Method and die for eccentricity prevention of injection molding and rubber coating of slender rod

A technology of injection-molded plastic wrapping and slender rods, applied in the direction of coating, etc., can solve problems such as eccentricity, and achieve the effect of reducing scrap rate and solving eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

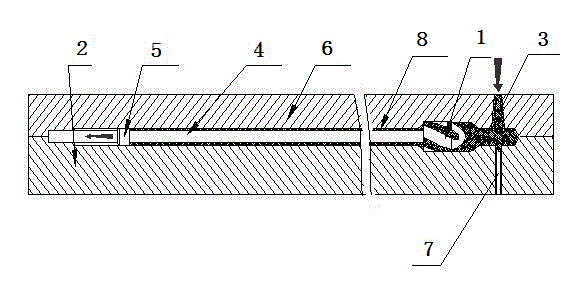

[0013] according to figure 1 As shown, the mold of the present invention includes a moving mold core 2 and a fixed mold core 6 installed on an upper shunt shuttle 1, a guide ring 5, and injection molding of a slender rod 4; the said shunt shuttle 1 is a bullet type, There are several spiral diverter grooves (three in this embodiment) on its surface; the diverter shuttle 1 is installed on one end of the mold cavity 8 of the movable mold core 2 and the fixed mold core 6, and communicates with the flow channel 3 of the fixed mold core 6; the guide ring 5 is installed in the mold cavity 8 of the movable mold core 2 and the fixed mold core 6, and can move in the mold cavity 8.

[0014] A shunt shuttle 1 is installed at the front end of the slender rod 4, and the guide ring 5 is set on the tail of the slender rod 4, and is installed in the cavity 8 of the movable mold core 2; Together with the shunt shuttle 1, it is lifted up by the thimble 7 at the bottom of the fixed mold core 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com