Multi-gear-position transmission

A multi-speed transmission, ring-shaped technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

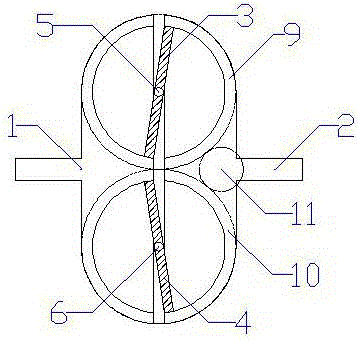

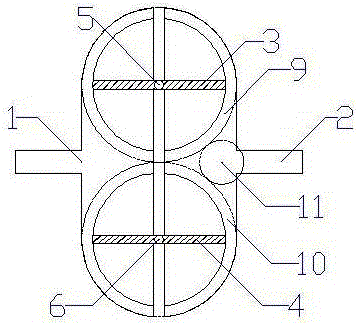

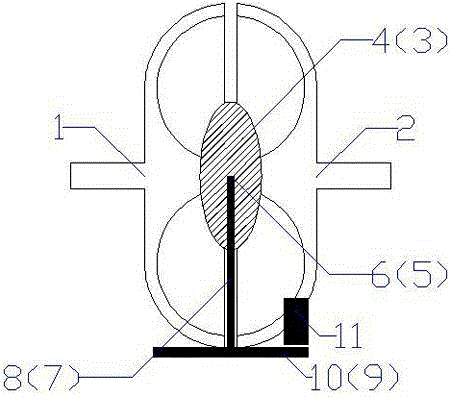

[0019] Such as Figure 1 to Figure 5 As shown, a multi-speed transmission includes a left gear 1 and a right gear 2 with the same structure. The left gear includes a left gear body and a left gear shaft, and the left gear body and the left gear shaft are integrally structured. The right gear includes a right gear body and a right gear shaft, and the right gear body and the right gear shaft are integrally structured. The left gear and the right gear are symmetrically arranged, the left gear body has an annular groove with a semicircular section opening to the right, the right gear body has an annular groove with a semicircular section opening to the left, the left gear body and The right gear bodies jointly form a circular cavity with a full circular cross-section. Disc-shaped connectors (3 and 4) are placed in the annular cavity, the annular cavity is a revolving body, and the left gear shaft and the right gear shaft coincide with the center line of the circular cavity. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com