Fragile hollow micro-sphere polishing machine and polishing method

A technology of hollow microspheres and polishing machines, which is applied in the field of polishing, and can solve the problems of processing polishing machines, inability to polish, poor mechanical strength of hollow microspheres, etc., and achieve the effect of high polishing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

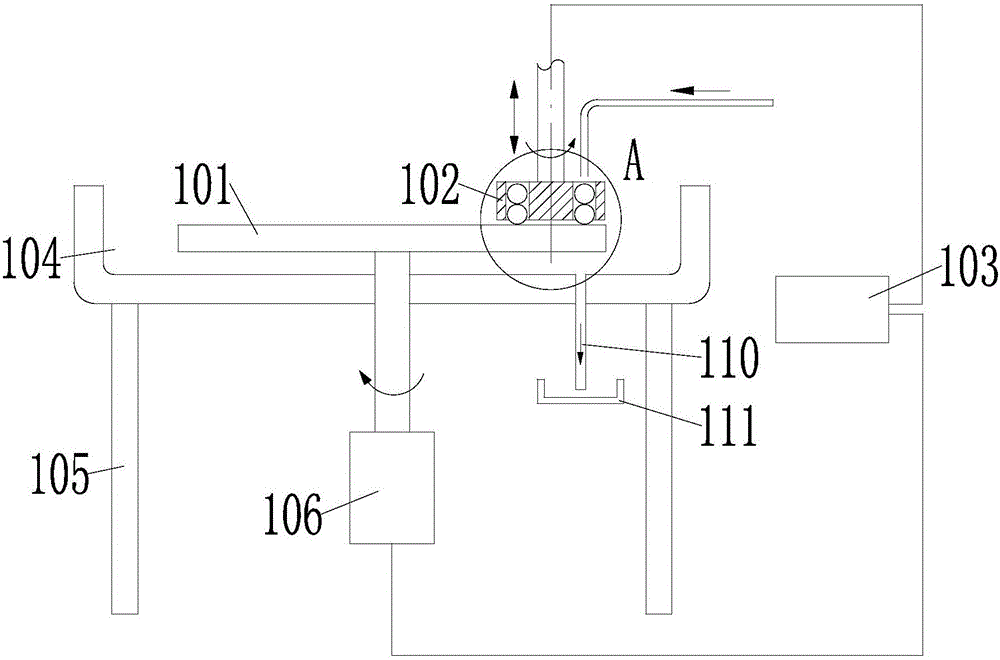

[0049] In the prior art, there is no polishing machine specially for fragile hollow microspheres with poor mechanical strength, and the common disc polishing machine and drum polishing machine for polishing microspheres are not suitable for fragile hollow microspheres.

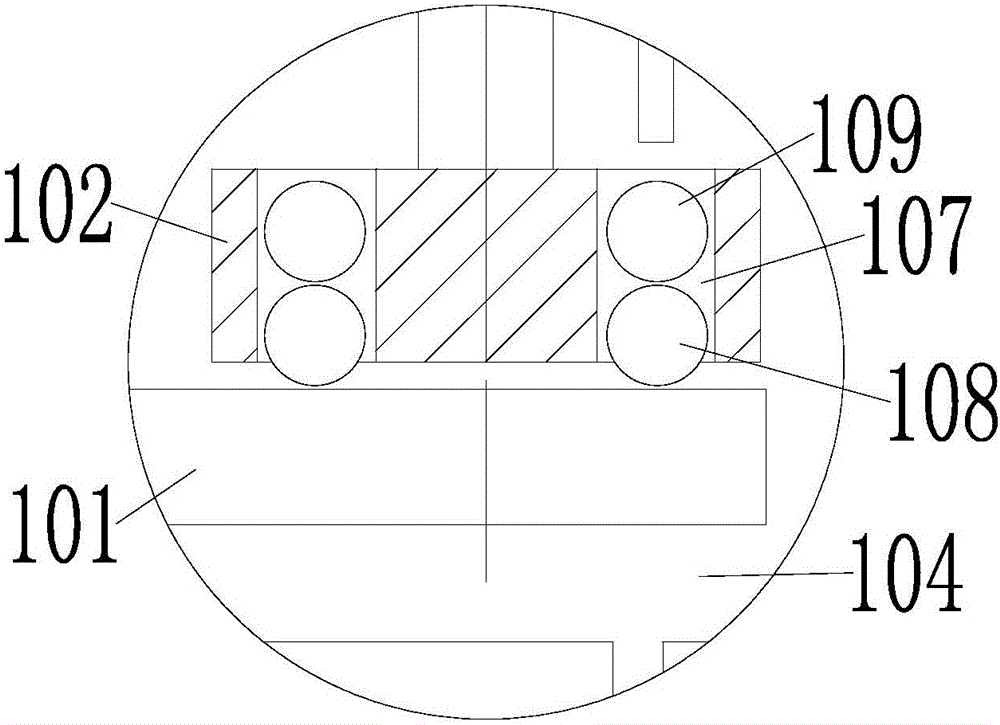

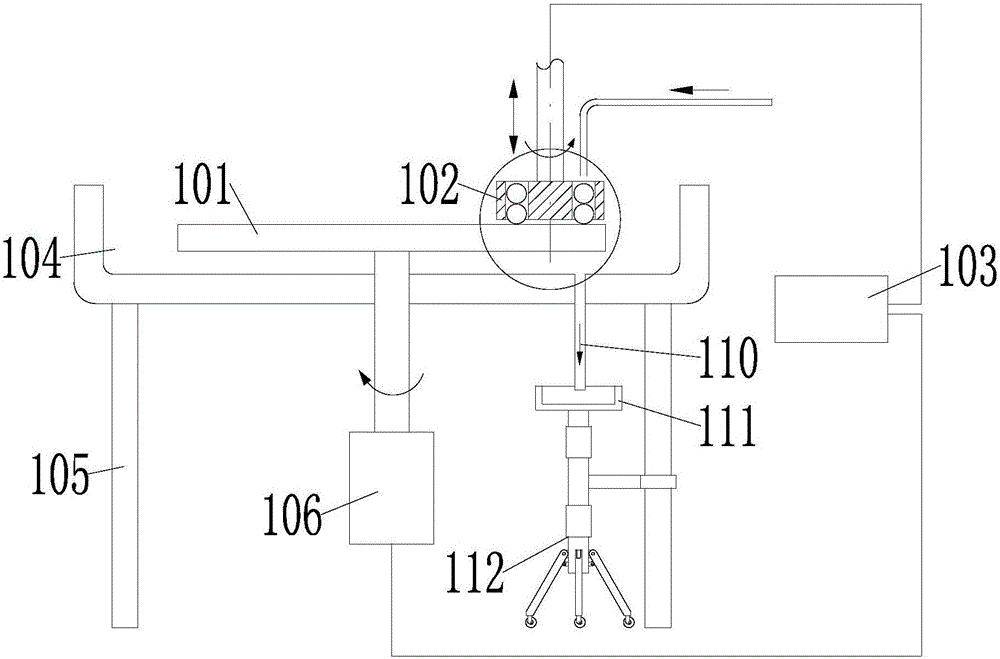

[0050] The invention provides a fragile hollow microsphere polishing machine and a polishing method, which realizes the variable speed and / or variable direction movement of the balls to be ground by simultaneously rotating the bottom plate and the top plate, and provides random relative friction of the balls to be ground to realize polishing , high polishing precision, especially suitable for fragile hollow microspheres with poor mechanical strength.

[0051] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com