Patents

Literature

60results about How to "Achieve variable speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

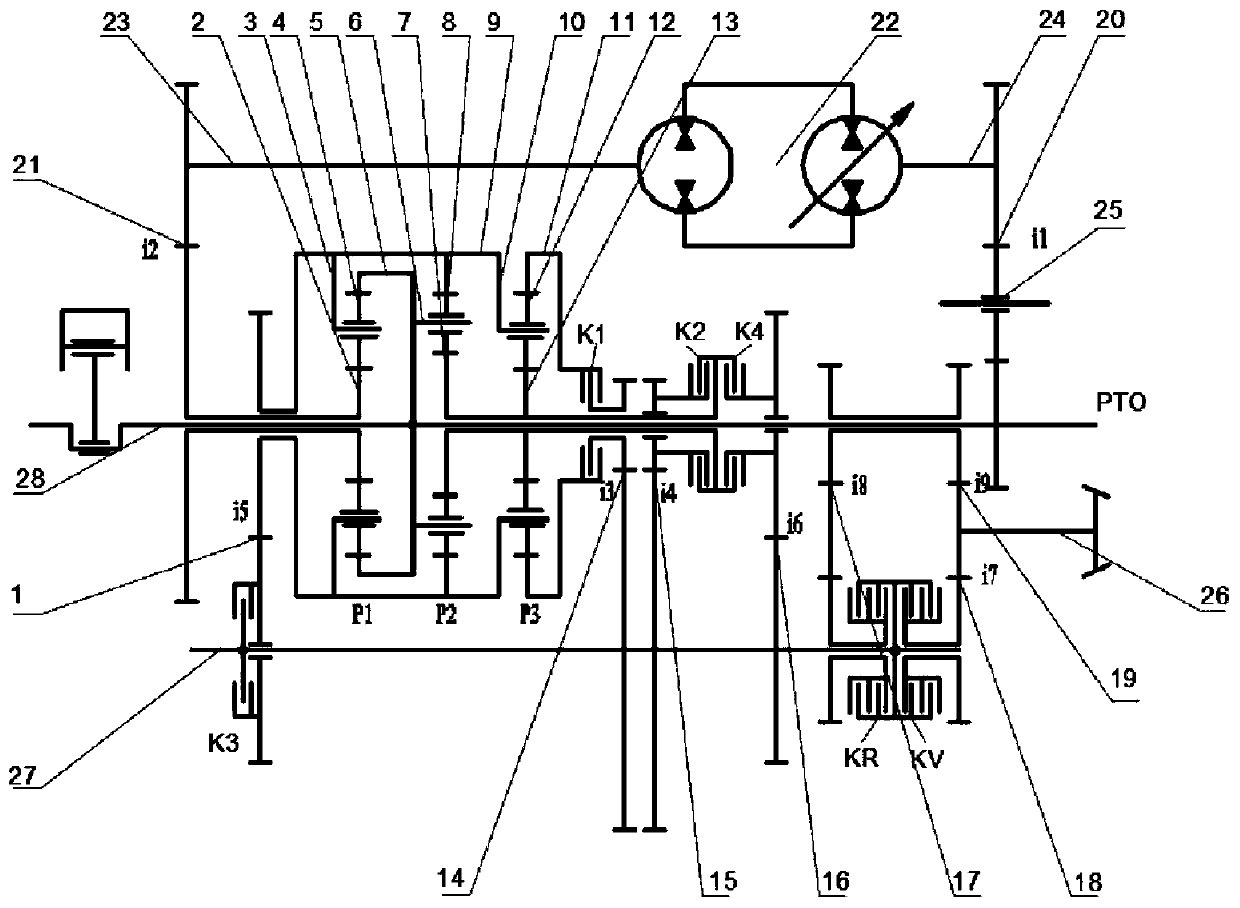

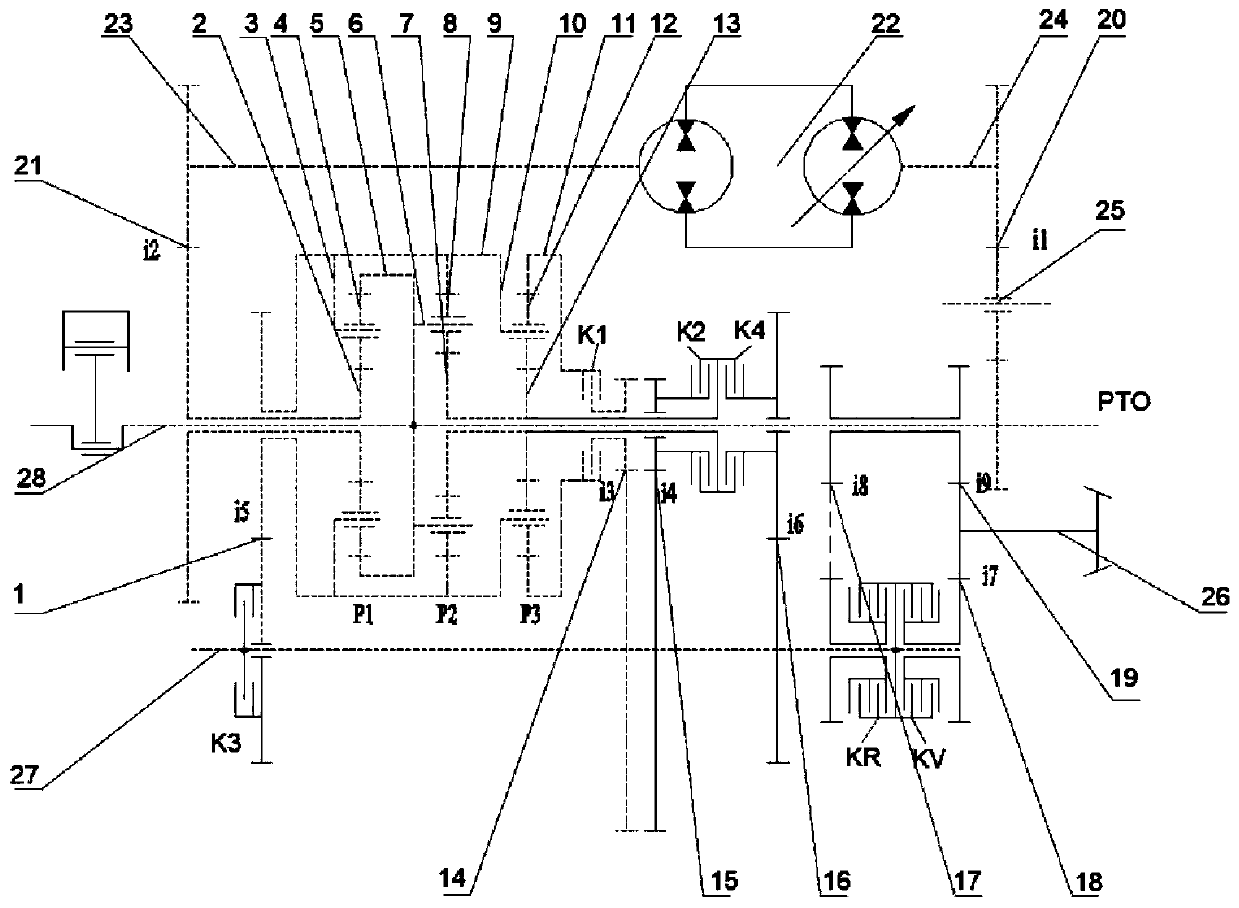

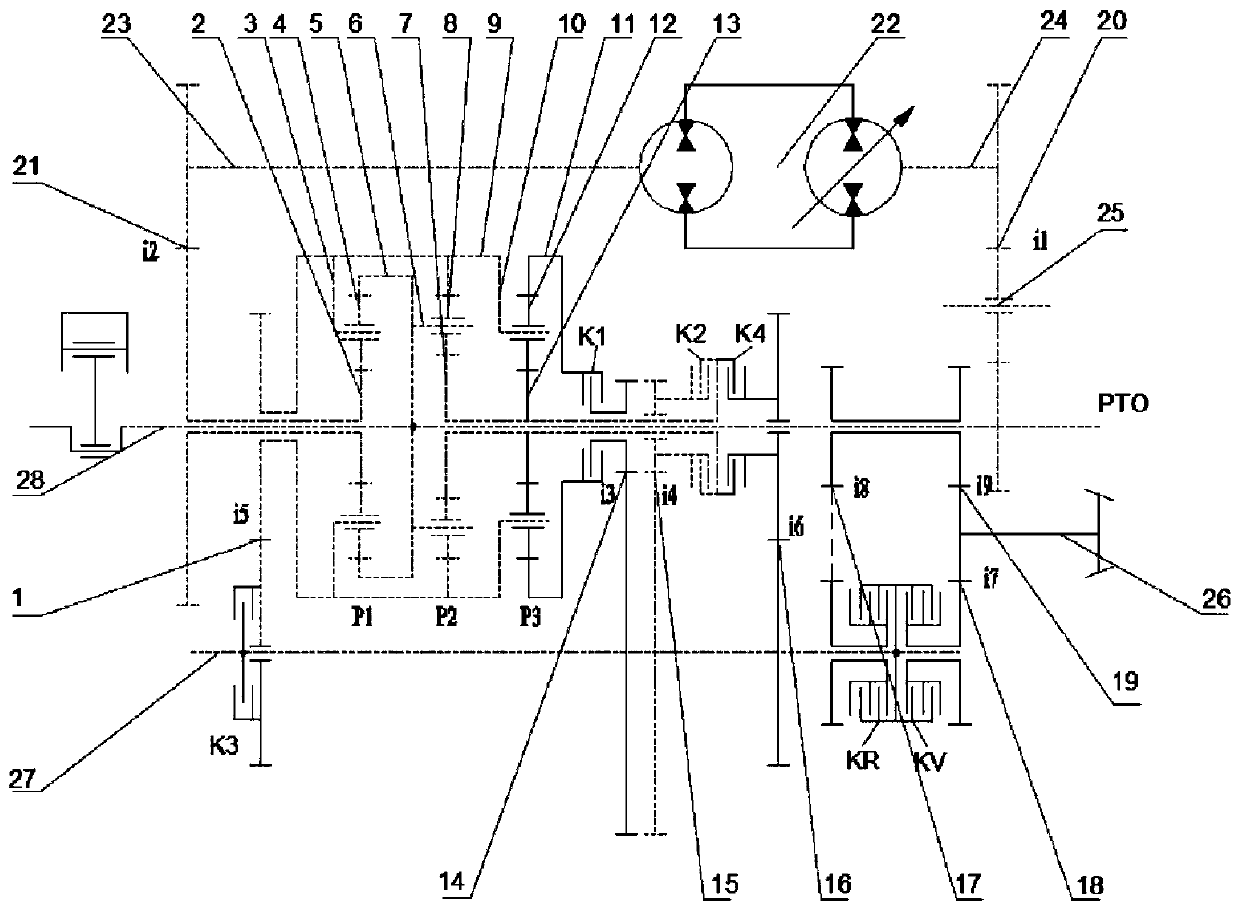

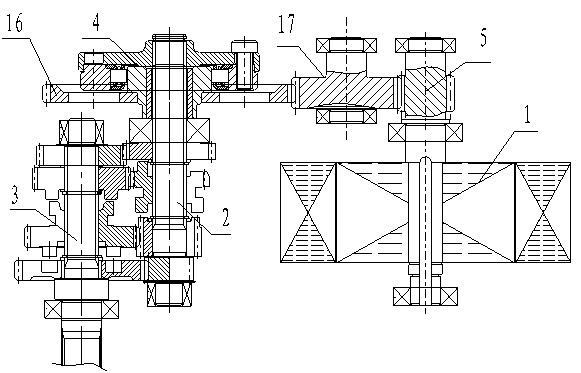

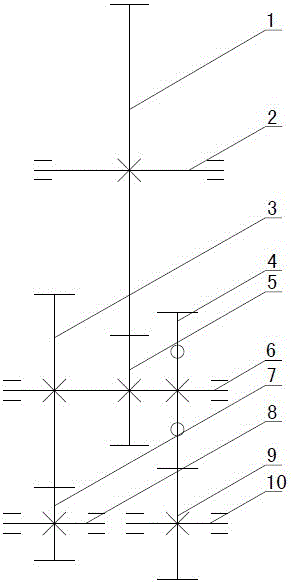

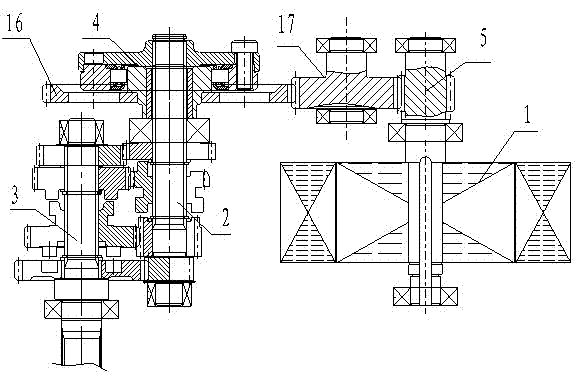

Three-planet row four-section hydraulic mechanical stepless transmission

PendingCN110056634AAchieve variable speedCompact structureGearing controlTransmission elementsGear wheelHydraulic machinery

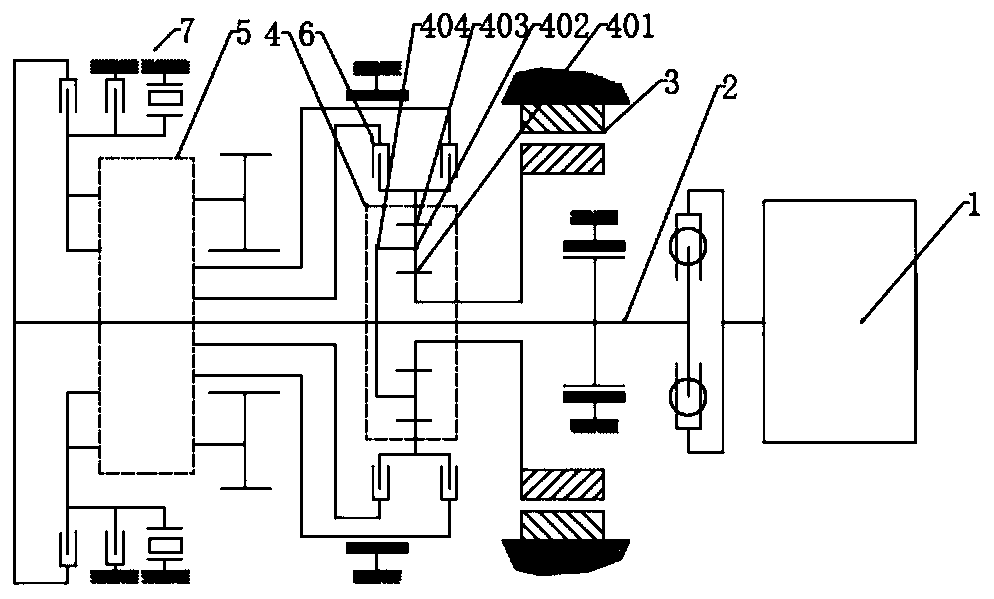

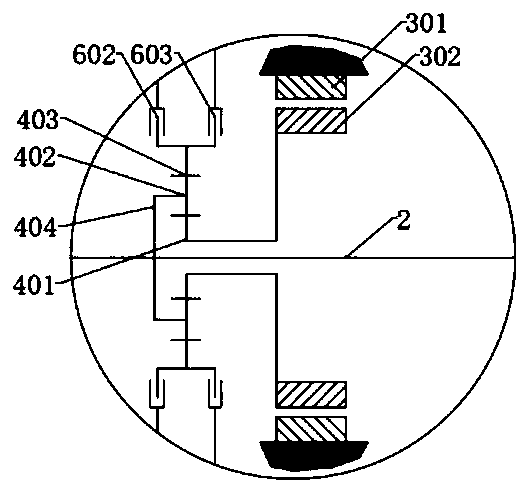

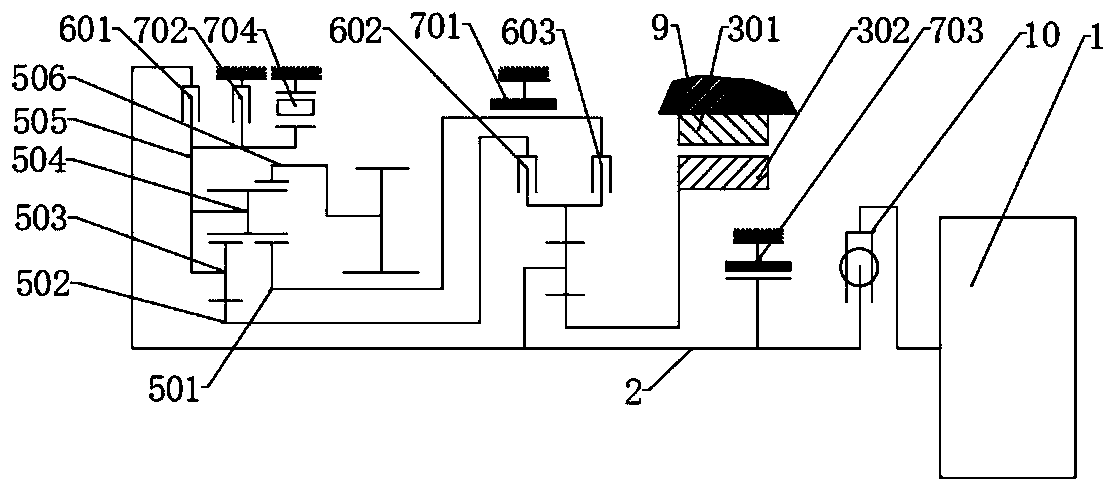

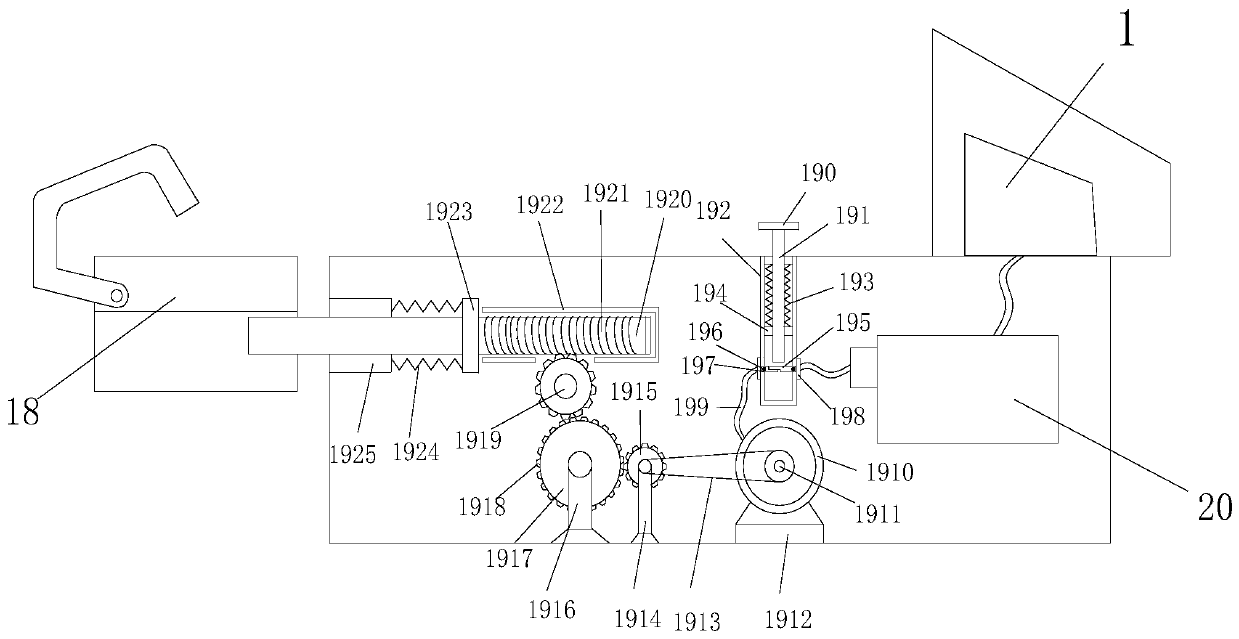

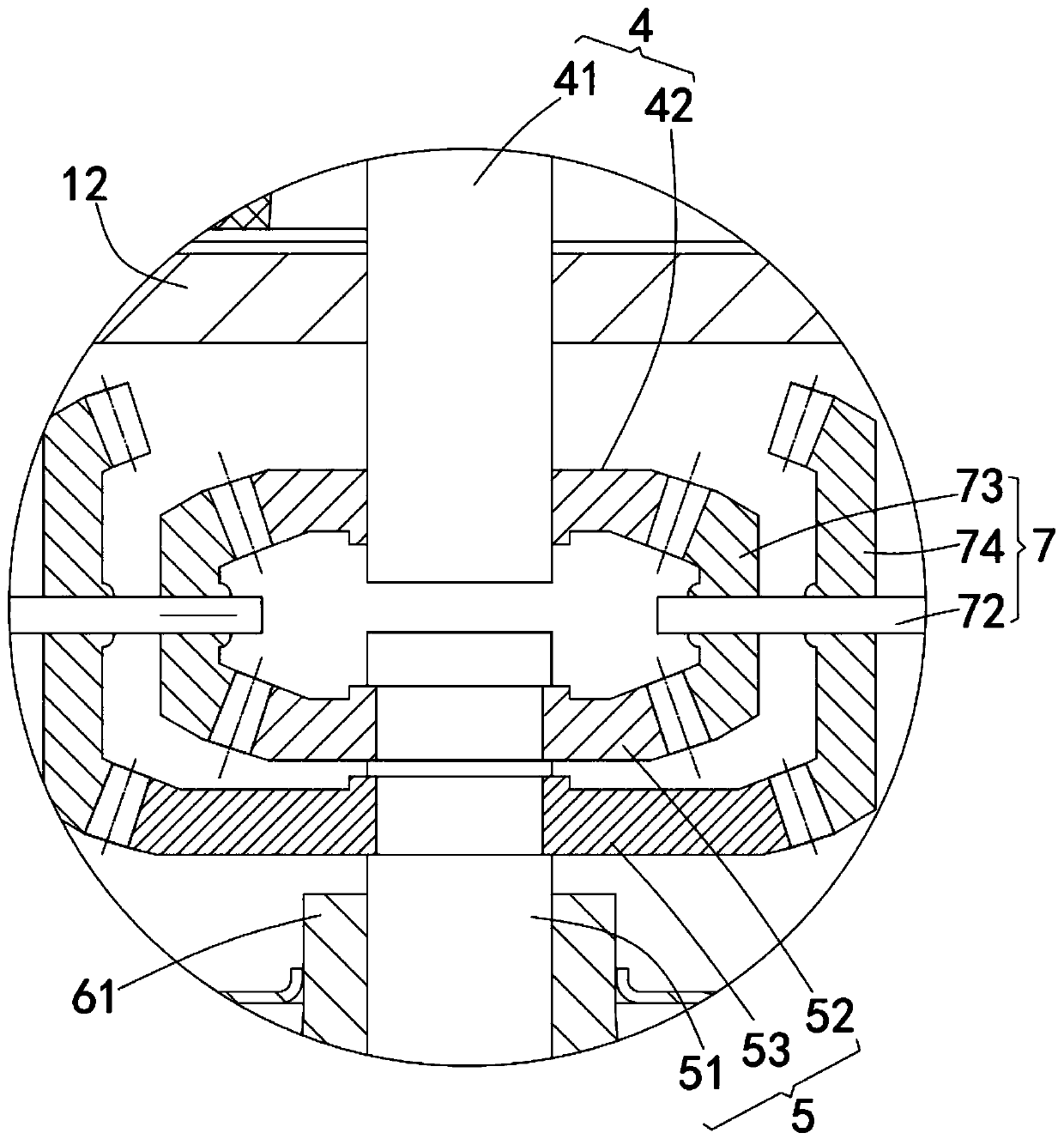

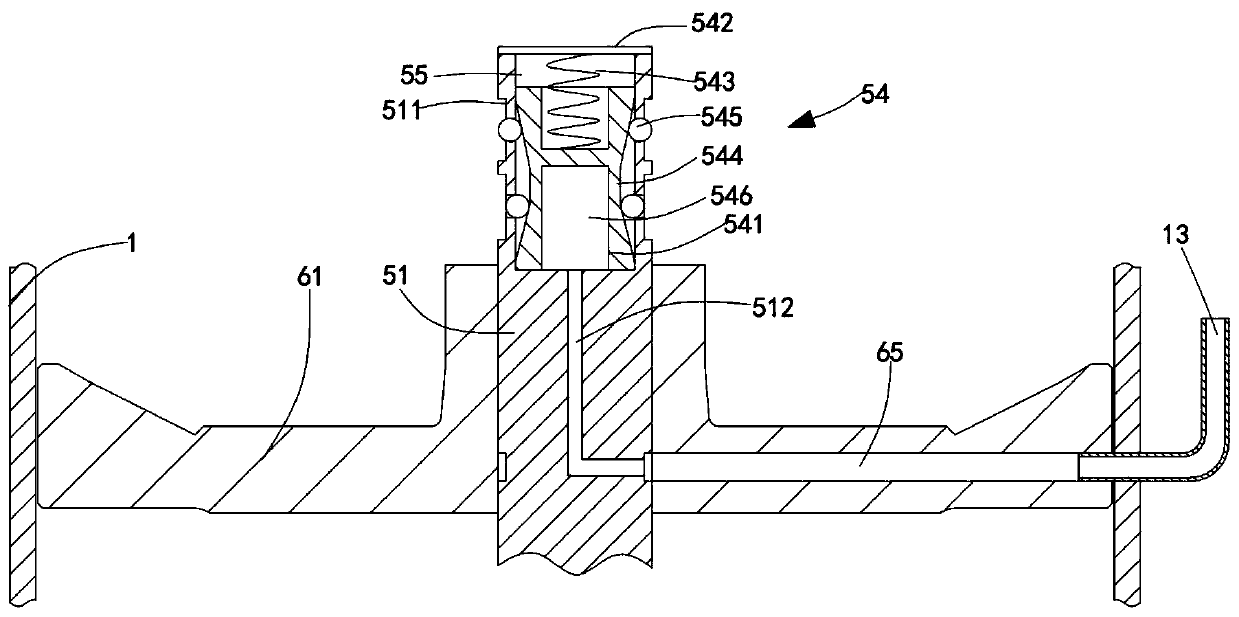

The invention discloses a three-planet row four-section hydraulic mechanical stepless transmission. According to the three-planet row four-section hydraulic mechanical stepless transmission, an integrated structure with a pump and a motor are adopted, the power of an engine is divided into a hydraulic path power input and a mechanical path power input through a hydraulic transmission system and amechanical transmission system, then convergence output of the two-strand power is carried out through three planetary rows of P1, P2 and P3, and finally, three power is output outwards by a third rowof gear rings, a duplex sun gear and a first planet carriers. The gearbox controls four gears to change speed by controlling the combination of the four clutches k1, k2, k3 and k4. According to the stepless transmission, four clutches K1, K2, K3 and K4 are controlled to combine to realize gear shifting, the first row of planet carriers, the second row of gear rings, a third row of planet carriersand a fifth fixed gear pair i5 are of an all-in-one rigid structure, so that synchronous rotation of the four components is ensured when the four components are operated, and high-efficiency and continuous stepless transmission of different sections is realized by switching the output modes of different components of the three planetary gear trains.

