Double-layer reverse rotation vertical-shaft wind-power machine using horizontal combination active wing

A technology of reverse rotation and movable wings, which is applied to wind turbines, wind turbines, wind turbine components and other directions at right angles to the wind direction, can solve the problems of easy accumulation of dirt on the wing shaft, increased manufacturing costs, poor operation, etc. The effect of reducing production cost, improving efficiency and improving cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

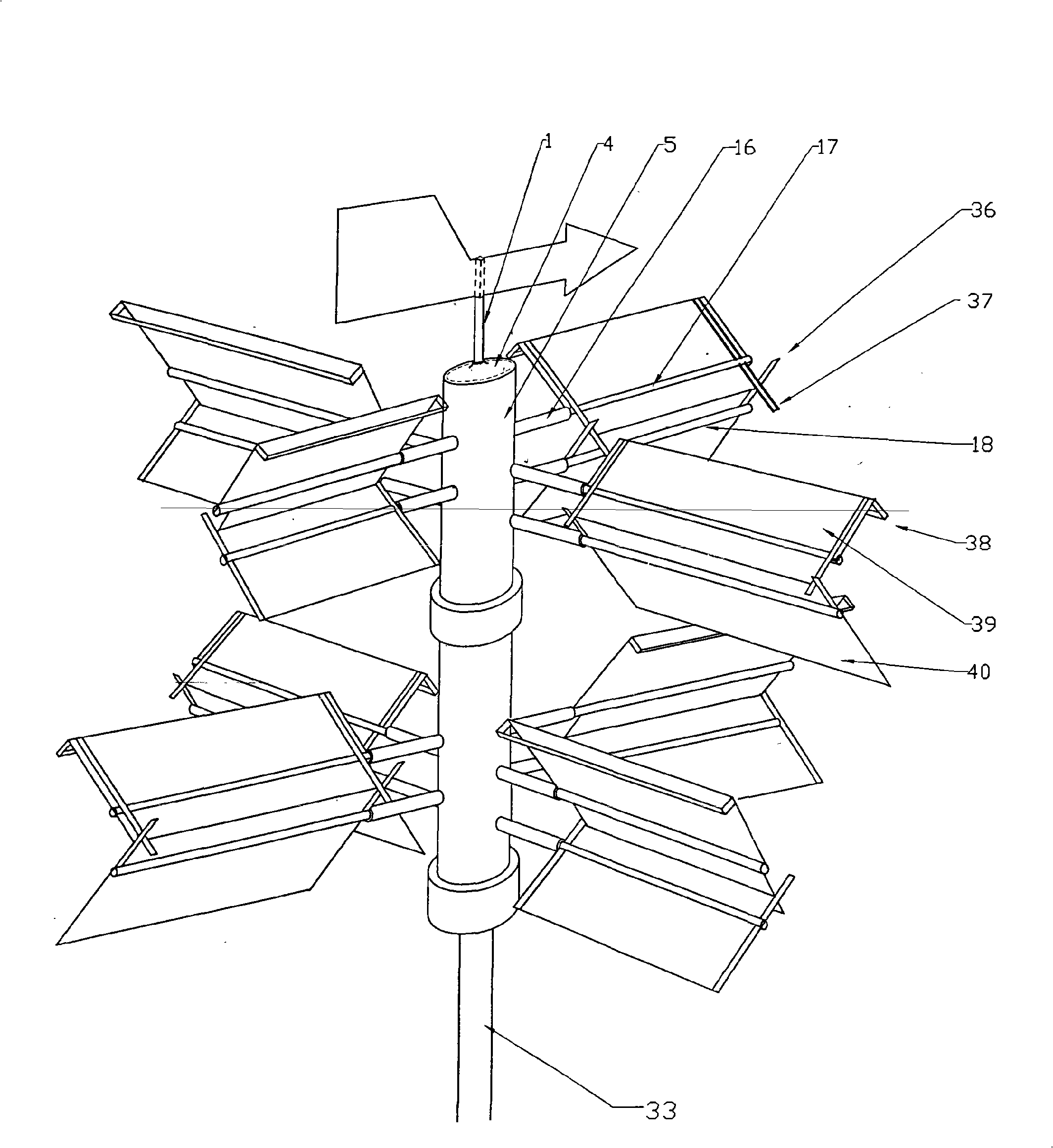

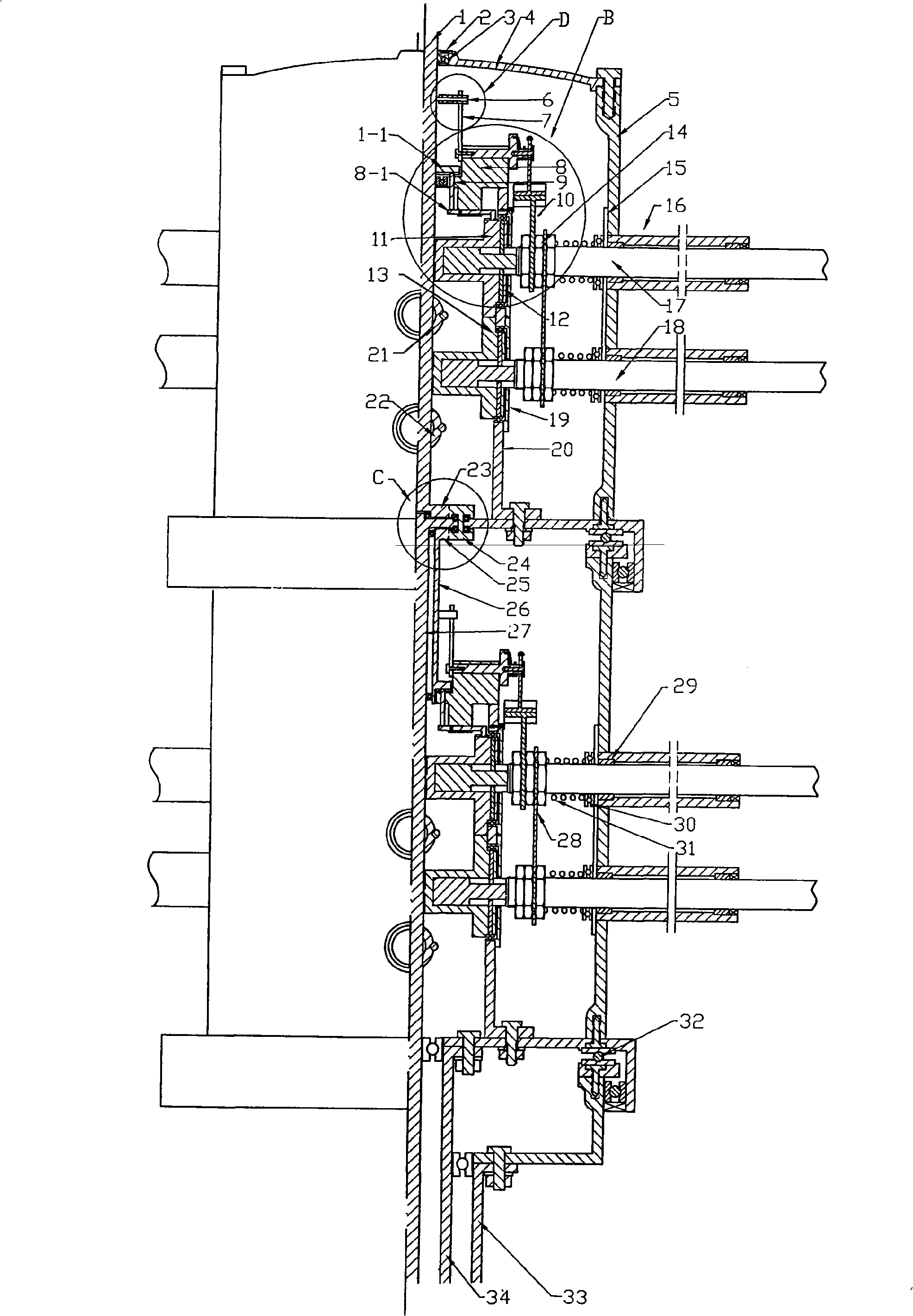

[0032] In order to make the explanation more concise and clear, I had to imagine a few nouns by myself (I don’t know how to say the terms, and I hope the teacher can correct me if I am wrong), so it is necessary to explain in advance:

