Automatic lamp holder turnover and transportation machine for LED (light-emitting diode) lamp

A technology of turning over a mechanism and a lamp head, which is applied in the mechanical field to achieve the effects of high work efficiency, few operation steps and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

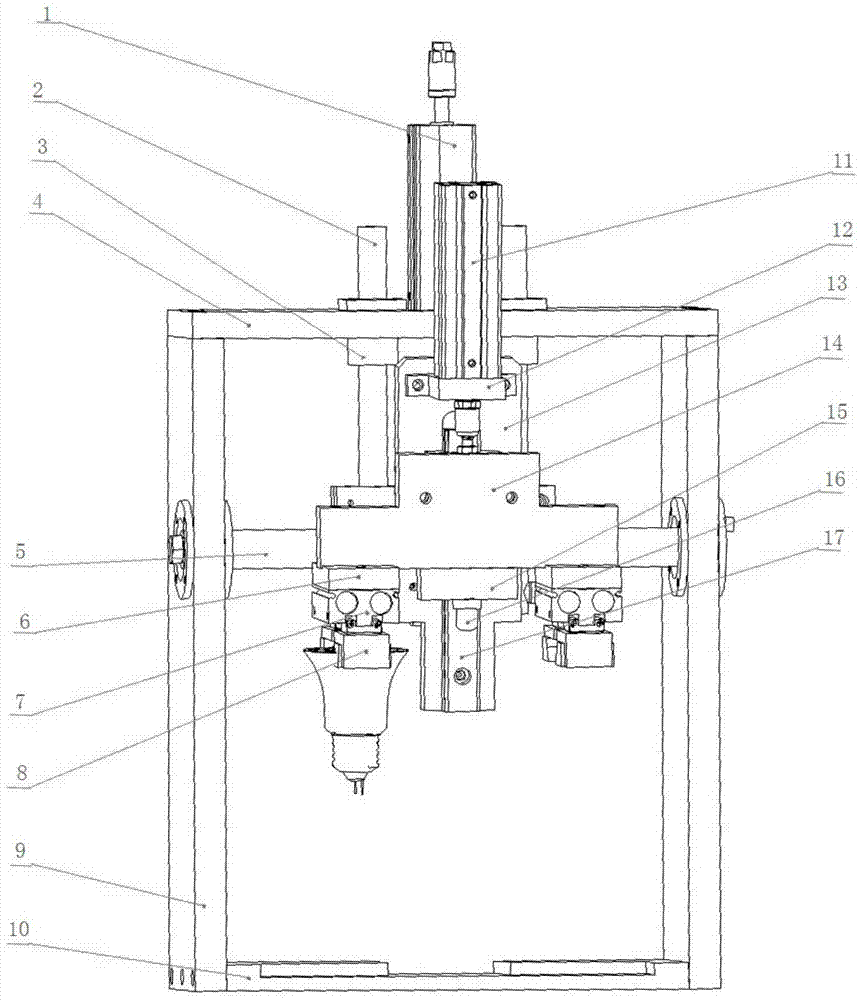

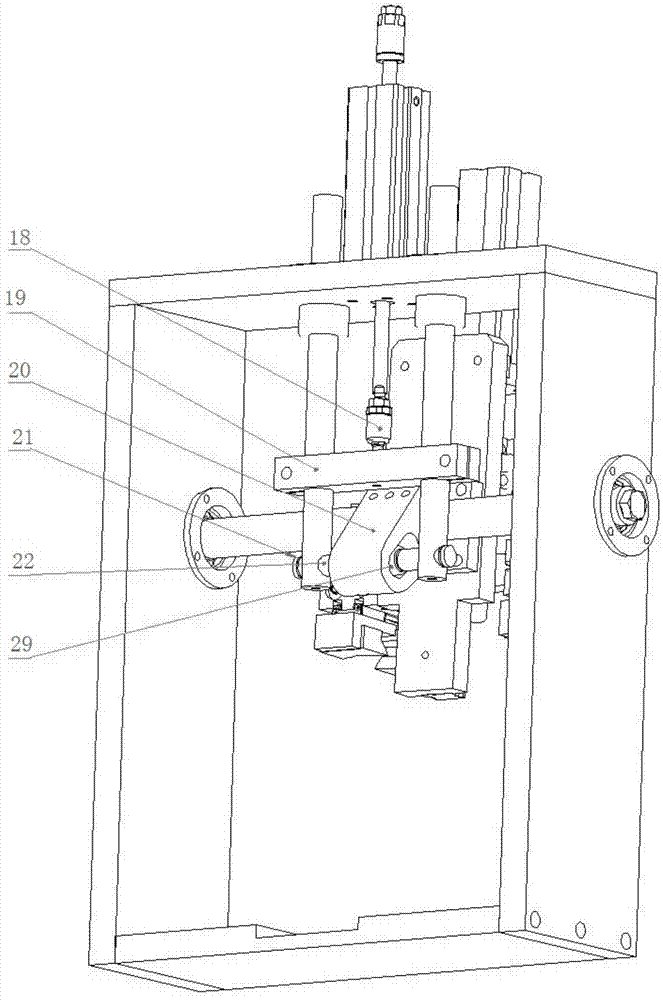

[0035] Such as figure 1 , figure 2 As shown, the turning mechanism includes turning cylinder 1, guide column 2, linear bearing 3, top plate 4, rotating shaft 5, cylinder seat 6, jaw cylinder 7, jaw finger 8, column plate 9, bottom plate 10, upper and lower cylinders 11, Cylinder block 12, panel 13, movable plate 14, linear guide rail 17, movable joint 18, connecting plate 19, swivel seat 20, jump ring 21, rotating shaft 22, needle roller bearing 29.

[0036] Turning cylinder 1 is fixed on top plate 4, and top plate 4 is screwed with two column plates 9. Turning cylinder 1 is connected with connecting plate 9 through movable joint 8. Two linear bearings 3 are fixed on the top plate 4, and two guide posts 2 pass through corresponding linear bearings 3 respectively. The two guide posts 2 pass through the connecting plate 9 arranged horizontally, and the connecting plate 9 and the two guide posts 2 are fixed together. The lower end of the guide post 2 is provided with a throu...

