Method of mounting and fixing purging plug brick on outer upper portion of ladle

A fixing method and technology of breathable bricks, which are used in casting molten material containers, metal processing equipment, casting equipment, etc., can solve problems such as economic losses, reduce the service life of breathable bricks, and breakout of breathable bricks, so as to prevent steel breakout accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

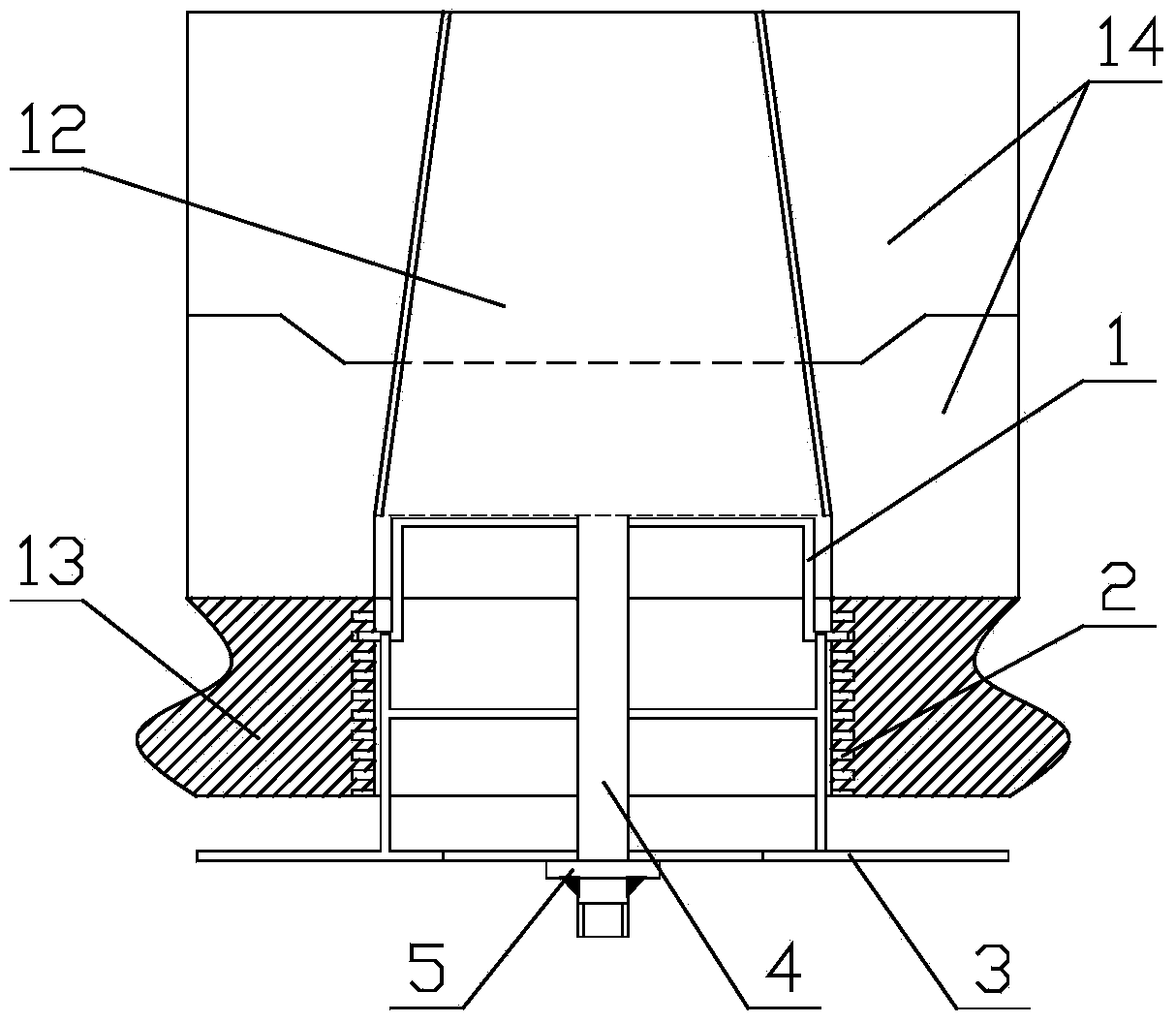

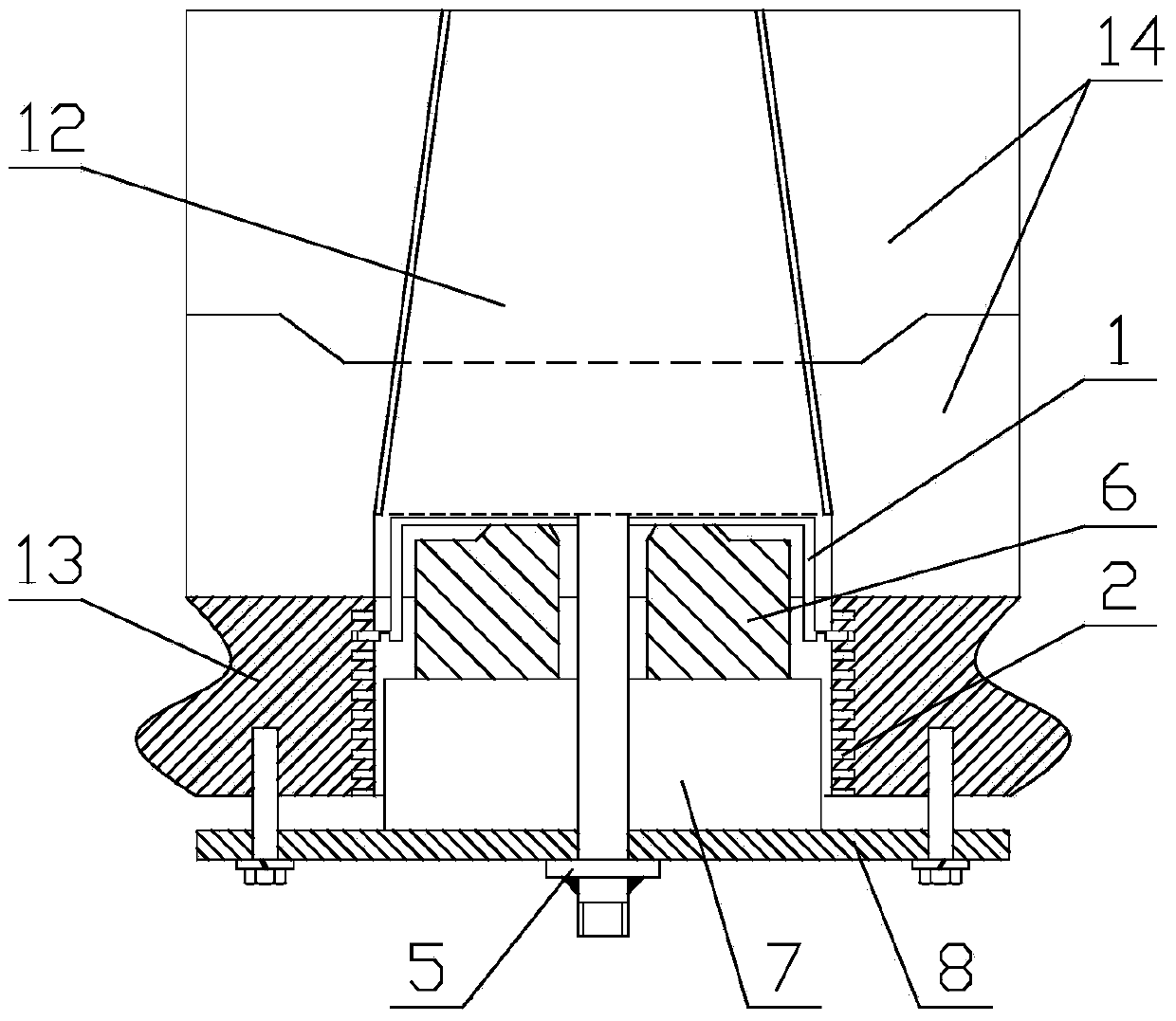

[0019] Such as Figure 1 ~ Figure 4 As shown, a method for installing and fixing air-permeable bricks on the outside of a ladle of the present invention comprises the following steps:

