Center-adjustable ball spherical hinge joint and center adjusting method of center-adjustable ball spherical hinge joint

A technology of ball joints and hinge joints, which is applied in the direction of rotating parts, bearings, and bearing components that resist centrifugal force, and can solve the problem that ball joints cannot meet the motion accuracy requirements of high-precision occasions, the motion accuracy decreases, and the gap between the ball head and the ball socket increases. Large and other problems, to achieve the effect of mature processing technology, reduce eccentricity error, and improve centering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

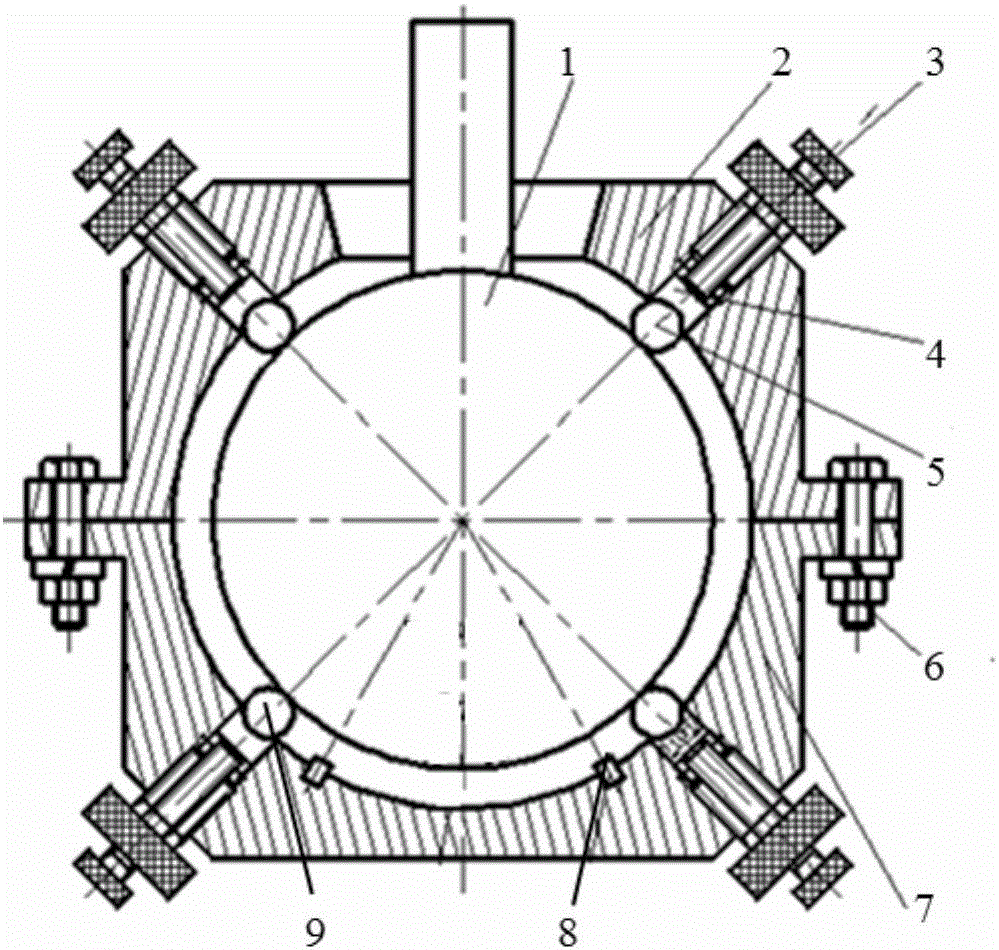

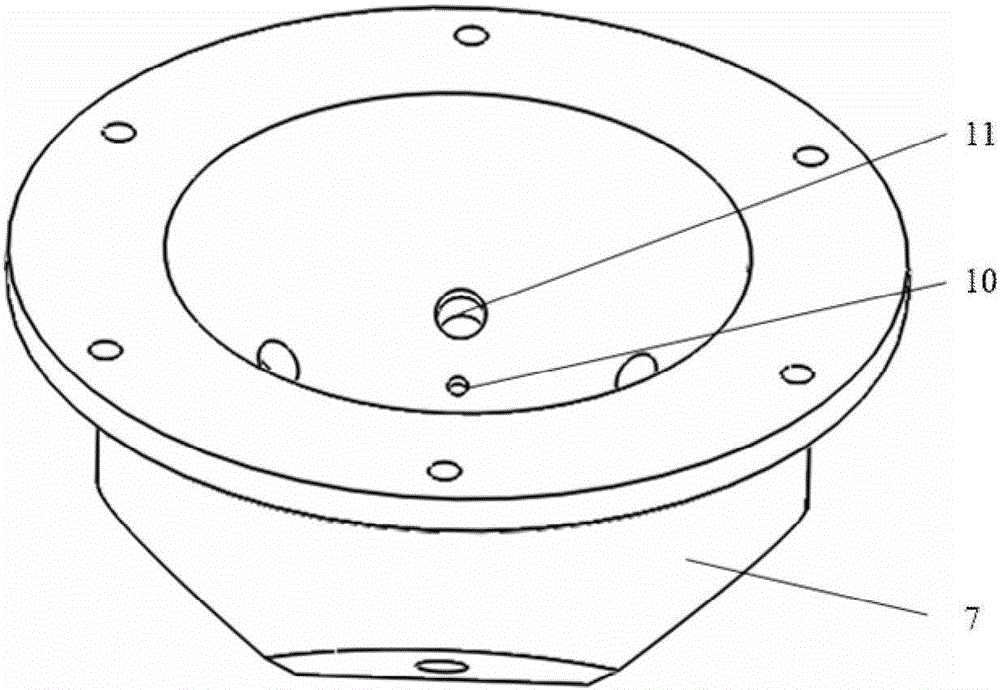

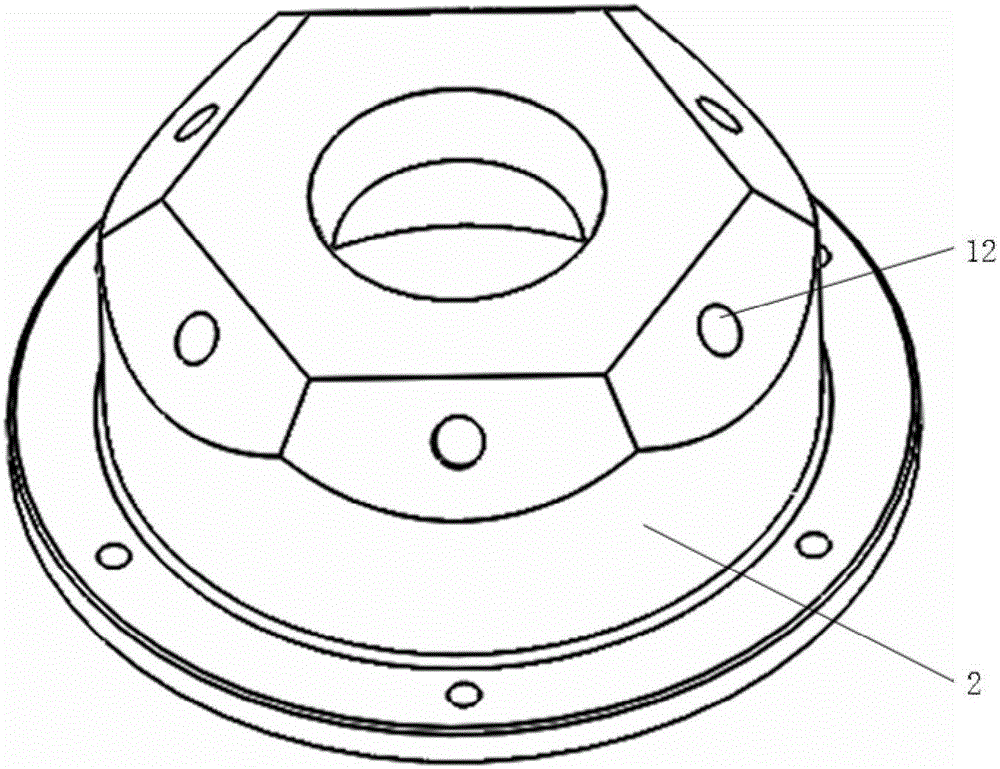

[0031] like figure 1 , 2 , 3 and 4, an adjustable ball joint, including ball head 1, constrained ball socket 2, double-threaded centering mechanism 3, cylindrical block 4, constrained ball steel ball 5, supporting ball socket 7, Support ball steel ball 9 and displacement detection system 8. The support ball socket 7 is used as the base of the present embodiment; the support ball socket 7 is provided with six support ball guide holes 11 evenly distributed along the circumference, and the double-threaded centering mechanism 3, the cylindrical block 4 and the support ball guide hole 11 are installed in the support ball socket 7. Ball steel ball 9; the tail plane end of the cylindrical block 4 in the ball guide hole is in contact with the double-threaded centering mechanism 3, and the arc surface of the head is in contact with the support ball steel ball 9; the six displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com