Locomotive for individual rapid transport system, and individual rapid transport system

A technology for rapid transportation and locomotives, applied in the field of rail transit, can solve the problems of reduced locomotive speed, affecting locomotive speed, and short service life, and achieve the effects of preventing large-scale roll, increasing operating speed, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

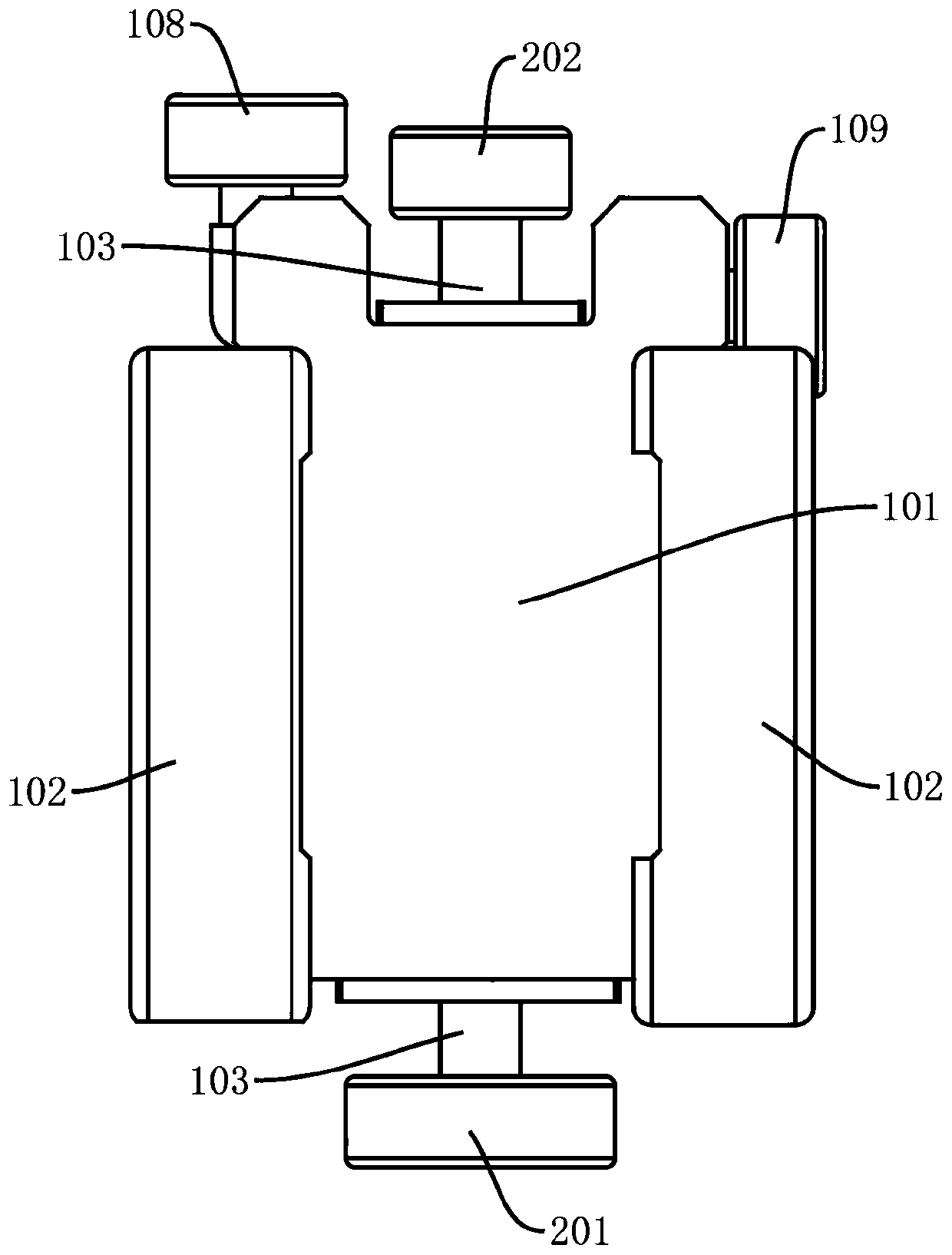

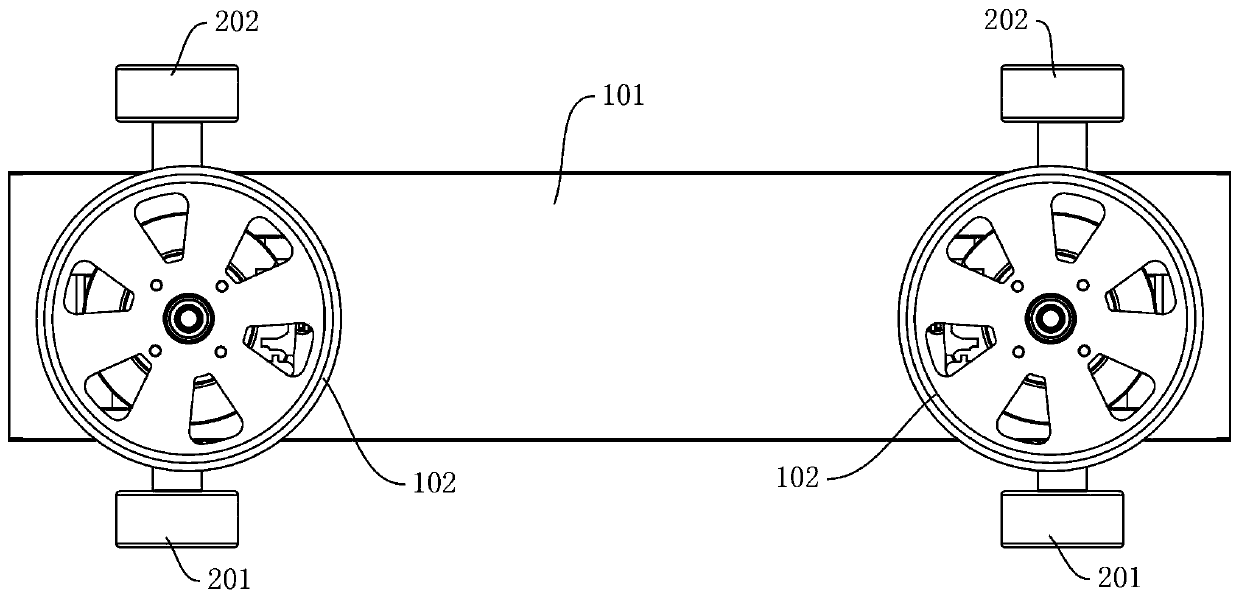

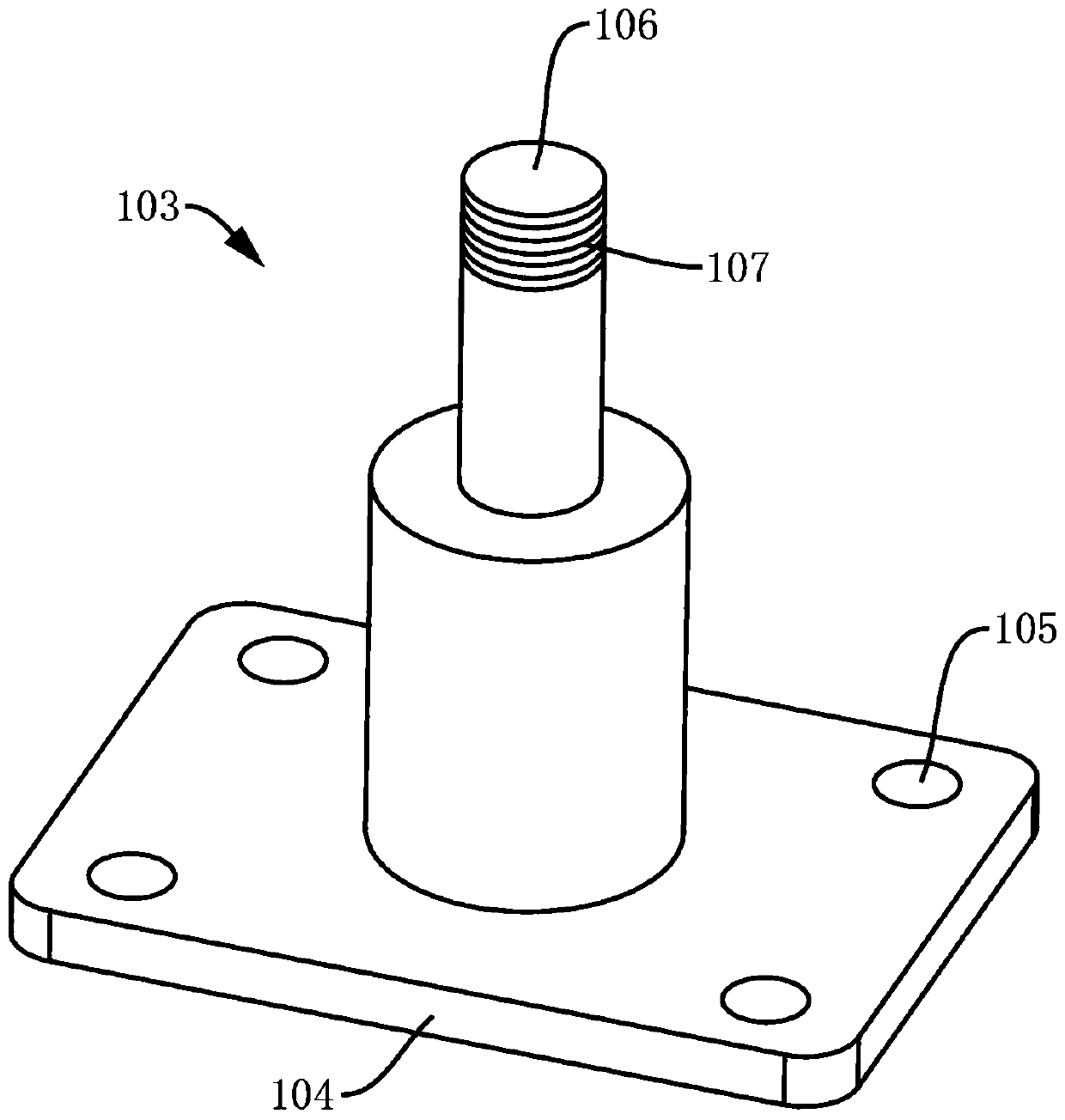

[0034] see figure 1 In this embodiment, a locomotive for a personal rapid transit system is provided, including a locomotive body 101, a first stabilizing wheel 201 for stabilizing the locomotive is provided under the locomotive body 101, and the first stabilizing wheel 201 of the locomotive The rotation axis is perpendicular to the length direction of the locomotive body 101, and the first stabilizing wheel 201 is used to roll (or rotate) along the track of the locomotive so as to balance the force on the locomotive and prevent the locomotive from sideways.

