Variable pitch radius based star chain transmission stepless speed change device

A technology of stepless speed change device and pitch circle radius, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc. It can solve the problems of easy damage of metal belt, high price of toothed chain, and large volume of hydraulic system, etc., to achieve The effect of eliminating the hydraulic system, low production cost, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

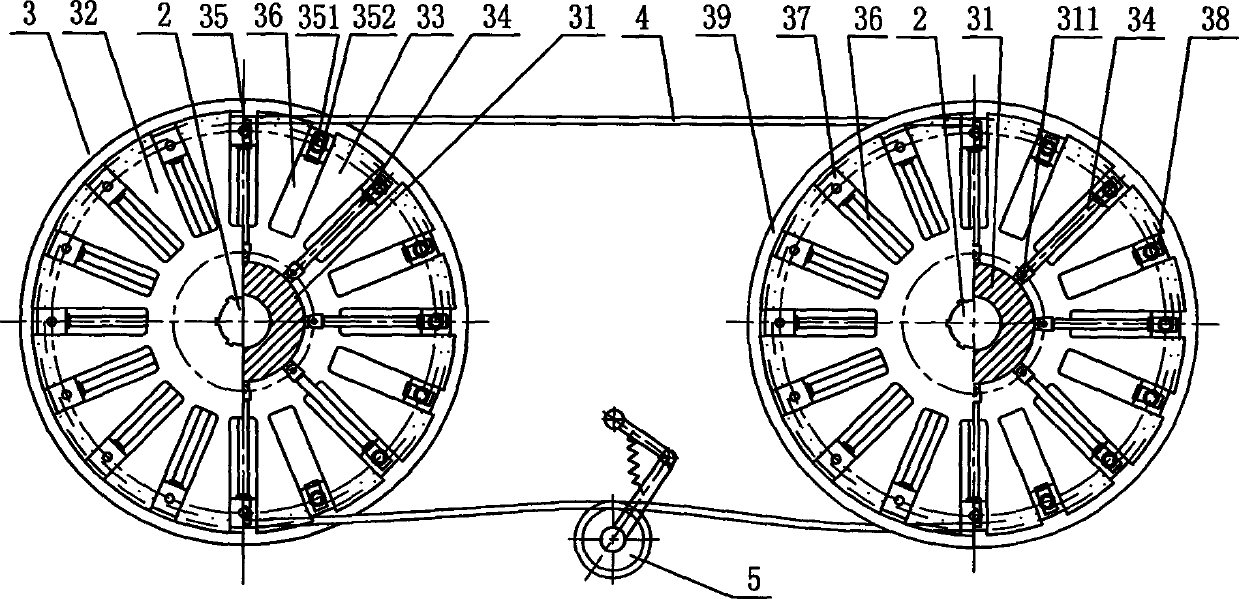

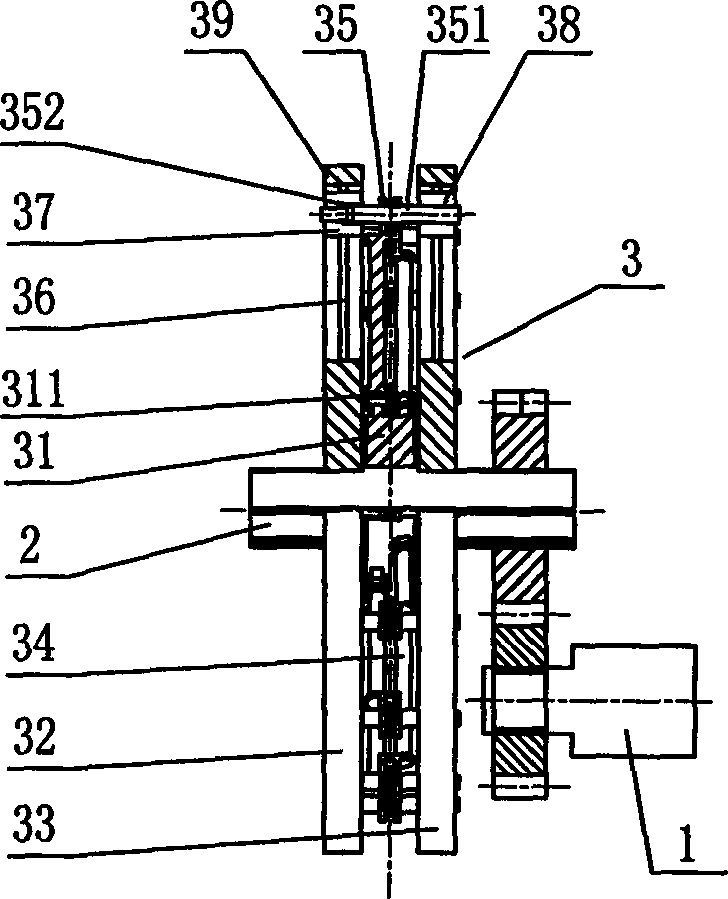

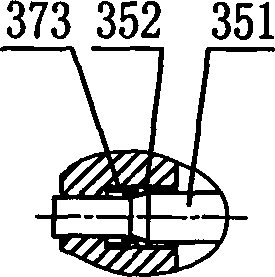

[0048]Combined with the accompanying drawings, the star-shaped chain transmission continuously variable transmission device based on the variable pitch circle radius is driven by the motor 1 to drive the star-shaped sprocket device 3 on the transmission main shaft 2, and the sleeve roller chain 4 cooperates to form a chain transmission pair. The star sprocket device 3 includes a control wheel 31 arranged on the transmission main shaft 2, a left sub-wheel 32 and a right sub-wheel 33 respectively arranged on both sides of the control wheel 31, and the inner diameter of the control wheel 31 body is provided with a control wheel connected to the transmission main shaft 2. The stator 312 and the control wheel rotor 313, the control wheel stator 312 is in interference fit with the drive shaft 2 through the spline, the control wheel rotor 313 cooperates with the control wheel stator 312, and the control wheel rotor 313 can wind around the control wheel stator 312 under the drive of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com