Patents

Literature

46results about How to "Joint smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

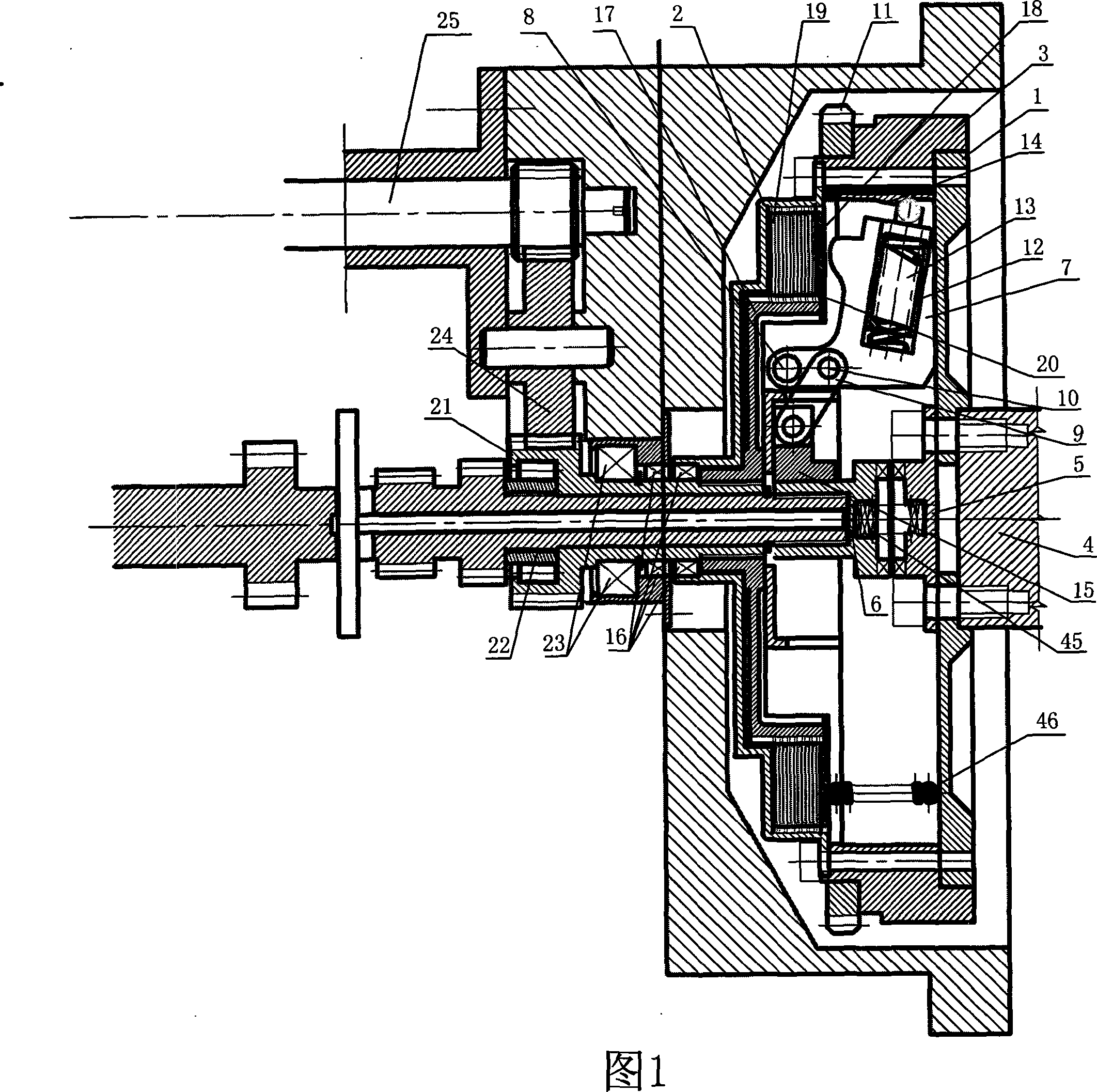

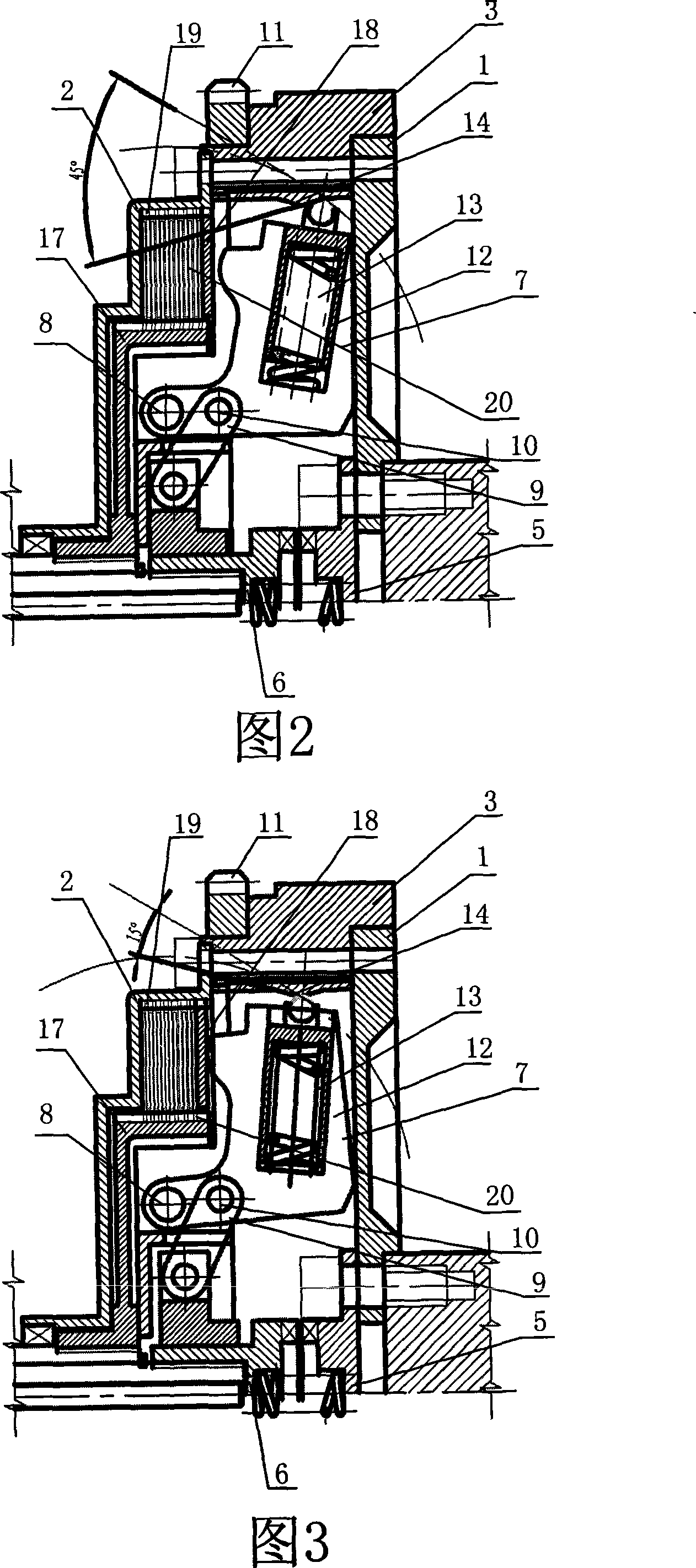