Owner:NANJING AGRICULTURAL UNIVERSITY

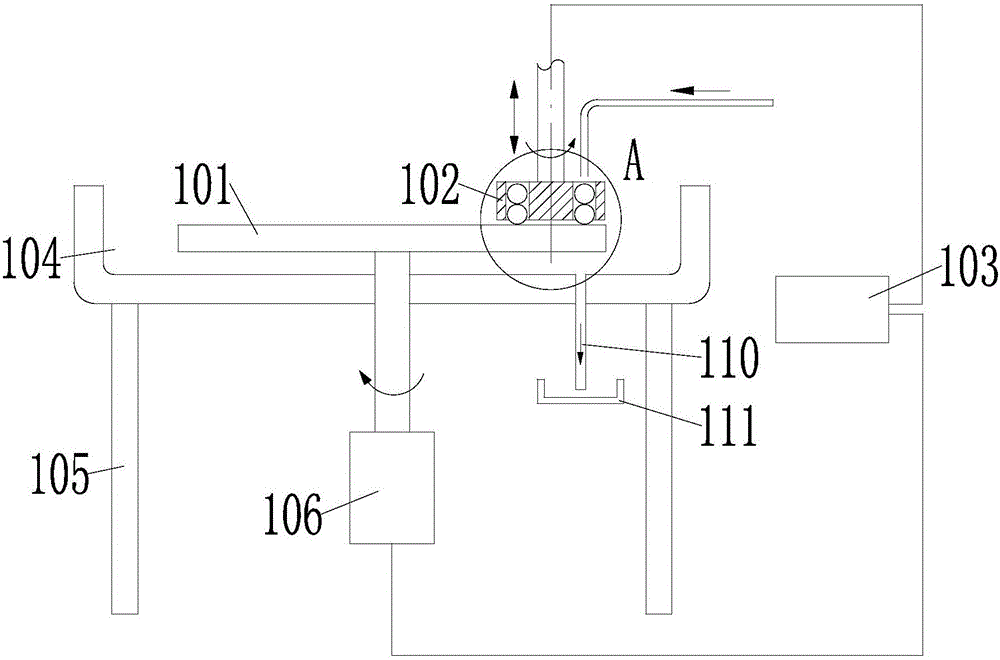

Fragile hollow micro-sphere polishing machine and polishing method

ActiveCN104985523AAchieve variable speedRealize and/or change direction of movementLapping machinesEngineeringElectric control

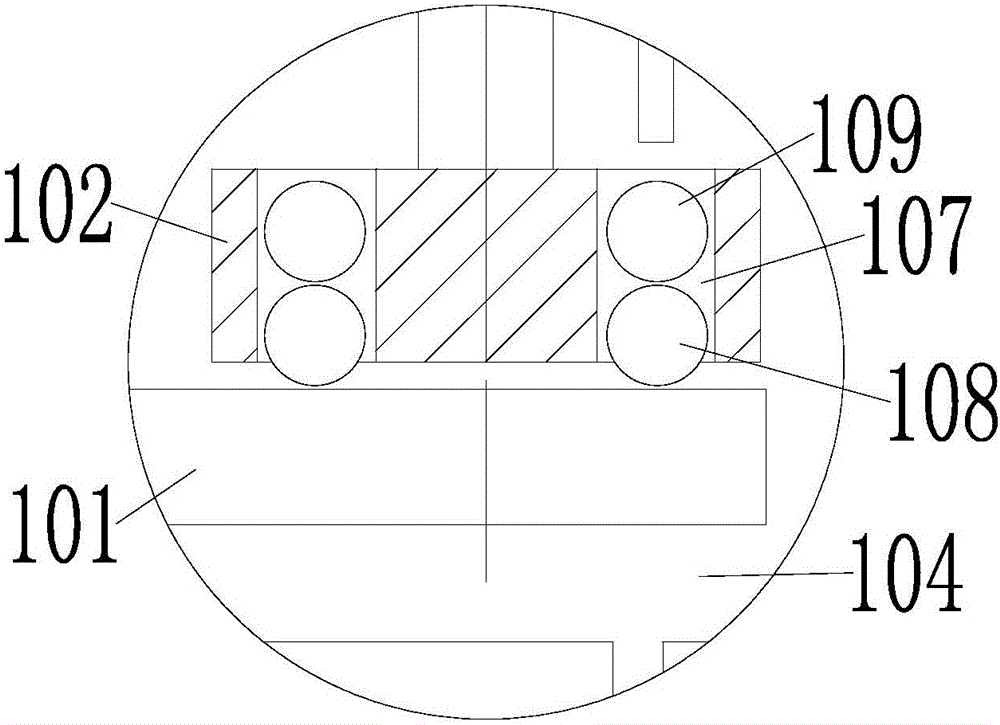

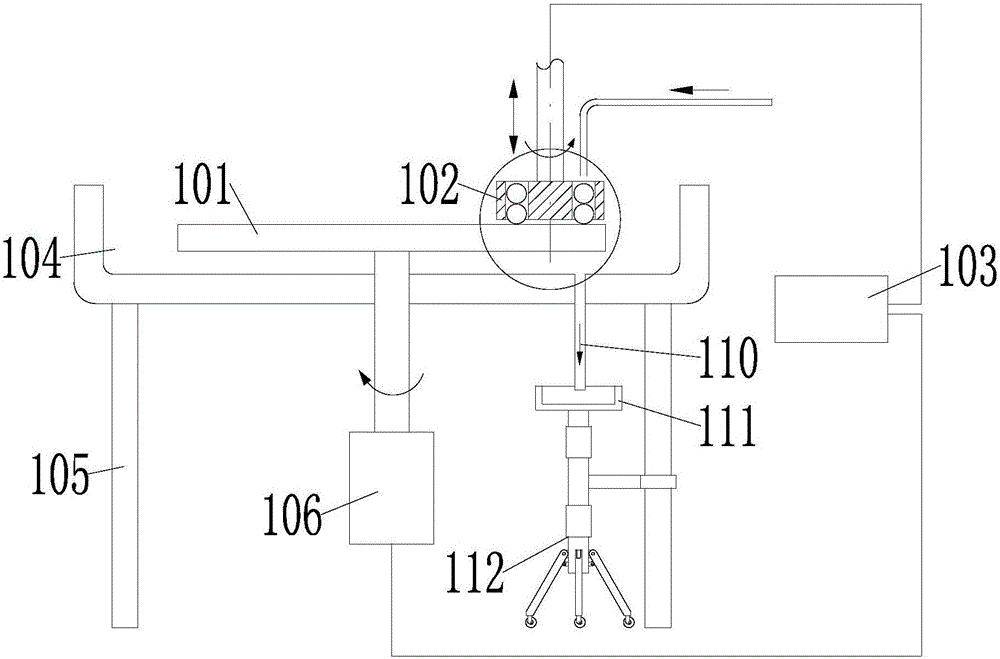

The invention provides a fragile hollow micro-sphere polishing machine and a polishing method, and belongs to the technical field of polishing. The polishing machine comprises a working table, a bottom disc, a top disc and an electric control system, and a cavity is arranged at the top end of the working table; the bottom disc and the top disc are arranged inside or above the cavity, and the rotation axis of the bottom disc and the rotation axis of the top disc are both arranged vertically; and the bottom disc and the top disc are driven by a motor; the top disc is arranged above the bottom disc, and at least one vertical through hole used for containing to-be-polished spheres is arranged on the top disc; and the electric control system is electrically connected with the motor and is used for controlling the rotating speed of the motor. The polishing method is used in the polishing machine, the bottom disc and the top disc are rotated at the same time to achieve speed changing and / or direction-changing motion of the to-be-polished spheres, polishing is achieved though relative friction of the to-be-polished spheres at random, the polishing accuracy is higher, and the polishing machine and the polishing method are particularly suitable for fragile hollow micro-spheres with poor mechanical strength.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

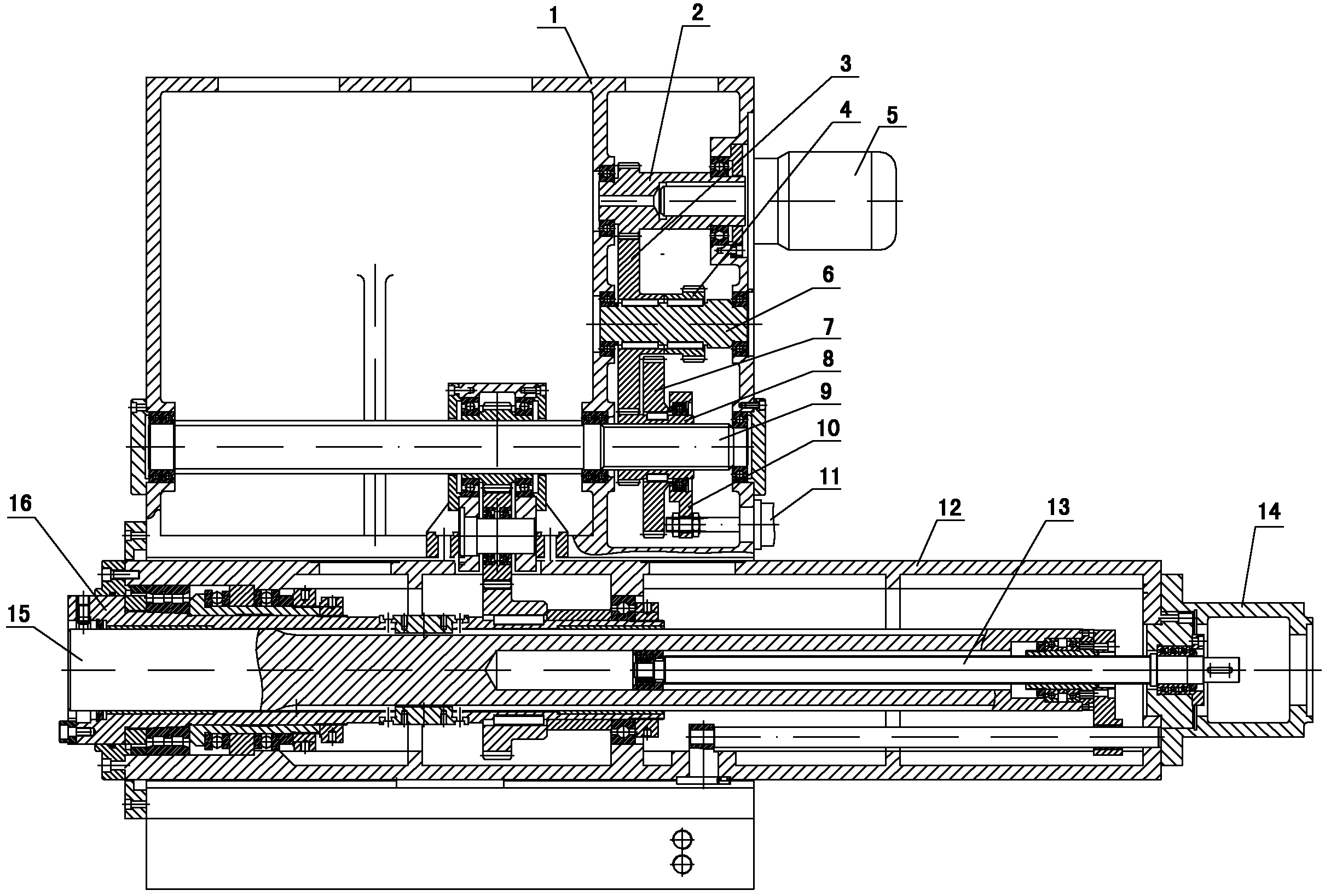

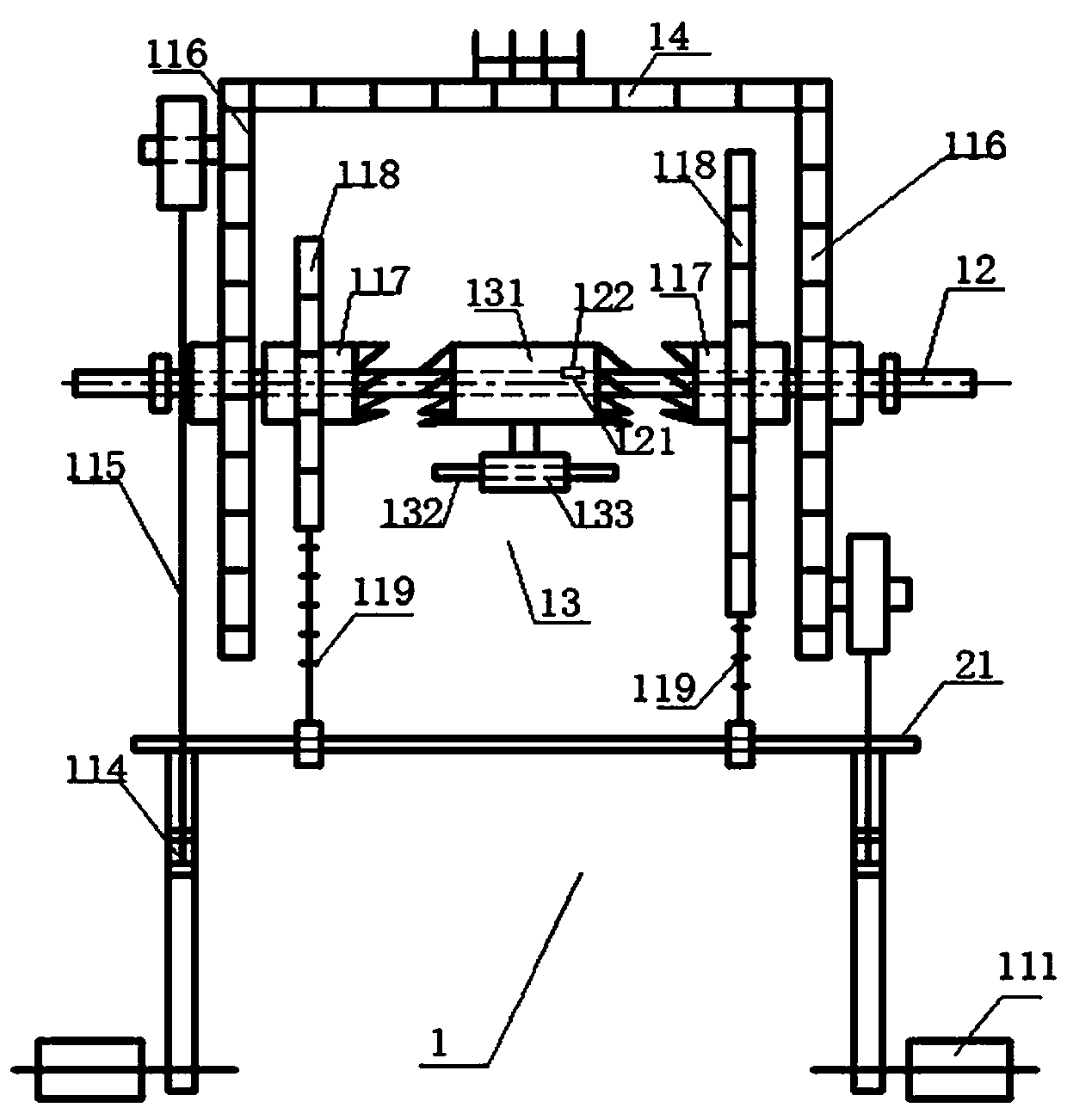

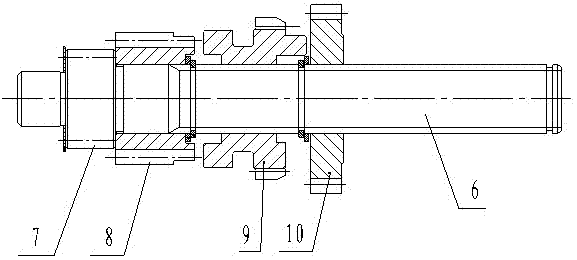

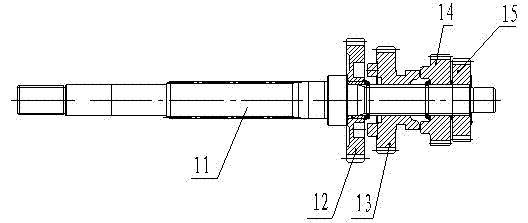

Single degree of freedom numerically controlled machine tool loading device and loading test method

InactiveCN103344449AAchieve variable speedRealize variable load loadingStructural/machines measurementSpecific testNumerical control

A single degree of freedom numerically controlled machine tool loading device is formed by a servo loading mechanism and a control system, wherein a mechanical part of the servo loading mechanism exerts load on a machine tool spindle through a port of the numerically controlled machine tool spindle; the servo loading mechanism comprises an X / Y axis horizontal loading module, a Z axis vertical loading module and a torque loading module, and the three loading modules can be independently used; the control system is used for achieving the functions of servo motor control, load calculation, signal processing and the like on the mechanical part of the servo loading mechanism. A single degree of freedom numerically controlled machine tool loading test method comprises the five steps that firstly, specific test requirements and a test scheme are determined; secondly, connecting operation of the machine tool spindle is completed; thirdly, installation operation of the loading modules and a machine tool work table is completed; fourthly, the load is exerted on the machine tool spindle, and the magnitude of the load is measured; fifthly, results are calculated and outputted. According to the loading device and loading test method, loading is carried out on two collinear directions of the machine tool spindle, and a single degree of freedom loading mode of a numerically controlled machine tool is effectively expanded.

Owner:BEIHANG UNIV

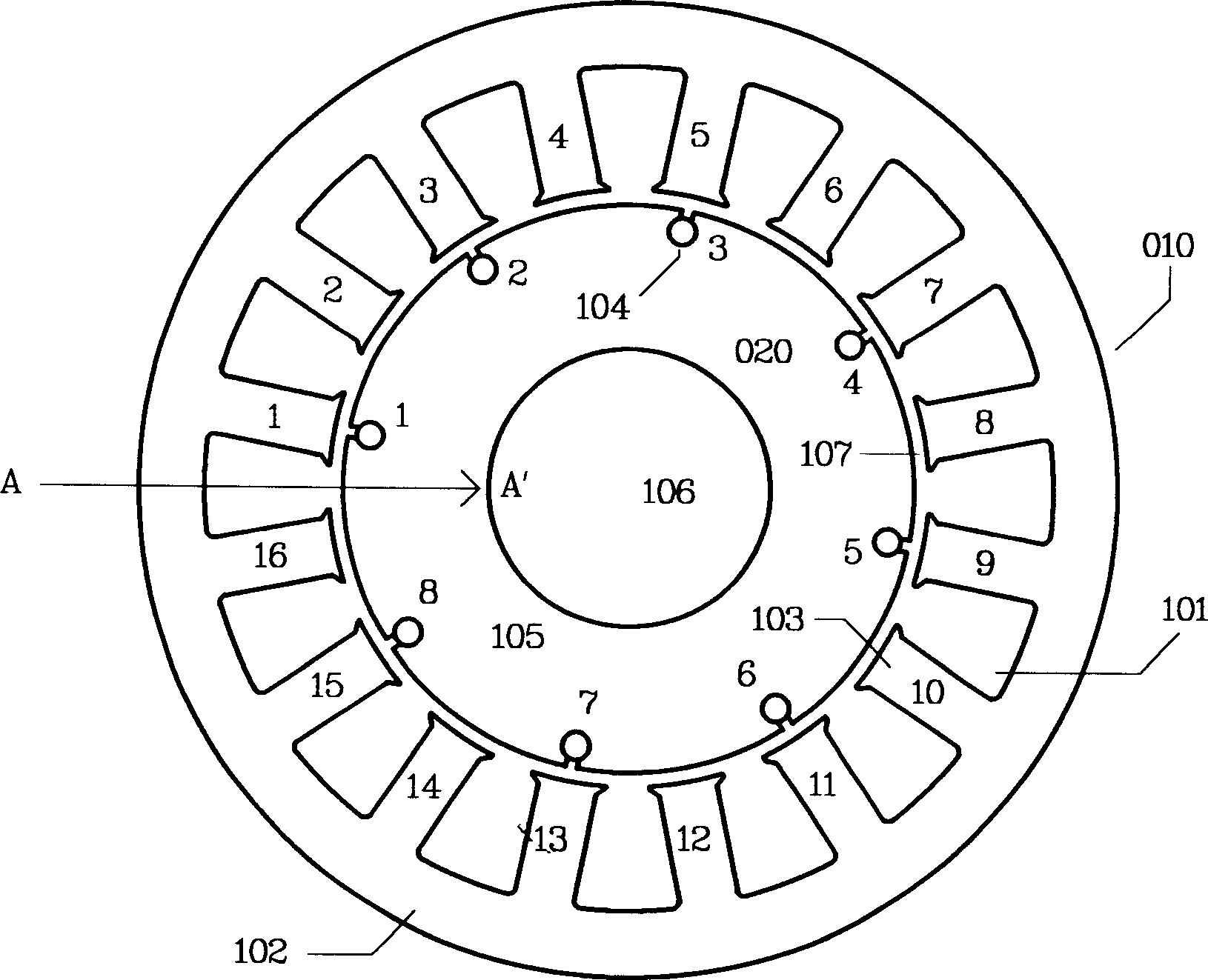

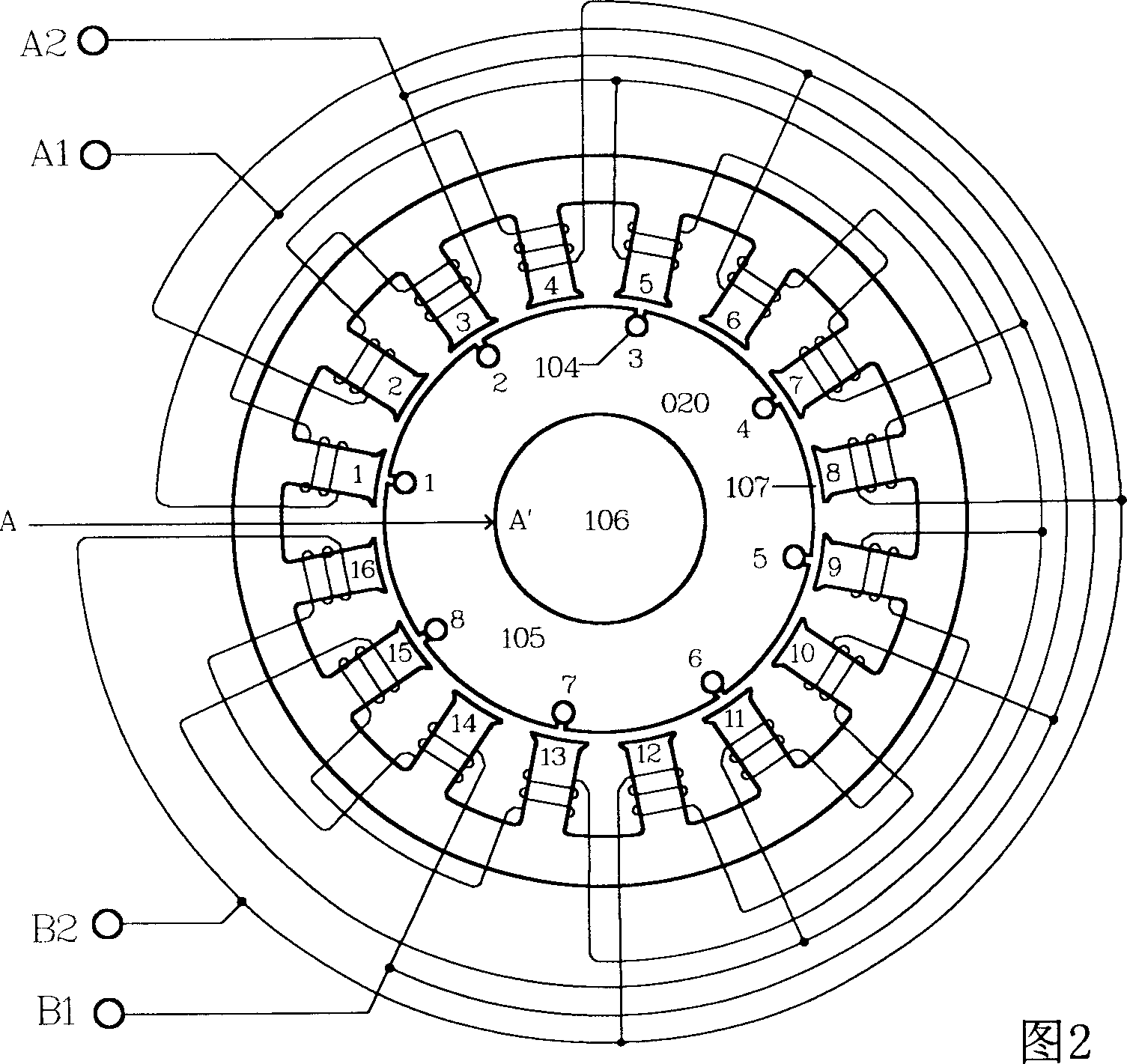

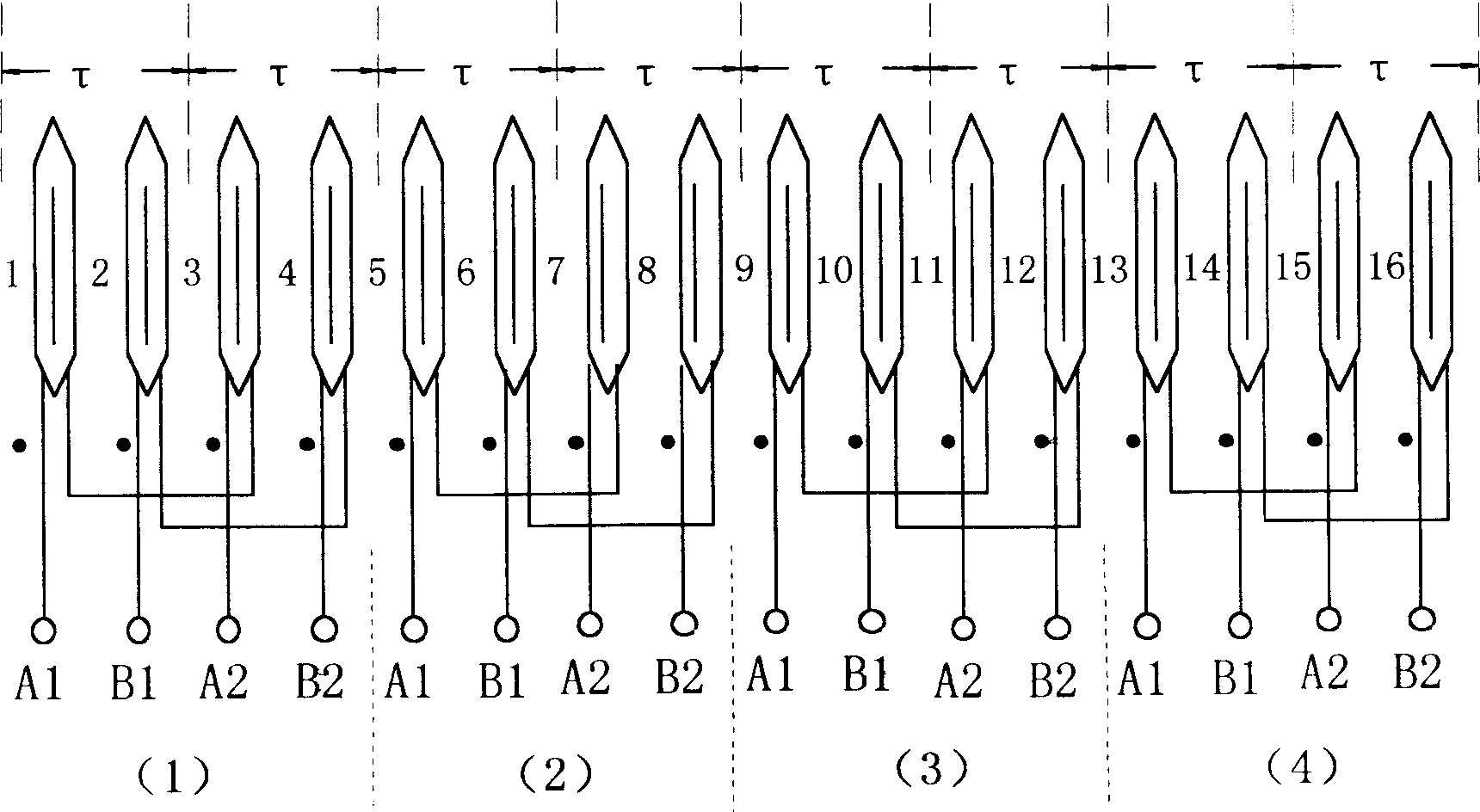

Audio Switch type AC induction motor

InactiveCN1437306AWide speed rangeAchieve variable speedMagnetic circuit rotating partsMagnetic circuit stationary partsInduction motorMagnetic poles

The audio switch type AC induction motor has stator and rotor iron cores comprising punched sheets of soft magnetic material or ferrite with proper frequency characteristics. The rotor is in squirrelcage structure and the stator magnetic poles operate in switching excitation mode with exciting voltage being pulse width or amplitude modulated voltage in audio or ultra-audio range. In the condition of the same output power, the motor of the present invention has volume and weight several times or over ten times smaller, low production cost, excellent mechanical characteristic and step-less speed regulation from zero to several thousand rpm.

Owner:黄有国

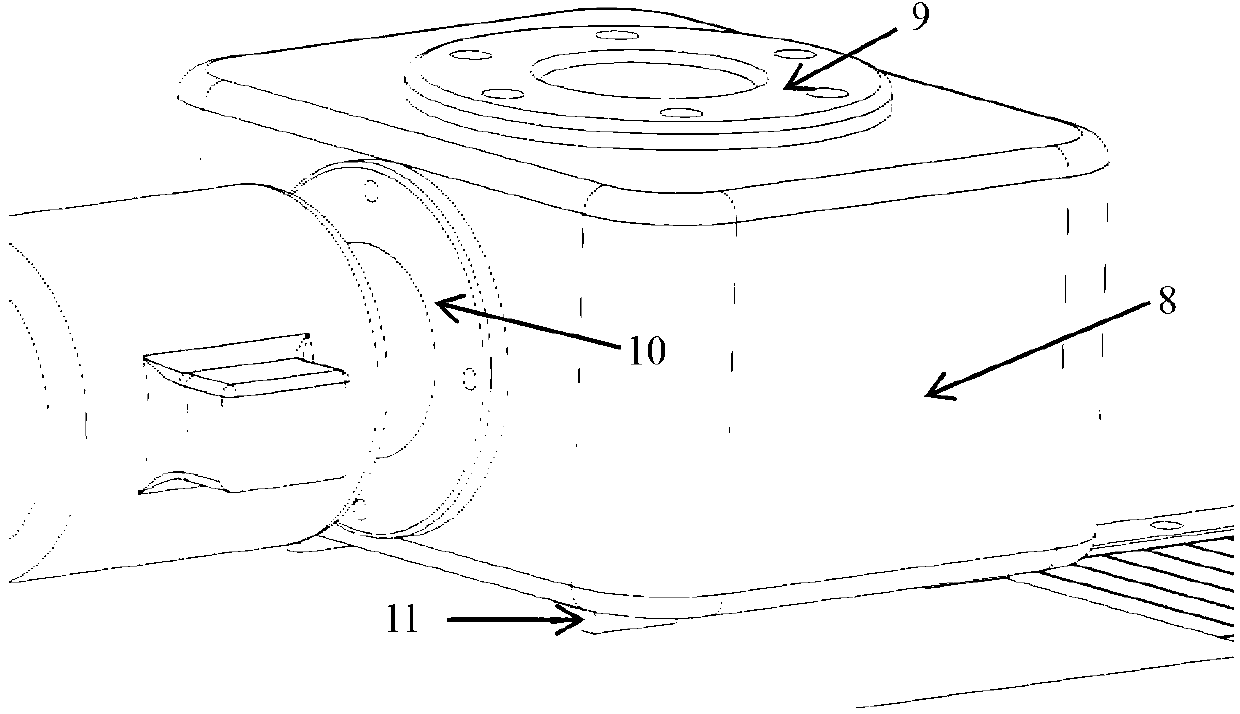

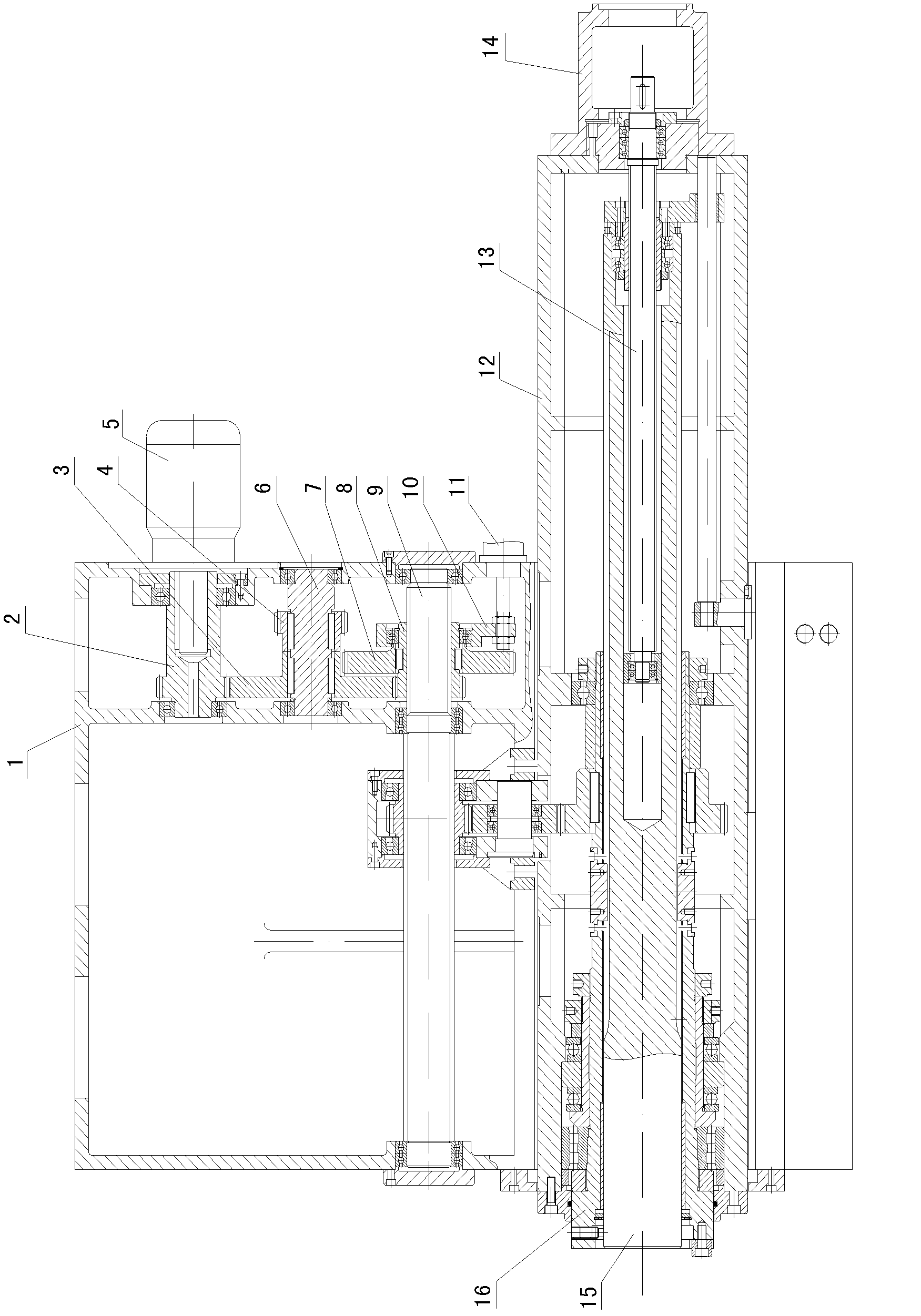

Boring and milling head

InactiveCN102554634AReasonable structureEasy to controlFeeding apparatusLarge fixed membersEngineeringMechanical engineering

