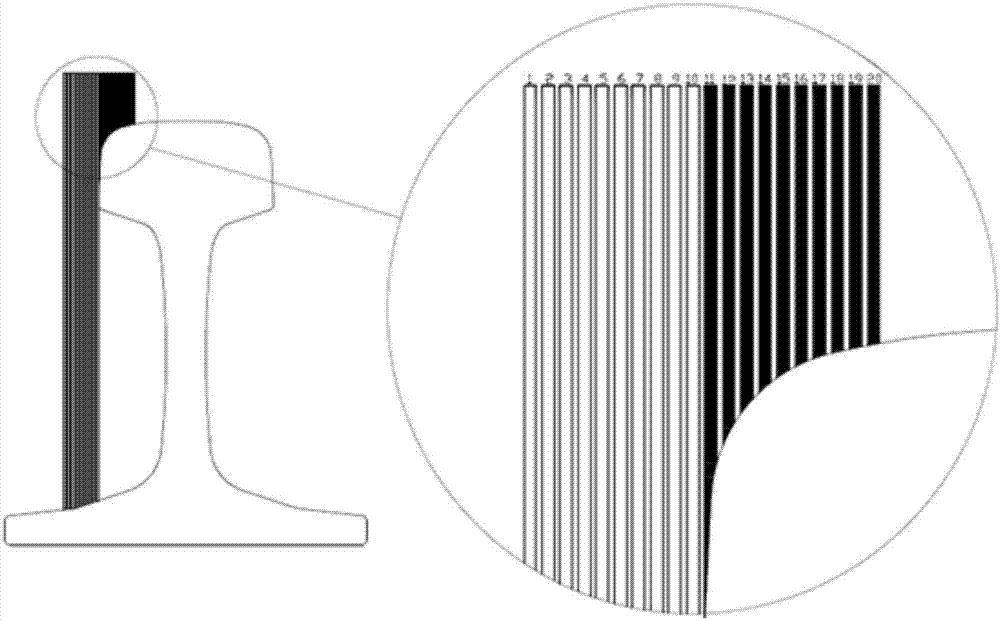

[0053] Such as Figure 5 As shown, adjacent laser switches 4 are arranged laterally at equal intervals on the laser detection module with the diameter of the laser beam as the lateral interval. Since the laser switch 4 itself has a certain size, and the laser switch 4 that is close to each other will generate signal interference, considering the actual application situation, such as Figure 6 As shown, in practical applications, in order to avoid signal interference f...

Embodiment 3

[0055] On the basis of the foregoing embodiment 1 and embodiment 2, this embodiment additionally provides an arrangement form of the laser switches 4 . When the detection range is large, the laser switches 4 arranged according to the arrangement of the laser switches 4 in Embodiment 1 and Embodiment 2 have a wider lateral width. In order to save the space occupied by the laser switches 4, in this embodiment, The laser detection module includes multiple laser switch groups arranged obliquely side by side, and the number of laser switch groups can be selected according to the detection range.

[0056] The number of laser switches 4 in each laser switch group is equal, and the number of laser switches in each laser switch group is multiplied by the laser beam diameter between multiple laser switch groups. At the same time, adjacent laser switches 4 in each laser switch group are arranged obliquely at equal intervals with the laser beam diameter as the transverse interval. At thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com