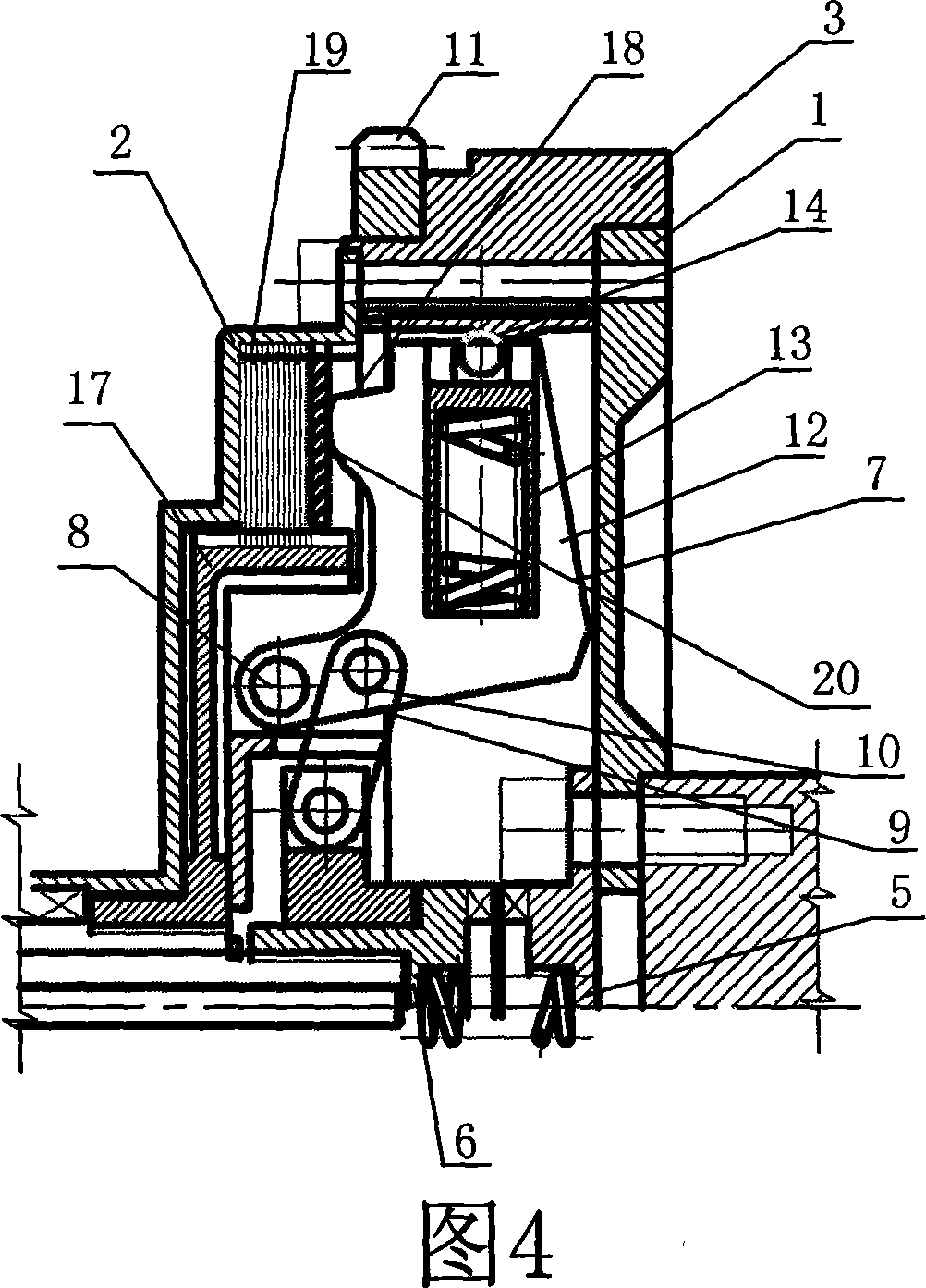

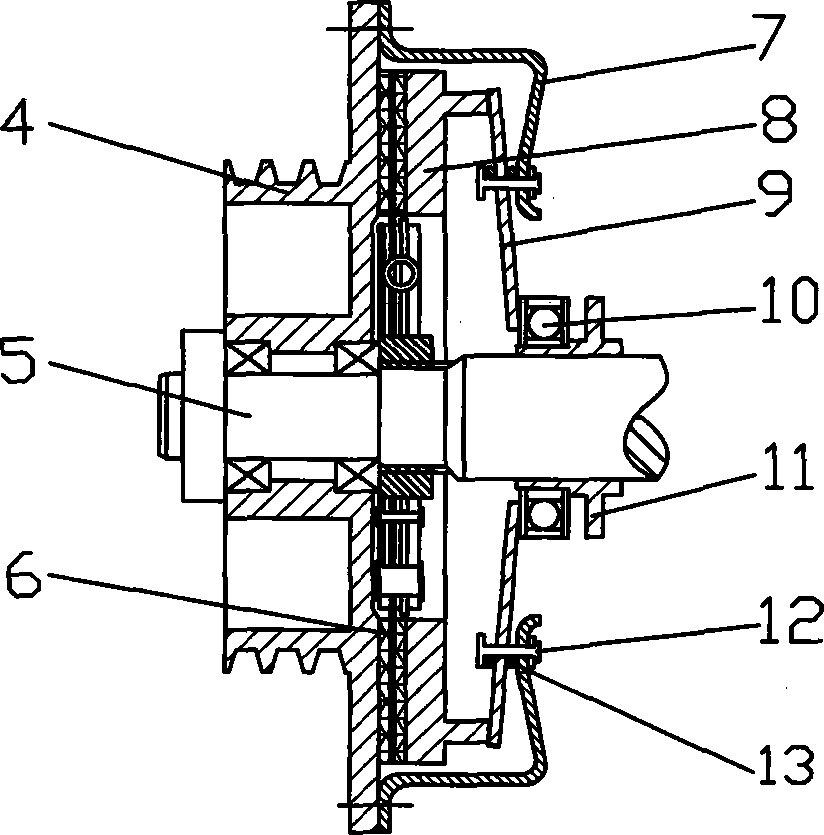

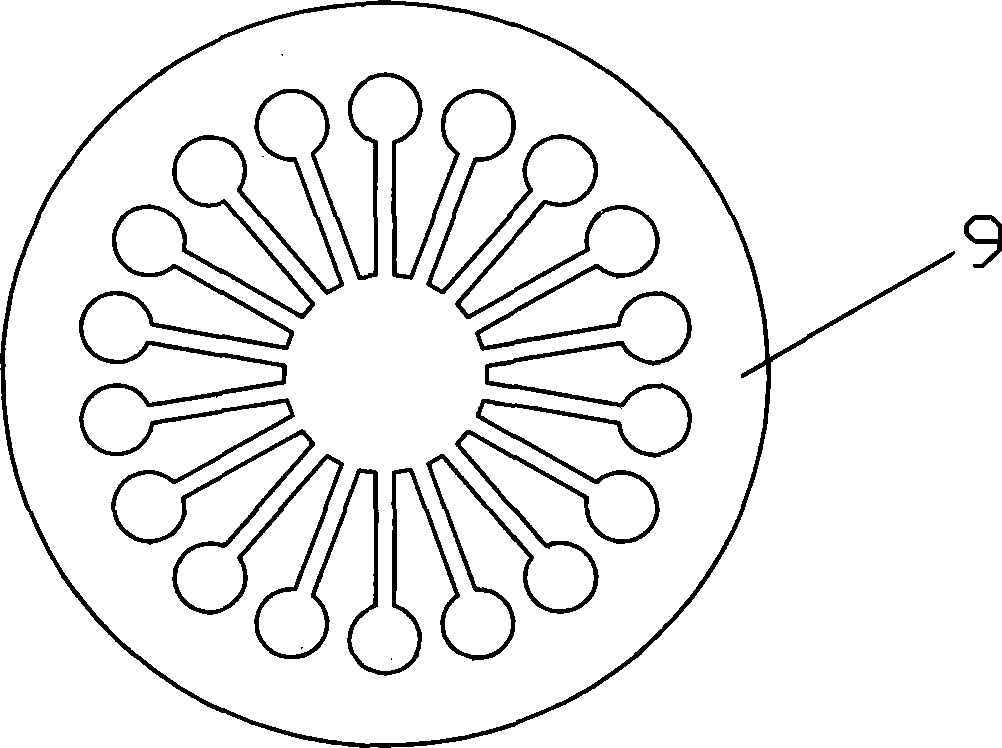

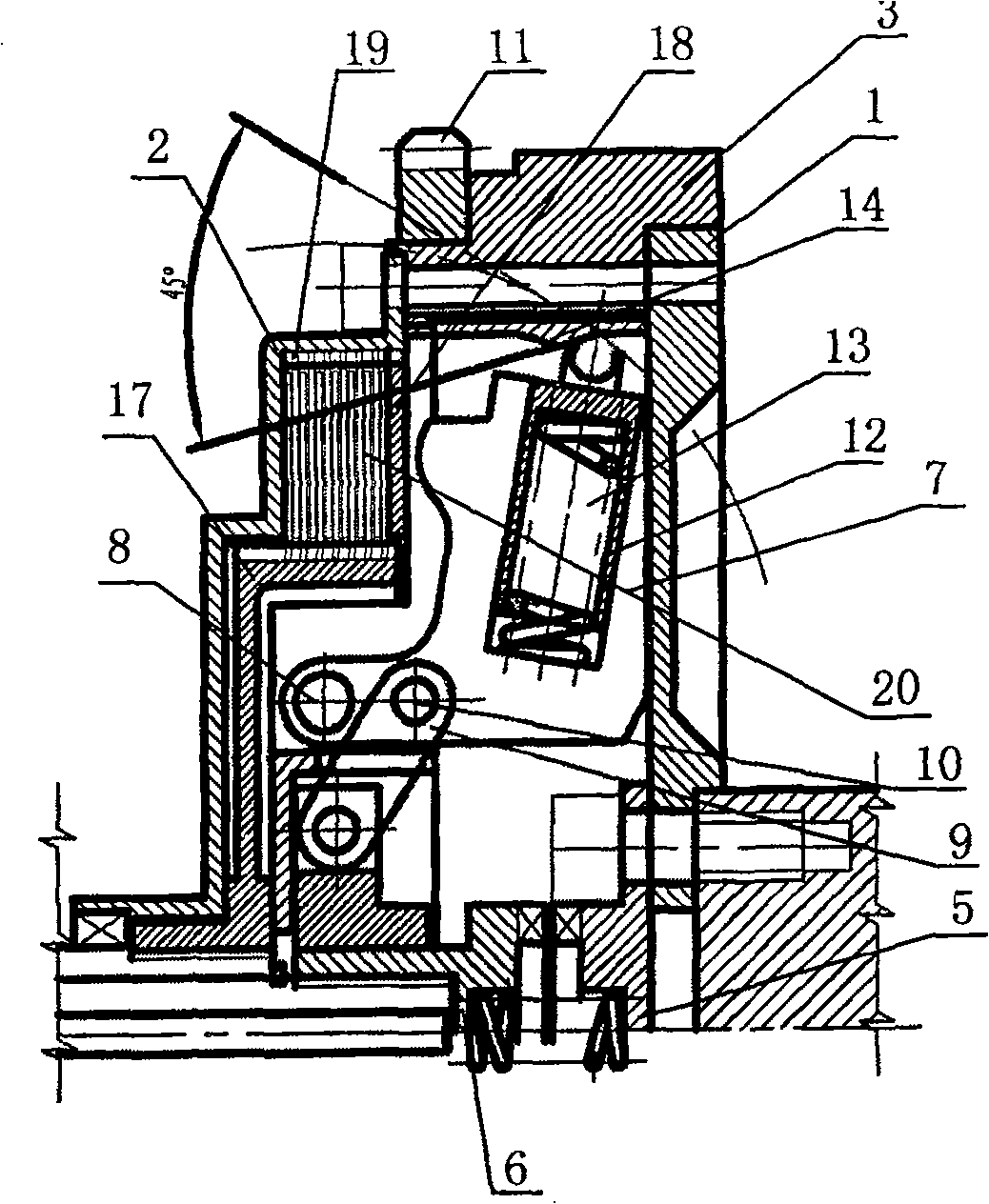