Embodiment 2

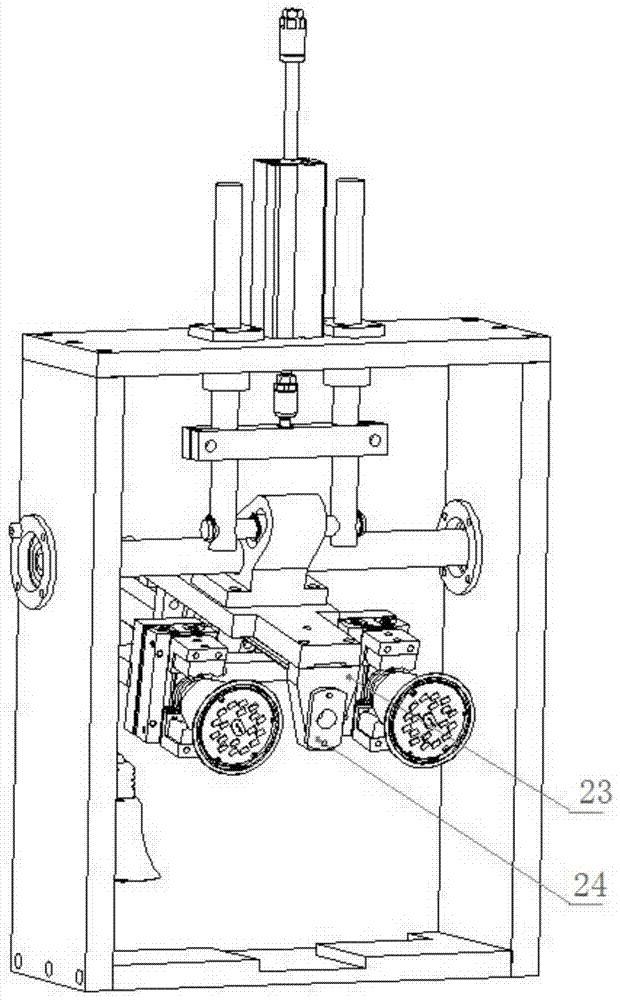

[0040] Such as image 3 As shown, the end of the movable plate 14 can also be fixed with a copper sleeve seat 24, and the copper sleeve seat 24 is fixed with a copper sleeve 23.

Embodiment 3

[0042] Such as Figure 4 As shown, a turning and handling machine is composed of a first turning mechanism 25 and a second turning mechanism 26. The first turning mechanism 25 and the second turning mechanism 26 have basically the same structure and are arranged axially symmetrically. Before turning over, the lamp head of the initial lamp body 27 faces upwards, and after being turned over and transported by the machine of the present invention, the bottom of the turned lamp body 28 faces down, and can move several distances on the same operating table or move from the first operating table to the second operating table. tower.

[0043] Compared with the second turning mechanism 26 of the first turning mechanism 25, the end of the movable plate 14 in the first turning mechanism 25 can also be fixed with a copper sleeve seat 24, and the copper sleeve seat 24 is fixed with a copper sleeve 23. The end of the movable plate 14 in the second turning mechanism 26 is fixed with a plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com