A double-proportioning-valve-controlled liquid fertilizer application system capable of timely amount changing

A valve-controlled, double-proportional technology, applied in the field of agricultural equipment, can solve the problems of liquid fertilizer flow and pressure restrictions, and the amount of liquid fertilizer that is difficult to apply, so as to reduce losses, improve the efficiency of liquid fertilizer use, and achieve fast fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

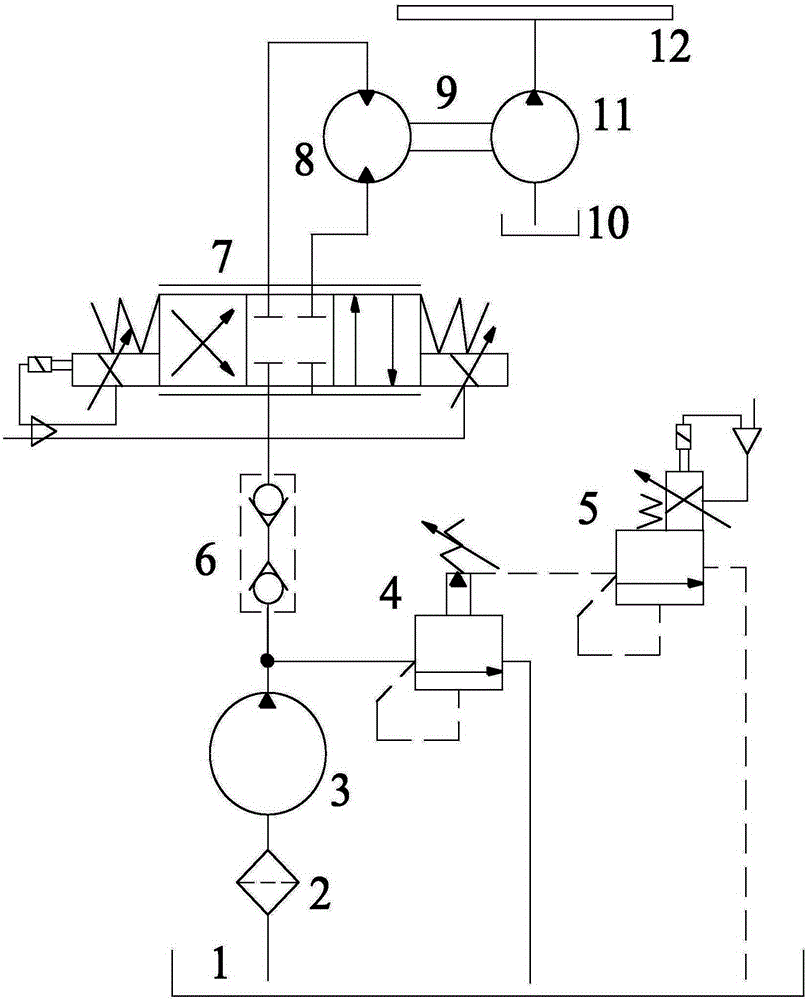

[0016] This embodiment includes the following components: hydraulic oil tank 1, filter 2, hydraulic pump 3, quick connector 6, electro-hydraulic proportional directional valve 7, hydraulic motor 8, coupling 9, liquid fertilizer tank 10, liquid spray pump 11, liquid spray Tube 12.

[0017] The inlet of the hydraulic pump 3 is connected to the hydraulic oil tank 1 through the filter 2, the outlet of the hydraulic pump 3 is connected to the outlet pipeline, and the outlet pipeline is connected to the electro-hydraulic proportional directional valve 7 through the quick joint 6. The electro-hydraulic proportional directional valve 7 includes four oil The ports are the oil inlet, the oil return port, the first oil outlet and the second oil outlet respectively, wherein the quick connector 6 is connected with the oil inlet, the oil return port leads to the hydraulic oil tank 1, the first oil outlet and the The second oil outlet is respectively connected to the two oil ports of the hyd...

Embodiment approach 2

[0020] On the basis of Embodiment 1, a pilot relief valve 4 is added. The pilot overflow valve 4 communicates with the outlet pipeline between the hydraulic oil tank 1 and the hydraulic pump 3 and the quick connector 6 respectively. The pilot relief valve 4 plays the role of overload protection, and the set pressure is 6MPa. When the hydraulic oil pressure in the outlet pipeline exceeds 6MPa, the pilot relief valve 4 opens, and the hydraulic oil flows through the pilot relief valve 4. , back to the hydraulic oil tank 1.

Embodiment approach 3

[0022] On the basis of the second embodiment, an electro-hydraulic proportional overflow valve 5 is added. The electro-hydraulic proportional relief valve 5 communicates with the hydraulic oil tank 1 and the pilot relief valve 4 respectively. The remote control port is connected to the electro-hydraulic proportional relief valve 5. The function of this valve is to realize stepless control of the system pressure through electric signals. When the hydraulic oil pressure in the outlet pipeline does not exceed the set pressure, and the operator wants to control the liquid injection When the injection flow rate of the liquid fertilizer in the pipe 12 is controlled, the electro-hydraulic proportional relief valve 5 is controlled so that the hydraulic oil in the outlet pipeline flows back to the hydraulic oil tank 1 through the electro-hydraulic proportional relief valve 5 after passing through the pilot relief valve 4, and the electro-hydraulic proportional relief valve 5 returns to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com