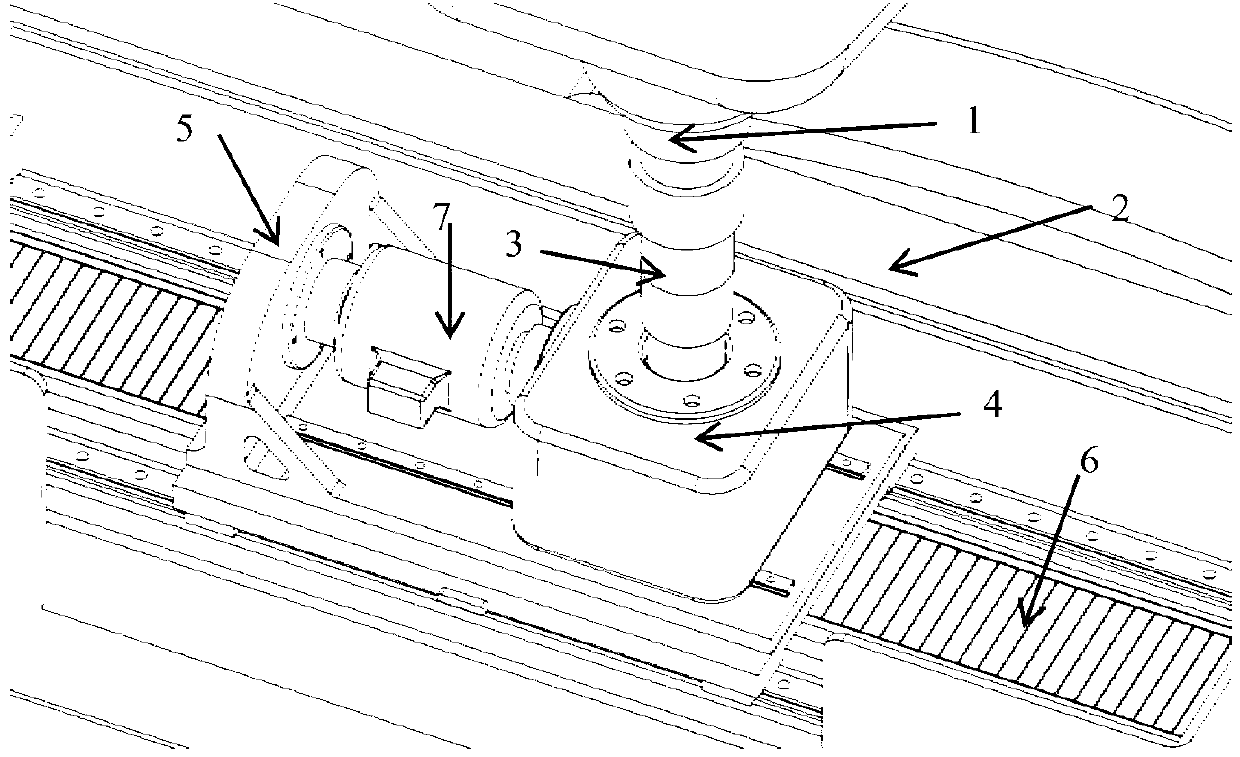

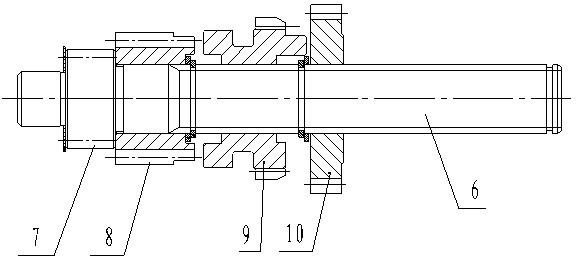

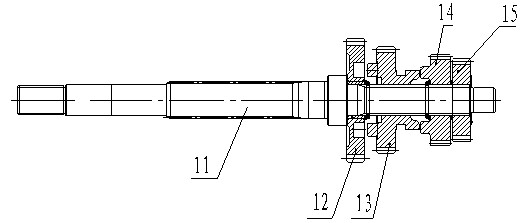

The invention relates to a boring and milling head. A square ram is arranged in a box body; a square ram feeding mechanism is arranged between the box body and the square ram; a boring shaft is arranged in the square ram; a boring shaft feeding mechanism is arranged between the boring shaft and the square ram; a driving gear shaft, an intermediate shaft and a transmission spline shaft are arranged in the box body; a big gear and a pinion are arranged on the intermediate shaft; the big gear is meshed with the driving gear shaft; a sliding pinion on the transmission spline shaft is connected with a sliding big gear; the rear end of the square ram is connected with a feeding box; a shifting fork is arranged on the sliding pinion; a cylinder is arranged on the box body; the shifting fork is connected with a piston rod of the cylinder; and a first feeding screw rod of the boring shaft feeding mechanism and a second feeding screw rod of the square ram are connected with a motor respectively. The cylinder is controlled to move the shifting fork, so transformation between cooperation of the sliding pinion and the sliding big gear and cooperation of the big gear and the pinion can be realized and speed variation of the transmission spline shaft can be realized. The two feeding screw rods are connected with the motor respectively, so the two feeding screw rods can be controlled respectively and the equipment structure is simplified.

Owner:蚌埠市行星工程机械有限公司

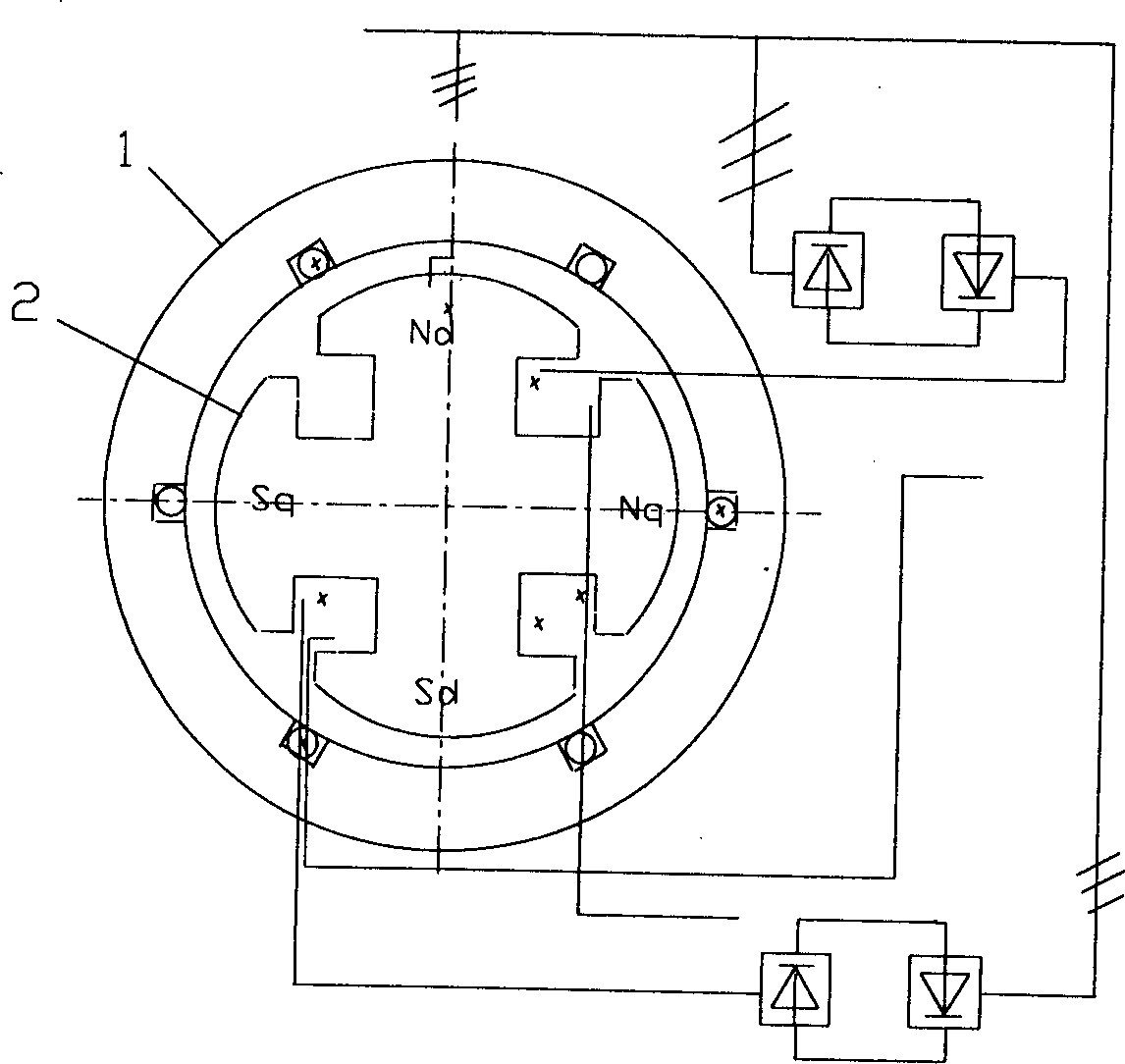

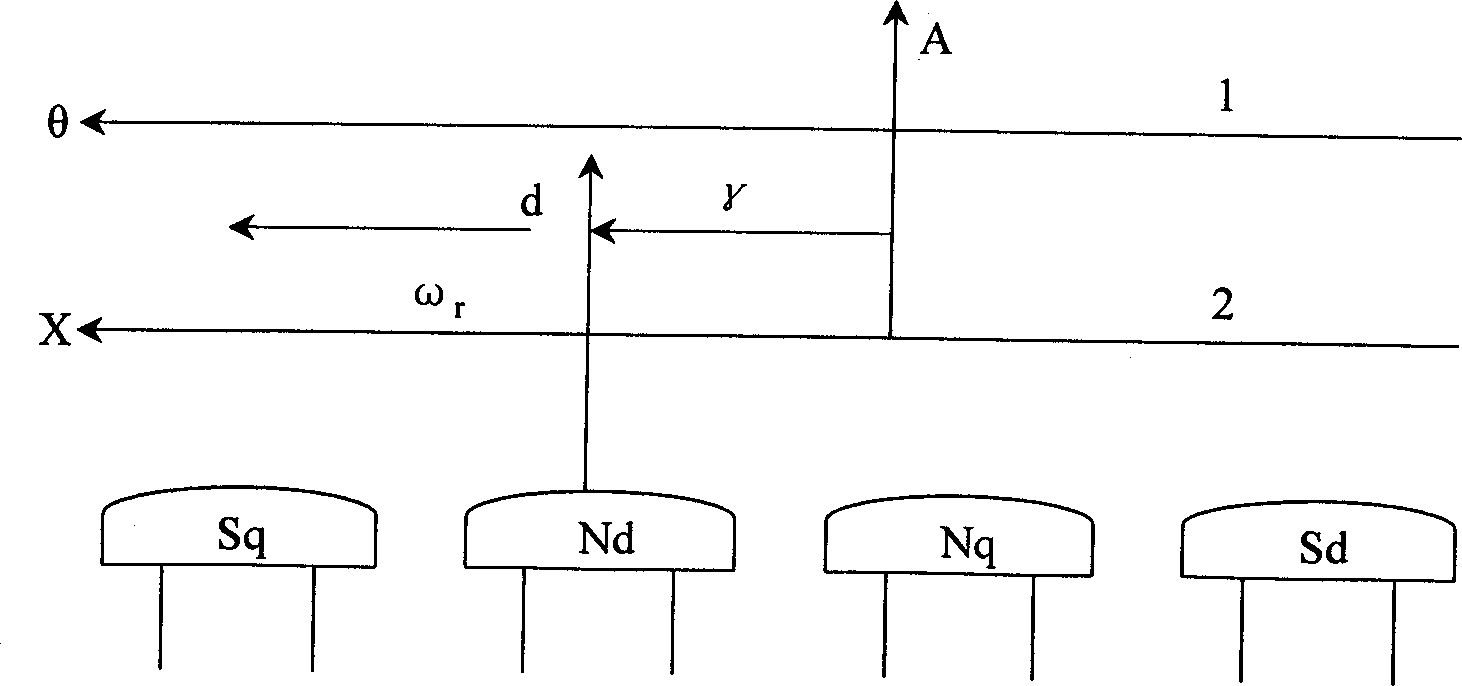

Double-feeding speed varying salient-pole synchronous motor

InactiveCN1335667AAchieve variable speedMeet the requirements of variable speed and constant frequencySynchronous generatorsElectricitySynchronous motor

The present invention relates to the motor principle of motor and the improvement of its structure and aims at realizing the speed varying of salient-pole synchronous motor, especially large-scale hydroelectric generating set. The motor of the present invention has stator with the same structure as common AC motor and P pairs of poles, and rotor structure with mP pairs of splited salient magneticpoles and exciting winding comprising m phase and P pairs winding units with m being 2-6. The double-feeding speed varying synchronous motor of the present invention can meet the requirement of large-scale hydroelectric generating set in energy accumulating power generation, second-term development and operation in optimized conditions as well as the requirement of power system to speed varying synchronous motor.

Owner:HUAZHONG UNIV OF SCI & TECH

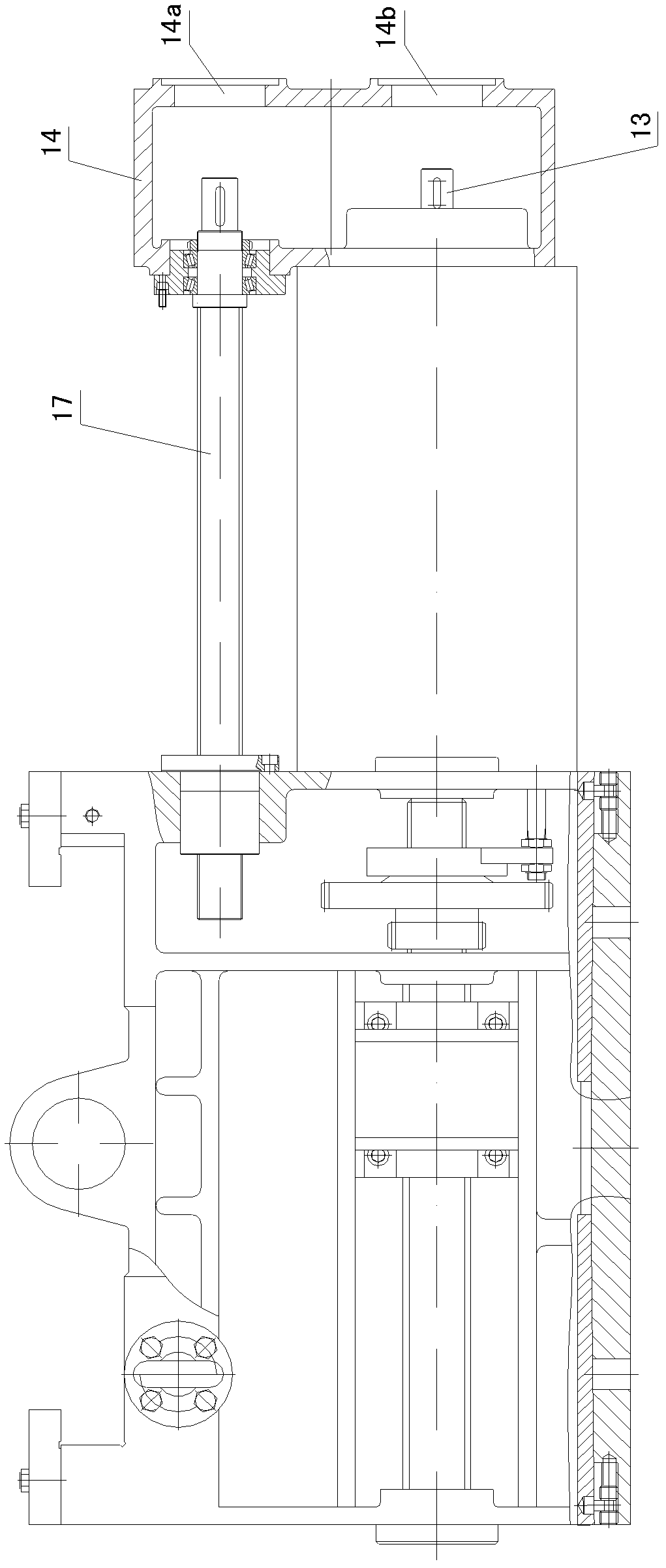

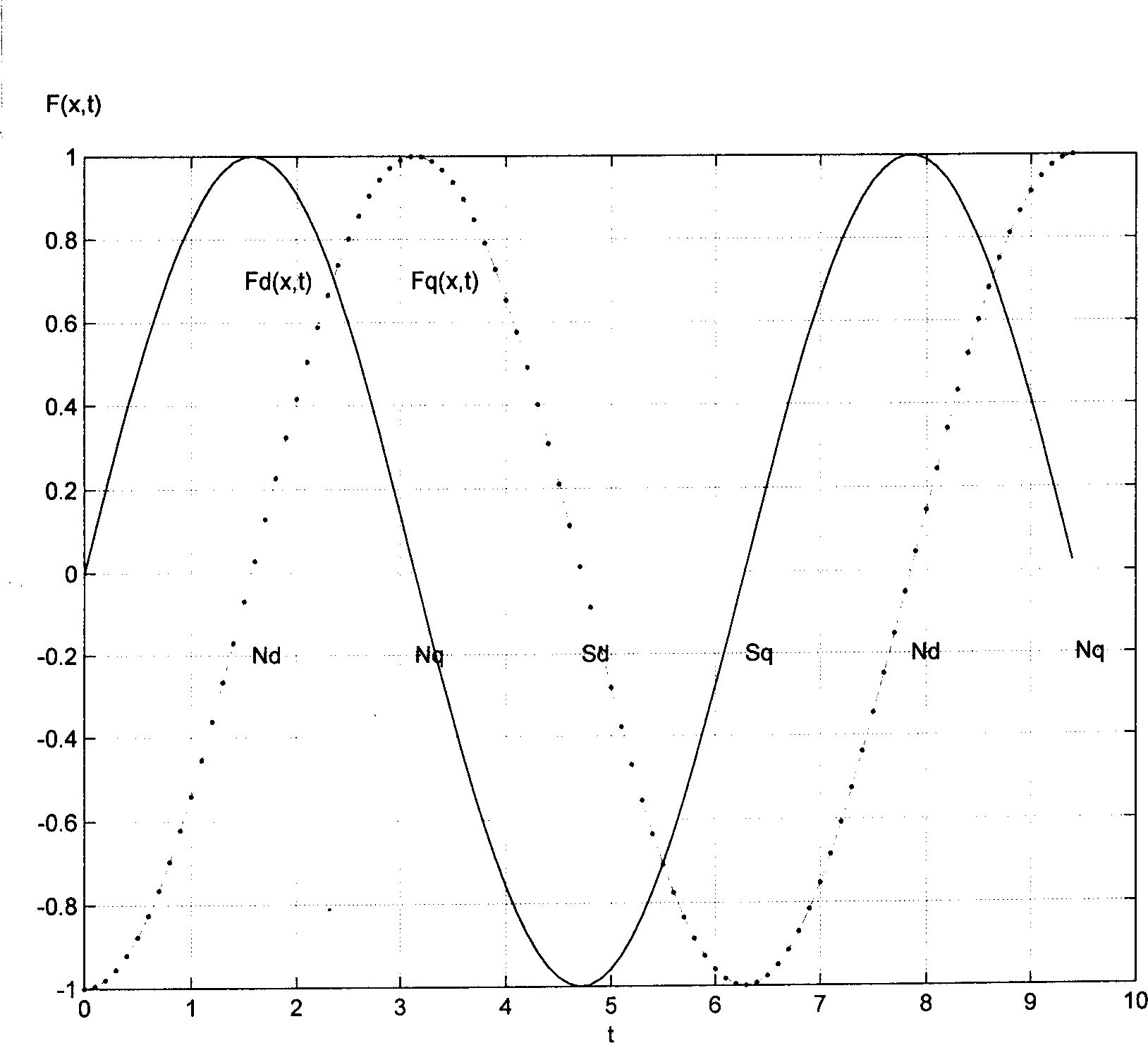

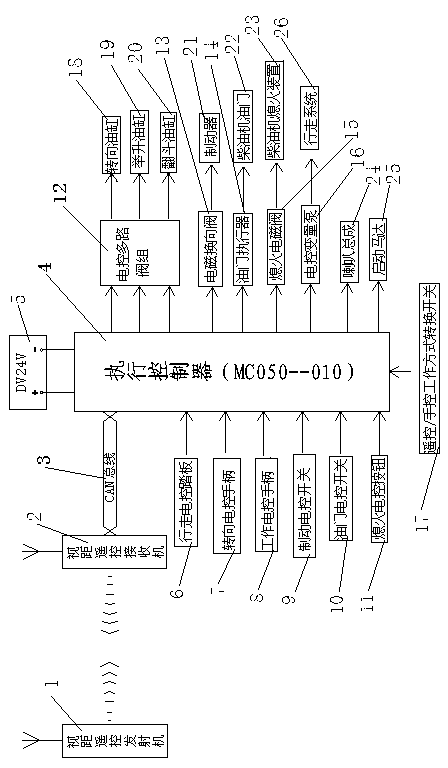

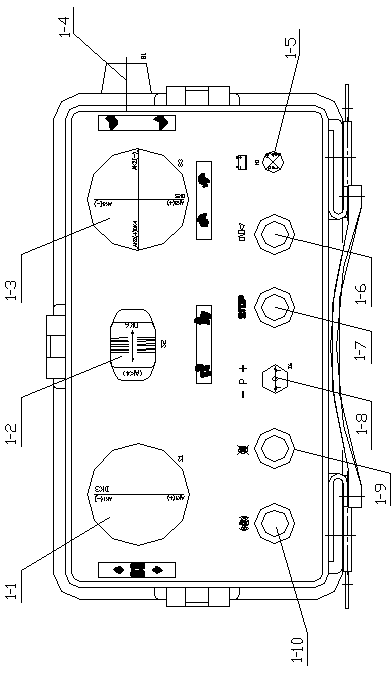

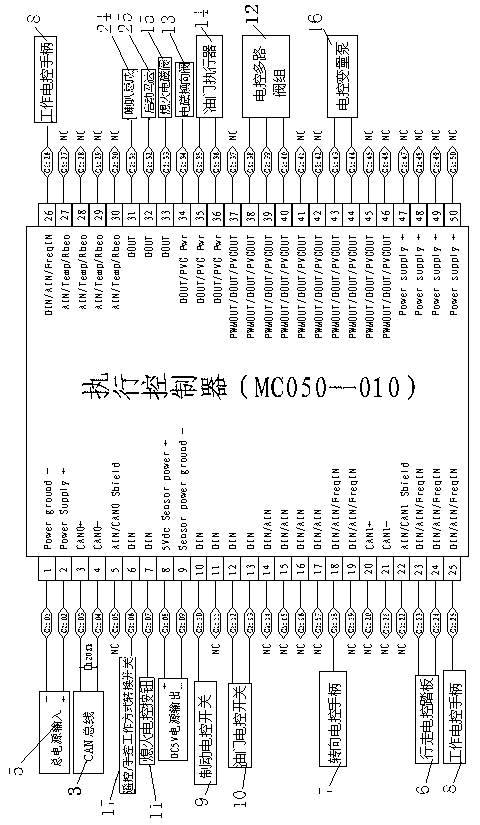

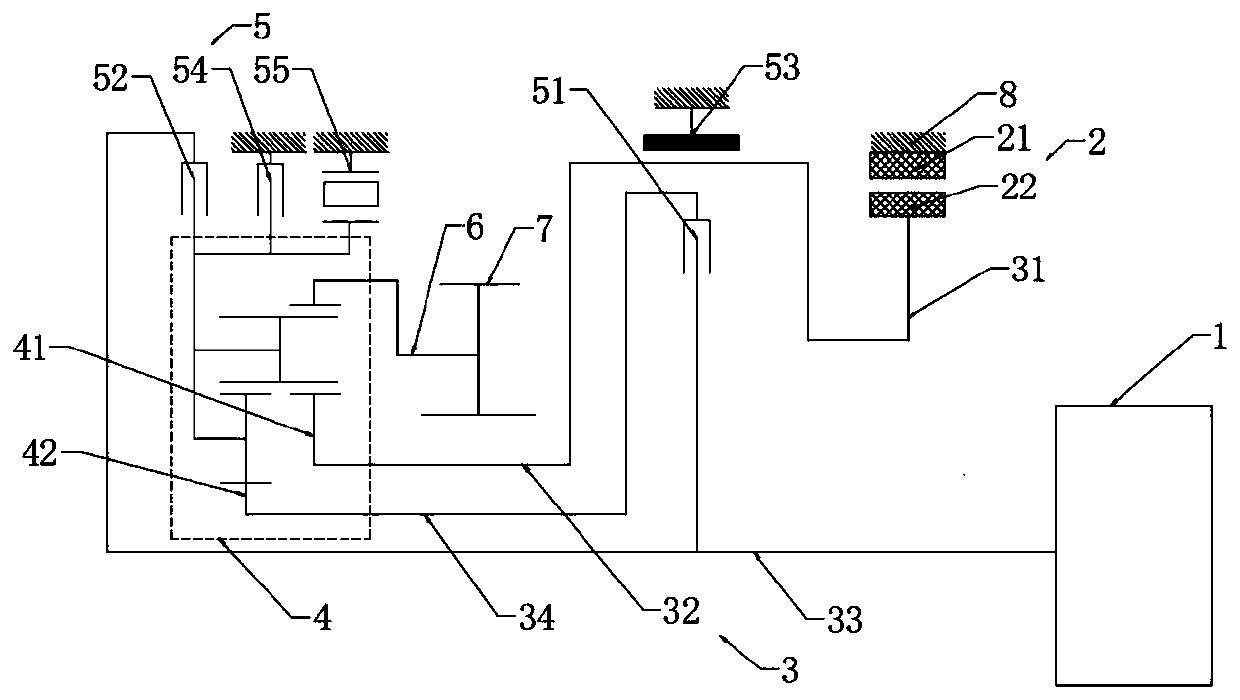

Wireless sight distance control system of small underground trackless carry-scraper

InactiveCN102991439AAchieve variable speedRealize shoveling and unloading operationsElectric/fluid circuitEngineeringElectromagnetic valve

The invention discloses a wireless sight distance control system of a small underground trackless carry-scraper. A sight distance remote receiver (2) is connected with an execution controller (4) through a CAN (Controller Area Network) bus (3); an electric control travelling pedal (6), an electric control steering handle (7), an electric control working handle (8), an electric control braking switch (9), an electric control accelerator switch (10), an electric control flameout button (11), a change-over switch (17), an electric control multiway valve group (12), an electromagnetic directional valve (13), an accelerator executor (14), a flameout electromagnetic valve (15), an electric control variable pump (16), a horn assembly (24), a starting motor (25) and the like are connected with the execution controller (4); and a slight distance remote transmitter (1) is provided with a travelling handle (1-1), a steering rocker (1-2), a working handle (1-3), a power switch (1-4), a power indicator (1-5), a horn button (1-6), an emergency braking button (1-7), an accelerator switch (1-8), a flameout button (1-9) and a starting button (1-10). The wireless sight distance control system is time-saving and labor-saving to operate, high in precision, small in occupied area, low in mechanical failure rate, capable of relieving the working intensity, safe and reliable.

