Camera actuator and camera module comprising same

An actuator and camera technology, which is applied to the focusing device of cameras, focusing devices of cameras and projectors, etc., can solve the problems of difficulty in ensuring light quantity, increase in power consumption, and reduce the accuracy of angular acceleration data, so as to improve image quality or resolution. efficiency, reduced frictional resistance, and improved control characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

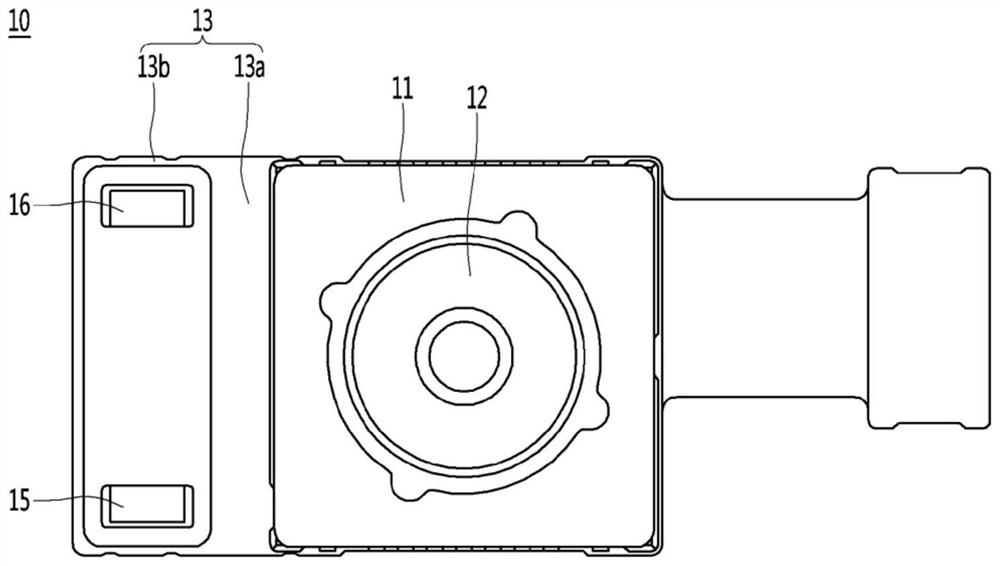

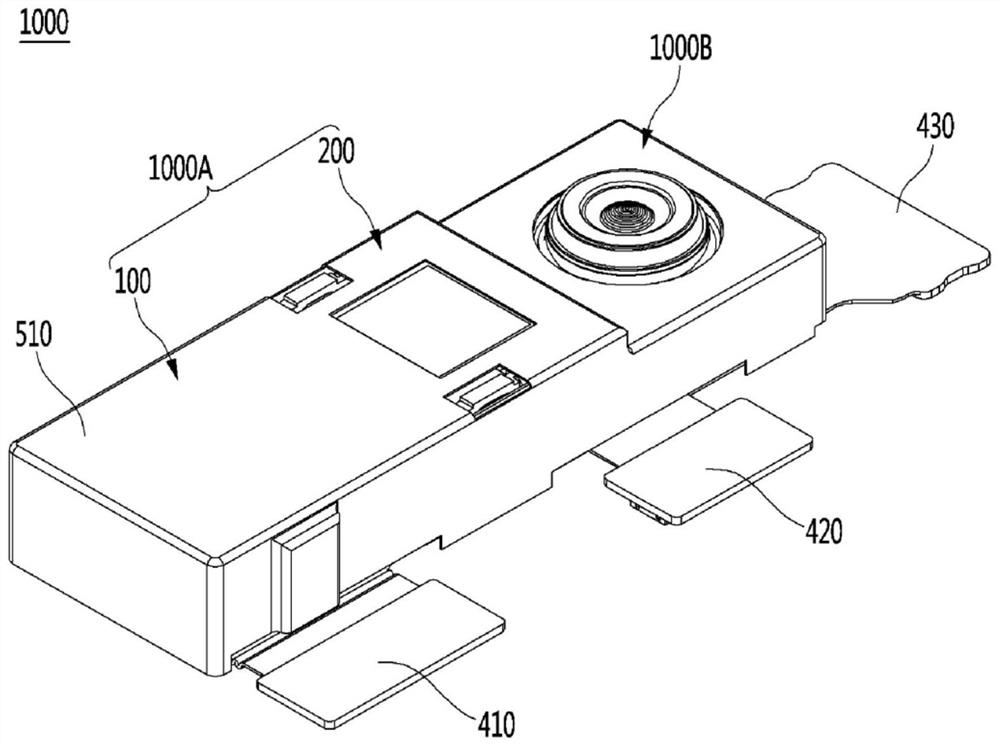

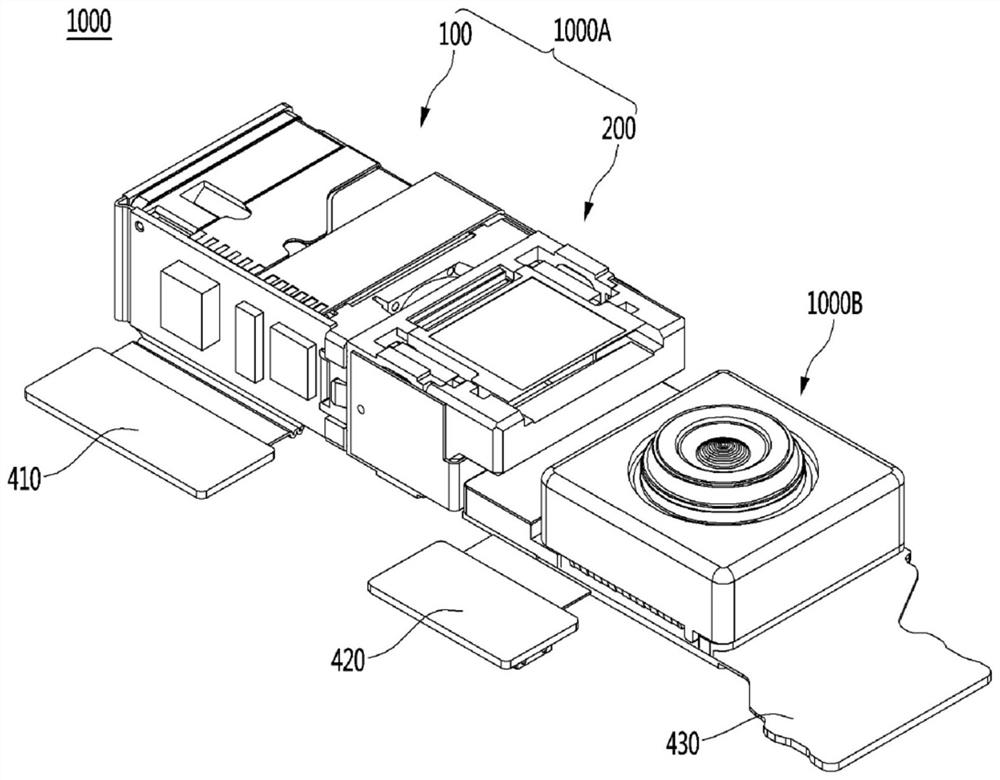

[0154] figure 2 It is a perspective view showing the camera module 1000 of the embodiment, Figure 3a is that the shield 510 is removed from the figure 2 a perspective view of the camera module 1000 of the illustrated embodiment removed, and Figure 3b yes Figure 3a A plan view of the camera module 1000 of the illustrated embodiment.

[0155] First, refer to figure 2 , the camera module 1000 according to the embodiment may include a single or a plurality of camera modules. For example, an embodiment may include a first camera module 1000A and a second camera module 1000B. The first camera module 1000A and the second camera module 1000B may be covered by a predetermined shield 510 .

[0156] Also refer to figure 2 , Figure 3a with Figure 3b , in an embodiment, the first camera module 1000A may include a single or a plurality of camera actuators. For example, the first camera module 1000A of the embodiment may include the first camera actuator 100 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com