A soft magnetic alloy magnetic powder for electromagnetic transmission devices

A soft magnetic alloy and electromagnetic transmission technology, applied in the direction of electrical components, circuits, magnetic objects, etc., can solve the problems of no wear resistance characteristics, decreased proportion of ferromagnetic elements, and decreased saturation magnetic induction intensity, etc., to achieve compensation Reduced magnetic transmission, improved friction performance, and low excitation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

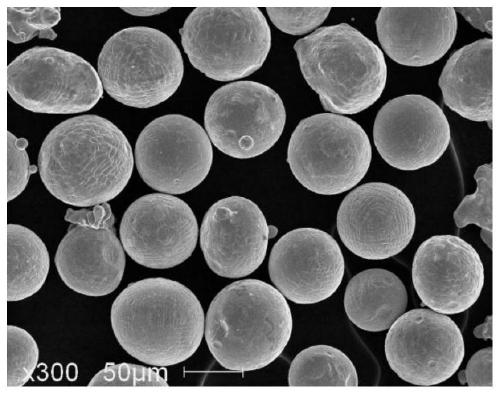

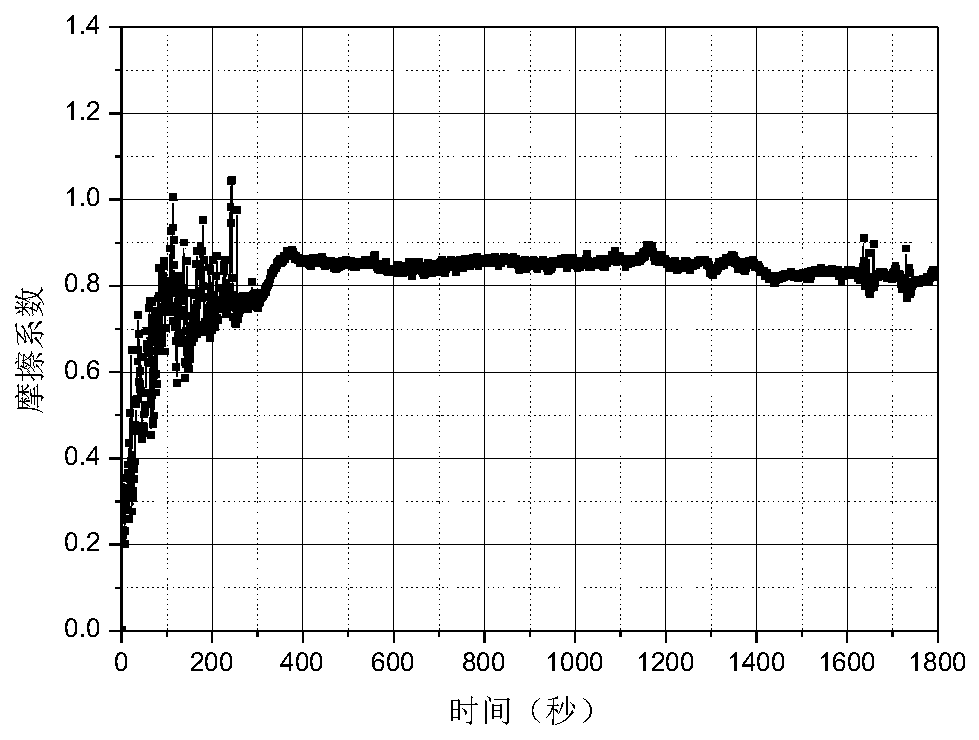

[0052] Use electrical pure iron, electrolytic cobalt, electrolytic nickel, electrolytic copper, high-purity metal chromium, pure silicon or high-purity ferrosilicon alloy (calculation of ingredients needs to deduct iron content) as raw materials, according to Fe65.21%, Co23%, Ni9.5% , Cu0.4%, Cr1.0%, Si0.8% by weight for batching, control the total amount of other metal elements Al, Mg, Ca, Ti, Ta, etc. in the raw materials to be less than 0.09%, and the total amount of V and Mn to be less than 0.11%, smelting under vacuum, keep the vacuum for 15 minutes for degassing after the molten steel is melted, then fill with nitrogen, and use nitrogen for gas atomization powder making, the oxygen content in the final alloy magnetic powder is ≤480ppm, and the carbon content is ≤52ppm . figure 1 It is the shape of magnetic powder particles with a particle size range of -200+250, which is a complete spherical particle. figure 2 It is the friction coefficient of the magnetic powder alloy...