Owner:山金设计咨询有限公司

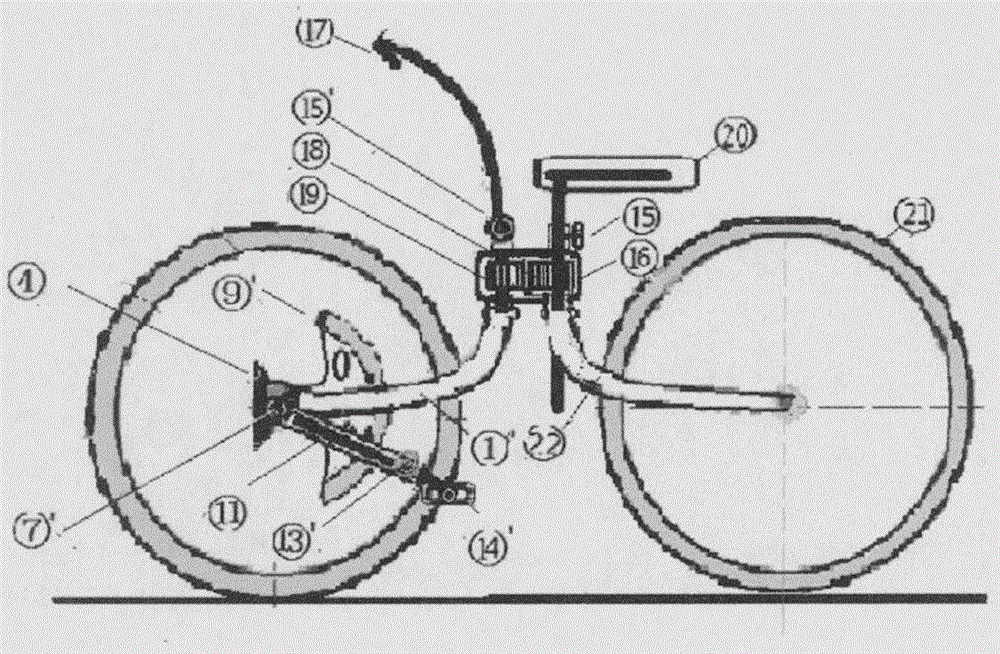

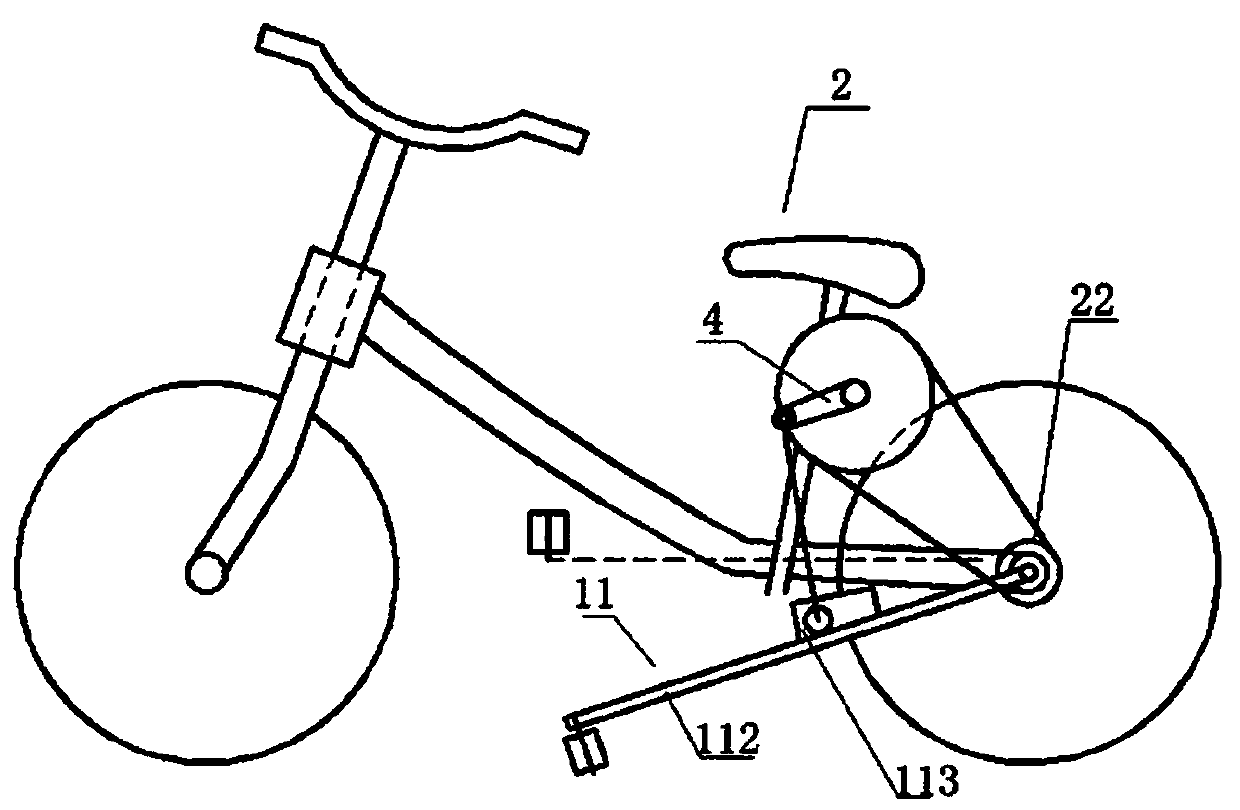

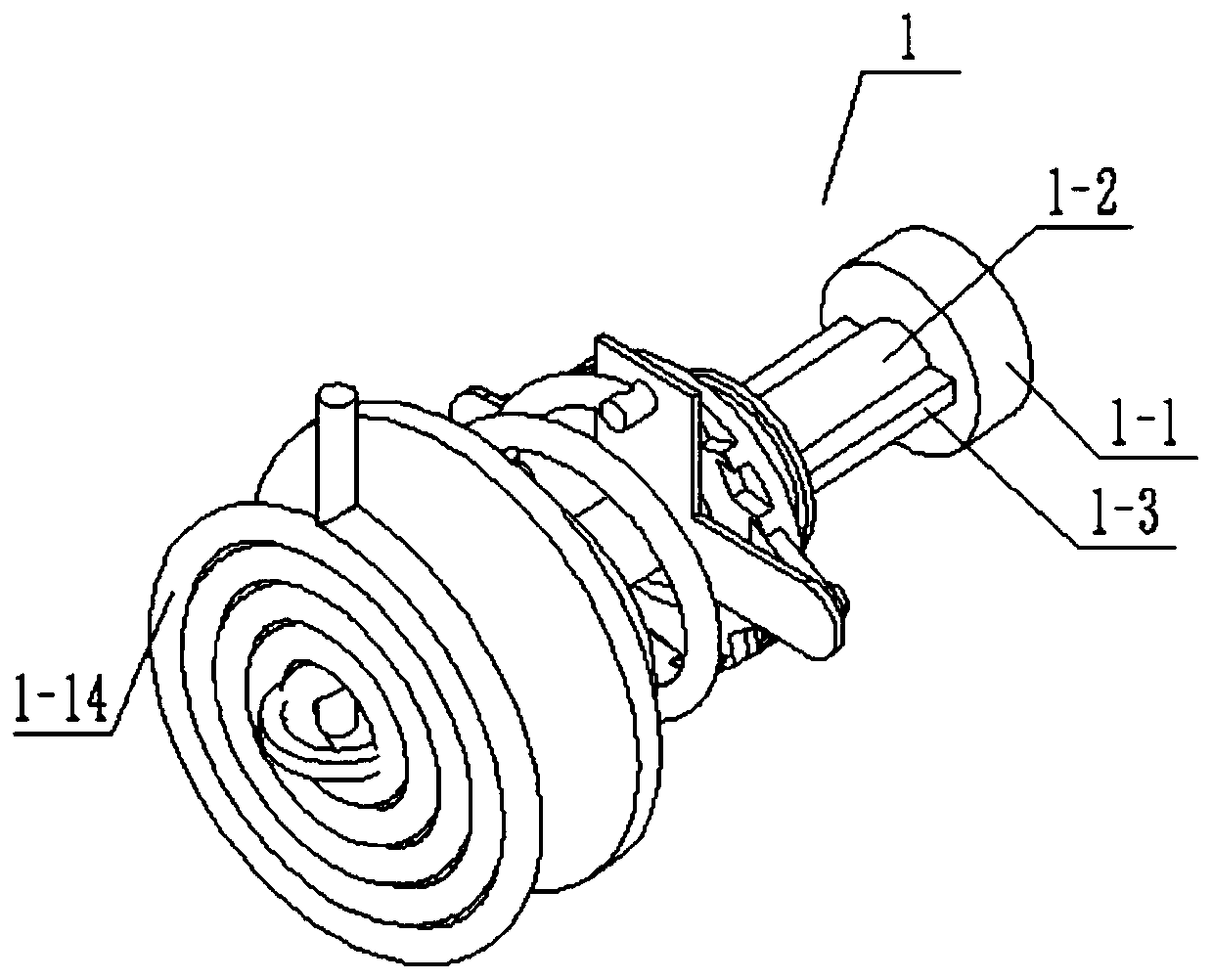

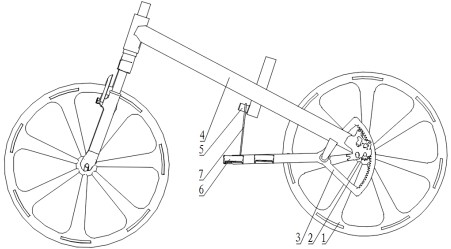

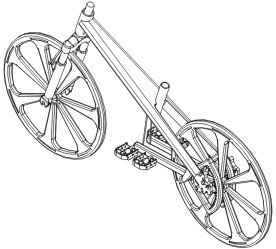

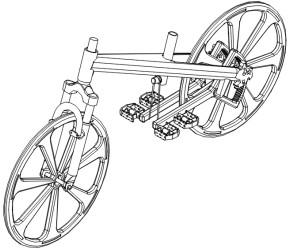

Stepping type no-chain no-middle-shaft infinitely-variable-speed folding bicycle

InactiveCN106428389AEnsuring continuous forward rotation torqueDiameter reductionWheel based transmissionFoldable cyclesGear wheelDrive shaft

The invention relates to a stepping type no-chain no-middle-axle infinitely-variable-speed folding bicycle. The stepping type no-chain no-middle-axle infinitely-variable-speed folding bicycle is characterized in that a hollow shaft, one-way bearings, gears, crank telescopic rods and the like are used for replacing an middle shaft, cranks, crank discs, a chain, flywheels, a variable speed device and the like of a bicycle in the prior art, and are arranged in composite wheel hubs, and whole close of wheels and shaft transmission parts is formed. According to the stepping type no-chain no-middle-axle infinitely-variable-speed folding bicycle disclosed by the invention, the driving form, the transmission mode, the speed change method, the appearance style and the folding situation of the bicycle throughout history are changed, and common steering of a front wheel and a rear wheel is adopted, namely that the circular pedaling driving type of the bicycle is changed into a stepping type; chain transmission or transmission shaft transmission is changed into gear transmission; the speed change through adjusting gear ratio is changed into the infinitely-variable speed change through extending (or contracting) crank rods; the functions of the middle shaft are achieved by a front shaft concurrently, and the middle shaft manner of the bicycle is omitted; and the front wheel steering is changed into the common steering of the front wheel and the rear wheel, and internal rotation and folding of the front wheel and the rear wheel are realized.

Owner:黄建

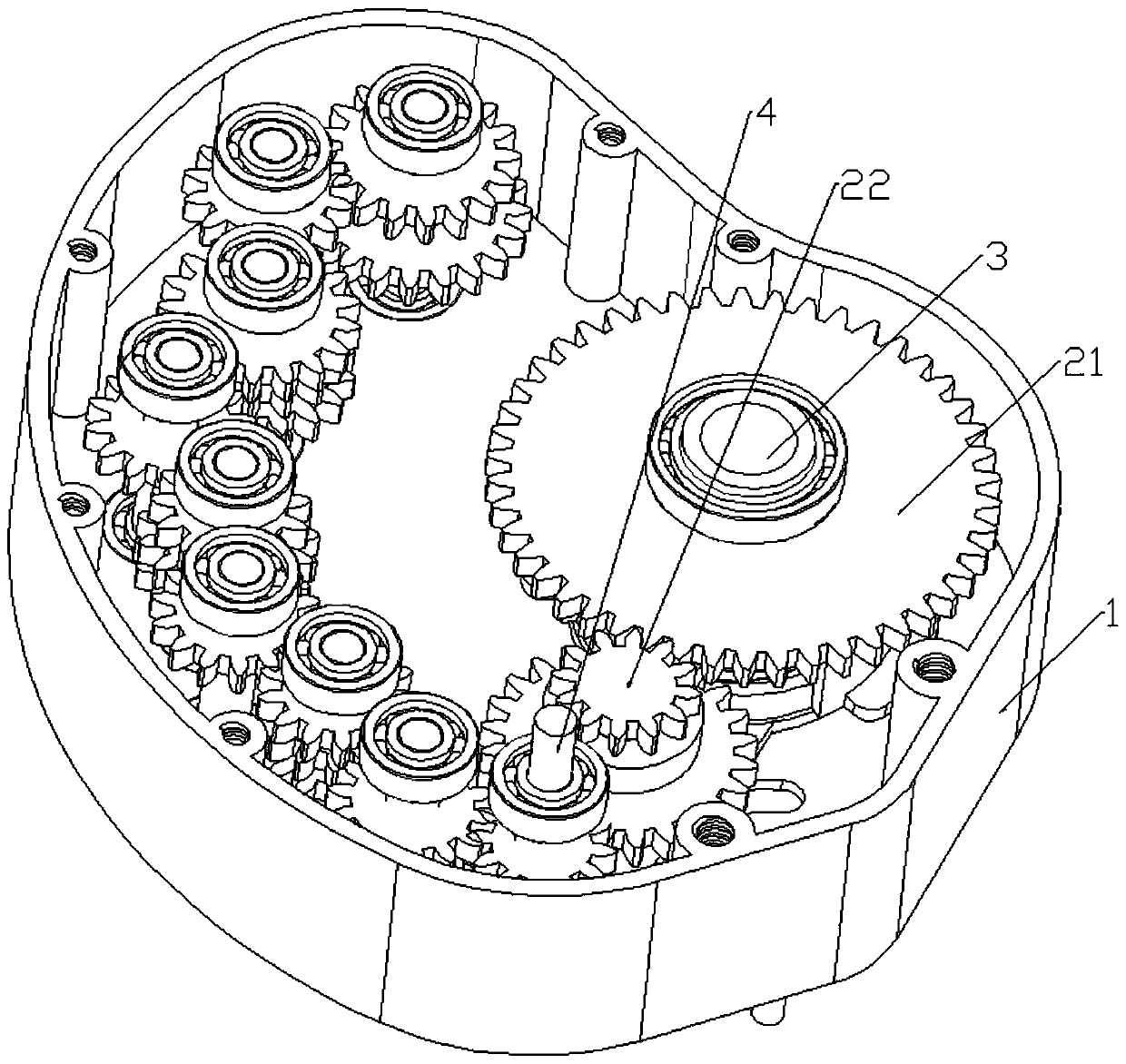

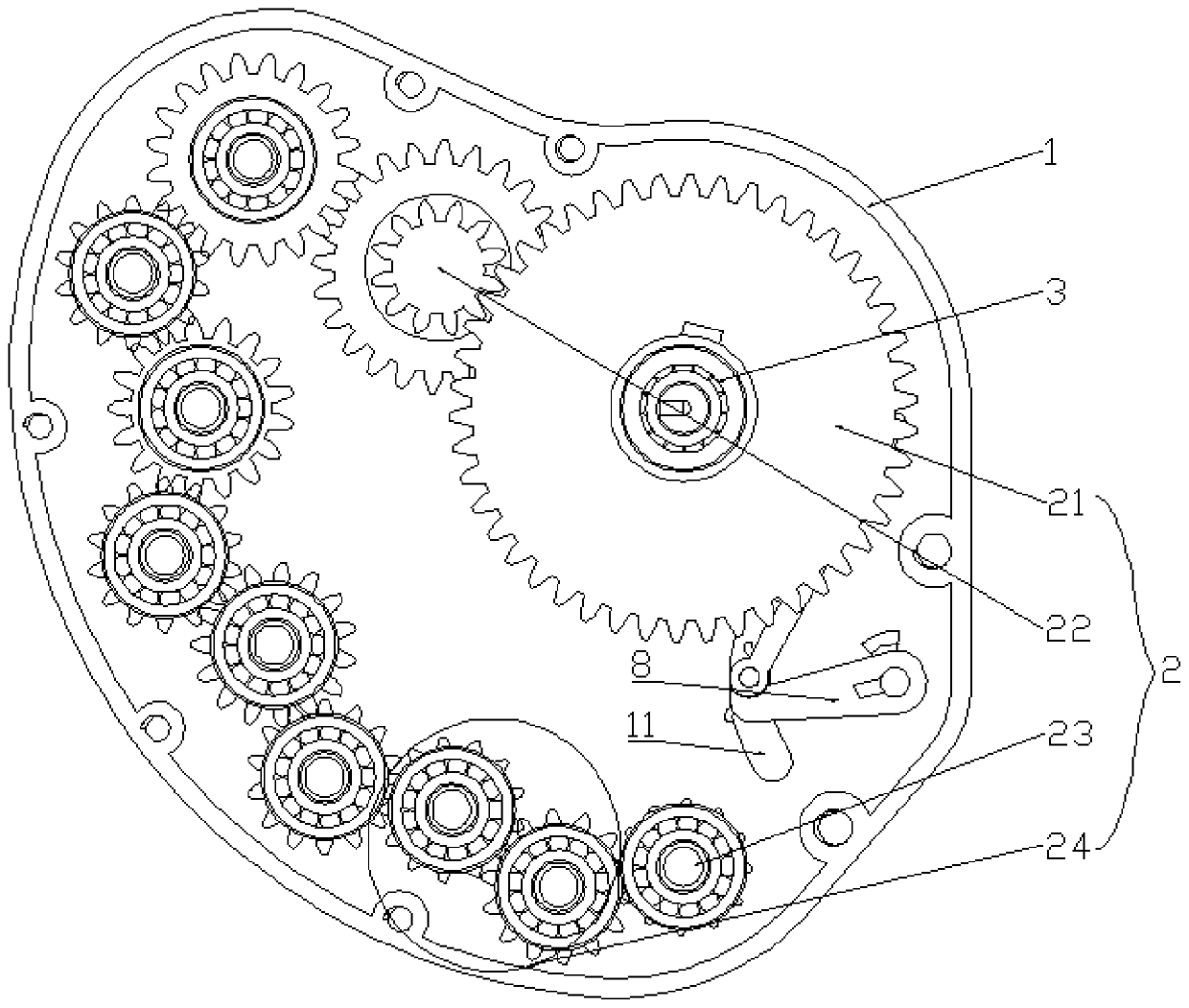

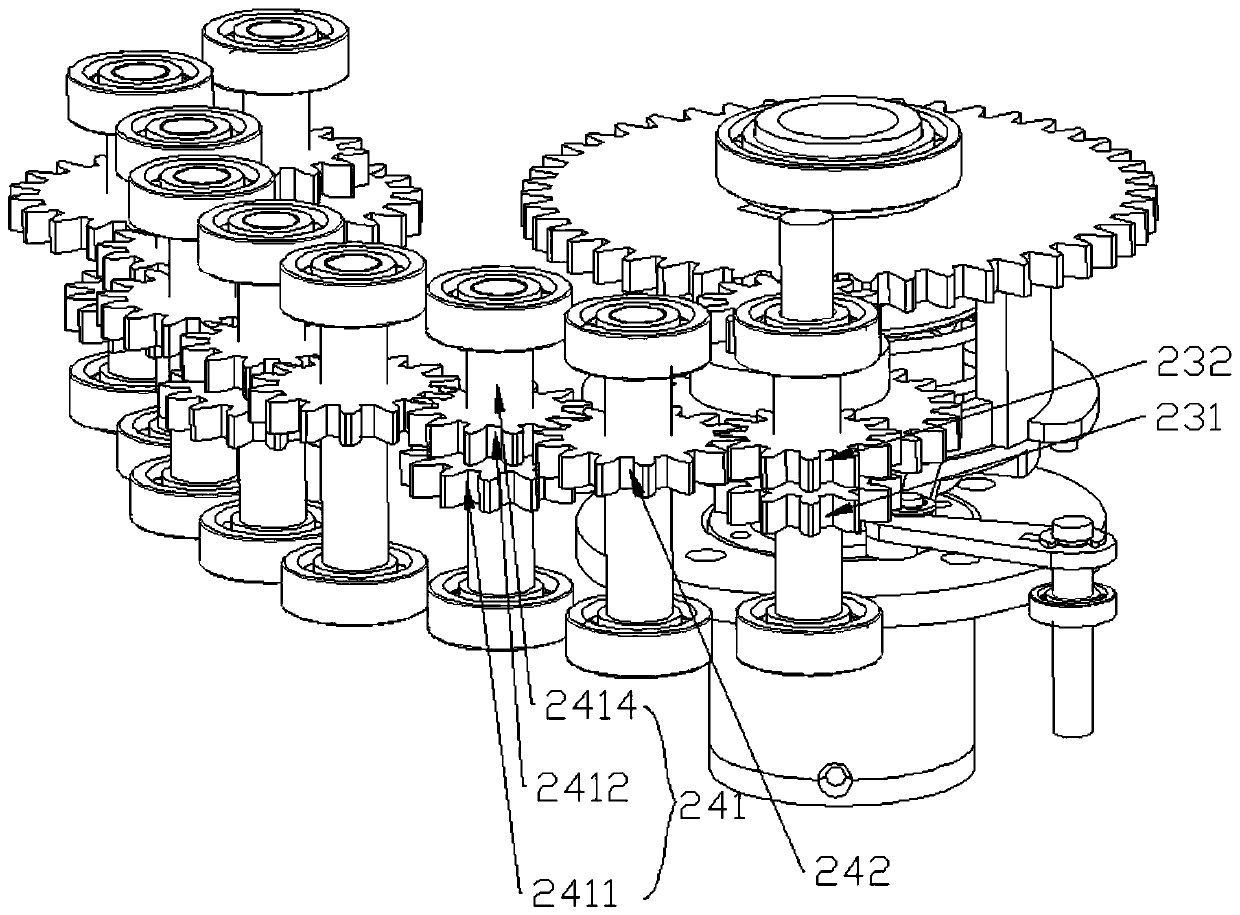

Automobile planetary gear transmission

InactiveCN110281759AAchieve power transmissionAchieve variable speedGas pressure propulsion mountingToothed gearingsEngineeringMechanical engineering

The invention discloses an automobile planetary gear transmission. The automobile planetary gear transmission comprises a split planetary gear set and a compound planetary gear set which are arranged on the same axis. The split planetary gear set comprises a split planetary sun gear, a split planetary ring gear, a split planetary carrier and a plurality of split planetary pinions; the split planetary sun gear is connected to a motor rotor; one end of the split planetary ring gear meshes with the plurality of split planetary pinions and the other end of the split planetary ring gear is separately connected to a second clutch and a third clutch; the plurality of split planetary pinions are supported on the split planetary carrier by bearings; the middle part of the split planetary carrier is connected to a first clutch and a third brake to be a whole through an engine output shaft; and through the engagement or disengagement of a plurality of engagement components and a plurality of braking components, the split planetary gear set and the compound planetary gear set output the rotation of a motor and an engine by speed changing. The automobile planetary gear transmission can reduce the impact of the transmission during gear shifting and improve the comfort of gear shifting.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

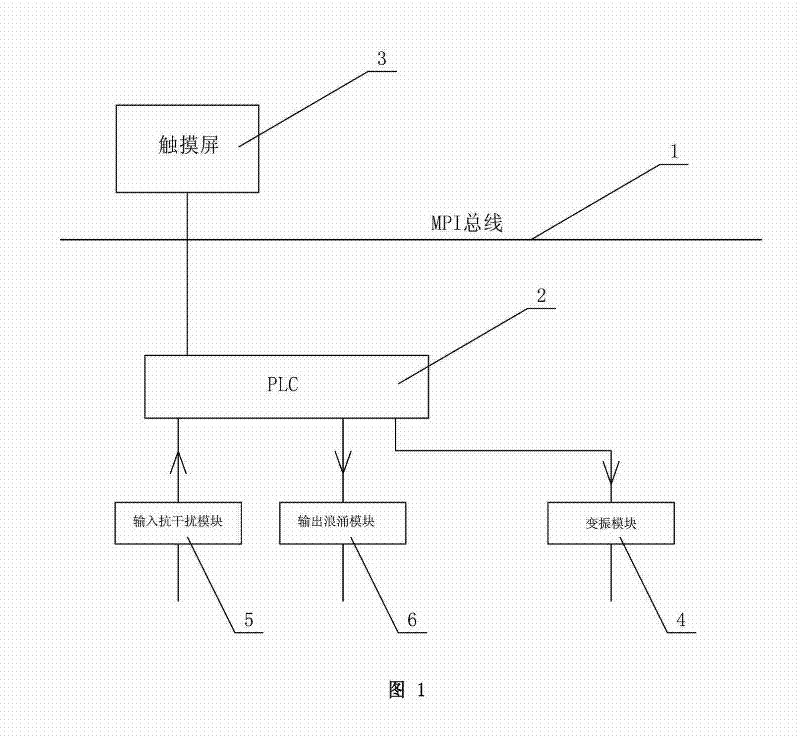

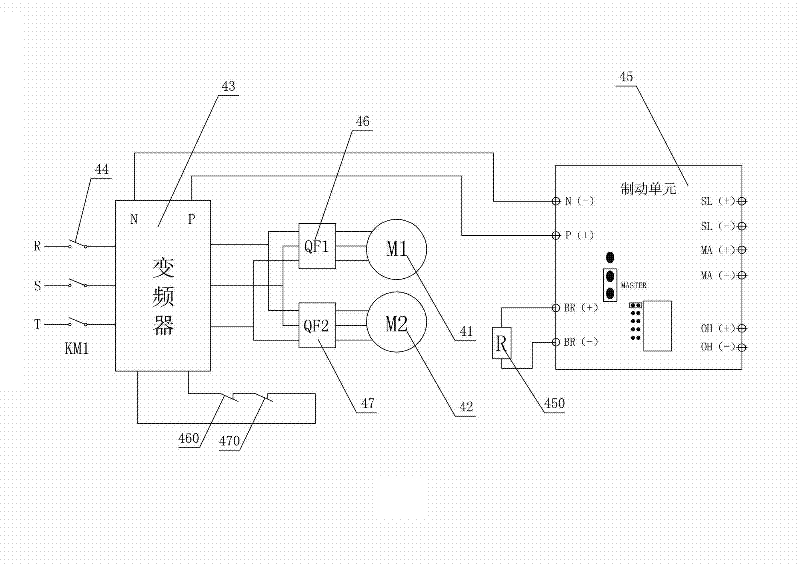

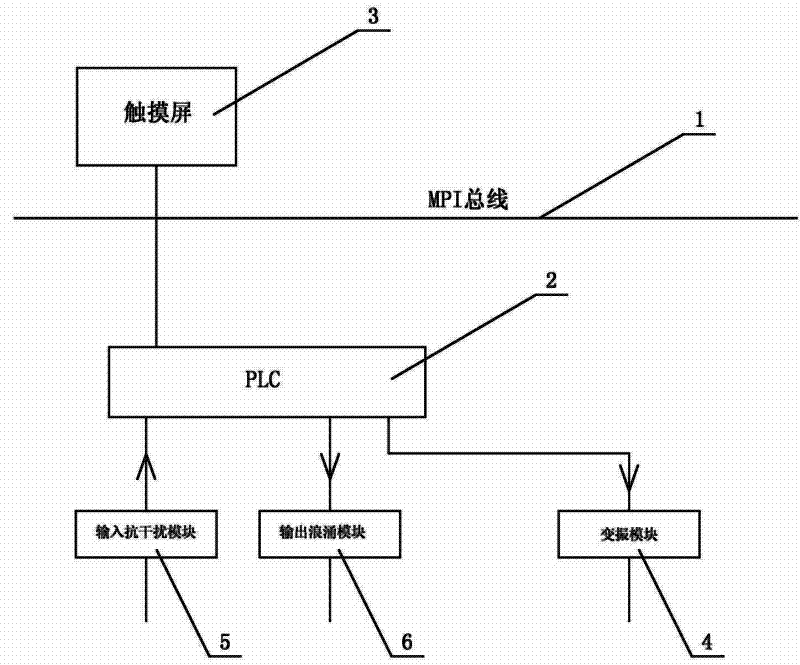

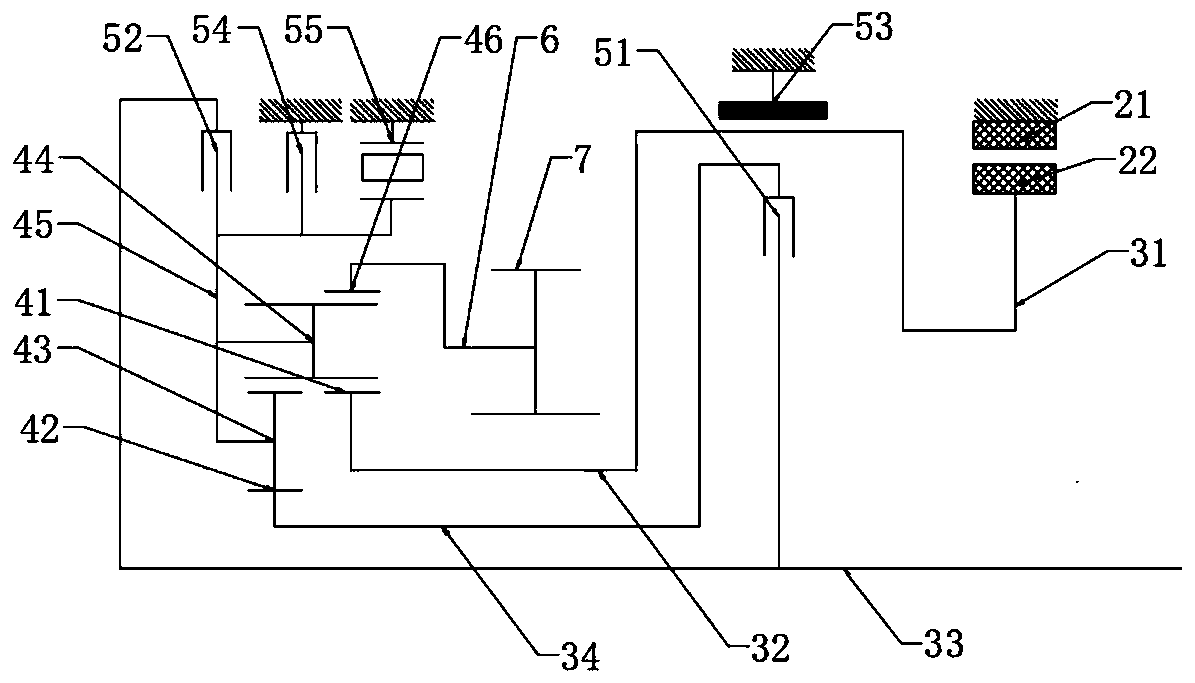

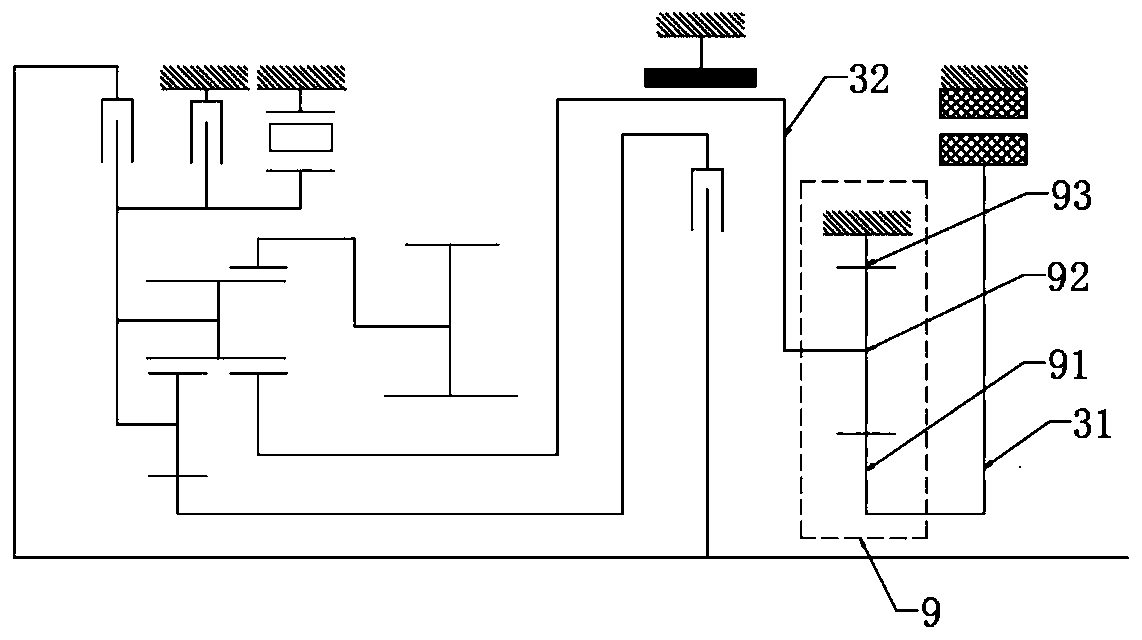

A control system applied to brick machine

InactiveCN102267161AStrong anti-interference abilityImprove reliabilityCeramic shaping apparatusContactorSurge control

A control system applied to a brick machine, including an MPI bus and a main control module and a control panel connected to the MPI bus, and also includes a variable vibration module for controlling a vibration device, an anti-jamming module for receiving action feedback signals, and The output surge module used to issue action commands, the variable vibration module, the anti-interference module and the output surge module are respectively connected to the main control module. The variable vibration module includes a power supply, two motors, a frequency converter, and is connected between the power supply and the frequency converter. A contactor, a braking unit electrically connected to the frequency converter, two air switches and two air switch contacts, the two air switches are respectively connected between the frequency converter and the two motors, and the two air switch contacts are connected in series and connected to the frequency converter. The main control module is used for program control, and the anti-jamming module and output surge module are used for signal transmission control with each part of the brick machine, which can realize the automatic production control of the brick machine; the variable vibration module has a soft start function, which can realize the two motors. Synchronous work.

