Automatic assembling device of rotor and end cover of permanent magnet synchronous motor

A permanent magnet synchronous motor and rotor technology, used in electromechanical devices, electric components, manufacturing of motor generators, etc., can solve problems such as motor vibration and abnormal noise, end cover deformation, and uneven matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

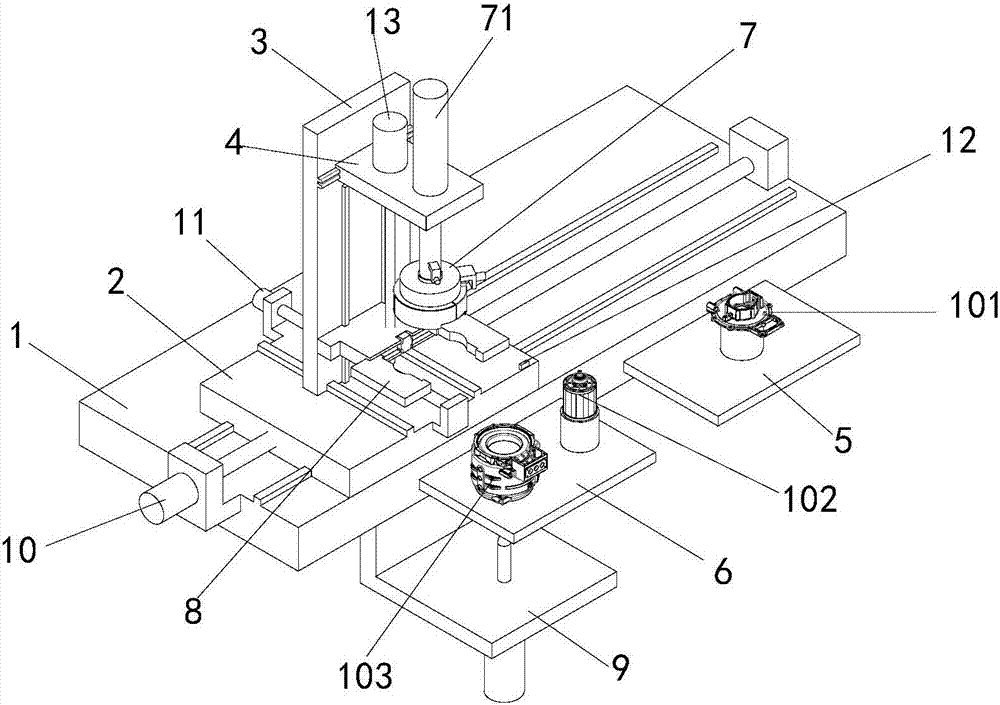

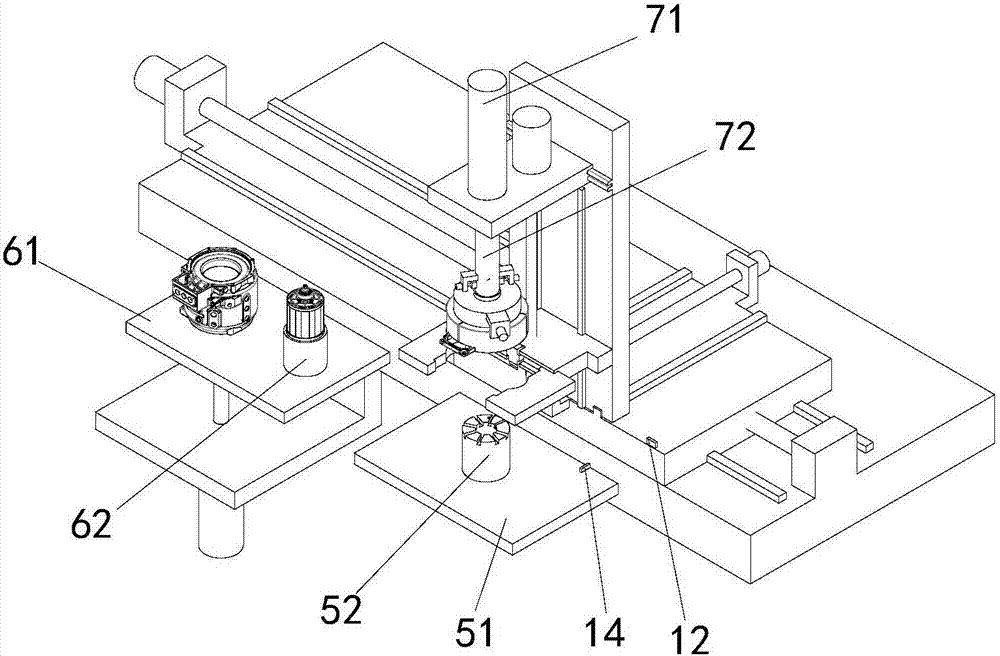

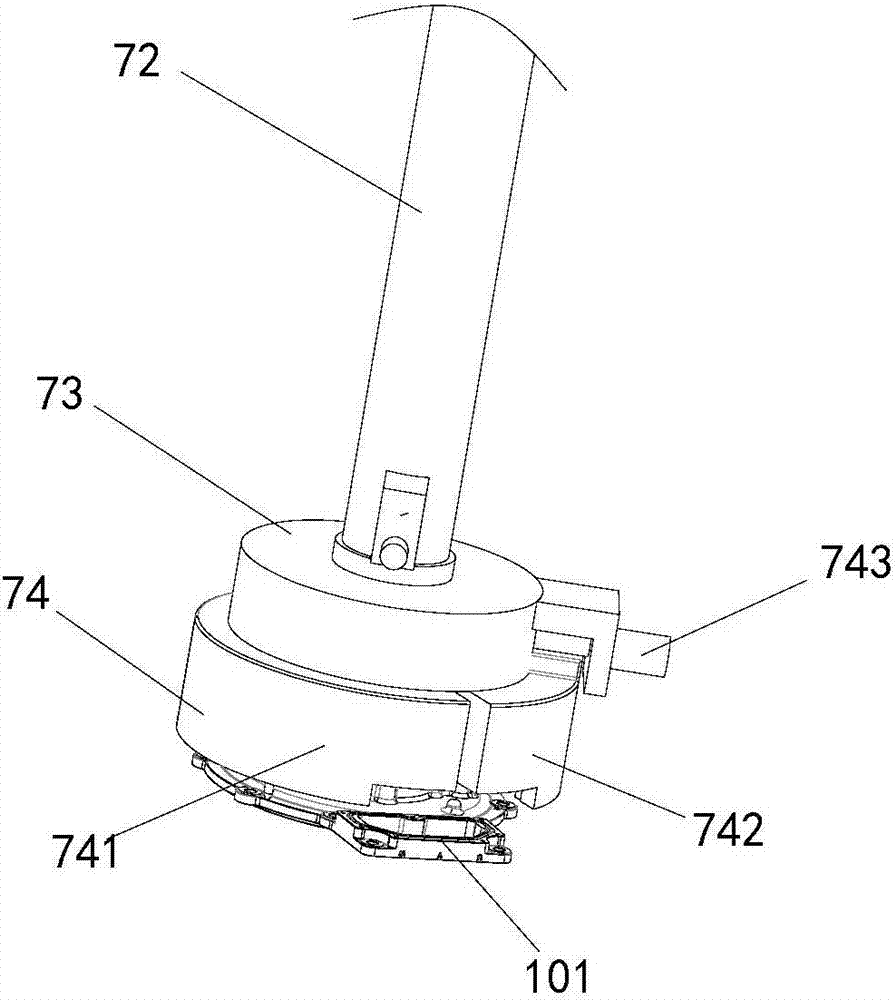

[0043] See figure 1 , See for cooperation Figure 2 to Figure 11 . The automatic assembly device of the permanent magnet synchronous motor rotor and end cover of the present invention includes an end cover 101, a rotor assembly 102 and a casing assembly 103. The automatic assembly device of a permanent magnet synchronous motor rotor and end cover includes Fixed platform 1, horizontal movement platform 2, radial movement platform 3, support platform 4, end cover transfer platform 5, rotor and casing transfer platform 6, end cover grabbing assembly 7, rotor grabbing assembly 8 and ejector rod assembly 9 .

[0044] A horizontal movement motor 10 is installed on the fixed platform 1.

[0045] The horizontal movement platform 2 is erected on the fixed platform 1 and can move horizontally along the fixed platform under the drive of the horizontal movement motor 10. A radial movement motor 11 and a radial displacement sensor 12 are installed on the horizontal movement platform.

[0046] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com