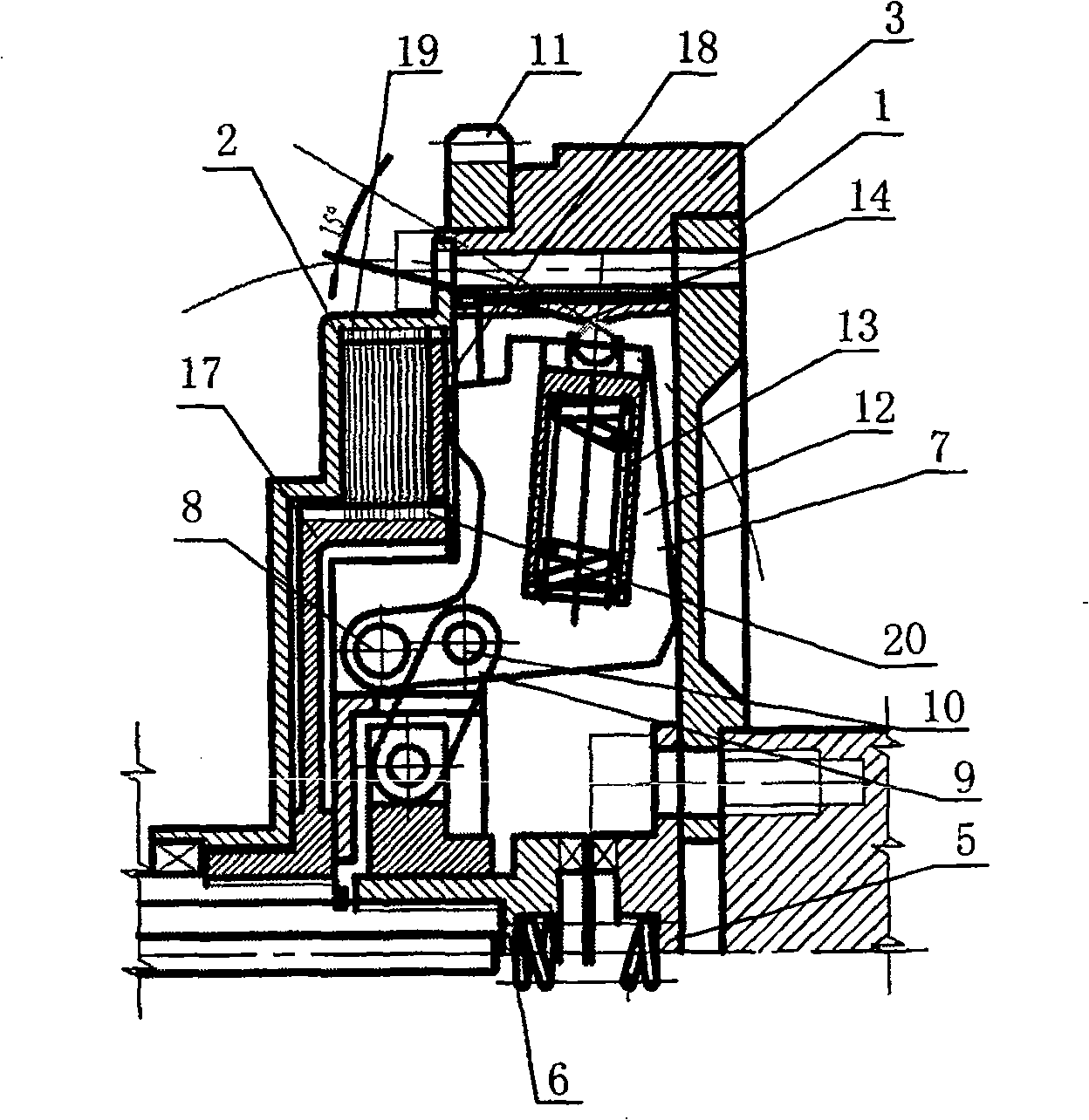

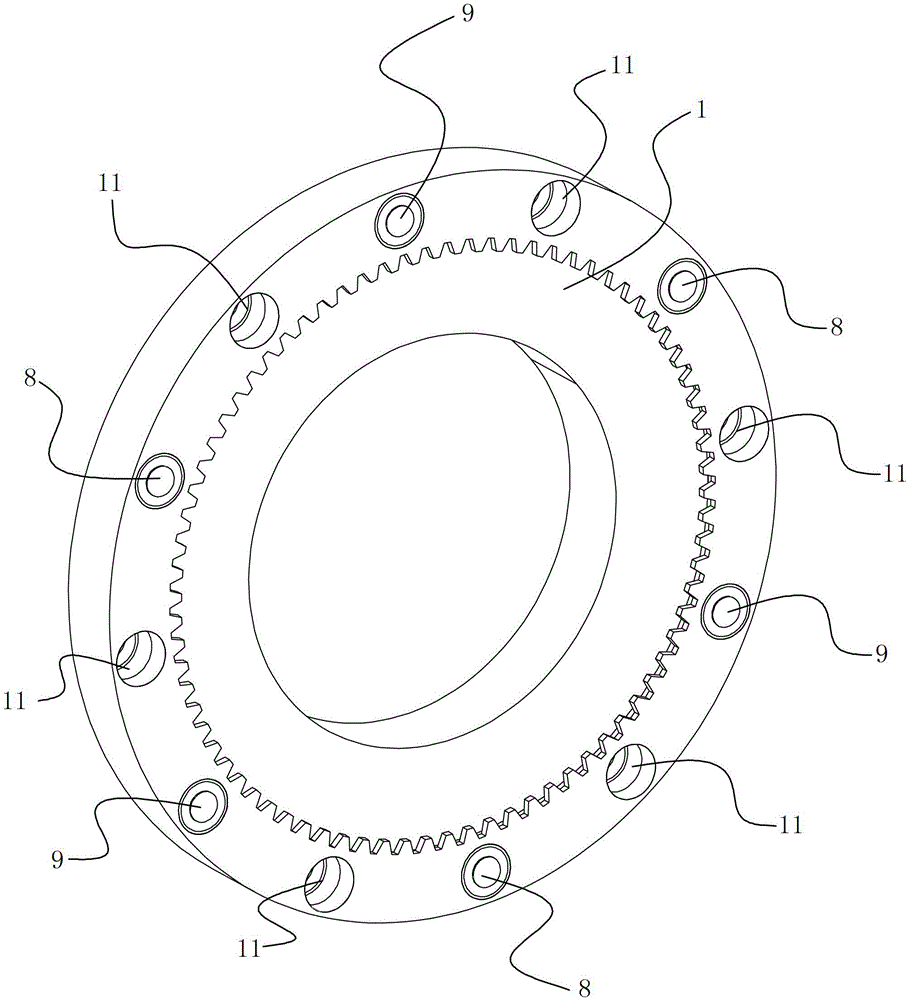

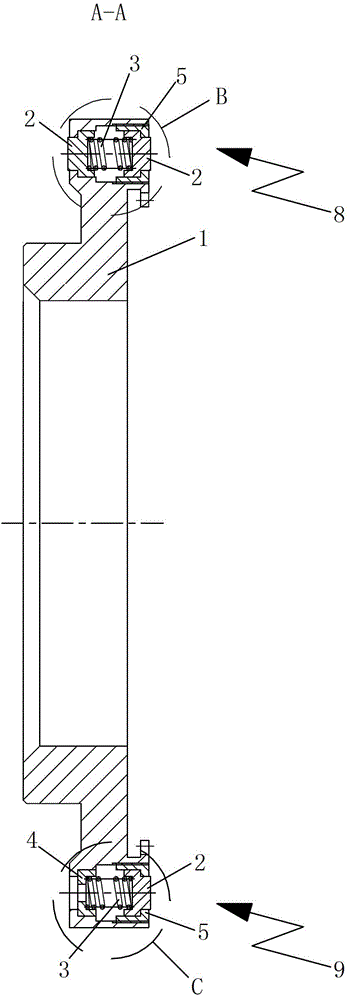

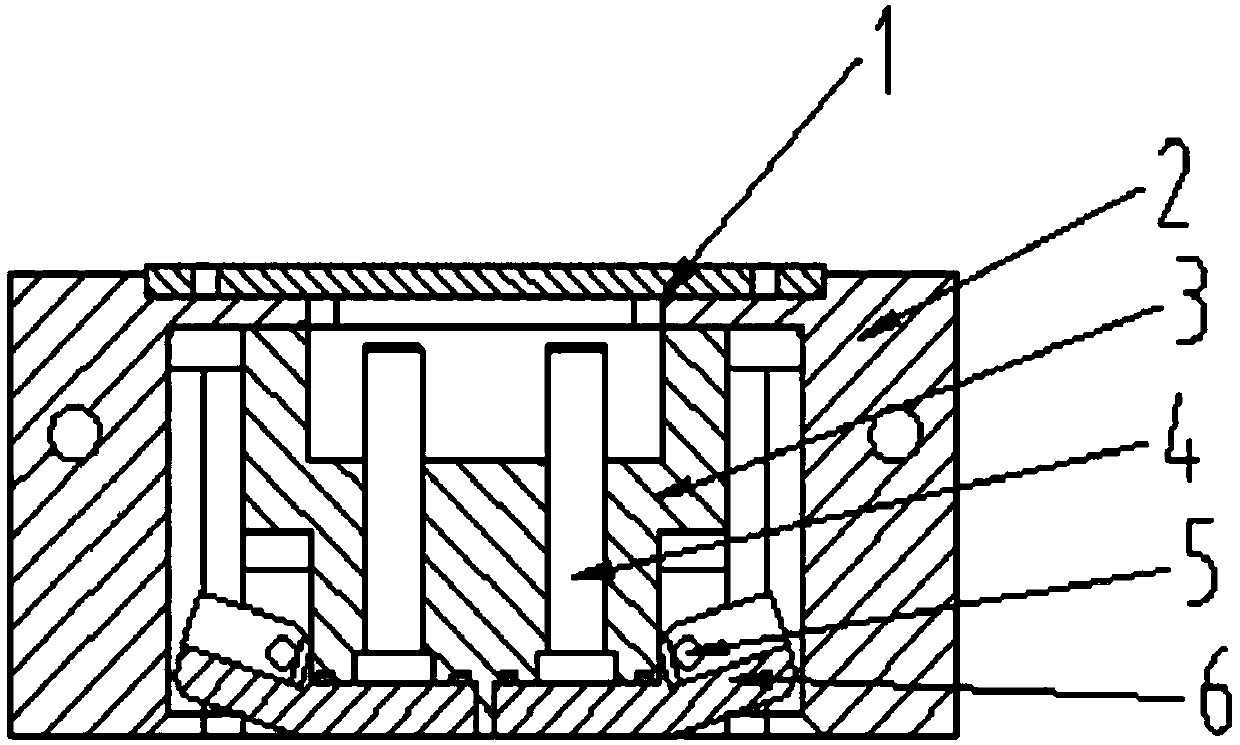

Automatic clutch for motorcycle