Owner:QUANGONG MACHINERY

Bicycle with swing arm device

ActiveCN107554673ASimple structureChange structureChain/belt transmissionRider propulsionTransmitted powerEngineering

The invention relates to a bicycle with a swing arm device. The bicycle comprises the swing arm device and a bicycle frame. The swing arm device is mounted on the bicycle frame and comprises power transmission devices symmetrically arranged on the two sides of a bicycle body. Each power transmission device comprises a swing arm lever, a pulley groove, a pulley, a connecting rod and a crankset. Oneends of the swing arm levers are connected with pedals, and the other ends of the swing arm levers are connected with a flywheel shaft. The pulley grooves are formed in the swing arm levers. The pulleys make movement in the pulley grooves. One ends of the connecting rods are connected with the pulleys, and the other ends of the connecting rods are connected with a crank throw. The crank throw andthe cranksets are mounted on a connecting shaft. The cranksets and a flywheel transmit power through chains. The structure is simple; by stepping the pedals up and down, the pulleys make linear movement in the pulley grooves, the connecting rods drive the crank throw to drive the cranksets to make circular movement, and thus the power is transmitted through the chains to enable the bicycle to advance; and the structure is simple and reasonable, an original crank throw type bicycle structure is changed, thus much labor is saved during riding, and the force transmission efficiency is improved.

Owner:吴监玉

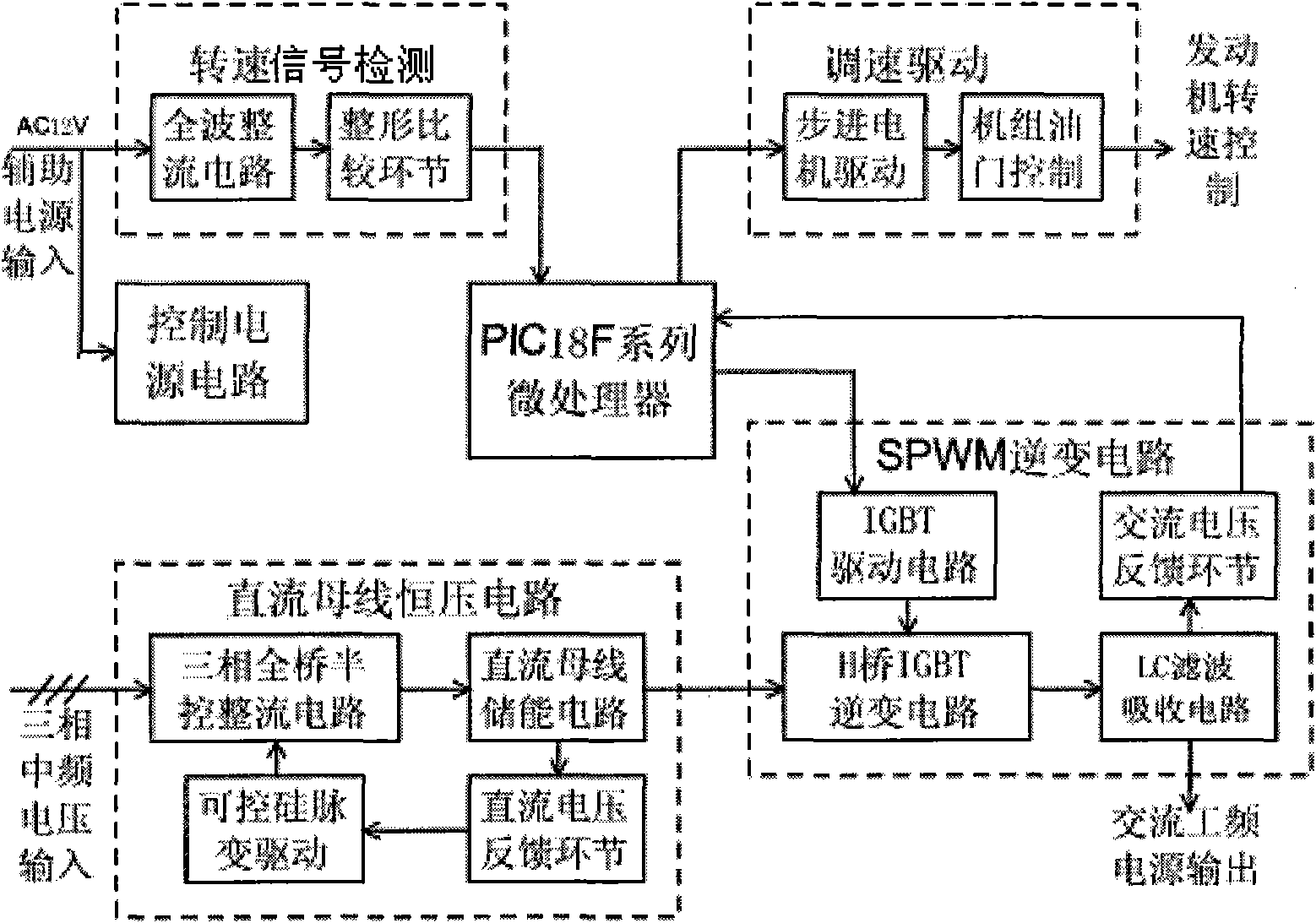

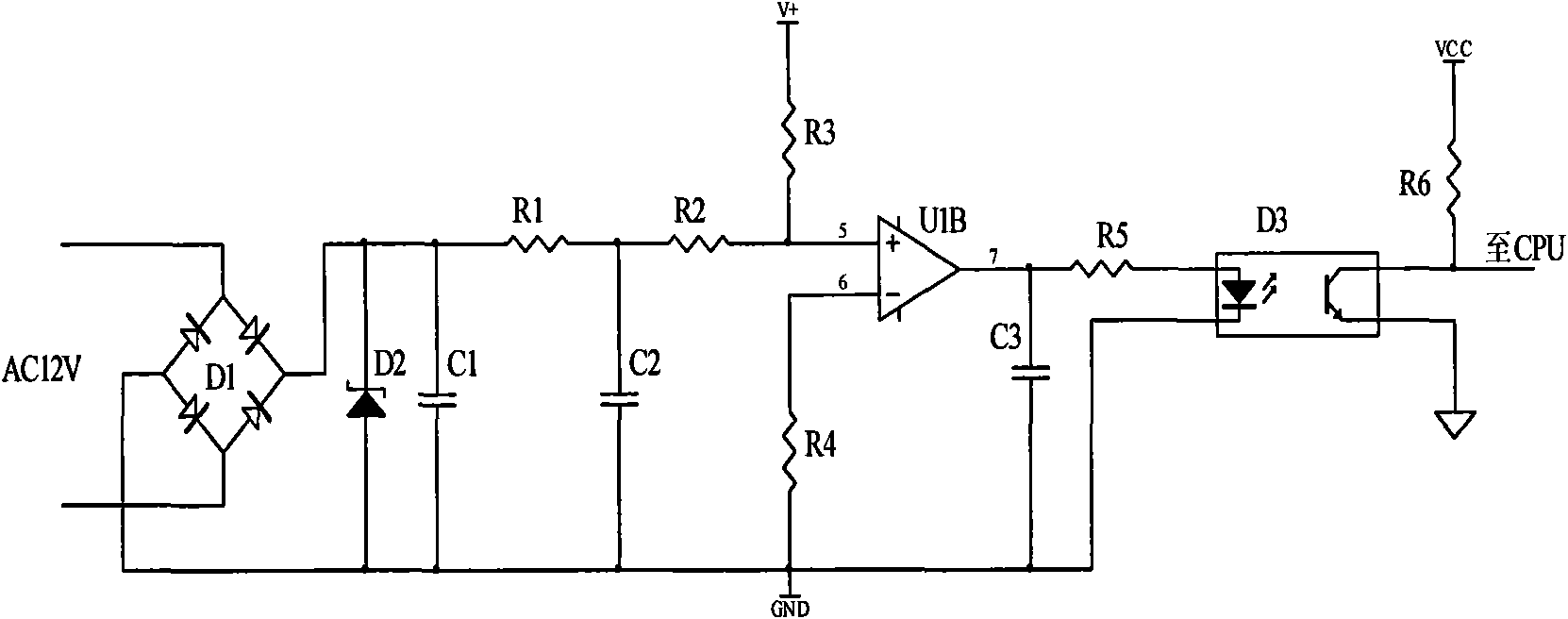

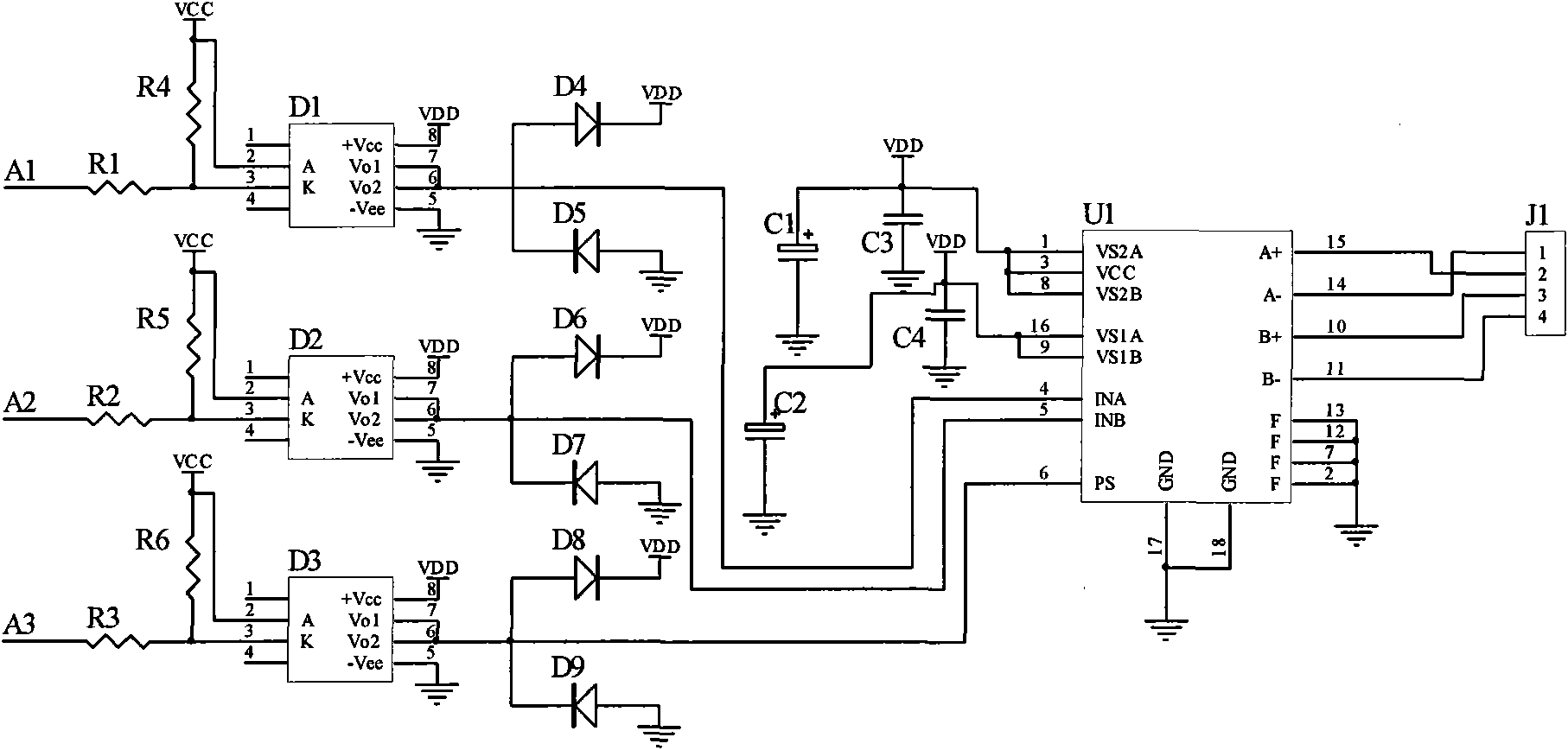

Speed regulating and inverting controller for generating set

InactiveCN101552590AImprove output qualityFlexible for constant speedAC motor controlAlternating currentAdjustable-speed drive

The invention discloses a speed regulating and inverting controller for a generating set. The controller comprises two main parts, namely, an engine speed regulating control circuit and a generator outputting and inverting control circuit. The engine speed regulating control circuit comprises rotating speed signal detection and speed regulating driving which are connected with a PICS18F series microprocessor respectively, the generator outputting and inverting control circuit comprises a direct current bus constant voltage circuit and an SPWM inverting circuit, the input end of the direct current bus constant voltage circuit is connected with the generator, the direct current output end is connected with the inverting main circuit of the SPWM inverting circuit, and the SPWM inverting circuit is connected with I / O of the PICS18F series microprocessor, thus forming a control circuit driven by an inverter. The controller realizes the stability and energy-saving running of the generating set and can ensure that the quality of the output power frequency alternating current reaches G3 grade demands regulated in GB / T2820.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

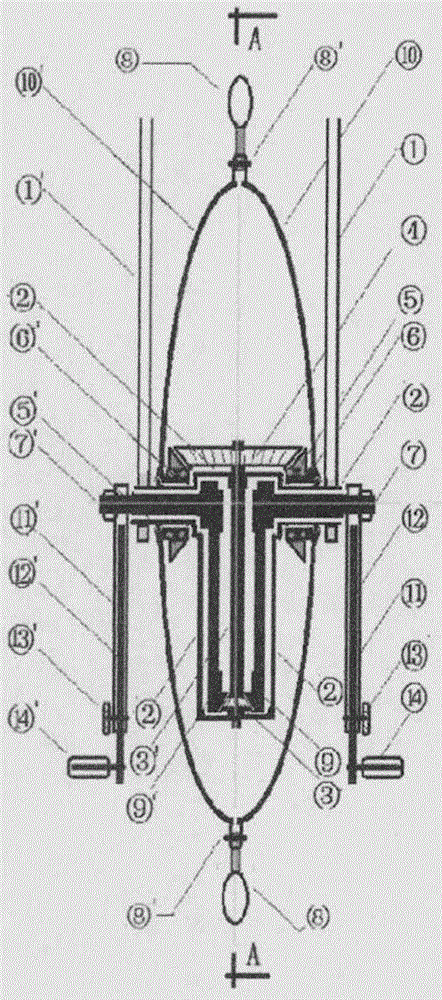

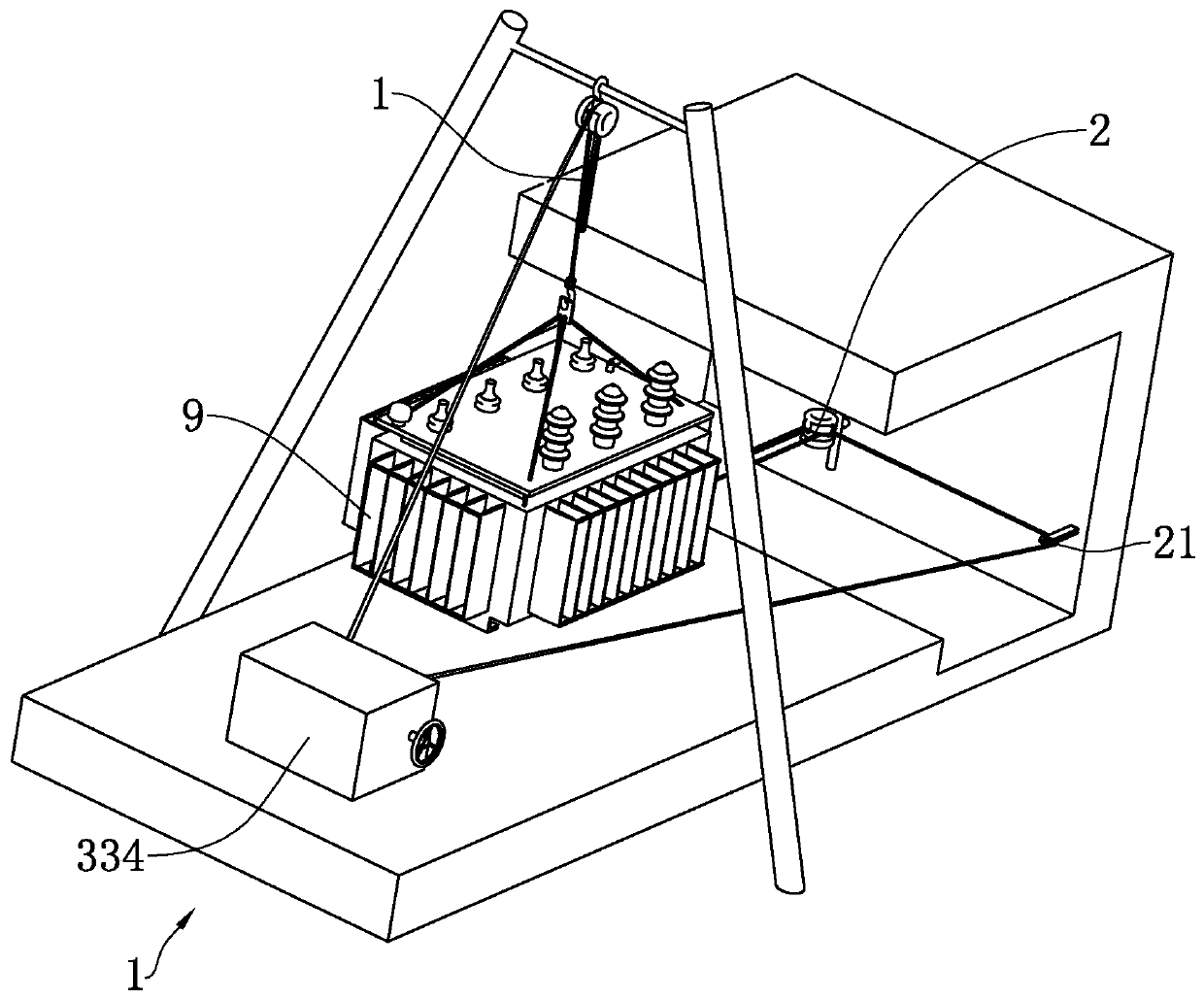

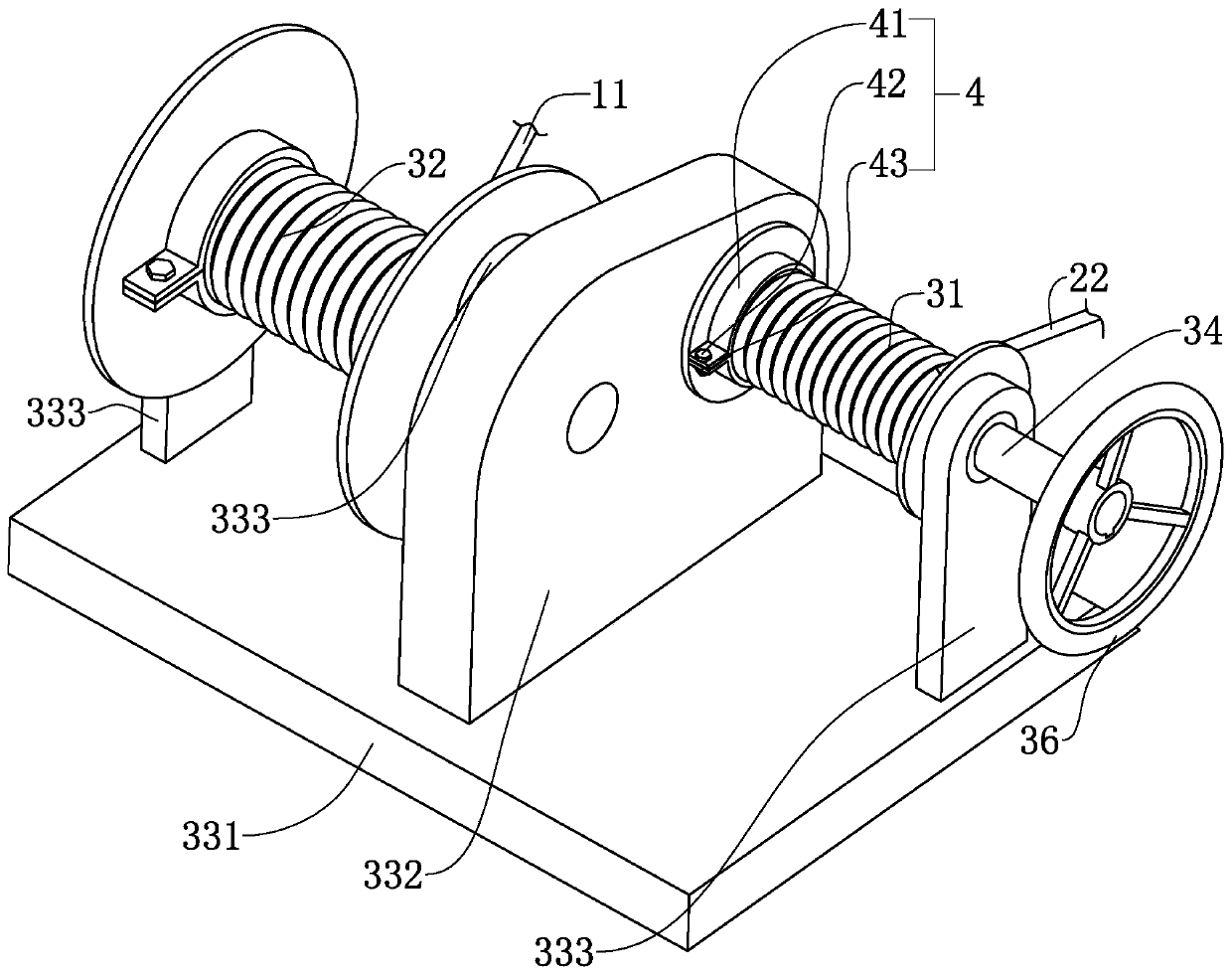

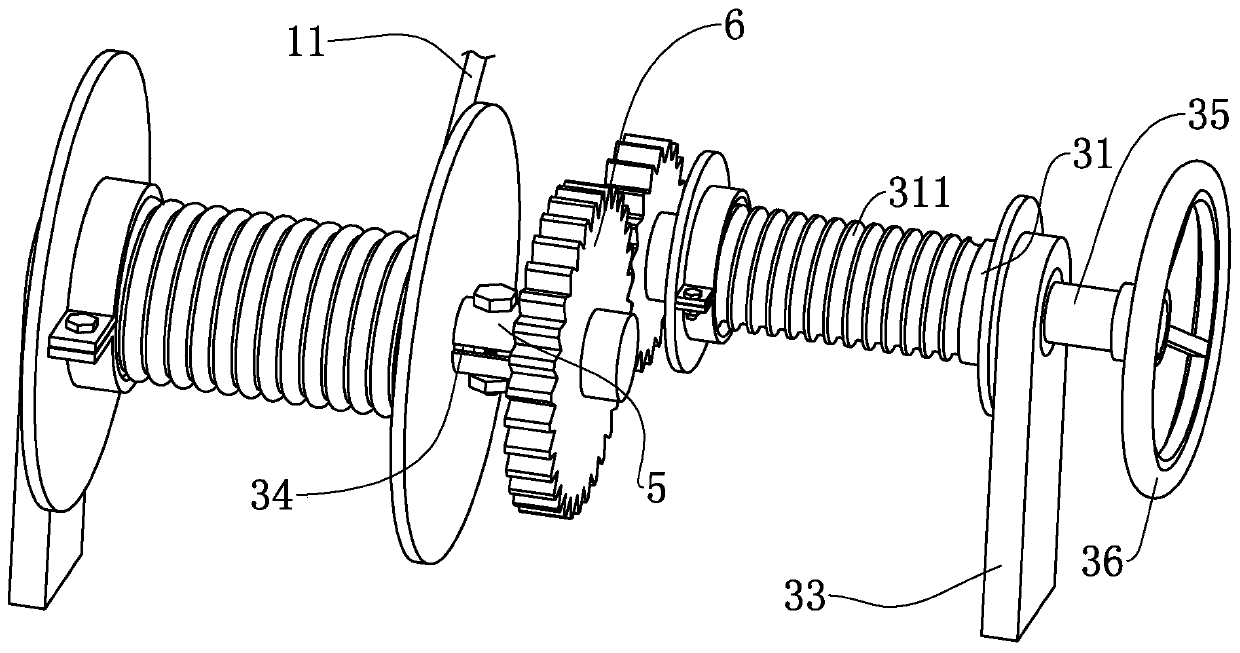

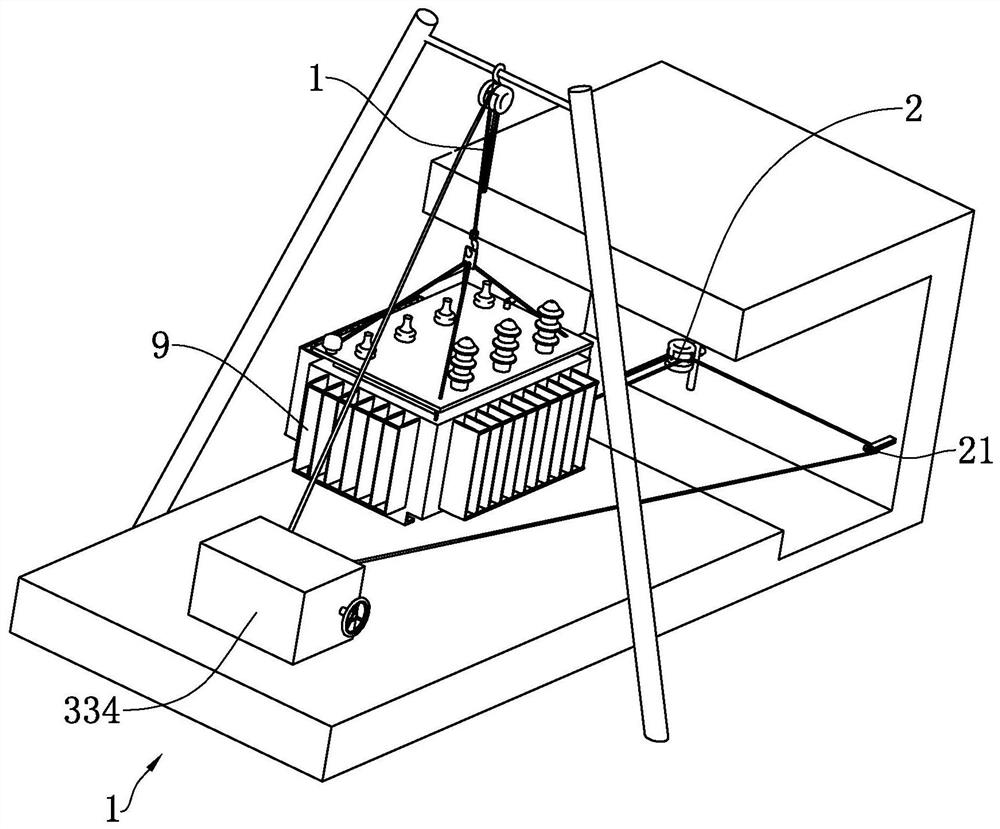

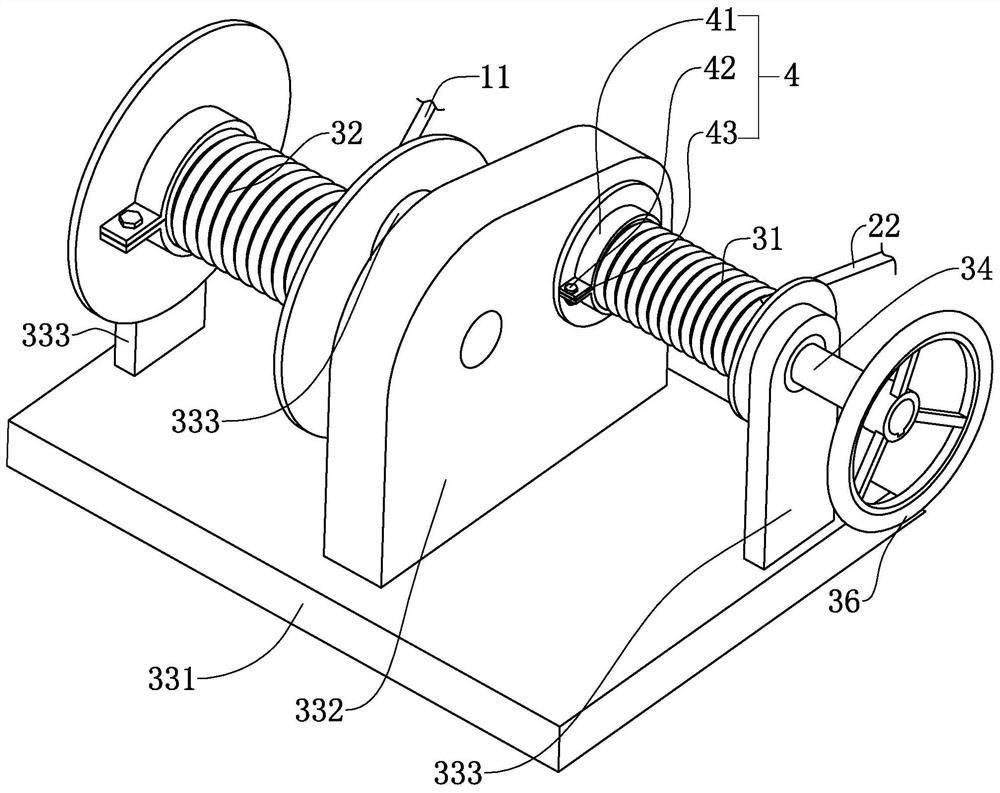

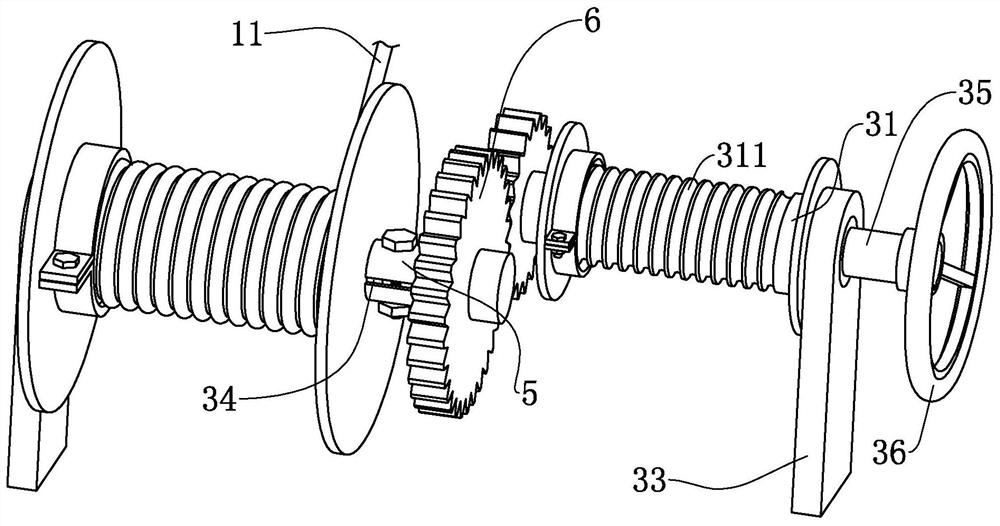

Transformer installation process and device

ActiveCN110993262AMobile stabilityEasy to operateTransformers/reacts mounting/support/suspensionInductances/transformers/magnets manufactureElectrical and Electronics engineeringMechanical engineering

The present invention discloses a transformer installation process and a transformer installation device. The device comprises a vertical chain block and a transverse chain block which are used for being connected with a transformer, the vertical chain block drives the transformer to move along a vertical direction, and the transverse chain block drives the transformer to move along a horizontal direction. An inclined mechanism is connected to the vertical chain block and the transverse chain block, comprises a vertical wheel which is detachably connected with the vertical chain block and a transverse wheel which is detachably connected with the transverse chain block and comprises the pressing mechanisms arranged on the vertical wheel and the transverse wheel respectively, and the pressing mechanisms can press and connect the vertical chain block and the vertical wheel and can press and connect the transverse chain block and the transverse wheel. The two chain blocks synchronously acton the transformer, so that the effect of stable movement of the transformer is improved.

