Connected bead and connected tube suitable for machine embroidery and manufacturing method

A manufacturing method and beading technology, which is applied to the mechanism of embroidery machines, textiles and papermaking, embroidery machines, etc., can solve the problems of unrecognizable machines, affecting the ornamental quality of fabrics and product grades, and low efficiency, and achieve beads or tubes falling Point accuracy, improve grade and appreciation, and save labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

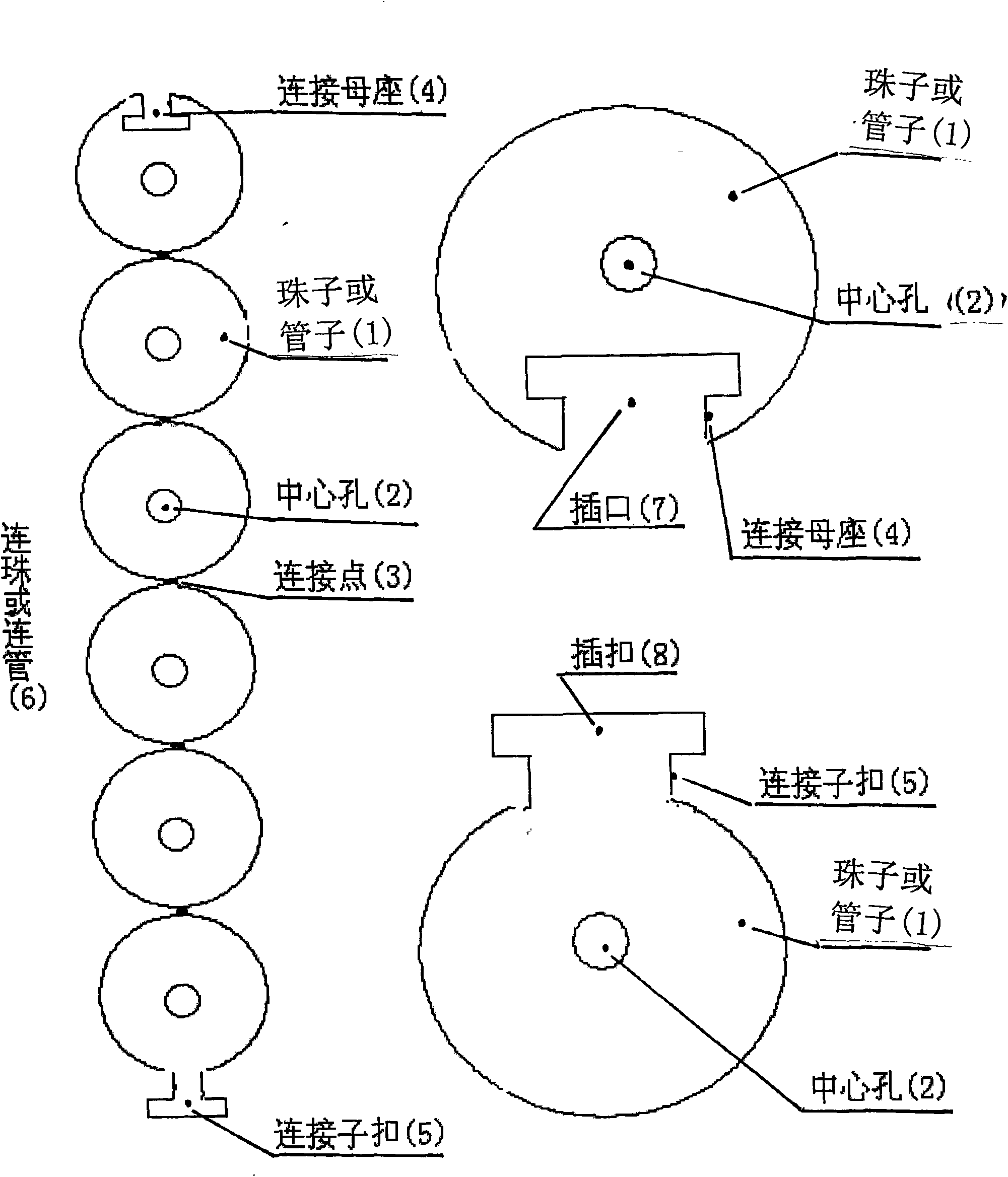

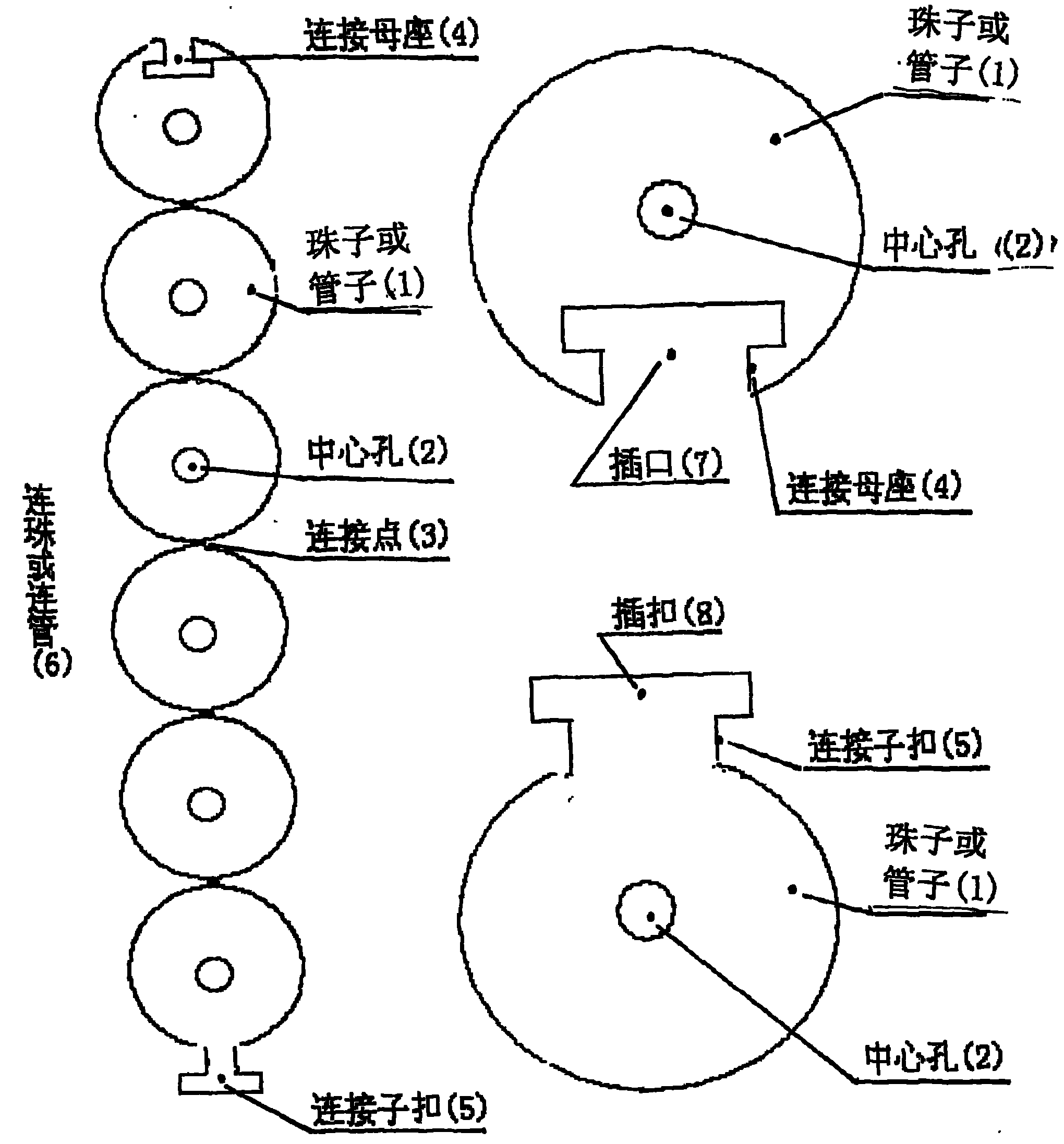

[0012] Embodiment 1: as figure 1 As shown, a bead and pipe and a manufacturing method suitable for machine embroidery. Including: bead or tube 1, central hole 2, connection point 3, connecting female seat 4, connecting buckle 5, bead or tube 1 is connected to a certain length of connecting beads or connecting tube 6 through connecting point 3, and central hole 2 is located in the bead or The center of the pipe 1 is provided with a connecting female seat 4 in front of the first bead or pipe 1 of the bead or the pipe 6, and a connecting buckle 5 is arranged behind the last bead of the bead or the pipe 6 or the pipe 1, The connecting sub-button 5 is inserted into the connecting female seat 4 to form a longer connecting bead or connecting pipe 6 for the continuous use of the embroidery machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com