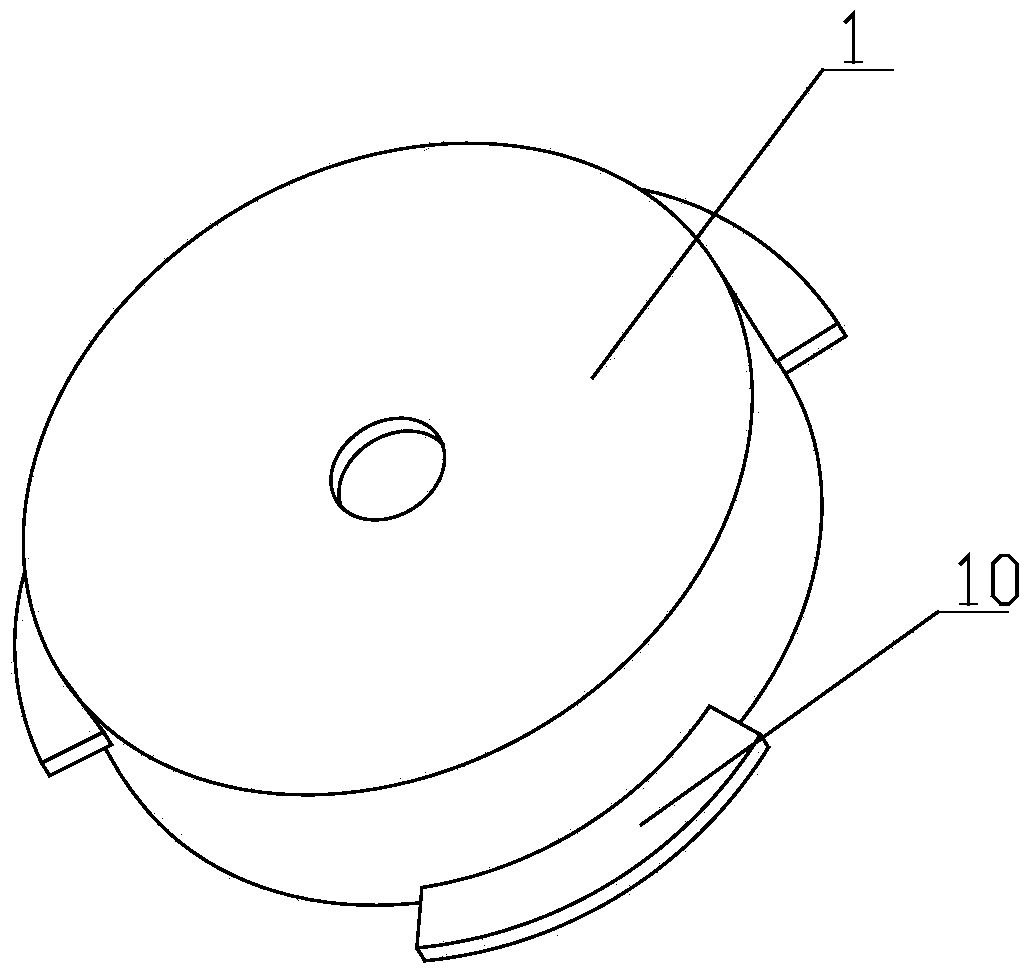

[0020] 1) First, fix the spiral slideway 2 inside the reference ring 13 of the breathable brick 12, fix the bolt 4 on the bottom of the breathable brick 12, coat the outer skin of the breathable brick 12 with gray, then put it into the breathable seat brick 14, and screw in 1 set of sliders On the outside of the bolt 4, the top surface of the screw-in slider 1 is pressed against the rear end surface of the air-permeable brick 12 at the same time, the sliding tooth 10 at the bottom end of the screw-in slider 1 is embedded in the spiral slideway 2, and the top of the automatic torque wrench 3 is inserted into the screw-in slider Block 1, then put nut 5 on the end of bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com