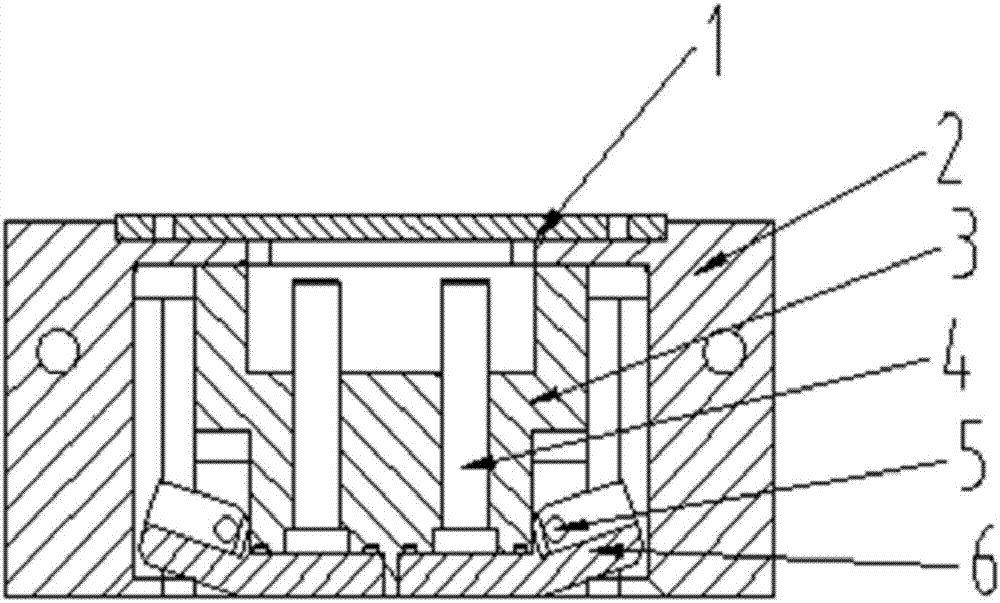

InactiveCN101201084AInversion does not affectReduce speedFriction clutchesFriction liningAxial displacementAbdominal cavity