Owner:北京中科中电电力工程管理有限公司

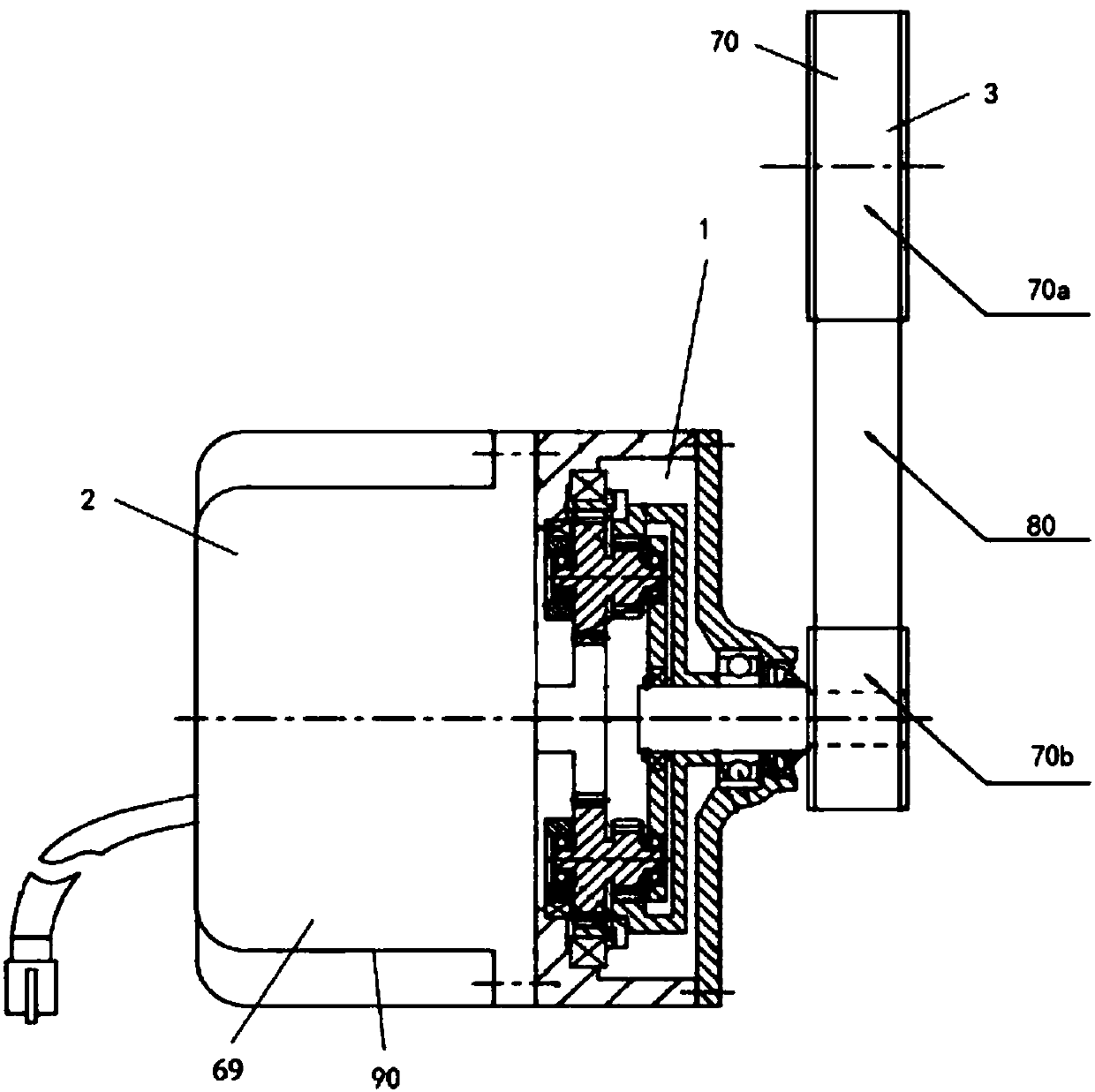

Driving mechanism of electric vehicle

ActiveCN102208844AExtended service lifeAchieve variable speedElectric machinesMechanical energy handlingFreewheelElectric machinery

The invention provides a driving mechanism of an electric vehicle. The driving mechanism comprises a driving motor and is characterized in that through a clutch the driving motor connects a transmission system which is provided with different shifts. According to the invention, a freewheel clutch is arranged between the driving motor and a trailing wheel. Through the transmission system which is provided with different shifts, power is transmitted to the trailing wheel, thus the speed change of the electric vehicle is realized. When riding the electric vehicle, the shift of the electric vehicle can be changed according to road condition to maximize the energy efficiency of the driving mechanism and guarantee the current of the driving motor in a normal scope of application. Thus the service life of the driving motor is prolonged and the mileage of the electric vehicle is increased.

Owner:CHONGQING ZONGSHEN GENERAL POWER MACHINE

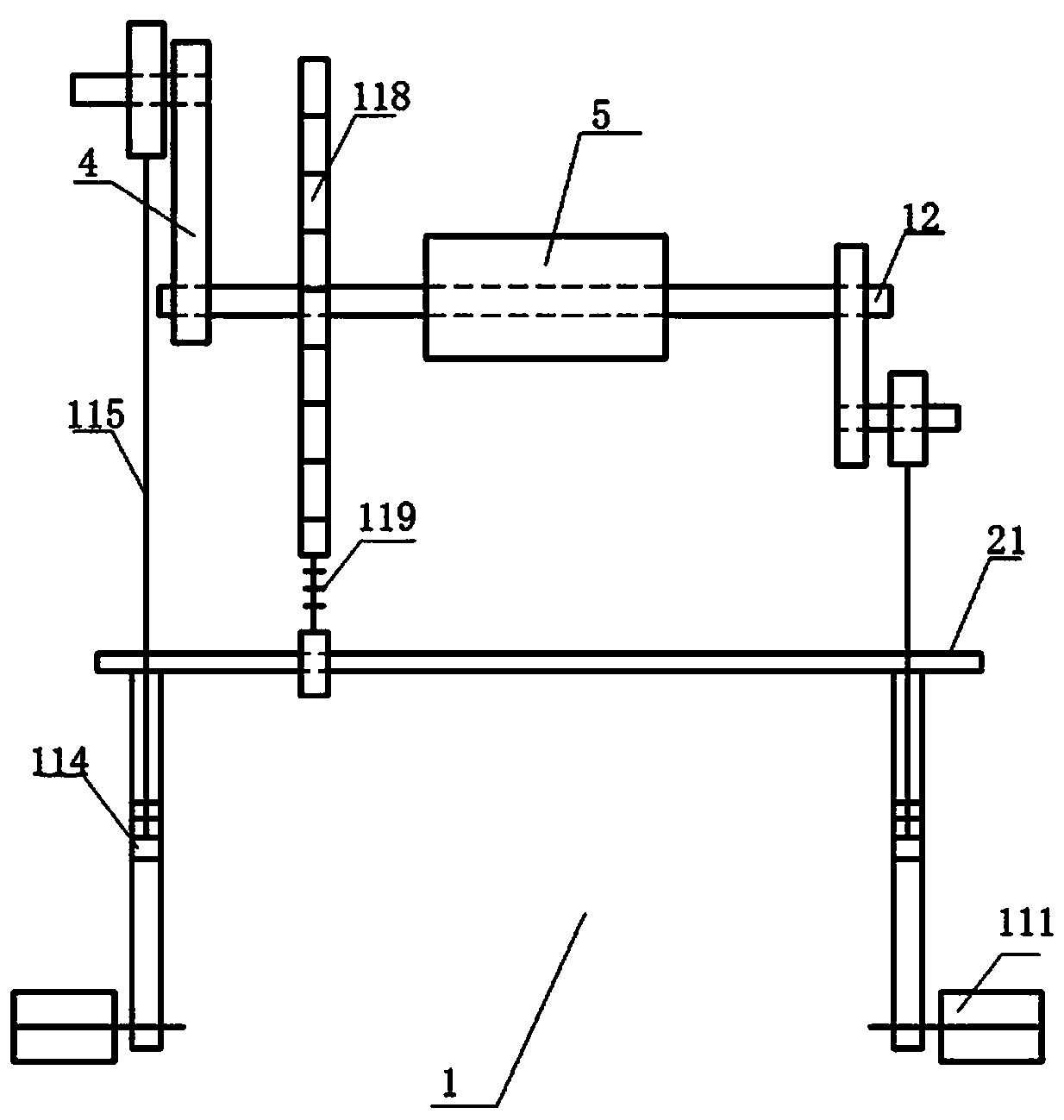

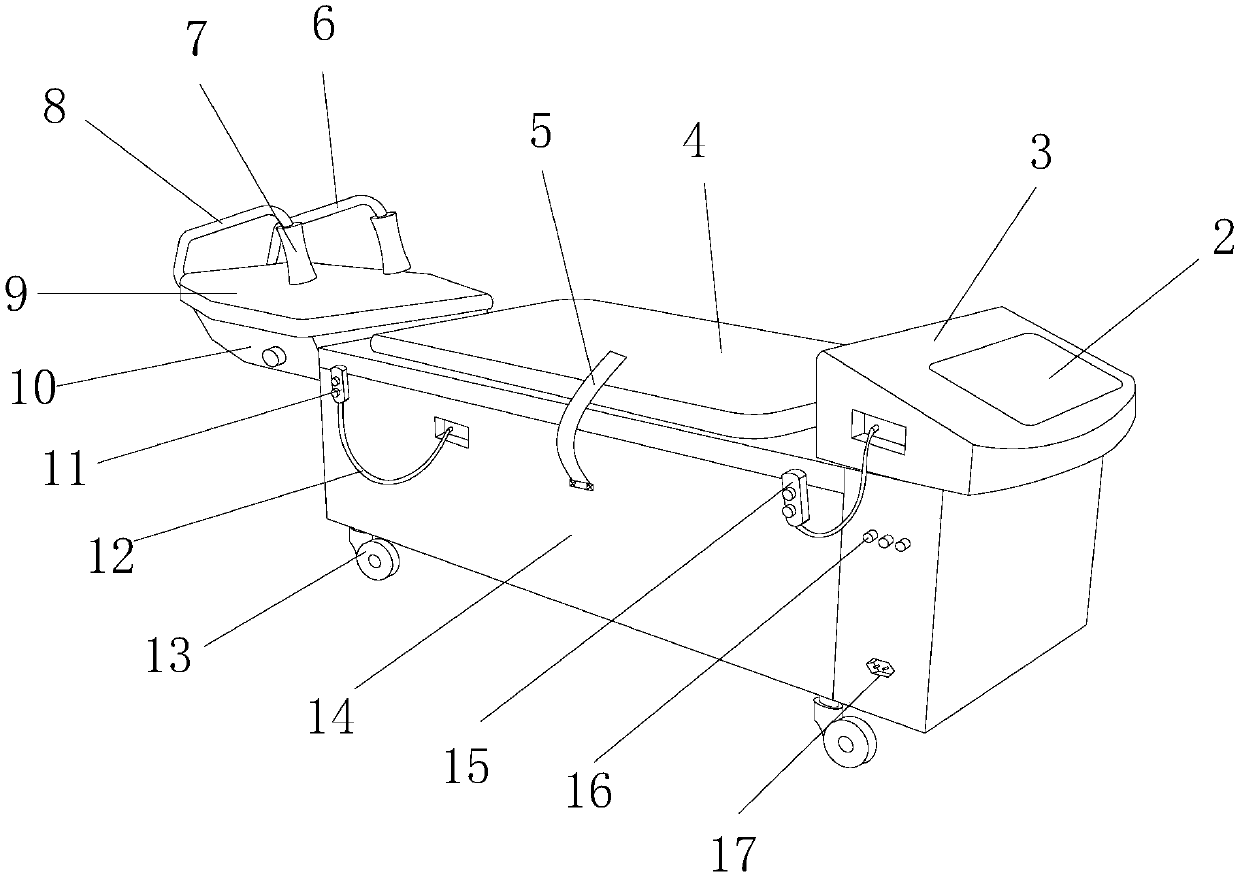

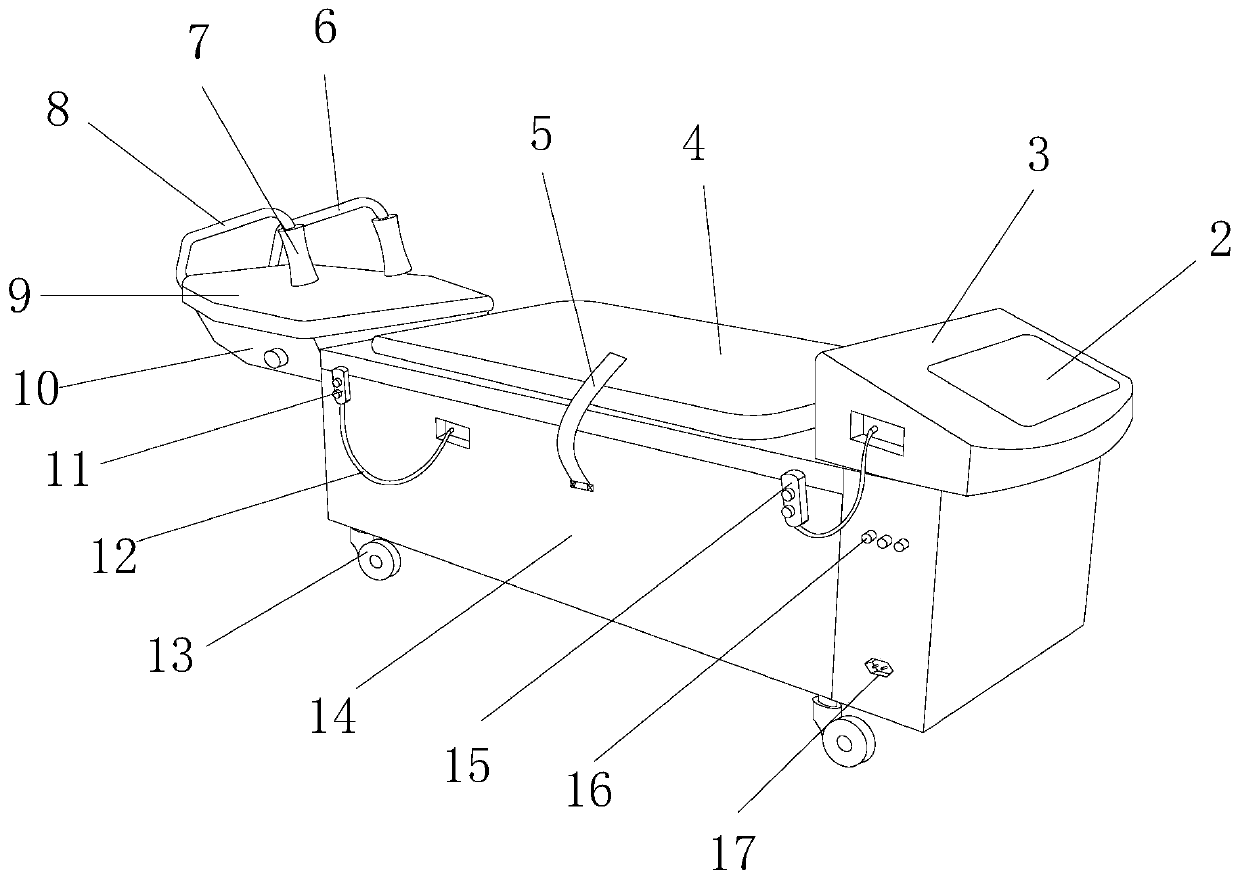

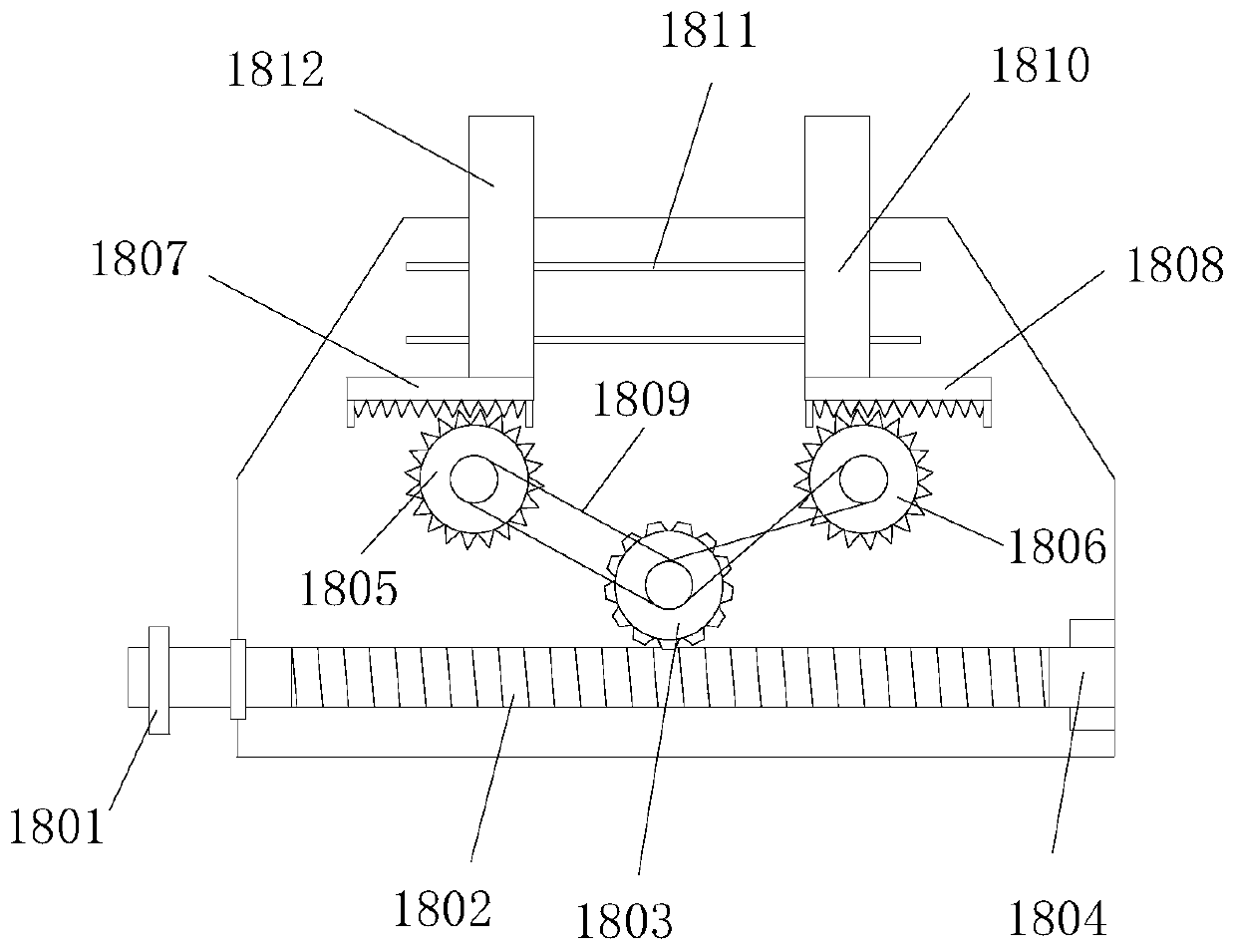

Auxiliary traction device for orthopedics

The invention discloses an auxiliary traction device for orthopedics. The auxiliary traction device for orthopedics structurally comprises a control box, an operation panel, an operation table, a mattress, a fixing belt, a right armpit rest, a sponge sleeve, a left armpit rest, a head rest, an telescopic rack, a front controller, a controller connection line, universal wheels, a bed body, a rear controller, a fuse, a power socket, an armpit rest adjustment mechanism, a transmission mechanism, and a storage battery, wherein the operation panel is arranged on the operation table, the control boxis arranged in the operation table, the control box is electrically connected with the operation panel, the mattress is arranged on the bed body, and the storage battery is electrically connected with the control box. The auxiliary traction device for orthopedics adopts a motor-driven method to assist traction, and an emergency stop mechanism is arranged between the motor and the storage battery;when a patient feels that the traction is too large, the emergency stop mechanism can operate to effectively reduce the potential danger and to protect the patient from secondary injury.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

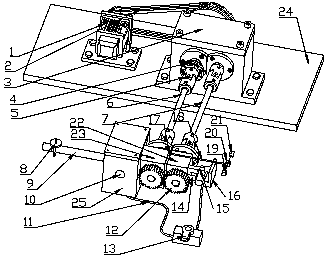

Plastic gear wear life testing machine for single support self-compensation loading system

InactiveCN109084979AAchieve variable speedAct as overload protectionMachine gearing/transmission testingInvestigating abrasion/wear resistanceSingle supportIndirect test

The invention discloses a plastic gear wear life testing machine for a single support self-compensation loading system. The machine is on the basis of an indirect test principle of a ''discontinuous phase method'', and uses an adjustable composite load loading system. A test gear pivot box is supported by a simple hinge, so as to realize the combination loading of a torque and a bending moment ina dynamic meshing simulation process of a test gear. According to the plastic gear wear life testing machine for the single support self-compensation loading system, the dynamic measurement of gear tooth wear can be completed, and the self-compensation loading function of the testing machine in a gear transmission process can be achieved.

Owner:UNIV OF JINAN

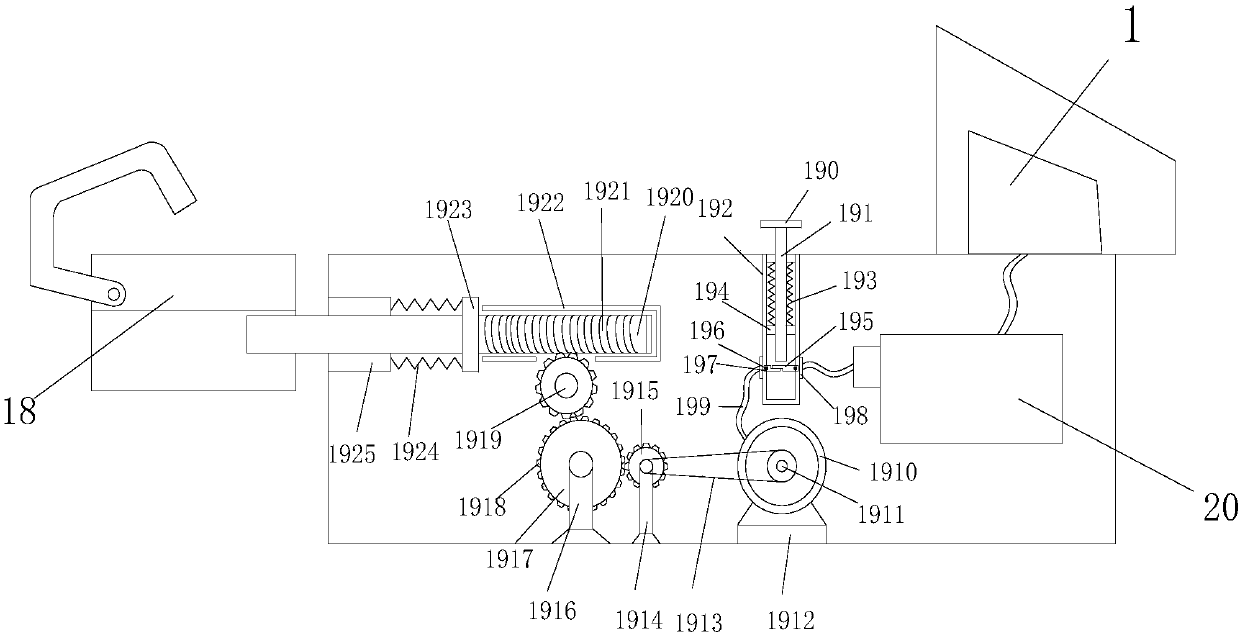

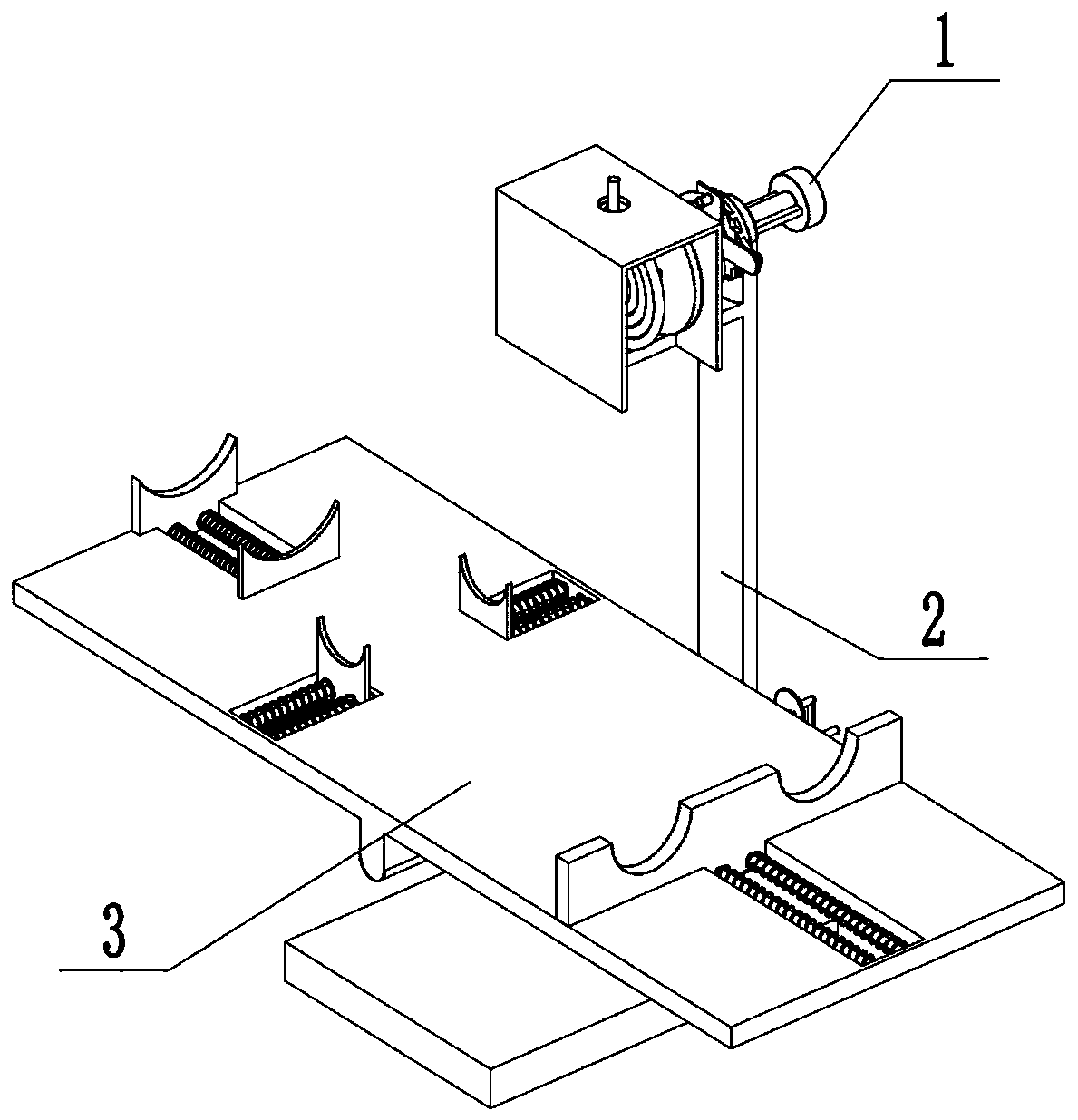

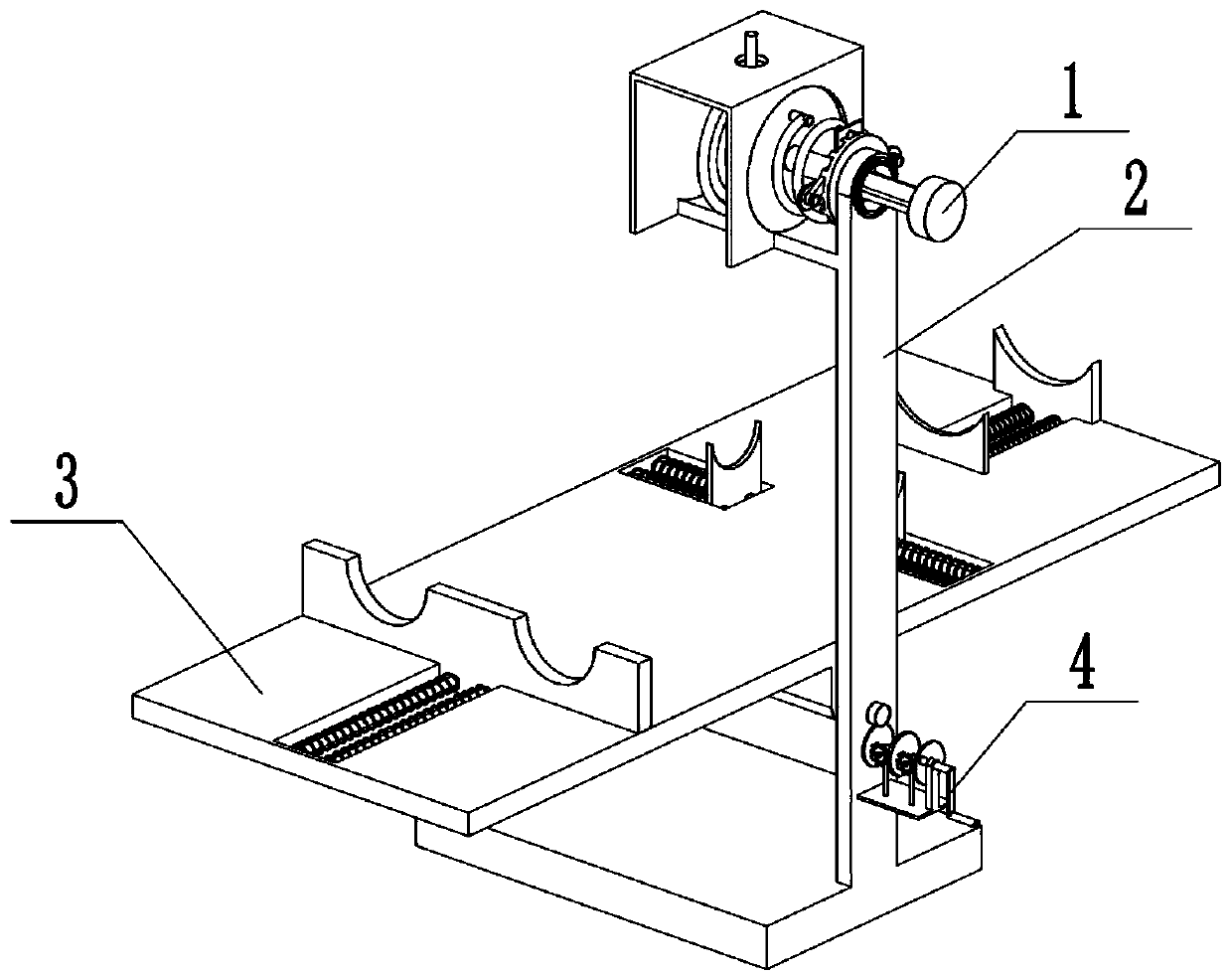

Gastric inspection device for digestive department

InactiveCN110403789AEasy to collectEasy to change collectionOperating tablesEndoscopesEngineeringScrew thread

The invention aims to provide a gastric inspection device for digestive department; a gastroscope can be automatically retracted and placed through an adjustment device, and the detection efficiency is respectively up-regulated; a patient can be placed through a lying board combined body; at the same time, the patient posture is convenient to adjust through a speed change device combined body, andthe gastroscope inspection device includes an adjustment device, a support outer frame, the lying board combined body and the speed change device combined body; a drive conical disc rotates once to drive rotation of a sliding hole, then the sliding hole is driven to rotate, the angle of the patient lying on a bottom board is convenient to change, and an image in a stomach of the patient is collected by the gastroscope conveniently; a manual rotating rod is pushed manually, and a ratchet tooth is separated from a one-way clamping groove, so that a driving disk rotates in reverse direction under driving of the torsion force of a torsion spring, and the gastroscope is rolled in reverse direction through the reverse rotation of the driving disk, so as to realize automatic recovery of the gastroscope; a manual threaded rod is adjusted manually, and the use position of a threaded sleeve is changed through the manual threaded rod.

