Novel dephosphorization wheel set

A phosphor wheel, a new type of technology, used in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as wheel sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

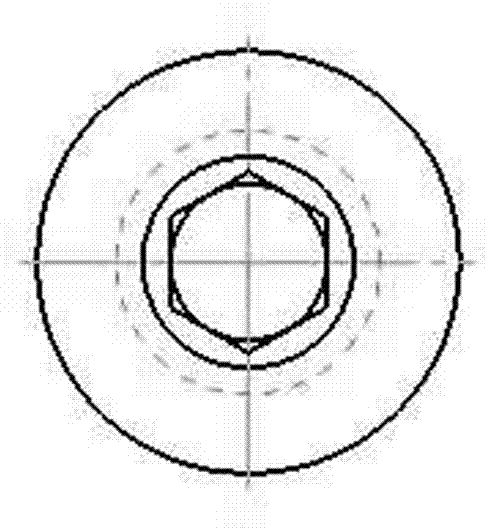

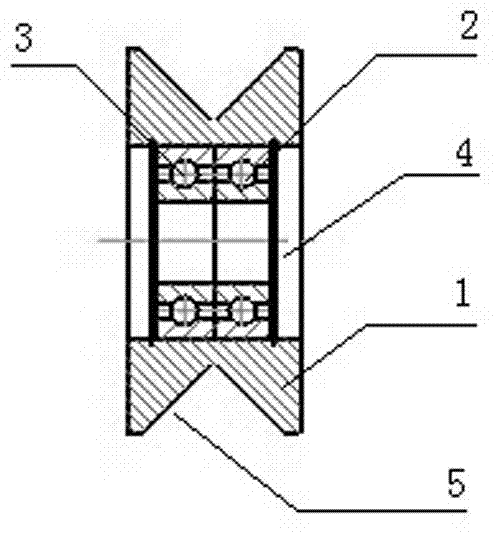

[0013] Such as figure 1 , figure 2 As shown, the phosphorus removal wheel set of this patent is composed of a phosphorus removal wheel 1, a first bearing 2, and a second bearing 3. The phosphorus removal wheel 1 is provided with a groove 5 along the circumferential direction, and the middle part of the phosphorus removal wheel 1 has a wheel shaft hole. 4. The first bearing 2 and the second bearing 3 are arranged in the axle hole 4 in parallel.

[0014] Furthermore, preferably the groove 5 is a V-shaped groove.

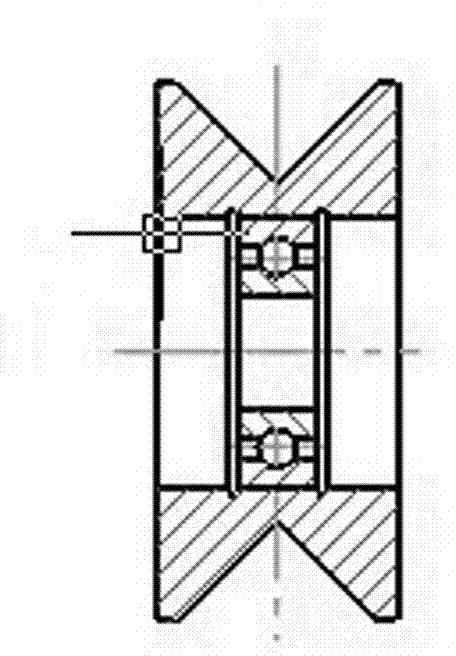

[0015] image 3 It is a sectional view of the current common dephosphorization wheel set structure. It can be seen in the figure that the dephosphorization wheel uses a bearing. The bearing is assembled in the phosphorus removal wheel. When the steel wire passes through the phosphorus removal wheel, it drives the bearing to rotate. Because the bearing surface area is much smaller than the phosphorus removal wheel The surface area of the dephosphorization wheel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com