Space three-dimensional multidirectional-adjusting aluminum alloy support system

An aluminum alloy, three-dimensional technology, applied in the field of three-dimensional multi-adjustment aluminum alloy support system in space, can solve the problems of low installation accuracy, time-consuming and laborious support adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

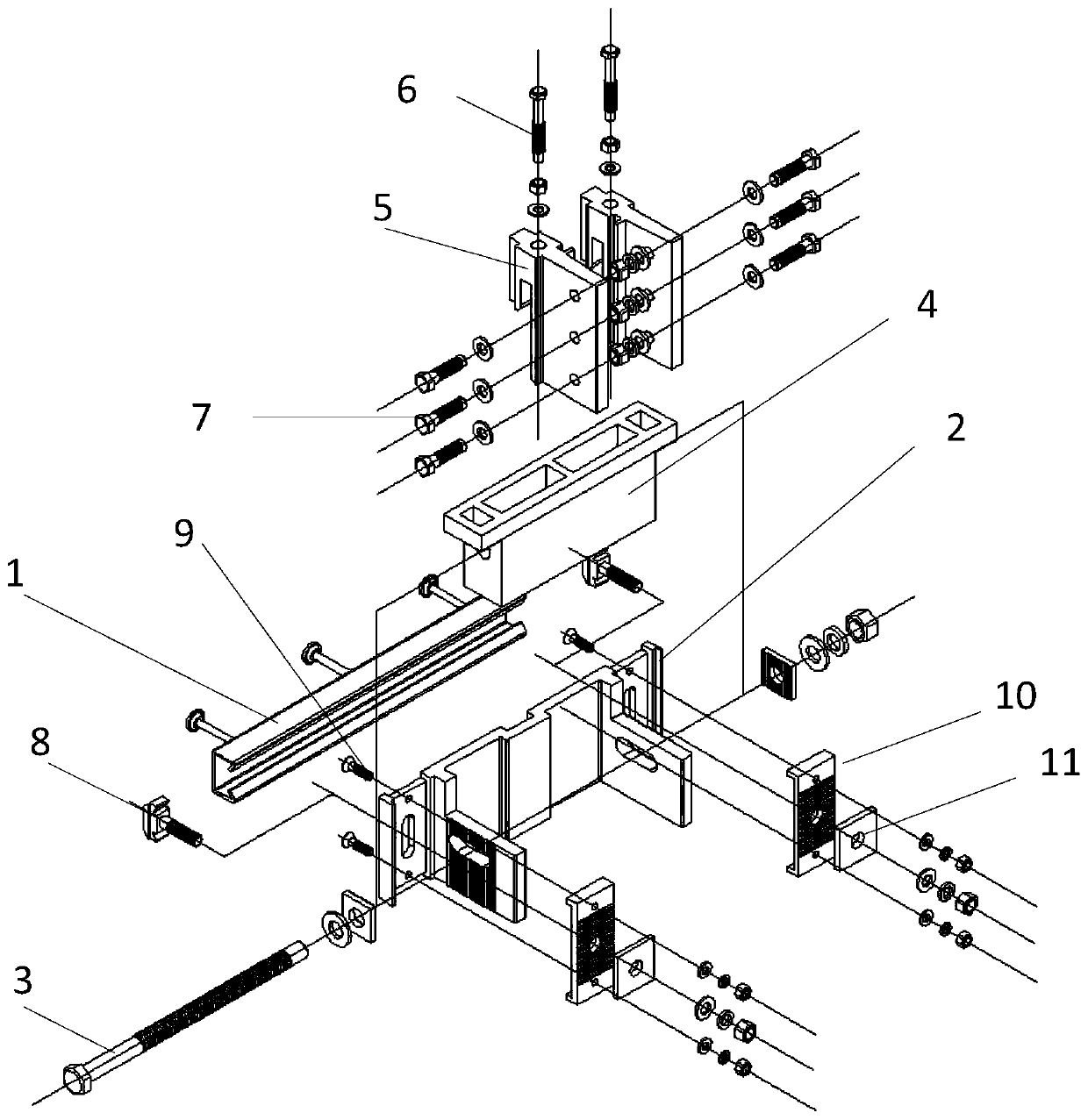

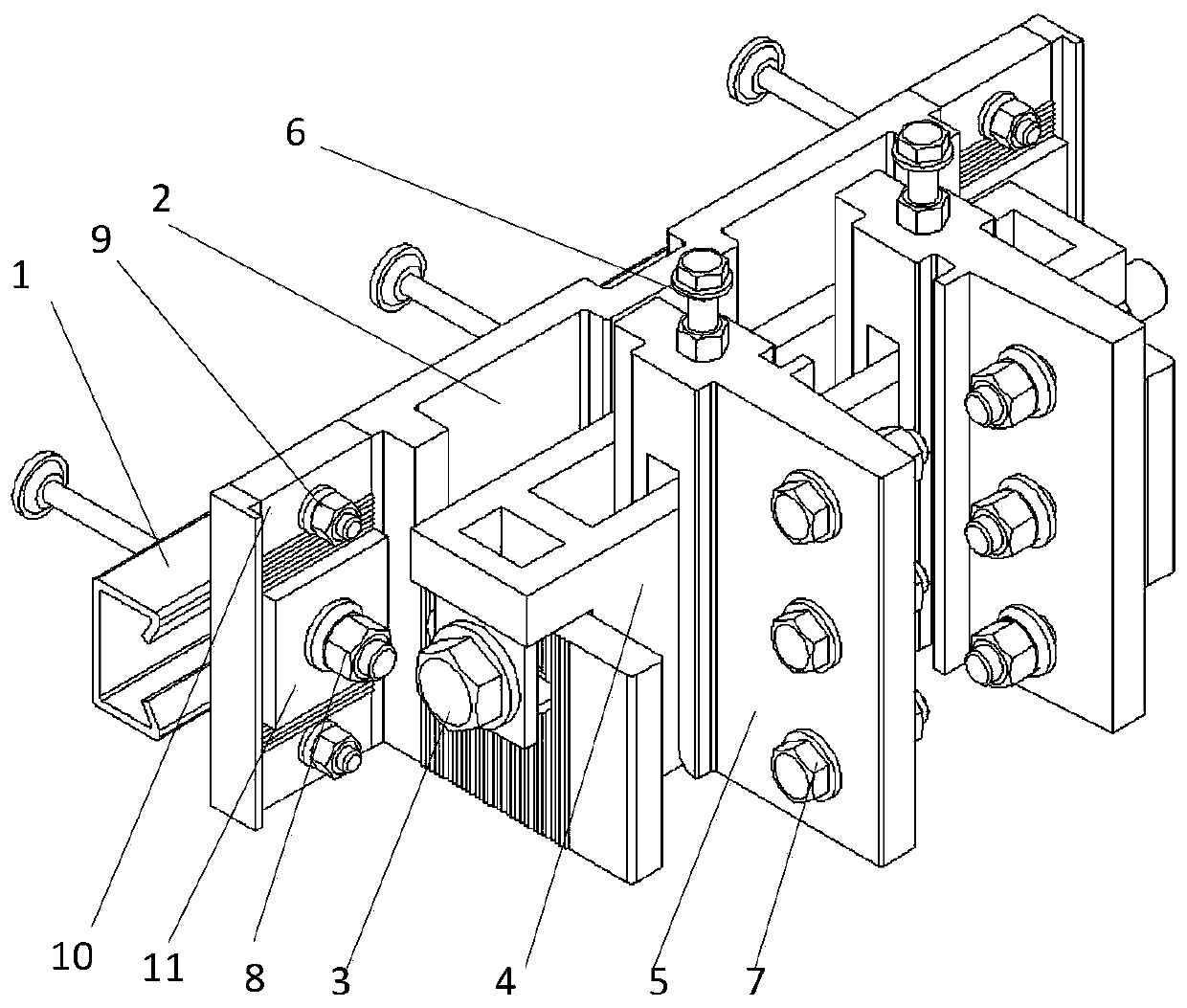

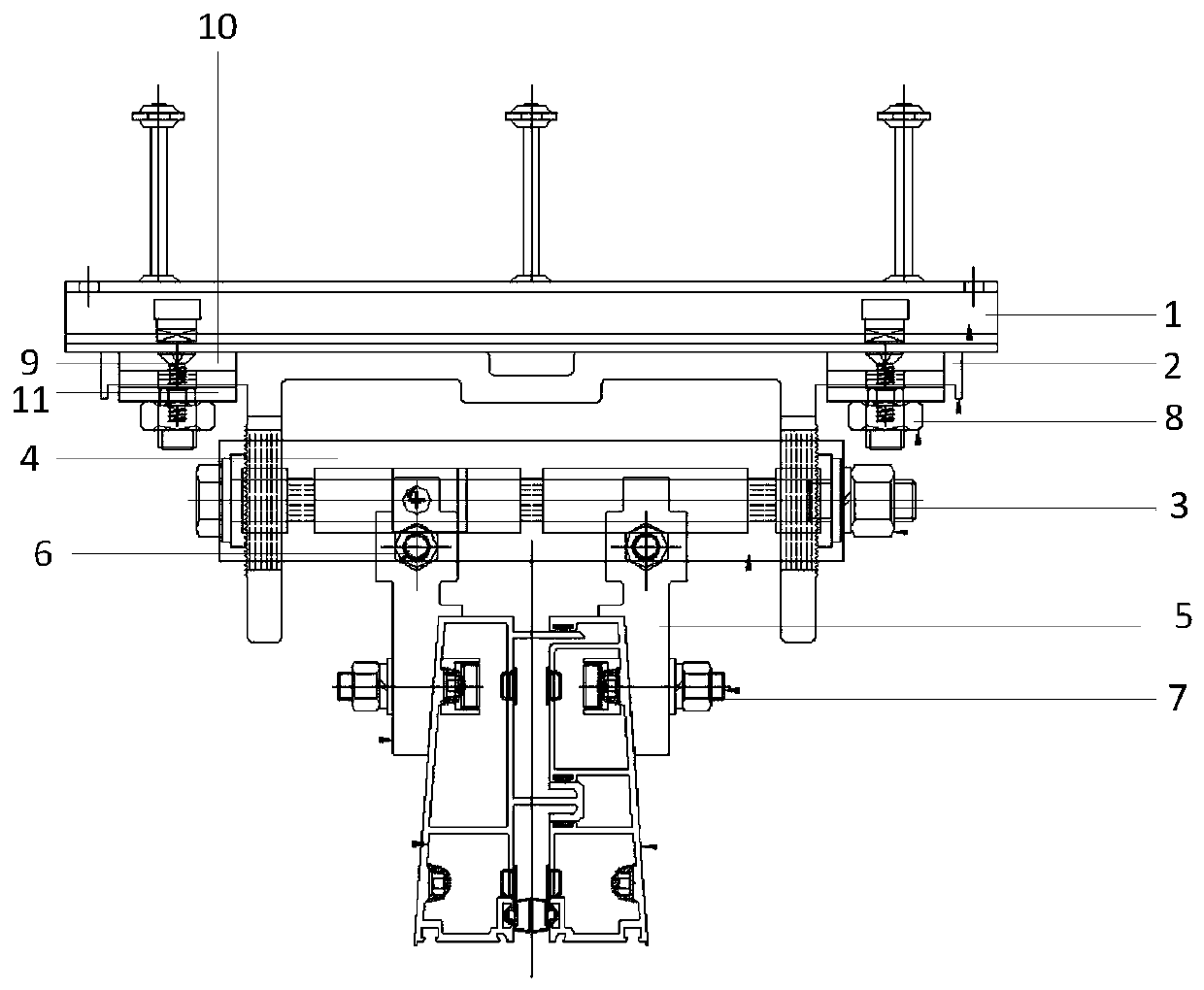

[0019] like Figure 1-3 As shown, a three-dimensional multi-adjustment aluminum alloy support system includes a Hafen slot 1 and an aluminum alloy embedded plate 2. One end of the Hafen slot 1 is set in the wall along the X-axis direction and its notch faces the outside of the wall. , the aluminum alloy buried plate 2 is closely arranged on the outside of the notch, the aluminum alloy buried plate 2 has a symmetrical structure on both sides, and the two sides are respectively provided with a connecting device and a vertical plate, and the connecting device includes a first waist-shaped hole arranged along the Z-axis direction; The two ends of the connection device are fitted with T-bolts 8, aluminum alloy transfer codes 10 and aluminum alloy transfer pads 11 respectively. One end of the T-shaped bolts 8 is connected to the notch, and the other end passes through the first waist-shaped hole, aluminum alloy Alloy transfer code 10 and aluminum alloy transfer pad 11, the connectin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com