[0035] In this embodiment, by arranging the first stabilizing wheel 201 under the locomotive, it replaces the solution of setting several wheels on both sides of the locomotive in the prior art, which has the following effects:

[0036] 1. The number of first stabilizing wheels 201 required is relatively small, usually only one or two can achieve a good stabilizing effect, thereby effectively saving costs.

[0037] 2. W...

Embodiment 2

[0046] This embodiment provides a personal rapid transit system, including a track and the aforementioned locomotive, the track includes an upper guide rail 301 and a lower guide rail 303, the upper guide rail 301 and the lower guide rail 303 are parallel to each other, and the locomotive is arranged on the upper guide rail 301 and the lower guide rail 303, and is used to run between the upper guide rail 301 and the lower guide rail 303.

[0047] Such as figure 1 As shown, in this embodiment, the side of the locomotive is respectively provided with two road wheels 102, and the two road wheels 102 are in contact with the lower guide rail 303 respectively, and move on the lower guide rail 303, and the upper part of the locomotive is provided with a track changing mechanism, The track changing mechanism includes two track changing swing arms and synchronous connecting rods. One end of the two track changing swing arms is respectively hinged to the synchronous connecting rod, and ...

Embodiment 3

[0053] The main difference between this embodiment 3 and the above-mentioned embodiment 2 is that in the personal rapid transit system provided by this embodiment, the track includes two upper guide rails 301 and two lower guide rails 303, such as Figure 6 As shown, the upper guide rails 301 respectively include rail changing parts 302 arranged along the length direction, the lower rails respectively include stable parts 304 arranged along the length direction, two lower guide rails 303 are arranged in parallel, and the first stabilizing wheels 201 are arranged Between the two stabilizing portions 304, and in contact with at least one stabilizing portion 304 (that is, either in contact with two stabilizing portions 304 at the same time, or only in contact with one of the stabilizing portions 304, and the stabilizing portion 304 is in contact with The track-changing wheel that is guiding the locomotive is on the same side of the locomotive), thereby balancing the force of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com