Embodiment 2

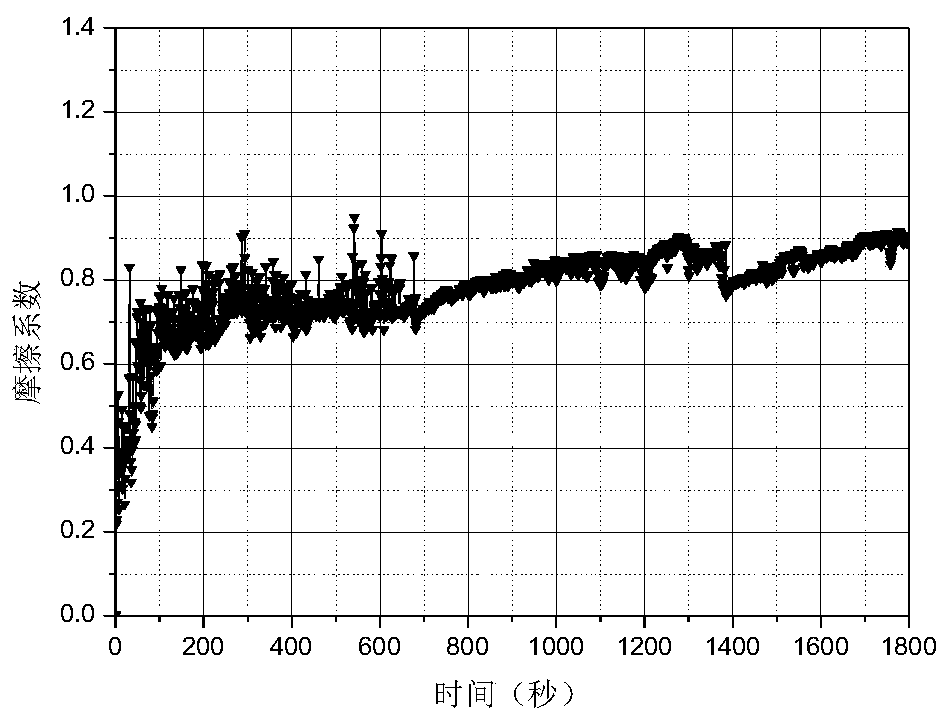

[0054] Using electrical pure iron, electrolytic cobalt, electrolytic nickel, electrolytic copper, high-purity metal chromium, pure silicon or high-purity ferrosilicon alloy (calculation of ingredients needs to deduct iron content) as raw materials, according to Fe67.43%, Co21.5%, Ni8. 7%, Cu0.3%, Cr0.75%, Si1.2% by weight for batching, control the total amount of Al, Mg, Ca, Ti, Ta, V, Mn in the raw materials to be less than 0.2%, under vacuum Carry out smelting, keep the vacuum for 15 minutes for degassing after the molten steel is melted, then fill it with nitrogen, and use nitrogen for gas atomization to make powder, the oxygen content in the final alloy magnetic powder is ≤520ppm, and the carbon content is ≤48ppm. image 3 is the coefficient of friction of the magnetic powder alloy of Example 2 (the average value is 0.8). Tables 1 to 8 are the properties of the magnetic powders of the examples, wherein the wear rate (0.01871%), hardness (HRC 30), bulk density (4.5g / cm3), f...

Embodiment 3

[0056] Use electrical pure iron, electrolytic cobalt, electrolytic nickel, electrolytic copper, high-purity metal chromium, pure silicon or high-purity ferrosilicon alloy (calculation of ingredients needs to deduct iron content) as raw materials, according to Fe67.7%, Co21%, Ni8.2% , Cu0.25%, Cr1.7%, Si1.0% by weight percentage for batching, control the total amount of other metal elements Al, Mg, Ca, Ti, Ta in the raw material to be less than 0.05%, V0.05%, Mn0. 1%, smelting under vacuum, keep the vacuum for 15 minutes for degassing after the molten steel is melted, then fill it with argon, and use argon for gas atomization to make powder, the oxygen content in the final alloy magnetic powder is ≤300ppm, and the carbon content ≤50ppm. Figure 4 is the coefficient of friction of the magnetic powder alloy of Example 3 (the average value is 1.5).

[0057] Table 1 is the performance of the magnetic powder of the examples, wherein the wear rate (0.01411%), hardness (HRC34), bulk ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com