Dual-drive two-gear automatic transmission

A technology of automatic transmission and speed ratio, which is applied in the direction of vehicle gearbox, transmission box, transmission element, etc., can solve the problems of large speed ratio difference between two gears, complex structure, weakened endurance, etc., and achieve smooth and smooth shifting process. The effect of high transmission efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

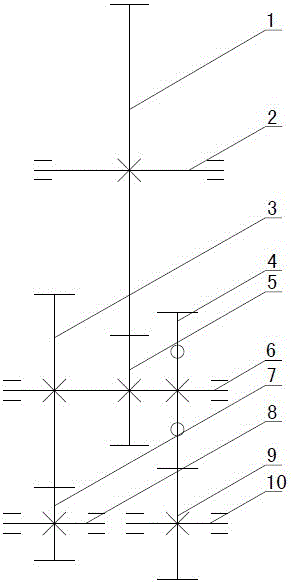

[0036] like figure 1 As shown, the dual-drive two-speed automatic transmission includes a casing (not shown in the figure) and a reduction mechanism arranged in the casing. The reduction mechanism includes: a driving gear shaft 2, a driving gear 1, and an intermediate gear 5 meshing with the driving gear 1 , The intermediate gear 5 is fixed on the intermediate gear shaft 6 . On the intermediate gear shaft 6, the first driven gear 3 and the second driven gear 4 are fixed simultaneously, and the first driven gear 3 and the second driven gear 4 are arranged on both sides of the intermediate gear 5 respectively, and are simultaneously provided with The first driving gear 7 meshed with the first driven gear 3 and the second driving gear 9 meshed with the second driven gear 4, the first driving gear 7 and the second driving gear 9 are respectively installed on the independent first driving gear shaft 8 and the second driving gear shaft 10. On both sides of the driving gear shaft 2...

Embodiment 2

[0046] The difference between Embodiment 2 and Embodiment 1 is that in this embodiment, a set of dual-drive two-speed automatic transmissions as shown in Embodiment 1 are respectively arranged on the front axle and the two rear axles of the electric vehicle, so that four driving motors (respectively denoted as drive motor A, drive motor B, drive motor C, and drive motor D) realizes the separate drive of the front axle and rear axle of the electric vehicle, and can control four different drive motors through different logics, so that Electric vehicles can have multiple speed ratios and multiple power driving states, which can respectively reach fifteen speed ratios and fifteen different power combinations: A, B, C, D, AB, AC, AD, BC, BD, CD , ABC, ACD, ABD, BCD, ABCD. At the same time, it is very simple to realize timely four-wheel drive.

Embodiment 3

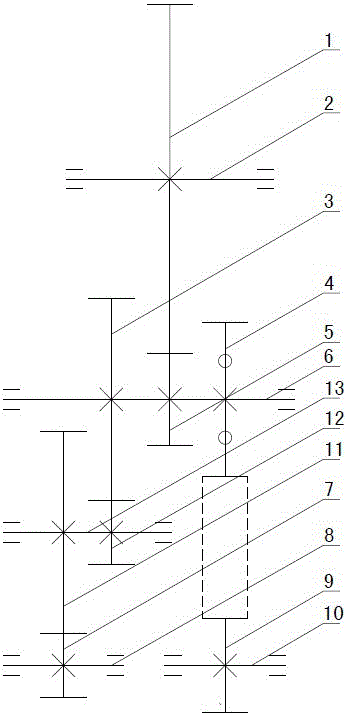

[0048] like figure 2 As shown, the difference between Embodiment 3 and Embodiment 1 is that the third driven gear 11 and the third driving gear are added to the above-mentioned first primary reduction mechanism composed of the first driving gear 7 meshing with the first driven gear 3 12, wherein the third driven gear 11 meshes with the first driving gear 7, the third driving gear 12 meshes with the first driven gear 3, and the third driven gear 11 and the third driving gear 12 are installed on the second intermediate gear at the same time on axis 13. Between the first driving gear shaft 8 and the intermediate gear shaft 6, a second intermediate gear shaft 13, a third driven gear 11, and a third driving gear 12 are added to realize high speed ratio transmission. The speed ratio can reach hundreds to one or higher.

[0049] In the first primary deceleration mechanism, two-stage deceleration or multi-stage deceleration is set, which can realize more abundant speed ratio settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com