Owner:詹玮

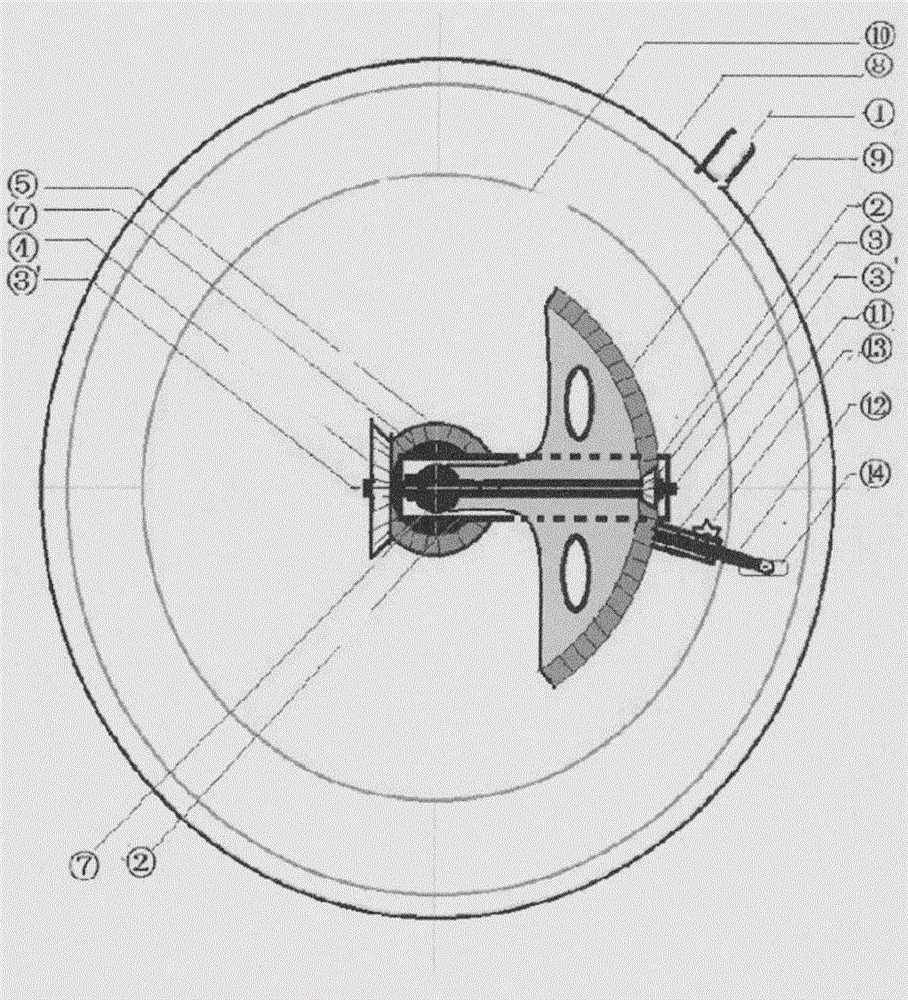

Bicycle gear transmission mechanism

InactiveCN112874688AGuaranteed linkageAchieve variable speedWheel based transmissionRider propulsionRatchetGear drive

The invention provides a bicycle gear transmission mechanism. The bicycle gear transmission mechanism comprises a double-ratchet rear wheel, pinions, fan-shaped inner gears, a rack, a fixed pulley, pedals and a rope. The two pinions are arranged on the double-ratchet rear wheel and then are respectively meshed with the fan-shaped inner gears. The fan-shaped inner gears are arranged on mandrels on two sides of the lower part of a frame. The pedals are installed on lever arms at the front ends of the fan-shaped inner gears, the length of a force arm can be changed by stepping on different positions of the pedals, and speed changing is achieved. The lever arms at the front ends of the two fan-shaped inner gears are wound around the fixed pulley installed on the rack through the rope to be connected together, and pedal linkage is guaranteed. Circumferential motion is replaced by vertical reciprocating motion during riding, work can be done by means of the gravity of a human body, the force exerting function of the human body structure is exerted to the maximum extent, unnecessary force exerting of the human body is reduced, the comfort of a rider is improved, the number of parts is small, design is reasonable, machining and maintenance are easy, transmission protection and sealing lubrication are easy, and large-scale popularization is easy.

Owner:辛永升

Electric vehicle gearbox

PendingCN110513446ARealize the purpose of step-by-step speed changePlay the role of output direction steeringToothed gearingsGearing controlTooth numberEngineering

The invention belongs to the technical field of gearboxes and discloses an electric vehicle gearbox. According to the purpose, electric vehicles and the like can better adapt to mountainous regions with large slopes. The electric vehicle gearbox comprises a gearbox shell, a variable speed gear device, an input shaft and an output shaft. The input shaft and the output shaft are fixed to the gearboxshell through a first bearing seat and a second bearing seat correspondingly. The variable gear device comprises a drive gear arranged on the input shaft in a sleeving manner, a transmission mechanism, an output mechanism and a variable speed mechanism, wherein the transmission mechanism, the output mechanism and the variable speed mechanism are arranged on one side of the drive gear. By means ofthe electric vehicle gear box, the variable speed is achieved by setting the tooth number of a gear in the variable speed mechanism; multiple variable speed assemblies are used for achieving corresponding variable speed accumulation, and the variable speed range is enlarged; and then a transmission mechanism is installed at different positions, and therefore the multistage variable speed is smoothly achieved. The electric vehicle gearbox is simple and practical in structure and capable of being widely applied to electric vehicles and other facility equipment with high-torque variable speed requirements.

Owner:陈龙

Orthopedic auxiliary traction device

The invention discloses an auxiliary traction device for orthopedics. The auxiliary traction device for orthopedics structurally comprises a control box, an operation panel, an operation table, a mattress, a fixing belt, a right armpit rest, a sponge sleeve, a left armpit rest, a head rest, an telescopic rack, a front controller, a controller connection line, universal wheels, a bed body, a rear controller, a fuse, a power socket, an armpit rest adjustment mechanism, a transmission mechanism, and a storage battery, wherein the operation panel is arranged on the operation table, the control boxis arranged in the operation table, the control box is electrically connected with the operation panel, the mattress is arranged on the bed body, and the storage battery is electrically connected with the control box. The auxiliary traction device for orthopedics adopts a motor-driven method to assist traction, and an emergency stop mechanism is arranged between the motor and the storage battery;when a patient feels that the traction is too large, the emergency stop mechanism can operate to effectively reduce the potential danger and to protect the patient from secondary injury.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Dual-drive two-gear automatic transmission

InactiveCN106286781AAchieve shiftAchieve variable speedGearboxesToothed gearingsVariatorElectrical and Electronics engineering

The invention discloses a dual-drive two-gear automatic transmission, and belongs to the technical field of electric automobiles. The dual-drive two-gear automatic transmission is characterized by comprising a speed reduction gear set, an input gear of the speed reduction gear set is connected with two power input mechanisms at the same time, and the two power input mechanisms drive the input gear to transmit at the different speed ratios. According to the dual-drive two-gear automatic transmission, a speed reduction mechanism and the two power input mechanisms engaged with the speed reduction mechanism at the same time are arranged, through switching of the power input mechanism, an output gear of the speed reduction mechanism transmits at the different speed ratios, gear shifting and speed change of an electric automobile during driving can be achieved, the phenomenon that in the prior art, the gear shifting process can be completed through gear switching is avoided, the gear shifting process is smoother, and due to the fact that the structure is quite simple, the beneficial effect of high transmission efficiency is achieved.

Owner:吕宏

Driving mechanism of electric vehicle

ActiveCN102208844BExtended service lifeAchieve variable speedElectric machinesMechanical energy handlingFreewheelElectric machinery

Owner:CHONGQING ZONGSHEN GENERAL POWER MACHINE

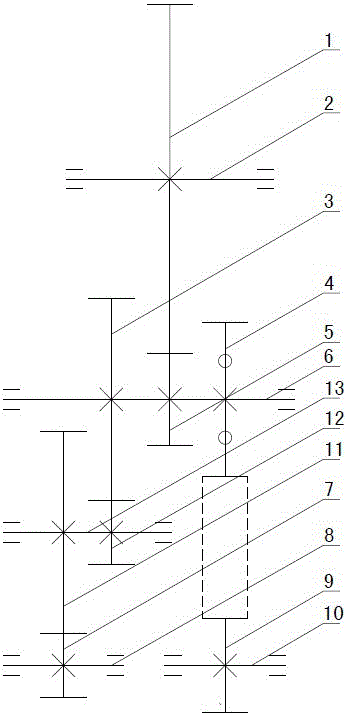

Single-motor multi-mode hybrid power system and automobile

ActiveCN111409444AReduced work modeSimple structureHybrid vehiclesGas pressure propulsion mountingElectric machineryControl theory

The invention discloses a single-motor multi-mode hybrid power system and an automobile. The system comprises an engine, a motor, a first transmission system, a second transmission system and a gear shifting executing mechanism, wherein one end of the motor power input shaft is connected with the motor rotor, and the other end is connected with the large sun gear connecting shaft; the large sun gear connecting shaft is connected with a large sun gear; an engine power input shaft is connected with the driving end of the first clutch and the driven end of the second clutch into a whole and coaxially rotates; one end of the small sun gear connecting shaft is connected with the driven end of the first clutch, the other end of the small sun gear connecting shaft is connected with the small sungear, and the second transmission system combines power of the engine and power of the motor so as to achieve variable speed output of different driving modes and various gears. The system has the advantages of being simple in structure, easy to repair, fast in response to speed change and capable of improving transmission efficiency.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

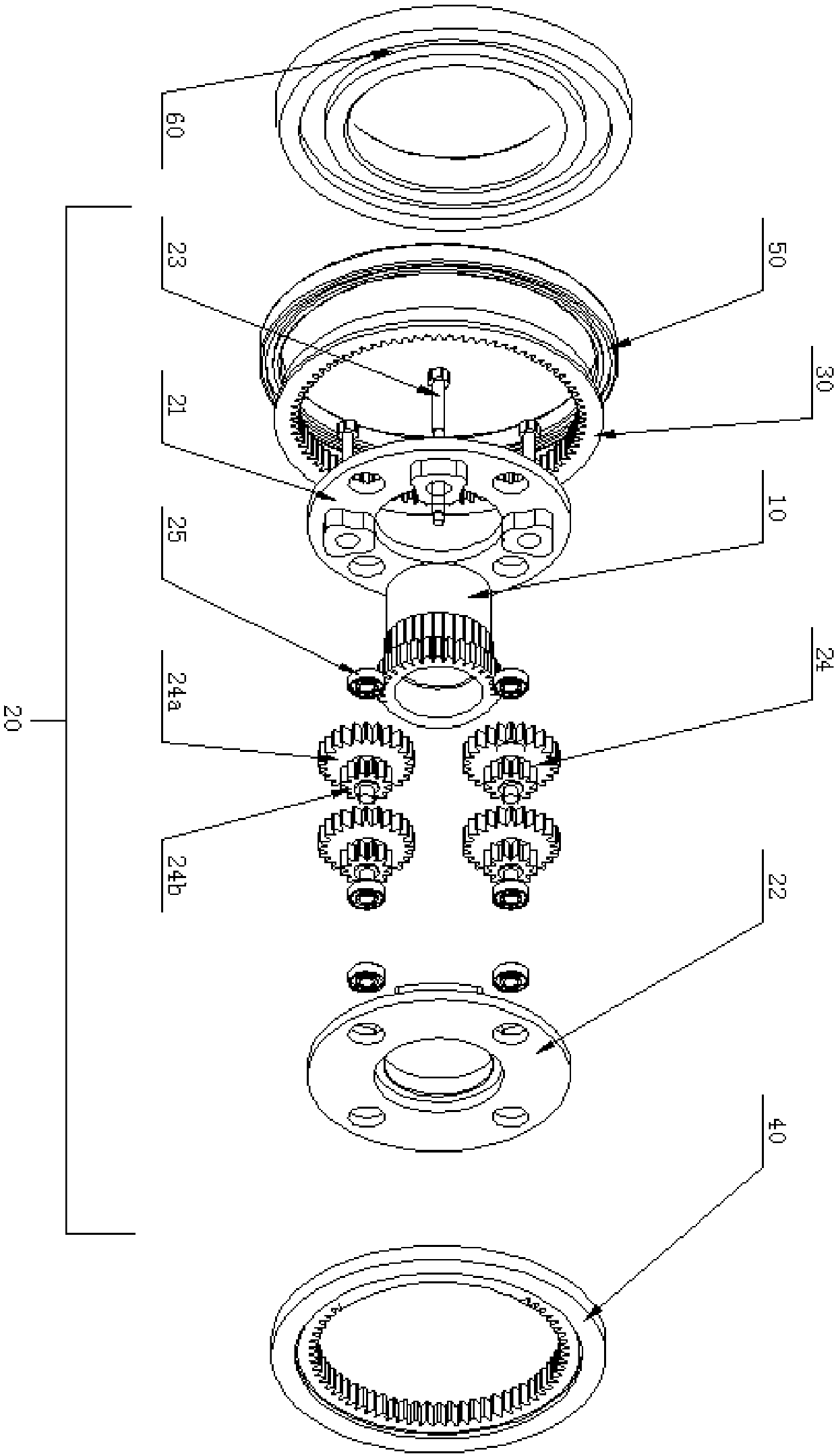

Motor device and electric vehicle provided with same

PendingCN109995185AAchieve variable speedAchieve long battery lifeElectric machinesMechanical energy handlingElectric machineGear wheel

The invention relates to a motor device used for an electric vehicle. The motor device comprises a driving device, a transmission device and a synchronization device; the driving device is used for providing power for the electric vehicle; and the transmission device comprises a sun gear, a planet gear assembly, a first gear ring and a second gear ring, the planet gear assembly comprises a first planet carrier cover plate, a second planet carrier cover plate, at least two planet gear shafts fixedly connected with the first planet carrier cover plate and the second planet carrier cover plate aswell as at least two planet gears rotatably sheathed on the at least two planet gear shafts and uniformly distributed at the periphery of the sun gear, wherein each of the at least two planet gears comprises a large planet gear and a small planet gear which can coaxially rotate and are fixedly connected together, and each large planet gear is meshed with the sun gear; the first gear ring is provided with internal teeth and is meshed with the large planet gears of the at least two planet gears; and the second gear ring is provided with internal teeth and is meshed with the small planet gears of the at least two planet gears.

Owner:M& SE DRIVING SYST CO LTD

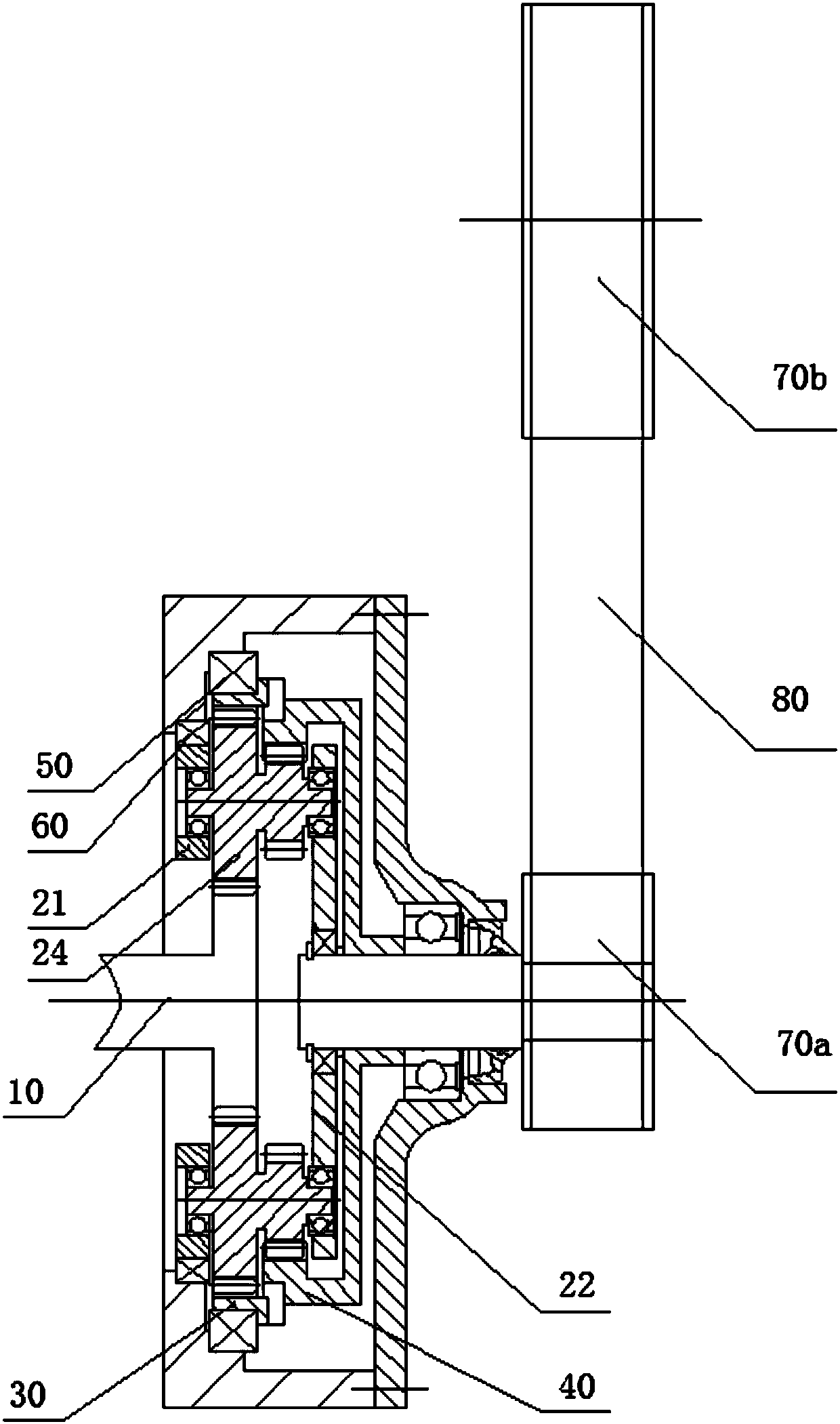

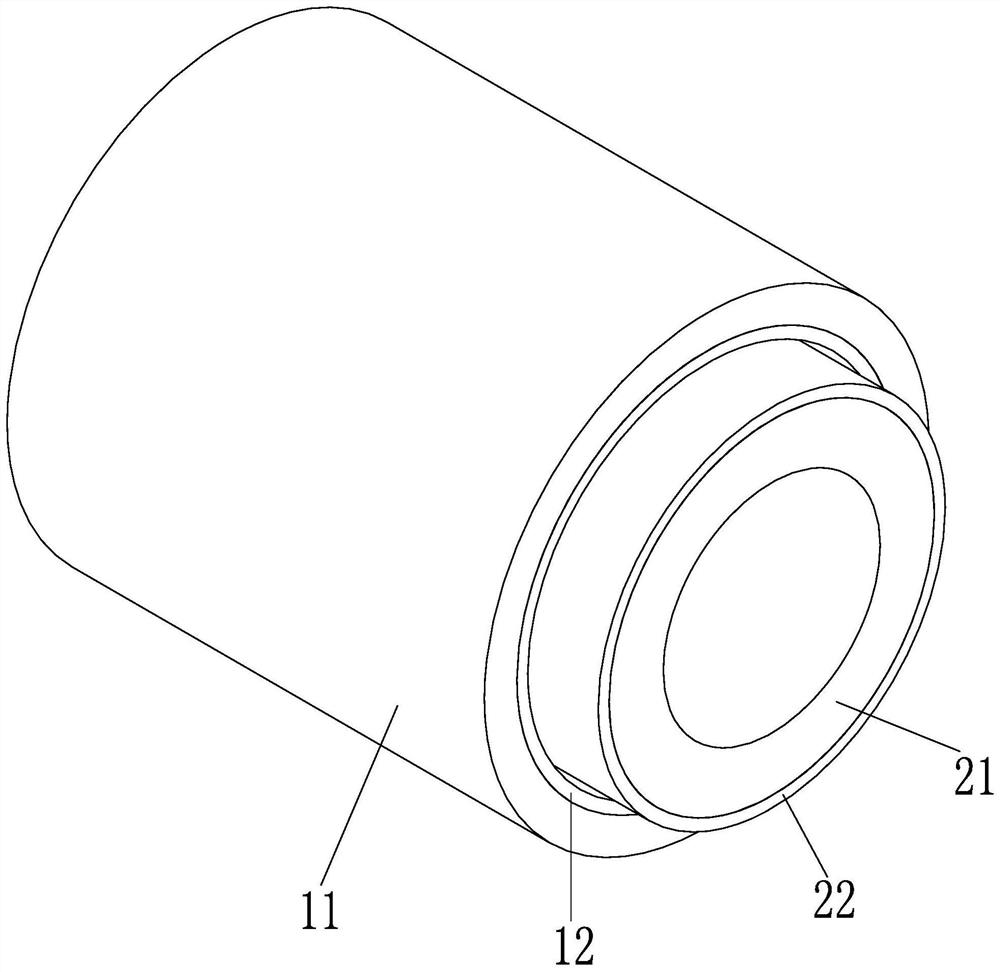

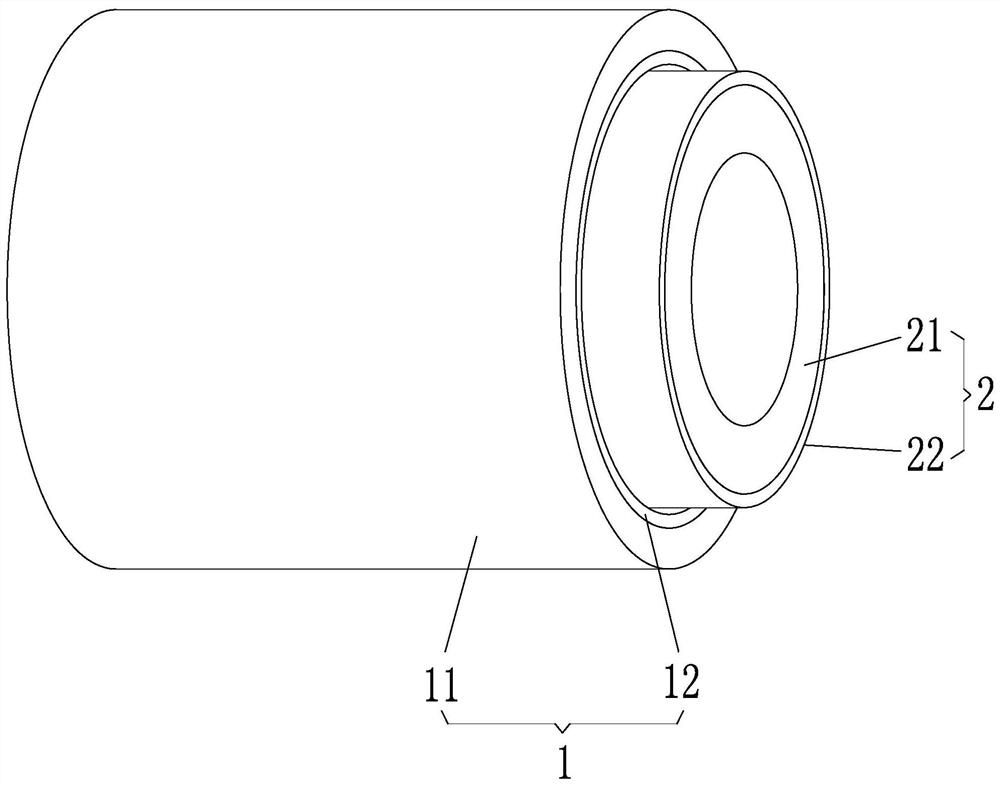

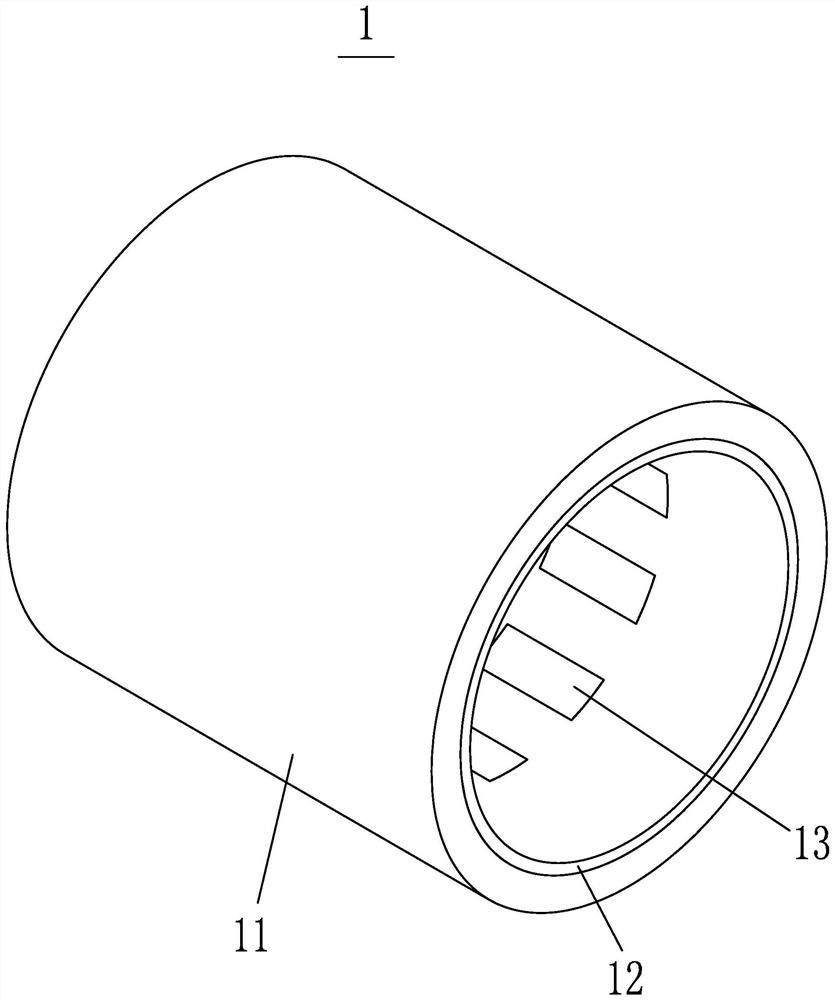

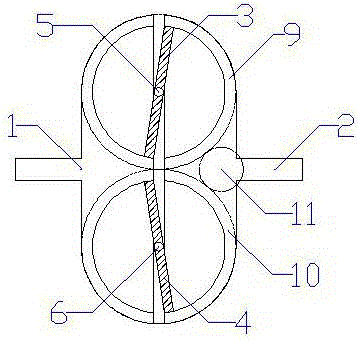

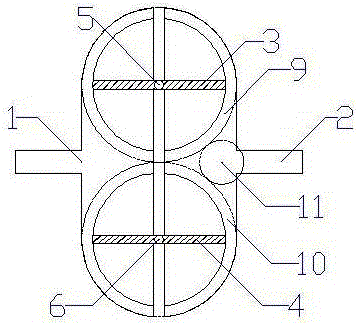

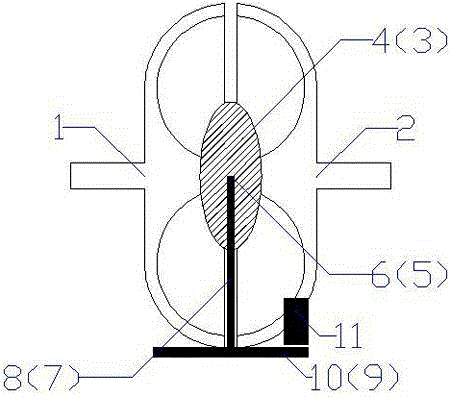

A cylindrical hybrid magnetic coupling

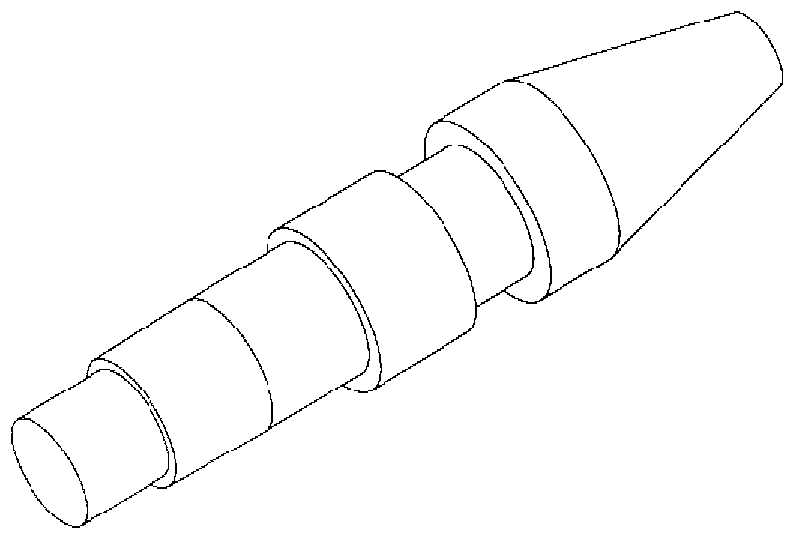

ActiveCN112821716BRealize asynchronous to synchronous effectChange magnetic momentAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesCouplingMagnet

The invention discloses a cylindrical hybrid magnetic coupling. The shaft coupling includes a cylindrical structure 1 and a cylindrical structure 2. The cylindrical structure 1 includes an outer cylinder, a mounting cylinder 1 and a plurality of magnets 1, and the cylindrical structure 2 includes an inner cylinder, a mounting cylinder 2 and a plurality of magnets 2. The installation cylinder one is located in the outer cylinder and is connected with the outer cylinder. A plurality of magnets are arranged around the central axis of the installation cylinder one and installed on the installation cylinder one. The second installation cylinder is located outside the inner cylinder and connected with the inner cylinder. A plurality of second magnets are arranged around the central axis of the second installation cylinder and installed on the second installation cylinder. There are two working conditions in the present invention. When the first magnet and the second magnet partially overlap in the radial space, the first working condition of the present invention is similar to the permanent magnet synchronous coupling; when the first magnet and the second magnet do not overlap in the radial space, this The second working condition of the invention is similar to the permanent magnet eddy current coupling; the present invention can change the magnetic moment by changing the axial relative position of the outer cylinder and the inner cylinder, so as to realize the stable conversion of the working condition during operation.

