Multi-clutch gear-shifting system and using method thereof

A multi-clutch and clutch technology, applied in the field of shifting systems, can solve problems such as unsuitable, difficult high-pressure liquid sealing, and large heat generation in the transmission system, achieving low energy loss and heat generation, easy production and implementation, and overall structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

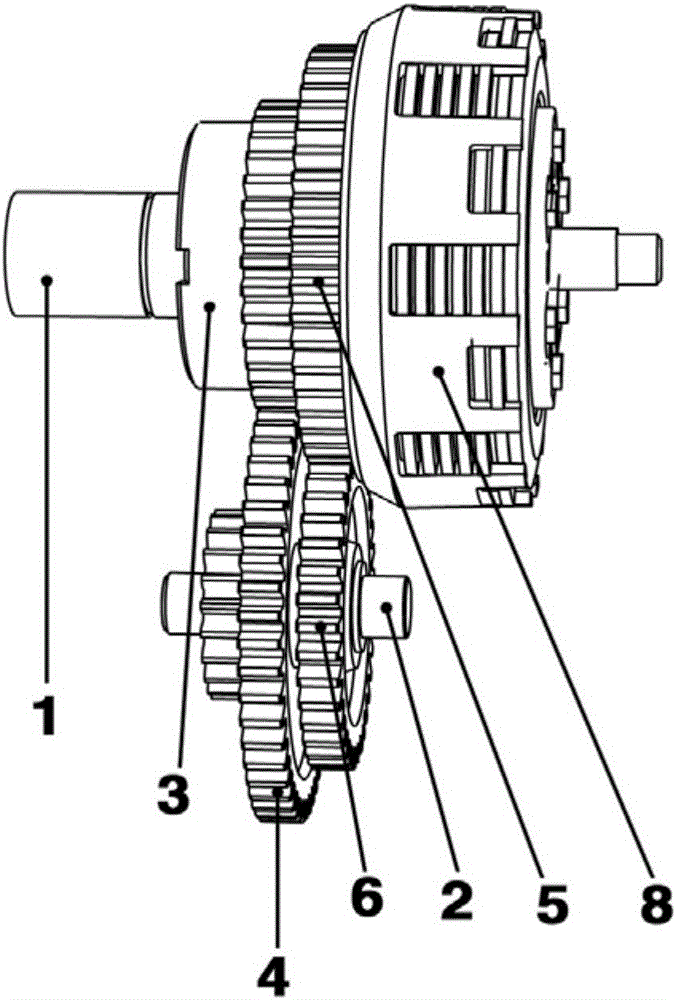

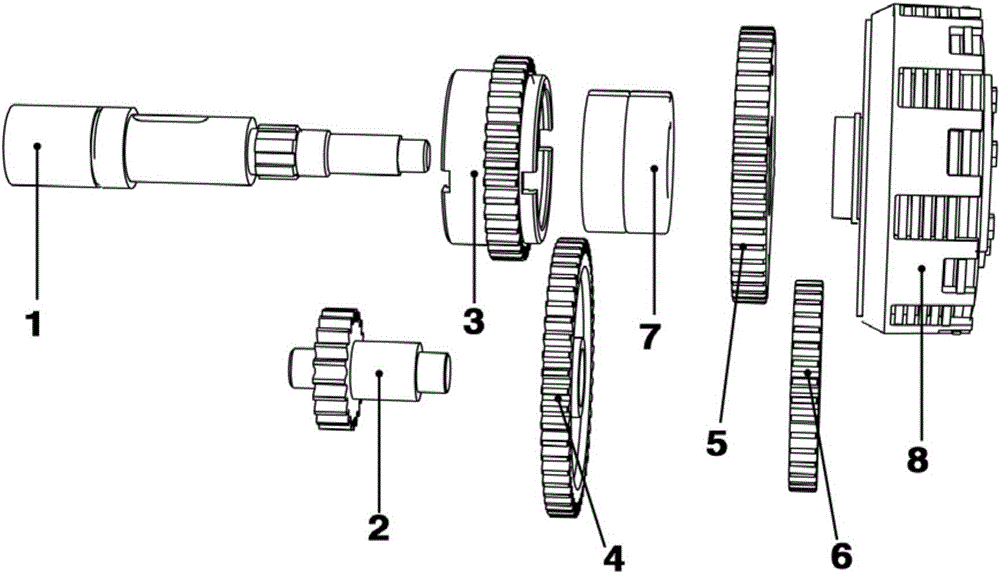

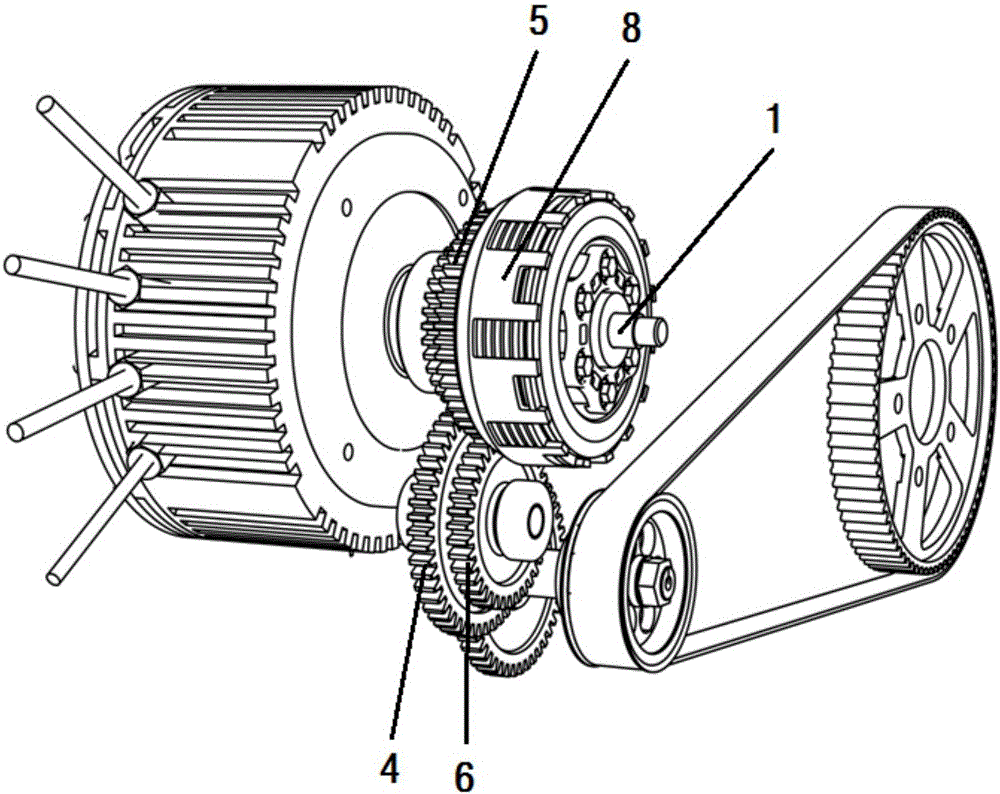

[0032] figure 1 It is a schematic diagram of an embodiment of a multi-clutch gear shifting system, figure 2 For an exploded diagram of an implementation of a multi-clutch gear shifting system, please refer to figure 1 with figure 2 shown. A multi-clutch shift system of a preferred embodiment is shown, including an input shaft 1 and an output shaft 2 .

[0033] Further, as a preferred embodiment, the multi-clutch shifting system includes several sets of gear pairs meshing with each other, each set of gear pairs has a different transmission ratio, and one gear of each set of gear pairs is sleeved on the input shaft 1 , the other gear of each group of gear pairs is sleeved on the output shaft 2.

[0034] On the other hand, as a preferred embodiment, the multi-clutch shift system includes a controllable clutch 8 . If the number of gear pairs exceeds two gears, the gear of the gear pair with the highest gear in several groups of gear pairs is sleeved on the input shaft 1 thr...

Embodiment 2

[0052] See figure 1 with figure 2 As shown, a multi-clutch shift system of a preferred embodiment is shown, including an input shaft 1 and an output shaft 2 .