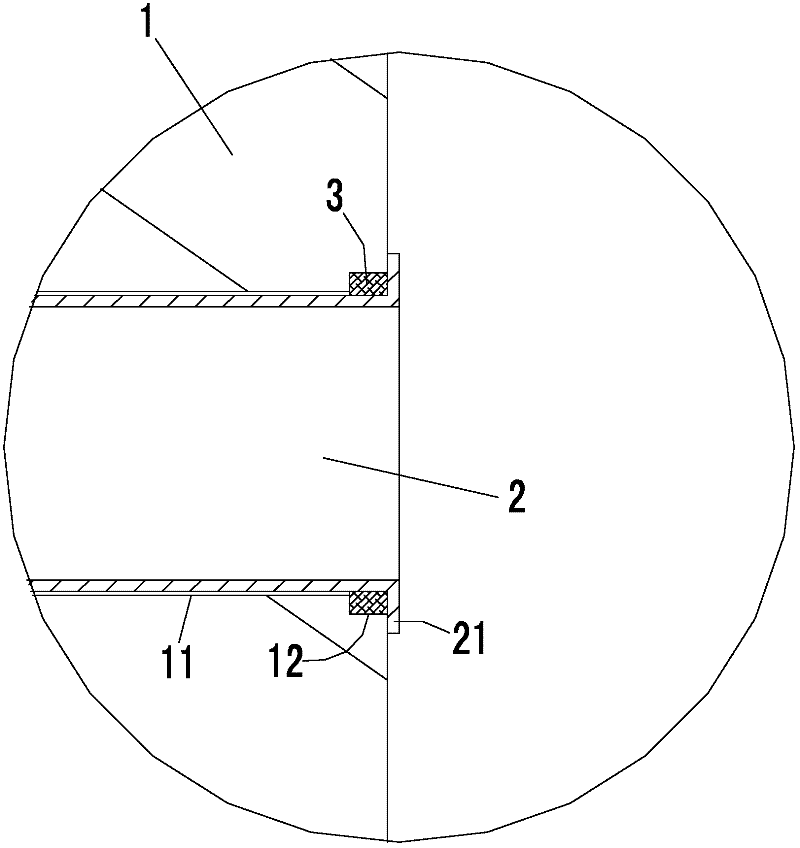

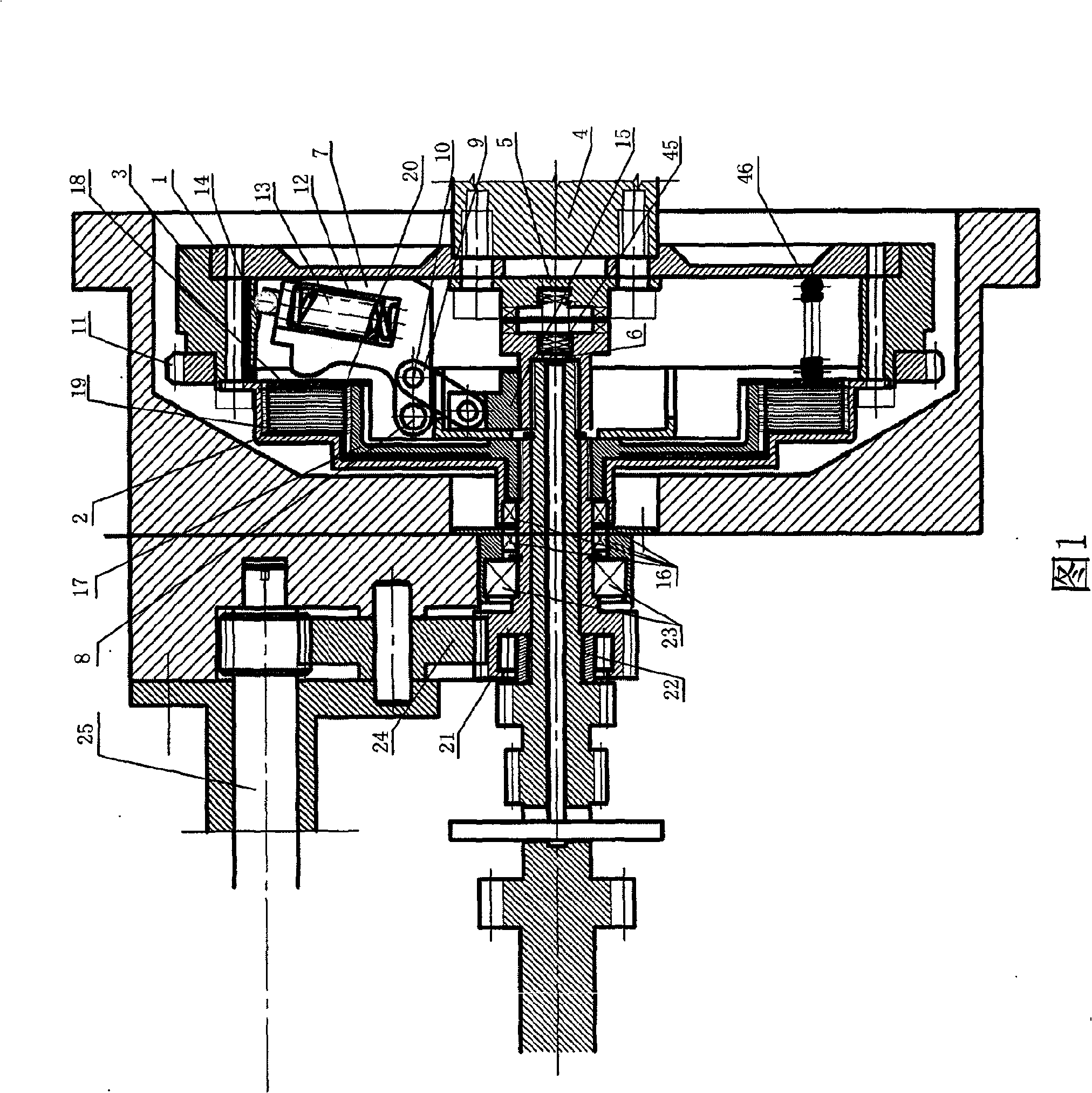

The invention discloses an automatic coupler for vehicles, which comprises a front tray, a back tray, and a middle tray. The invention is characterized in that the central part of the left end of the middle tray is in wall shape and forms a cavity together with the wall of the back tray to restrict the axial displacement of a driven tray shaft arranged at the left side. An abdominal cavity of the middle tray is coaxially and uniformly hinged with 2 to 6 fly hammers which bear and transmit power. A hammer handle is arranged at the left part of the fly ball and a hammer body is arranged at the right part. The left end of the handle is provided with a pivoting hole which is hinged on the hinge base at the middle part of the left side of the middle tray. The right side of the hammer handle is also provided with a hole hinged with a connecting rod. The left side of the right part hammer body is provided with a pressing finger pressed at the right end of a clutch pressure plate. A cavity of the hammer body in the right part is provided with an offset piston and an offset piston spring. The spherical top end of the offset piston reciprocates on an orbit on a cavity wall of an inner hole of the middle tray. The high-speed centrifugal force of an engine leads a fly hammer group to be pressed and arranged in a clutch membrane group in the back tray and transmits power to an output tray connected with a gearbox. The invention has the advantages of simple structure, god self-moving responsiveness, regular joint, high transmission efficiency, long service life and proper cost.

Owner:江大建 +1

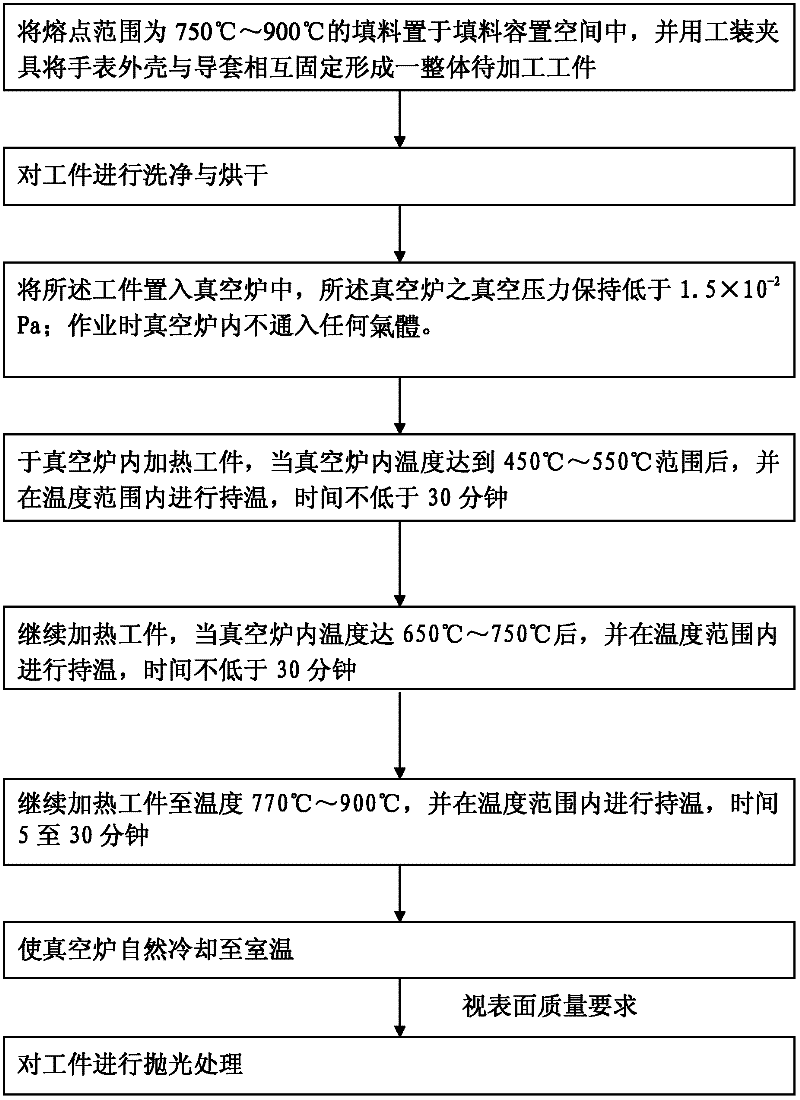

A processing method for bonding between titanium or titanium alloy watch parts with high finish

ActiveCN102266993AUniform temperatureHigh surface hardnessSoldering apparatusVacuum pressureShielding gas

The invention relates to a treatment method for jointing titanium or titanium alloy watch parts. The treatment method comprises the following procedures of: (1) placing an alloy filler with melting point range of 750-900 DEG C in a filler accommodating space and fixing the watch housing and the guide sleeve with each other by a tooling fixture to form an integrated workpiece to be machined; (2) placing the workpiece into a vacuum furnace, wherein the vacuum pressure of the vacuum furnace is kept to be lower than 1.5*10<-2>Pa in the operation process until the manufacture procedure is finished, wherein shielding gases and any oxidizing gas are not introduced into the vacuum furnace during operation; (3) heating the workpiece in the vacuum furnace; and after the temperature in the vacuum furnace reaches the temperature range of 450-550 DEG C, preserving the heat within the temperature range for no less than 30 minutes; (4) continuing to heat the workpiece; and after the temperature in the vacuum furnace reaches 650-750 DEG C, preserving the heat within a temperature range for no less than 30 minutes; (5) continuing to heat the workpiece to the temperature of 770-900 DEG C and preserving the heat within the temperature range for 5-30 minutes; and (6) naturally cooling the vacuum furnace to the room temperature. According to the invention, the jointing quality and surface hardness of the titanium or titanium alloy watch parts can be effectively improved.