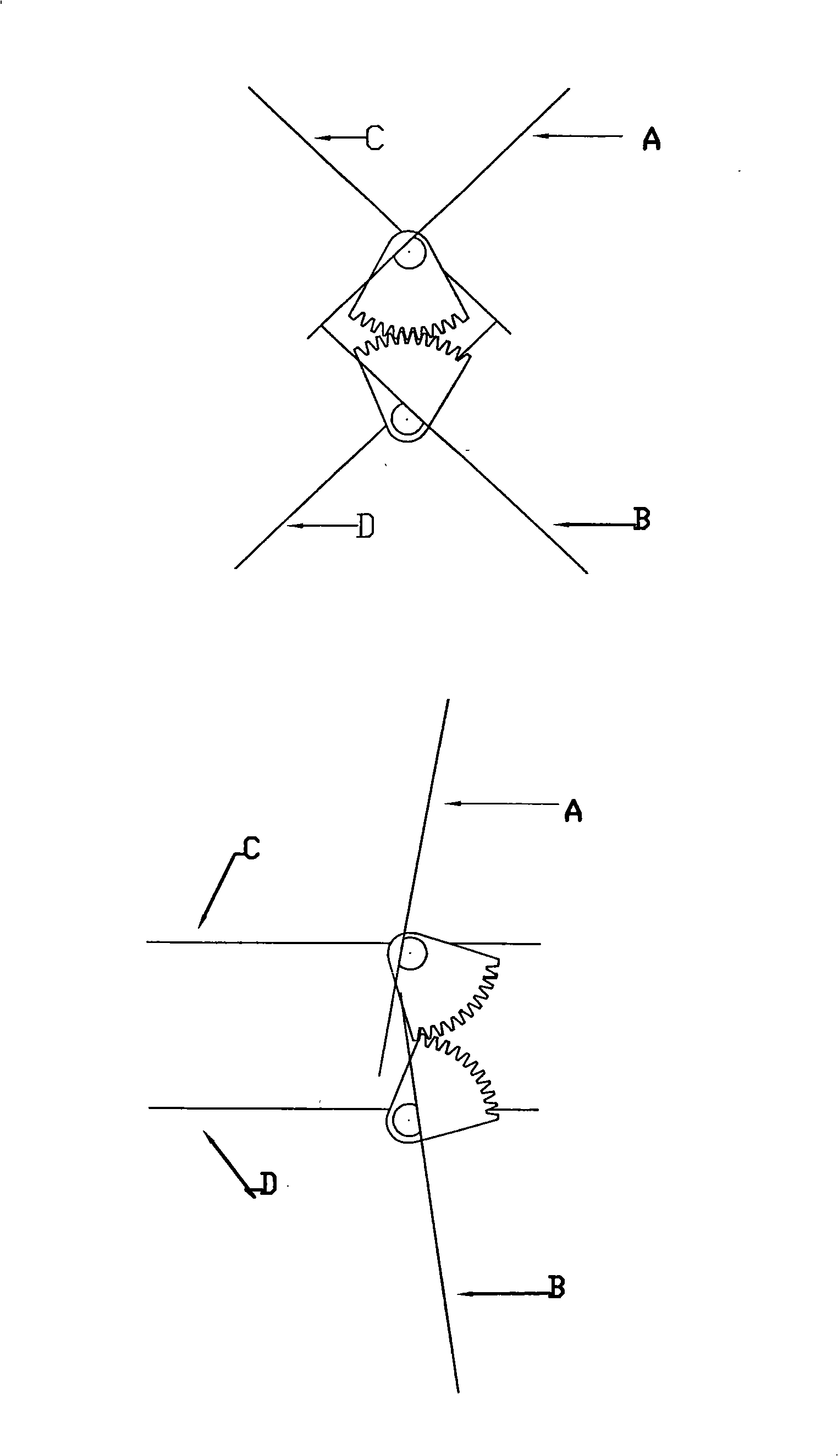

[0033] Blade—the so-called blade in the present invention refers to an independent part installed on the blade shaft and used to combine the blades associated with the upper (or lower) of the wind turbine on this floor to form a movable wing.

[0034] Wing—the so-called wing in the present invention refers to a blade group composed of upper and lower movable blades on the same side associated with each other in a single-layer wind turbine.

[0035] Downwind wing - the wing that does work under the action of the wind, we call it the downwind wing.

[0036] Upwind wing - the wing corresponding to the downwind wing on the wind turbine, we call it the upwind wing.

[0037] Quasi-downwind wing——When the wind turbine rotates, the angle between the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com