[0053] Further, as a preferred embodiment, the multi-clutch shifting system includes several sets of gear pairs meshing with each other, each set of gear pairs has a different transmission ratio, and one gear of each set of gear pairs is sleeved on the input shaft 1 , the other gear of each group of gear pairs is sleeved on the output shaft 2.

[0054] On the other hand, as a preferred embodiment, the multi-clutch shift system includes a one-way clutch 7 . If the number of gear pairs exceeds two gears, the gear of the gear pair of the lowest gear among several groups of gear pairs is sleeved on the input shaft 1 through the one-way clutch 7 .

[0055] Furthermore, as a preferred embodiment, the multi-clutch shifting system includes several controllable clutches 8, and the gears of each high-speed gear pair except t...

Embodiment 3

[0060] A multi-clutch shifting system in a preferred embodiment includes an input shaft and an output shaft.

[0061] Further, as a preferred embodiment, the multi-clutch gear shifting system includes several groups of gear pairs meshing with each other, each group of gear pairs has a different transmission ratio, and one gear of each group of gear pairs is sleeved on the input shaft. The other gear of each group of gear pairs is sleeved on the output shaft.

[0062] On the other hand, as a preferred embodiment, the multi-clutch shifting system includes controllable clutches. If the number of gear pairs exceeds two gears, the gear of the gear pair of the highest gear in several groups of gear pairs is sleeved on the output shaft through a controllable clutch.

[0063] Furthermore, as a preferred embodiment, the multi-clutch shifting system includes several one-way clutches, and the gears of each low-speed gear pair except the highest speed gear in several sets of gear pairs p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com