Owner:中山源谥真空科技有限公司

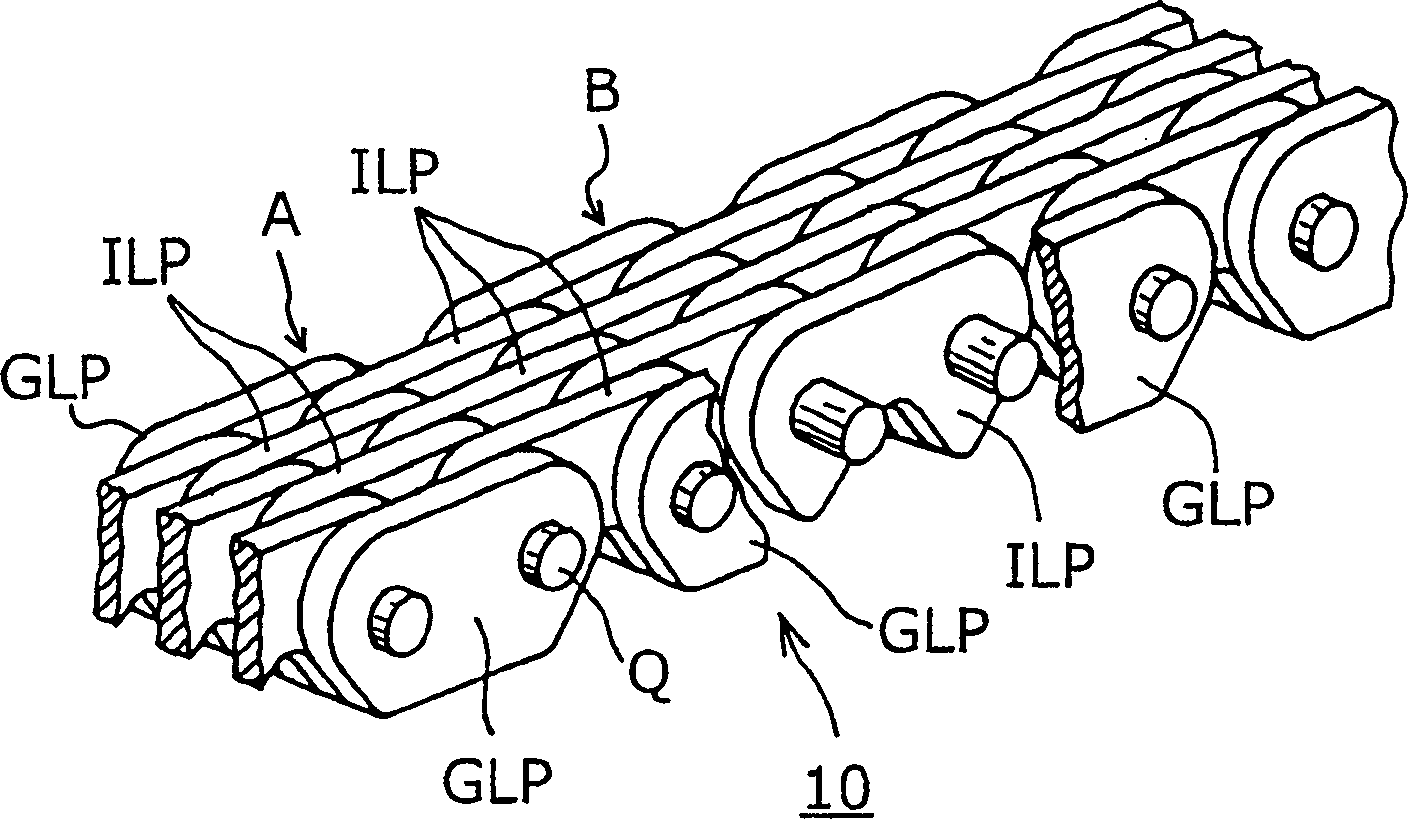

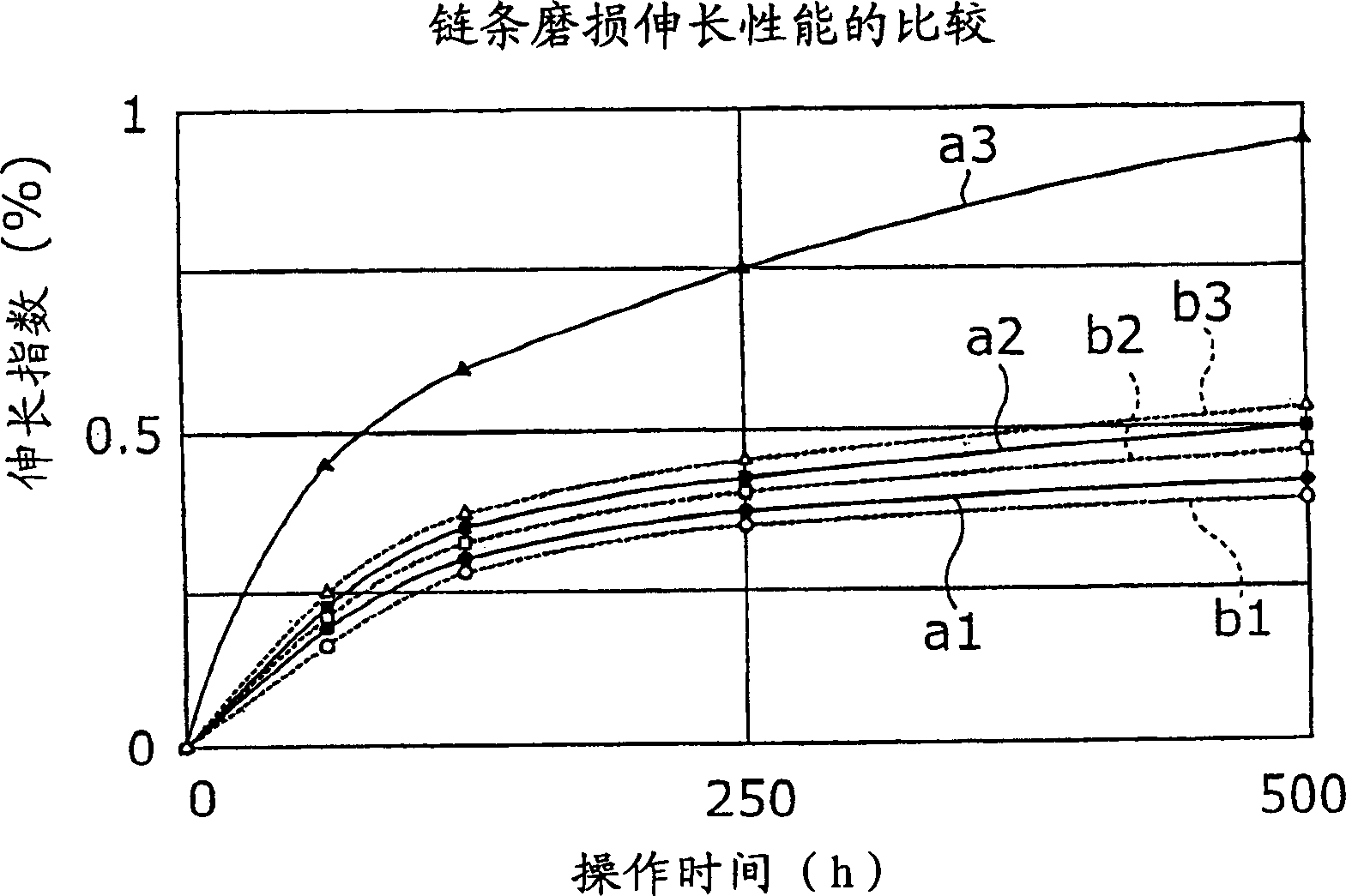

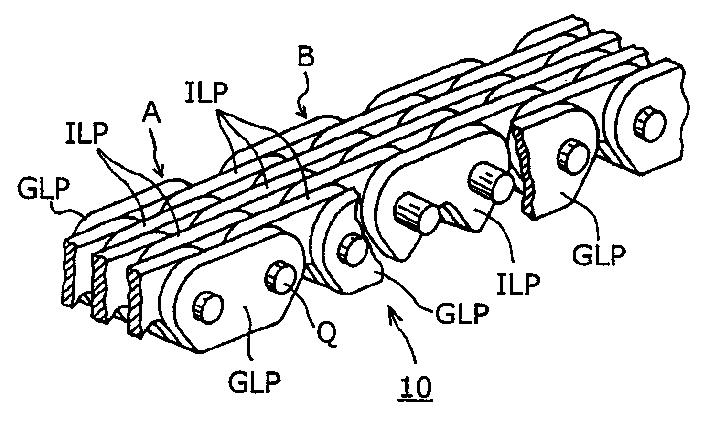

Noiseless chain

InactiveCN1451895AImprove oxidation resistanceNo abnormal wear elongationMetallic material coating processesDriving chainsMartensitic stainless steelEngineering

To provide a silent chain which engages and slides smoothly over a long period of time without abnormal wear elongation even when extremely deteriorated lubricating oil having a high degree of oxidation is used. The silent chain comprises a guide link plate (GLP), a link pin (Q) fixedly mounted in a pin hole of said link plate and an inner link plate (ILP) with meshing teeth, said link pin being loosely fitted in an internal connection In the pin hole of the plate, it is characterized in that the inner connecting plate is made of a steel selected from heat-cured austenitic stainless steel, martensitic stainless steel, precipitation hardening steel, high carbon chromium bearing steel and alloy tool steel Matrix material.

