Combination type inner-burr cleaning and weld guiding device

A guiding device and combined technology, which is applied in the field of devices combining steel pipe in-line burr removal and welding seam guide rollers, can solve the problems of affecting production speed, large swing and twist of the cutter head, and difficulty in fixing, etc., to achieve installation and use It is convenient to change specifications, enhance the overall structural strength, and enhance the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

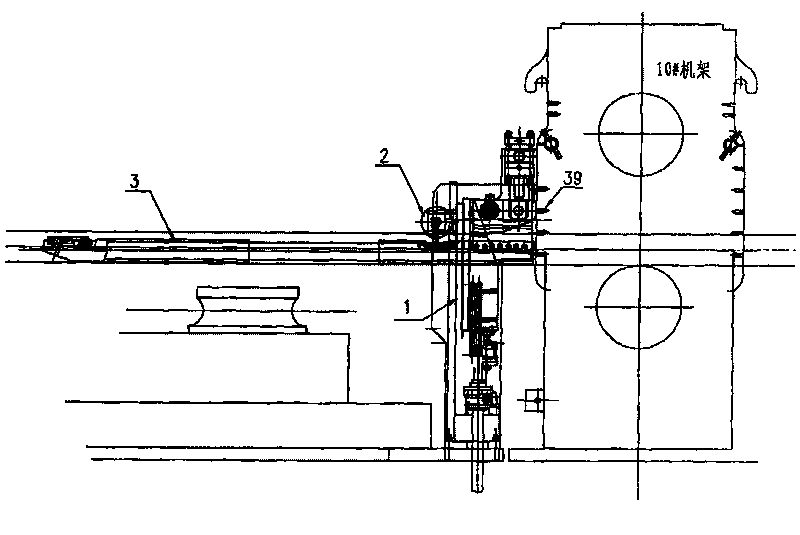

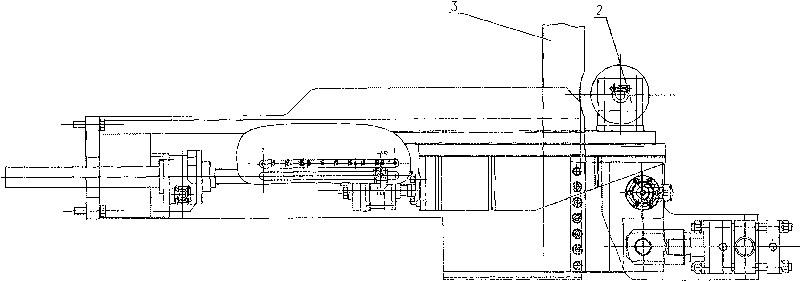

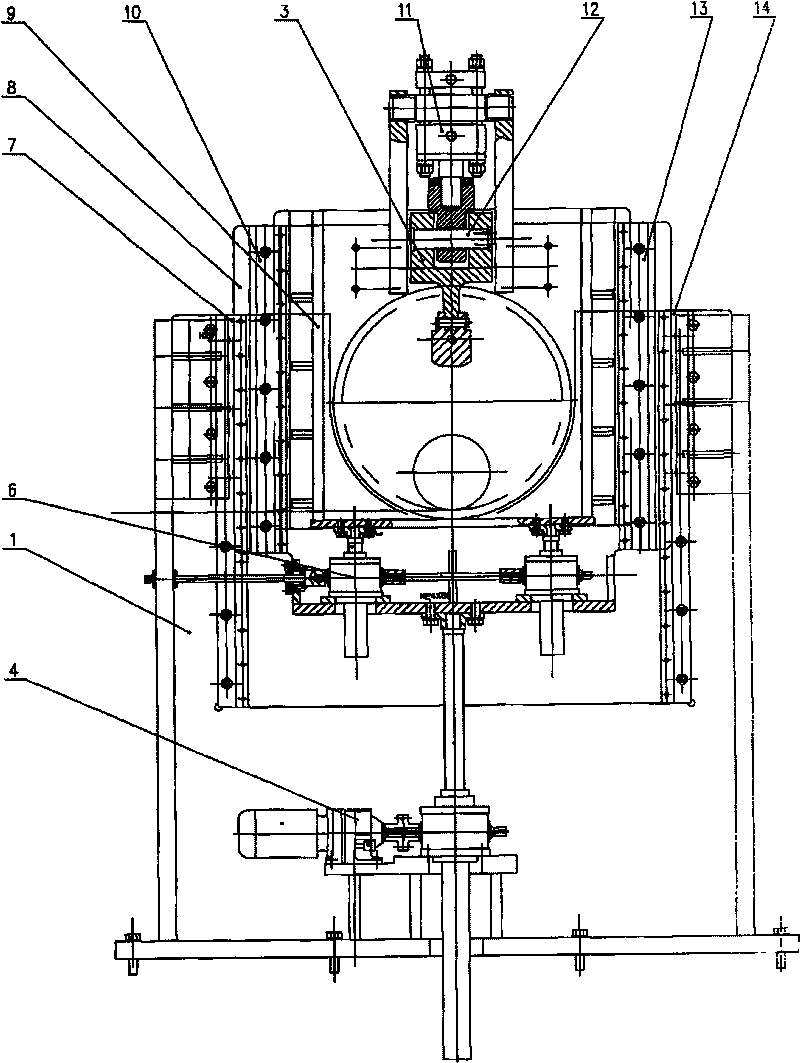

[0028] refer to figure 1 , 2 , 3. The combined internal burr removal and weld guide device is divided into three parts as a whole. The fixed bracket 1 is installed on the side of the tenth forming frame through bolts 39. The weld guide roller assembly 2 is installed on the fixed bracket 1. The knife The tail portion of the rod assembly 3 is installed on the fixed bracket 1 to form a combined type with a simple and practical structure.

[0029] The fixed support 1 is equipped with a total of two planks, a large plank 8 and a small plank 9. The large plank 8 is fixed on the fixed support 1 with the first left pressing plate 7 and the first right pressing plate 14, and can slide up and down. Electric adjustment mechanism 4 is arranged below and can be manually operated to regulate the integral height of cutter bar by different steel pipe specifications; Be equipped with welding seam guide roller 2 with bolt 15 on the left side of big plank 8, and small plank 9 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com