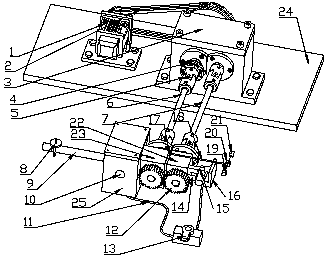

Plastic gear wear life testing machine for single support self-compensation loading system

A loading system and plastic gear technology, which is applied in the testing of machine gears/transmission mechanisms, mechanical components, and machine/structural components, etc. It can solve problems such as thermal failure, affecting the normal use of gears, and reducing transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] specific implementation

[0007] The motor and gearbox of the driving part of the testing machine are fixed on the desktop of the test bench; the motor drives the gearbox part through the belt to provide power for the testing machine; the friction clutch has two parts, which are connected by bolts, and the two parts of the friction clutch can be Relatively rotate at a certain angle, rotate and tighten with bolts, so that the position of the contact point of the test gear pair changes; the pivot block assembly box B slides relatively on the light, and under the action of the hydraulic cylinder, the pivot block assembly box A and B The gap between the two test gears decreases, which increases the pressure at the contact point of the teeth of the two test gears to achieve loading; the weight tray is welded to the loading rod; after the test gear is worn, the pivot block assembly box B can rotate around the hinge support; the hydraulic cylinder base passes through The bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com