Owner:TSUBAKIMOTO CHAIN CO

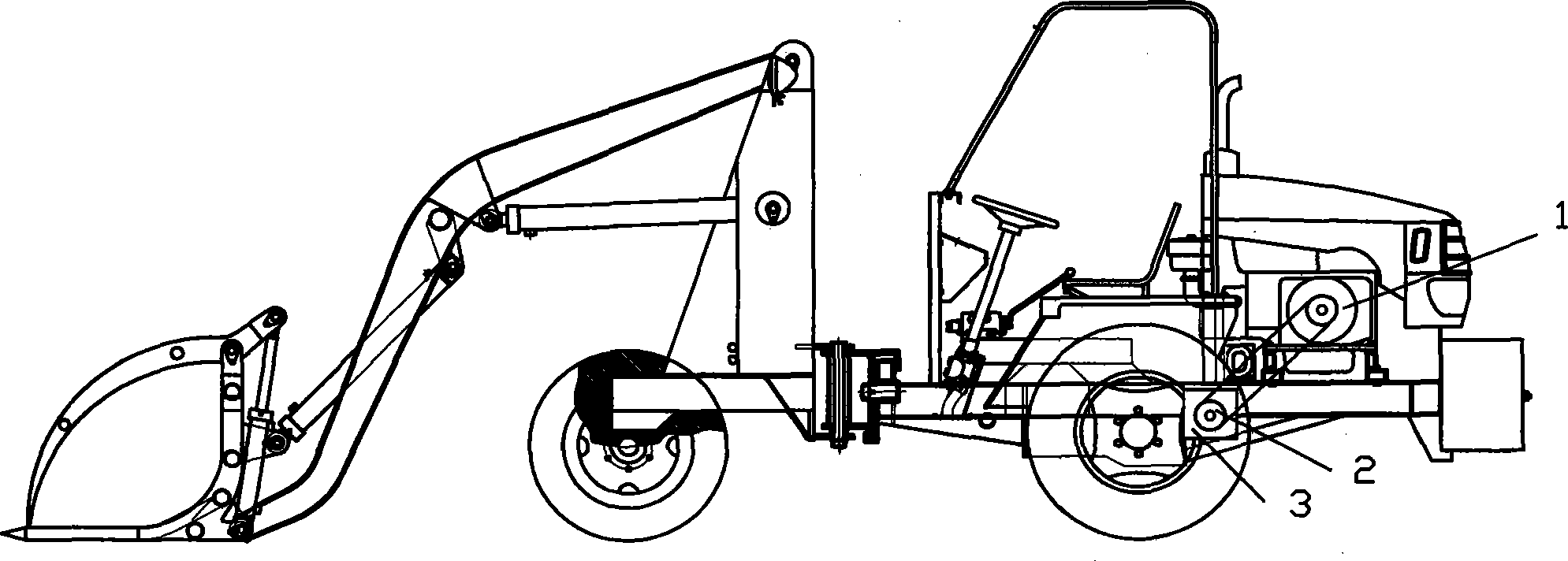

Grass grasping machine with diaphragm spring clutch

InactiveCN103362975AAutomatically adjust the pressing forceSeparation saves effortMechanical machines/dredgersFriction clutchesTorque transmissionRivet

The invention discloses a grass grasping machine with a diaphragm spring clutch. A clutch is the diaphragm spring clutch, and comprises a clutch cover, a friction plate, a pressure plate, support rings, a diaphragm spring and a driving spring, wherein a clutch belt pulley is fixedly connected with the outer edge of the clutch cover; the friction plate is clamped between the end face of the clutch belt pulley and the pressure plate; the driving spring is connected to the outer peripheral surface of the pressure plate; the other end of the driving spring is connected with the clutch cover; the inner edge of the clutch cover is connected with the diaphragm spring through rivets; two support rings which are same are arranged between the two lateral surfaces of the diaphragm spring and the rivets; the outer periphery of the diaphragm spring contacts with the raised part of the lateral surface of the pressure plate; and the inner periphery of the diaphragm spring contacts with a separation bearing. According to the grass grasping machine, a riveting structure is adopted for a diaphragm of the diaphragm spring clutch of the grass grasping machine, and separation gaps between every two of a plurality of separation claws are the same, and are not required to be regulated respectively; and the clutch of the grass grasping machine functions as a pressure element and a separation lever, so that the clutch is uniform in pressure, stable and reliable in torque transmission, smooth in jointing and convenient to operate.

Owner:LINYING COUNTY YING MACHINERY MFG

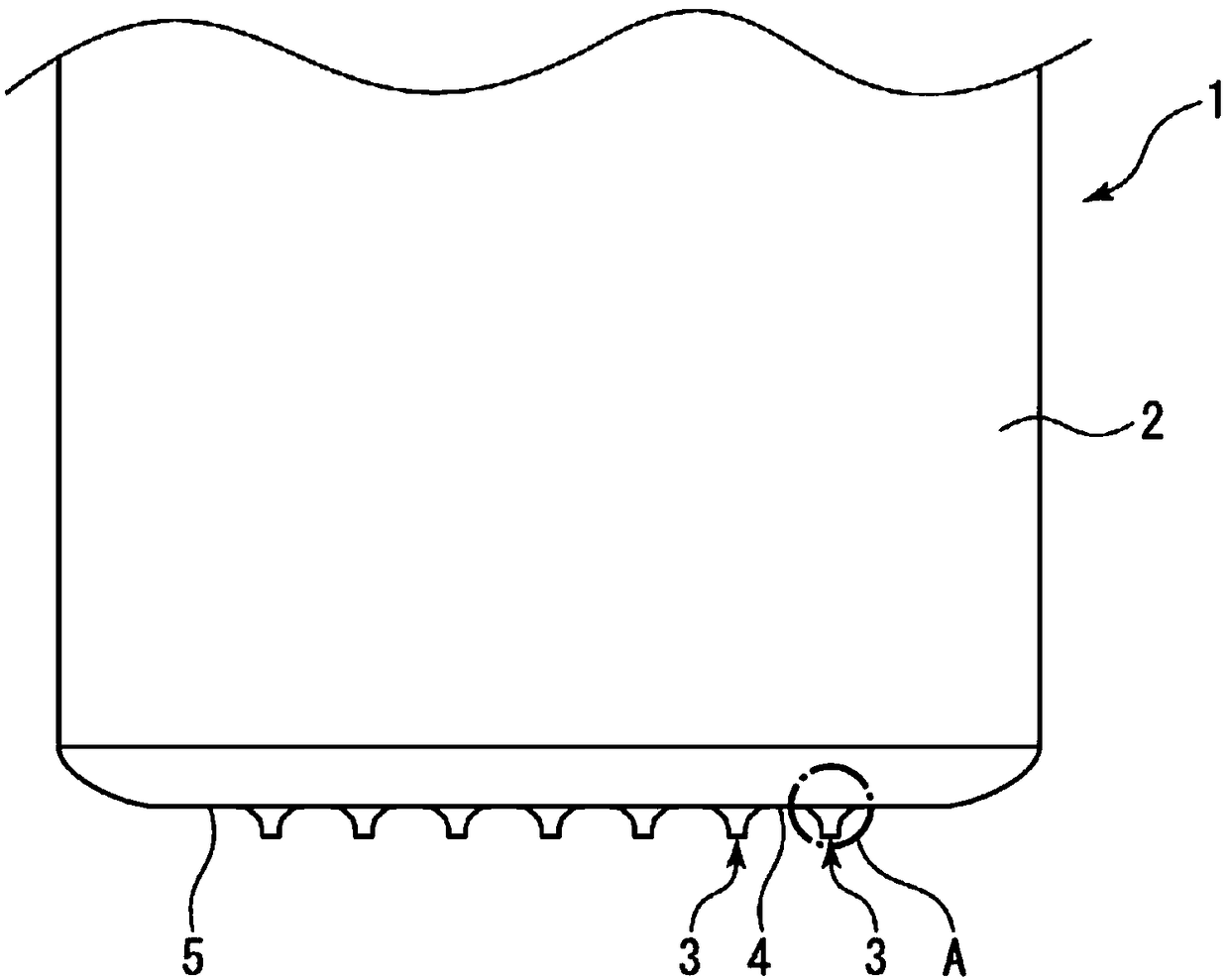

Corrugated board full paper barrel

The invention provides a corrugated board full paper barrel, which is mainly characterized in that a corrugated board barrel body is made into a section of flat board through removing one to two flutes from one end of a single-side corrugated board in the vertical direction of the flutes, the other end and the flat board are intersected and glued for forming a corrugated board barrel body. Surface paper is glued on the outer side of the flutes of the corrugated board barrel body, or one layer or more than one layer of single-side corrugated board barrel is glued on the outer side of the flutes of the corrugated board barrel body to be made into the corrugated board barrel bodies in various specifications. The invention solves the problem that joints parts are overlapped, and the mechanized production can not be realized in the prior art. Compared with the prior art, the invention has the advantages of both the original full paper board barrel and the corrugated paper box, and also has the advantages of high intensity, high toughness, strong integral structure, high compression strength, labor and time saving during package, beautiful appearance, convenient beautification, decoration and the pattern color printing on the outer surface of the barrel, difficult package loosening and damage in the transportation process, good use performance and the like. In addition, the mechanized production can be realized conveniently, and the cost can be greatly reduced.

