Construction process of open sea fan foundation rock-socketed pile

A construction technology and fan foundation technology, which is applied in the direction of foundation structure engineering, foundation structure test, sheet pile wall, etc. The effect of horizontal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

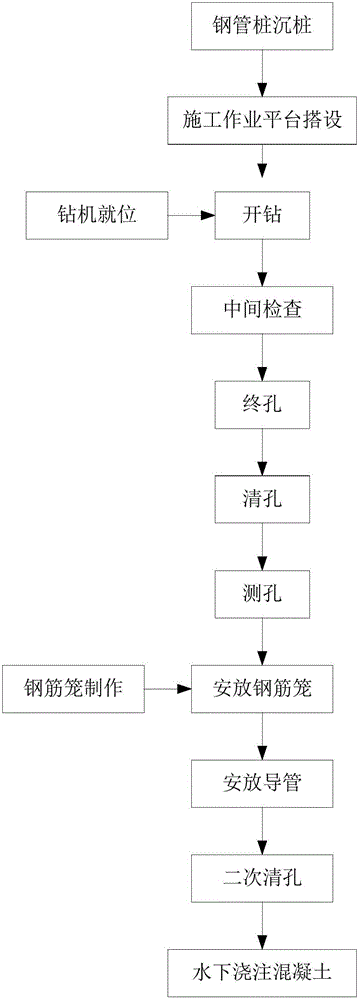

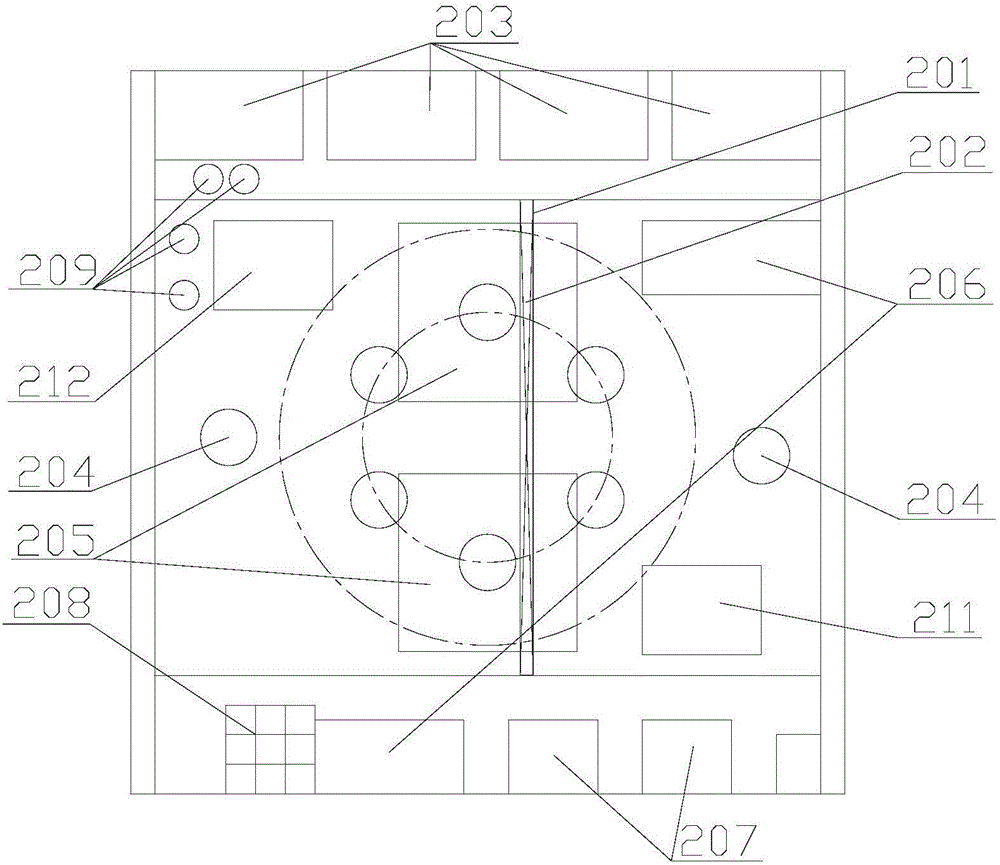

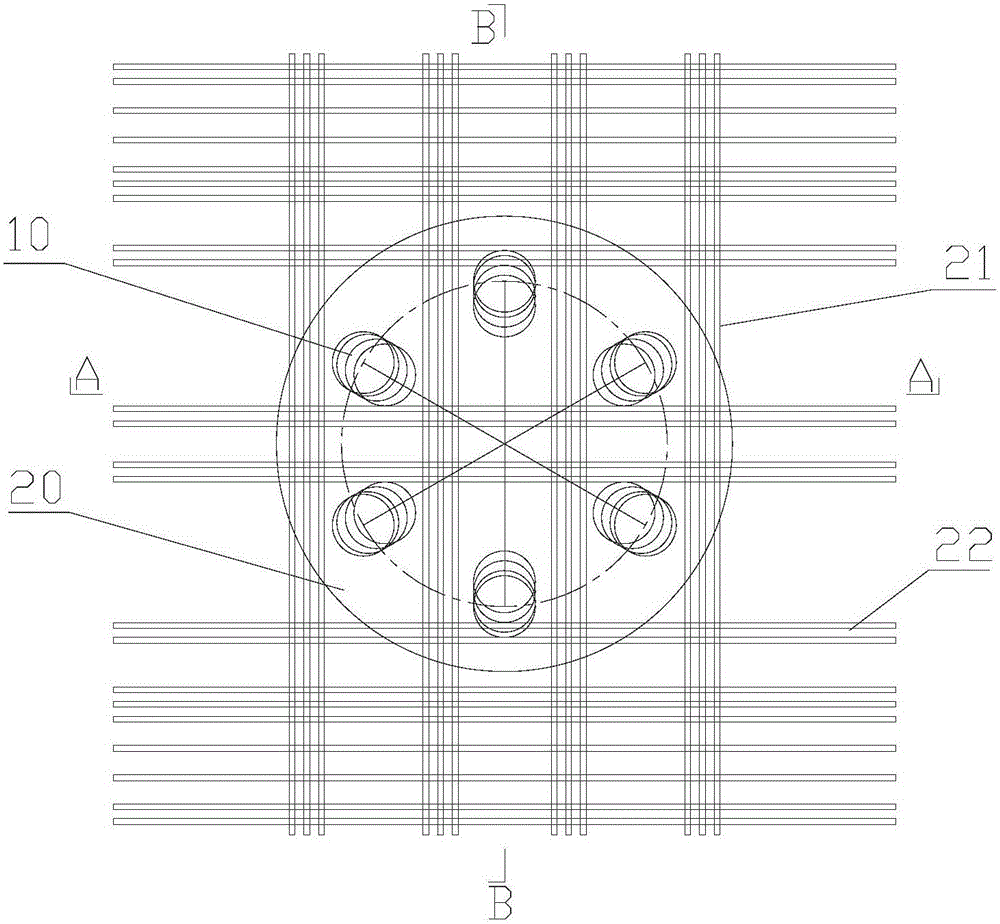

[0036] see Figure 1 to Figure 4 , the construction process of rock-socketed piles for offshore wind turbine foundations of the present invention includes steel pipe pile sinking, construction work platform erection, drilling, intermediate inspection, final hole, hole cleaning, hole measurement, placing steel cages, placing conduits, secondary Hole cleaning and underwater concrete pouring process.

[0037] When carrying out the steel pipe pile sinking process, a special piling ship is used to sink six steel pipe piles with a slope of 5:1 and uniformly distributed on a circular track curve with a diameter of 10m into the foundation by driving piles.

[0038] When erecting the construction operation platform, first use the steel pipe piles to construct the concrete layer of the bottom cover of the platform, and then build the working platform on the concrete layer of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com