Owner:HEFEI UNIV OF TECH

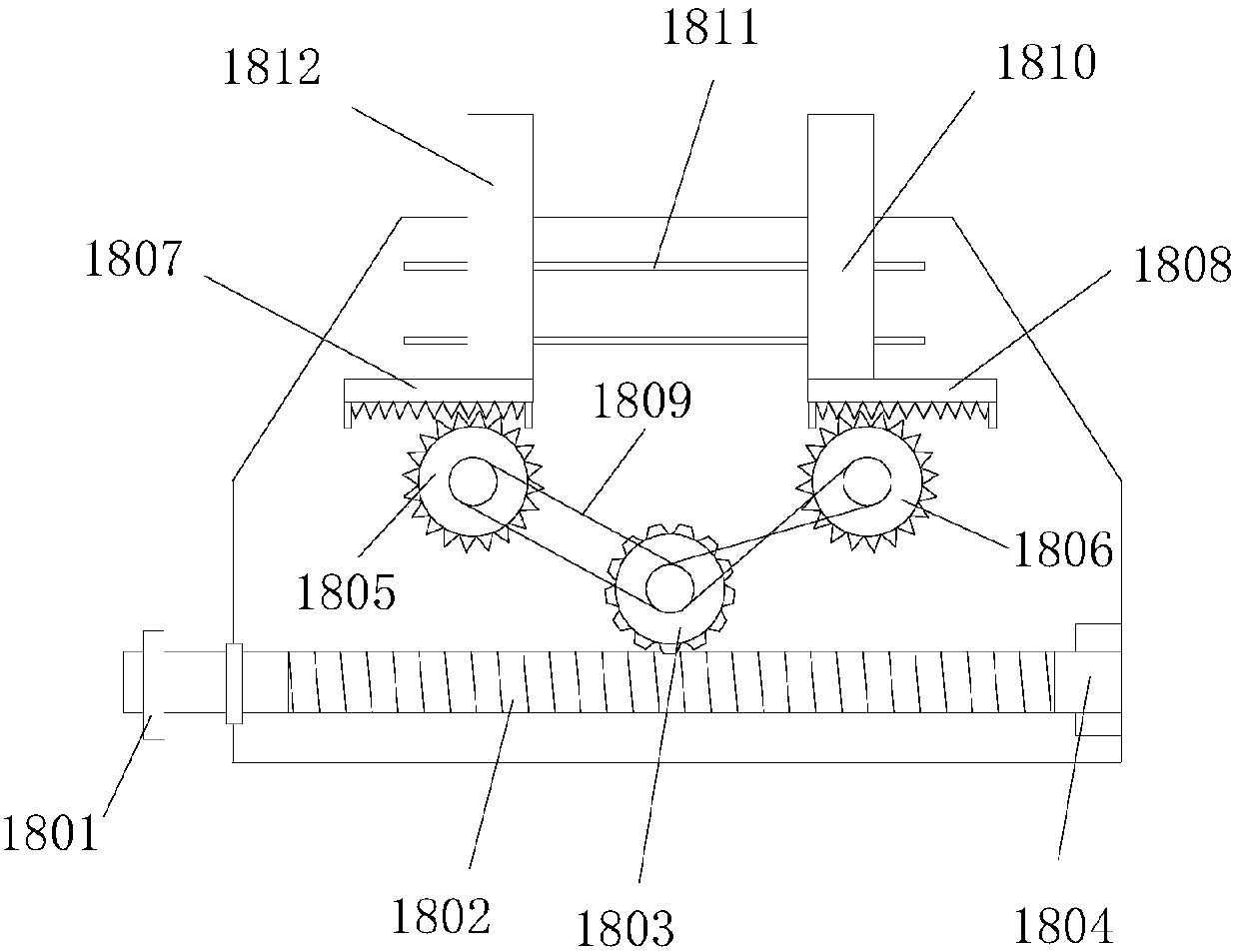

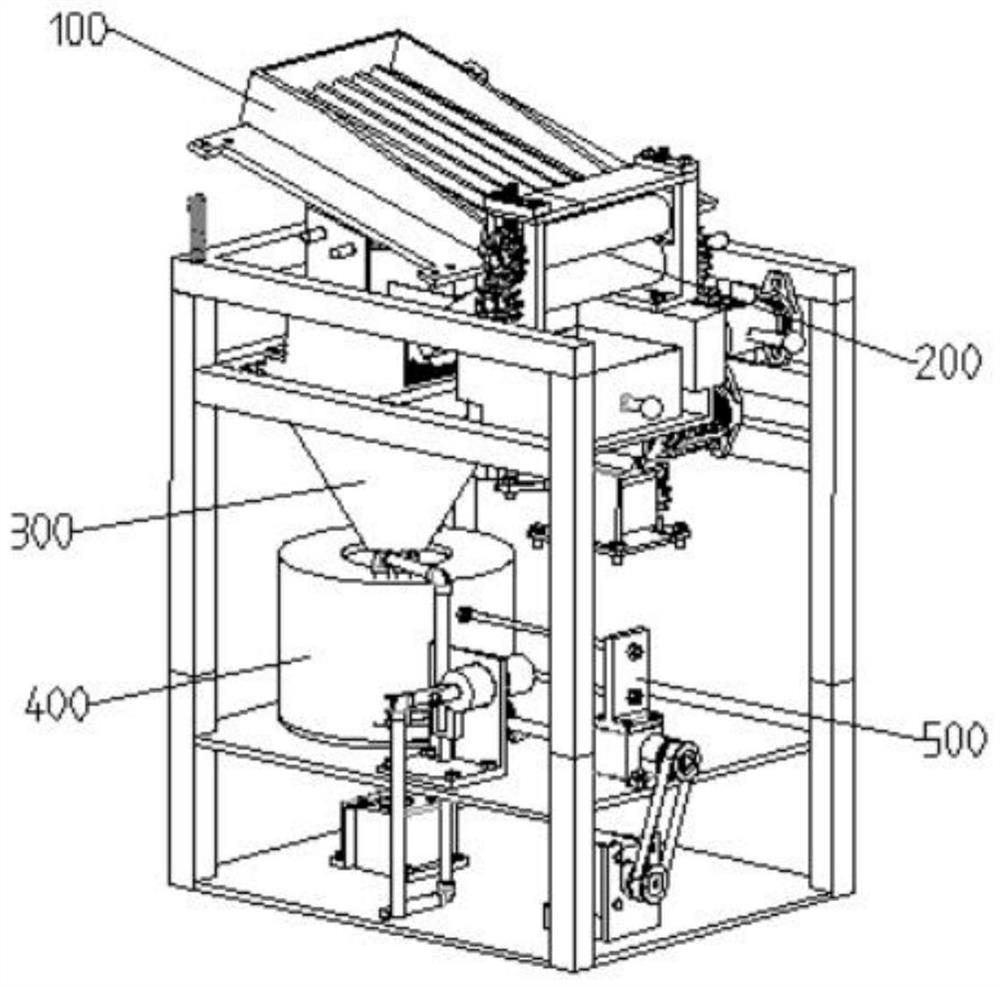

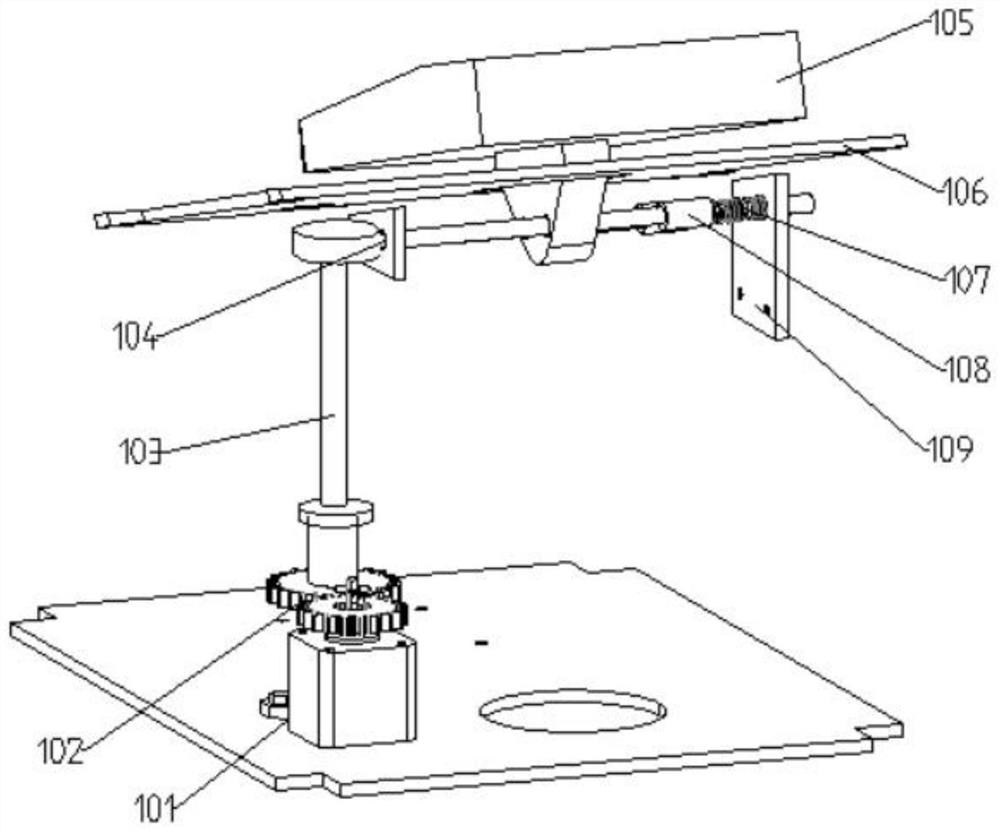

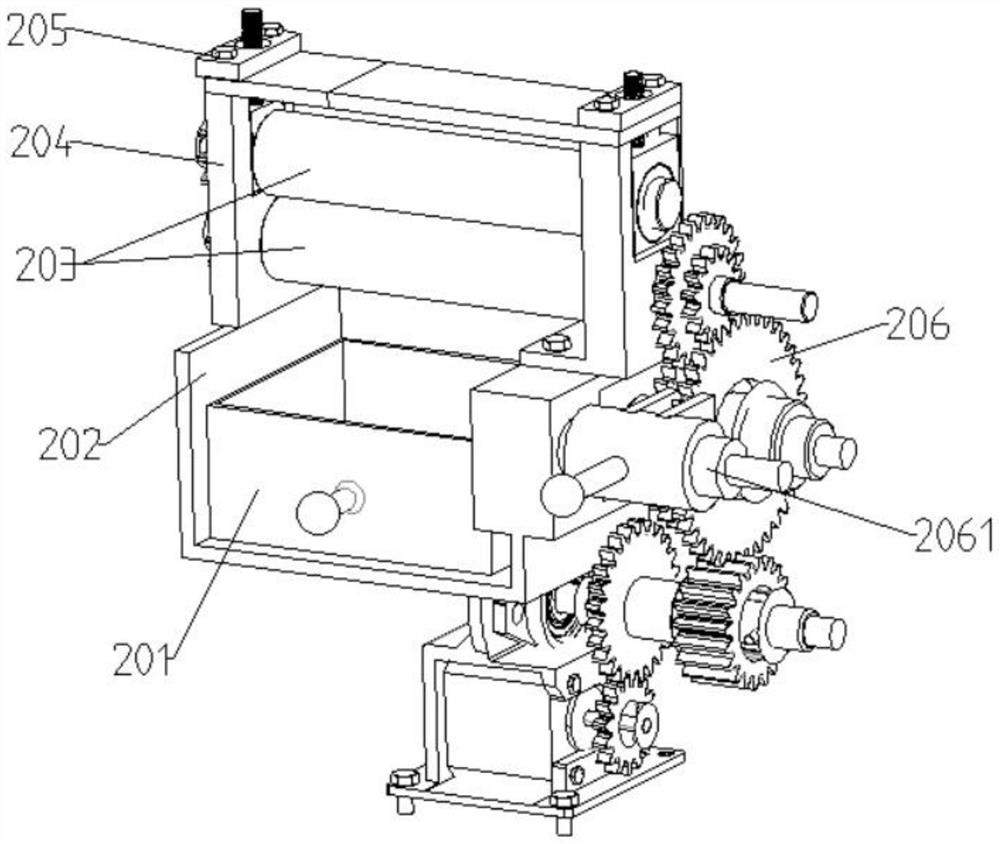

Bean peeling and washing all-in-one machine

ActiveCN114304685AReduce the burden onSmooth and precise movementSievingScreeningGear driveGear wheel

The invention relates to the technical field of bean processing machinery, in particular to a bean peeling and washing all-in-one machine. The bean husking machine specifically comprises a shaking mechanism, a husking mechanism, a sorting mechanism, a cleaning mechanism and a push rod mechanism, the shaking mechanism is used for uniformly feeding beans to be husked into the husking mechanism, the husking mechanism husks the beans through relative movement of rollers and feeds the beans into the sorting mechanism, the sorting mechanism separates the husked beans from other impurities and then feeds the beans into the cleaning mechanism, and the push rod mechanism is used for pushing the beans into the cleaning mechanism. The cleaning mechanism is used for cleaning the surfaces of the beans, and the push rod mechanism pushes the cleaned beans out for standby application. A gear transmission structure is adopted, the motor drives the gear, the gear moves stably and accurately, and speed change can be achieved through left-right moving and meshing of the gear; the size is small, cleaning is convenient, the cleaning mechanism and the husking mechanism can be detached, and use in a family kitchen is facilitated; the impeller is driven by the motor, so that the water flow speed can be adjusted, the cleaning degree of beans can be automatically selected, the beans are peeled and washed integrally, and time and labor are saved.

Owner:浙江机电职业技术学院

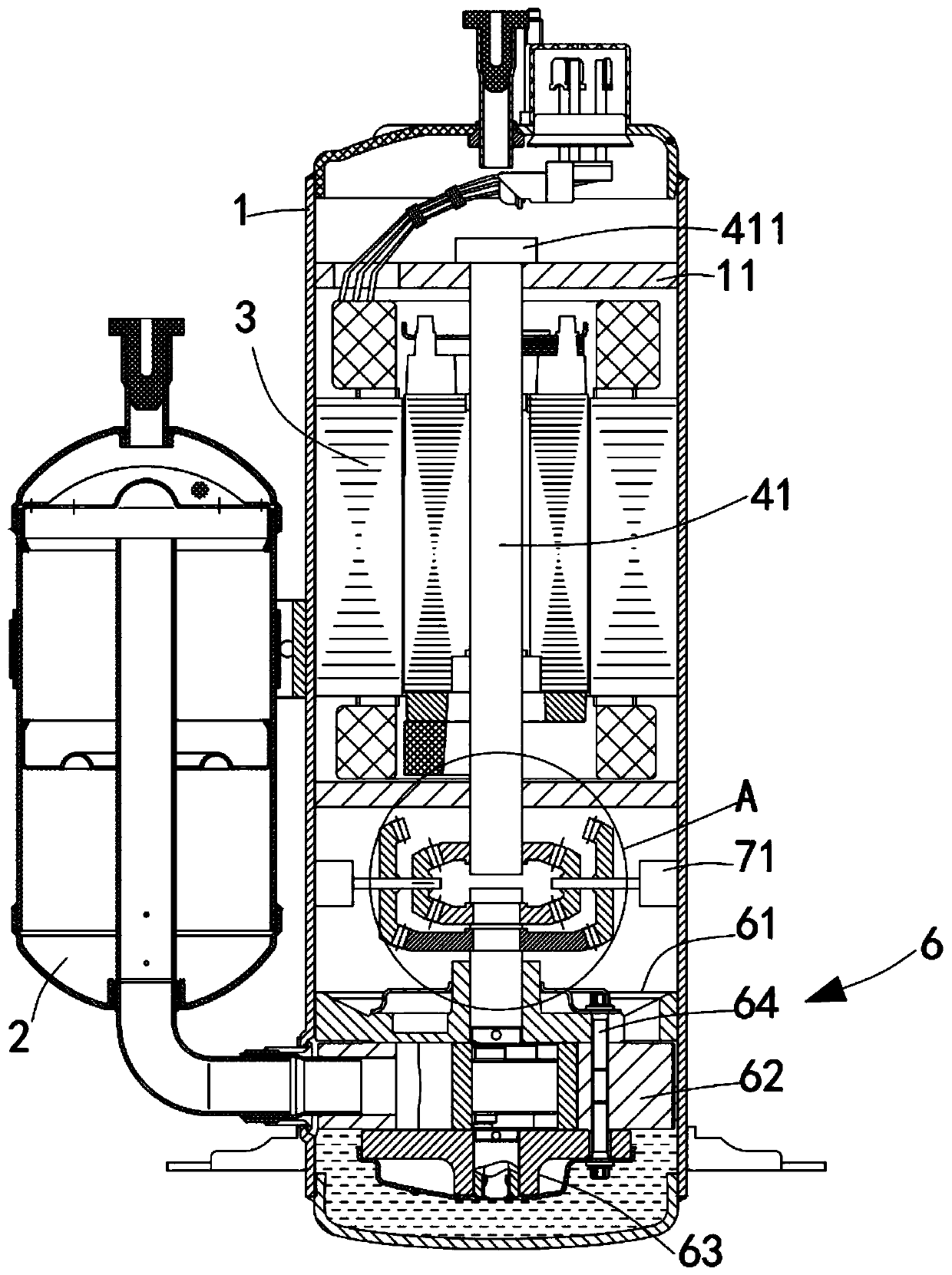

Variable-speed compressor and air conditioner

PendingCN110701051AReduce power consumptionLow costMechanical energy handlingRotary/oscillating piston pump componentsPhysicsElectric machinery

The invention relates to the technical field of compressors, in particular to a variable-speed compressor. The variable-speed compressor comprises a shell, a pump body assembly arranged below the motor, a liquid storage tank communicating with the shell, a first transmission mechanism used for transmitting motor power, and a second transmission mechanism correspondingly arranged with the first transmission mechanism in a transmission mode; and the first transmission mechanism and the second transmission mechanism are in variable transmission through at least one third transmission mechanism arranged on the inner wall of the shell. According to the variable-speed compressor and the air conditioner, two driven gears with different tooth numbers are arranged in the second transmission mechanism, meanwhile, locking assemblies are arranged in the driven shafts, high-low pressure cold medium is sprayed inside the locking assemblies through injection pipes, locking or unlocking of the two driven gears can be flexibly achieved, one of the driven gears is selected to be connected with the third transmission mechanism for transmission, the speed change of the compressor is achieved, then thepower consumption of the compressor is reduced, the cost is low, and the volume fraction and the mechanical efficiency are high.

Owner:ZHUHAI LANDA COMPRESSOR +1

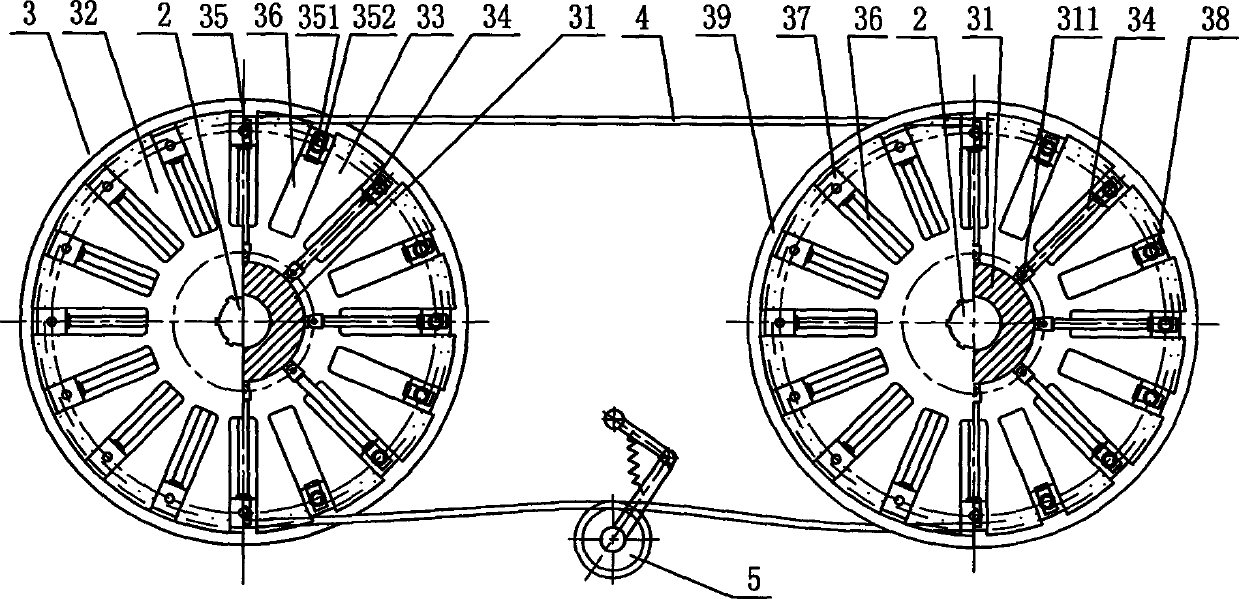

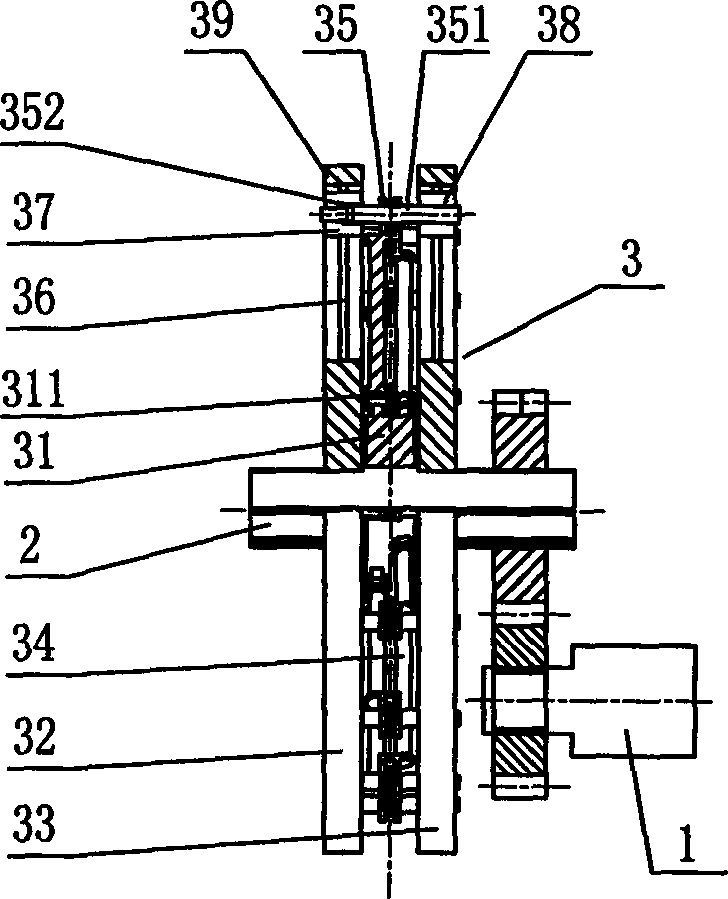

Variable pitch radius based star chain transmission stepless speed change device

InactiveCN102494094BLarge torque transmissionNo precision requiredGearingLow speedAgricultural engineering

The invention provides a variable pitch radius based star chain transmission stepless speed change device. The device is characterized in that: a star sprocket device on a transmission main shaft is driven by adopting a motor, and forms a sprocket transmission pair by combining with a bush roller chain; the star sprocket device comprises a control wheel arranged on the transmission main shaft, and left and right auxiliary wheels which are arranged on two sides of the control wheel respectively; a control wheel stator and a control wheel rotor which are connected with the transmission main shaft are arranged on the inner diameter of the control wheel body; two rows of staggered supports are uniformly distributed on the circumference of the outer profile of the control wheel, and are connected with synchronizers on the left and right auxiliary wheels through connecting rods. According to the variable pitch based star chain transmission stepless speed change device, the problems that a conventional traditional friction type stepless gearbox can not complete power transfer without friction, a high-power stepless gearbox can not realize high push power adjustment without a hydraulic system, and a silent chain transmission stepless gearbox system has higher price and the like can be solved. The variable pitch radius based star chain transmission stepless speed change device is suitable for various heavy construction equipment under heavy-load low-speed conditions, such as middle-high class cars, machine tools, hoisting machinery, heavy-load vehicles, lorries, elevators, transmission machinery.

Owner:HUNAN UNIV OF SCI & TECH

Transformer installation process and equipment

ActiveCN110993262BEasy to moveEasy to operateTransformers/reacts mounting/support/suspensionInductances/transformers/magnets manufactureTransformerControl theory

The present invention discloses a transformer installation process and a transformer installation device. The device comprises a vertical chain block and a transverse chain block which are used for being connected with a transformer, the vertical chain block drives the transformer to move along a vertical direction, and the transverse chain block drives the transformer to move along a horizontal direction. An inclined mechanism is connected to the vertical chain block and the transverse chain block, comprises a vertical wheel which is detachably connected with the vertical chain block and a transverse wheel which is detachably connected with the transverse chain block and comprises the pressing mechanisms arranged on the vertical wheel and the transverse wheel respectively, and the pressing mechanisms can press and connect the vertical chain block and the vertical wheel and can press and connect the transverse chain block and the transverse wheel. The two chain blocks synchronously acton the transformer, so that the effect of stable movement of the transformer is improved.

Owner:北京中科中电电力工程管理有限公司

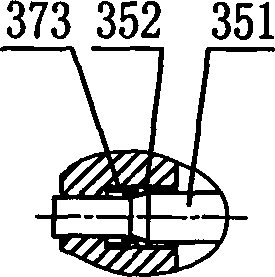

Multi-gear-position transmission

The invention provides a multi-gear-position transmission. The multi-gear-position transmission comprises a left gear and a right gear. Circular ring grooves are formed in a left gear body and circular ring grooves are formed in a right gear body. The left gear body and the right gear body together define circular ring cavities in an enclosing mode. Disc-shaped connecting bodies are put in the circular ring cavities. Teeth arranged at intervals are formed at the outer edges of the disc-shaped connecting bodies. Multiple teeth rings are formed in the surfaces of the circular ring grooves of the left gear body. Multiple teeth rings are formed in the surfaces of the circular ring grooves of the right gear body. The disc-shaped connecting bodies are engaged with part of teeth in one teeth ring on the left gear body and part of teeth in one teeth ring on the right gear body. Rotary shafts are disposed in the centers of the disc-shaped connecting bodies. The whole circular cross sections, passing through the center points of the disc-shaped connecting bodies, of the circular ring cavities are first planes, and the rotary shafts are located on the first planes. The left gear rotates to drive the disc-shaped connecting bodies to rotate around the rotary shafts, and the disc-shaped connecting bodies drive the right gear to rotate. The multi-gear-position transmission has the advantage that multiple gear positions are easy to arrange.

Owner:姜叶彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com