Owner:枣阳天立包装实业有限公司

Magnetic fastener clip

A magnetic fastener clip includes a cup having at least one hole, and an overmold is attached to the cup and a magnet. The overmold has: a cup cover is injection molded on an outside portion of the cup, and an inner ring is injection molded on at least part of an inside portion of the cup. The inner ring is attached to the cup cover via the at least one hole. The magnet operably attaches into the inner ring. According to one embodiment, a turn coupler attaches to the cup cover. The magnetic fastener clip is operative for blind attachment into a structure, such as a vehicle chassis i.e. a pillar, door frame, chassis or roof.

Owner:TERMAX CORP

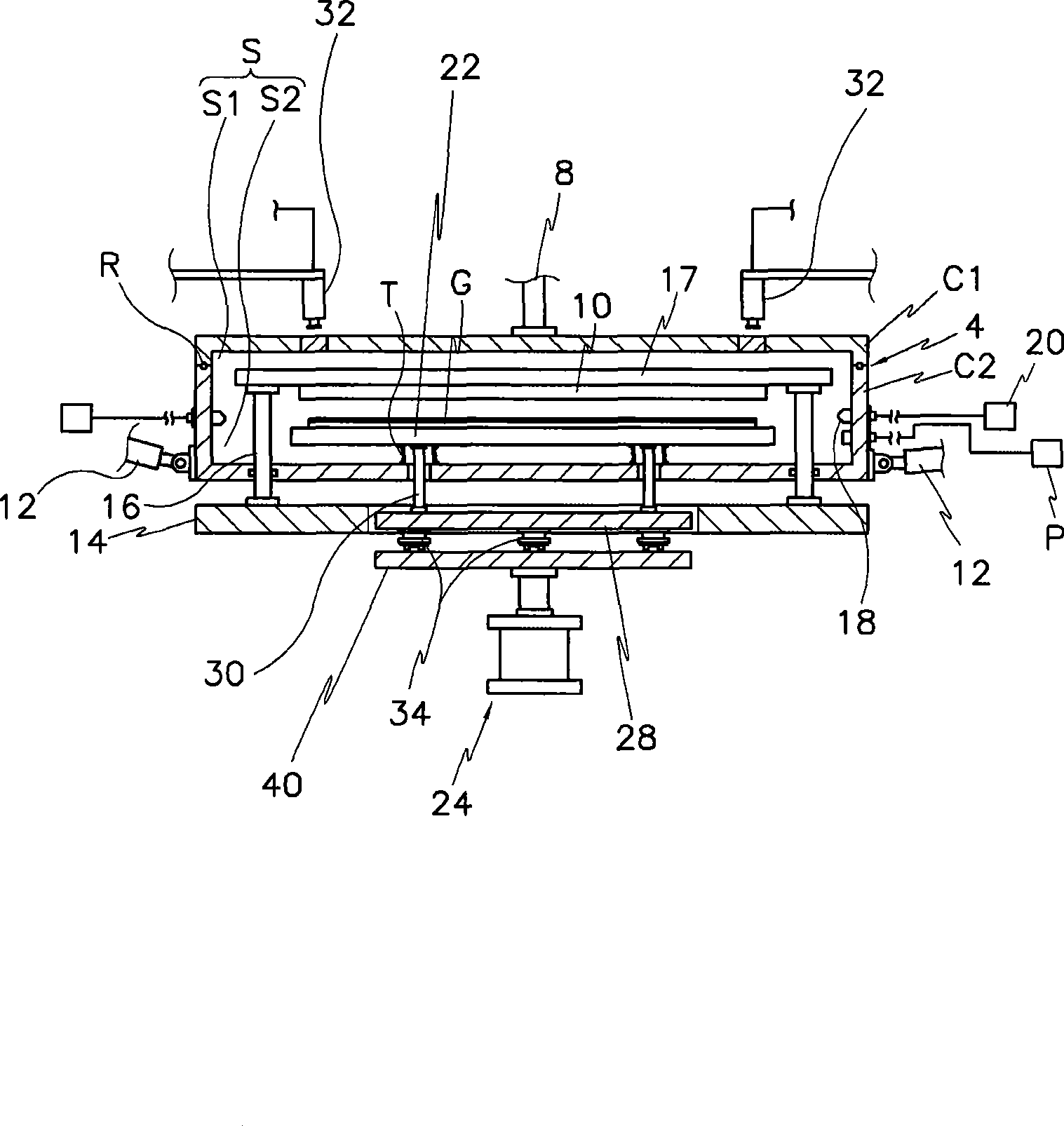

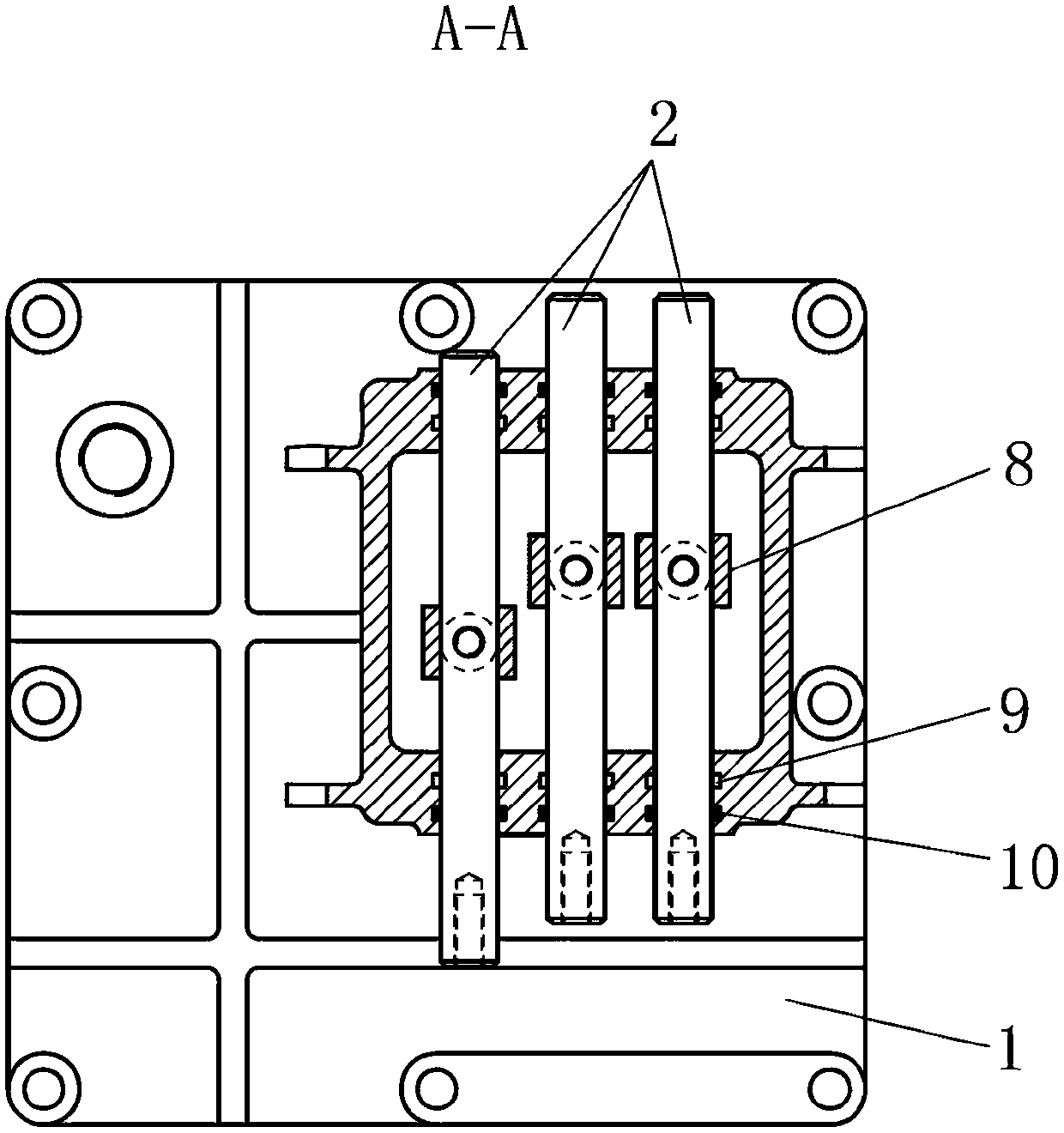

Stamping apparatus

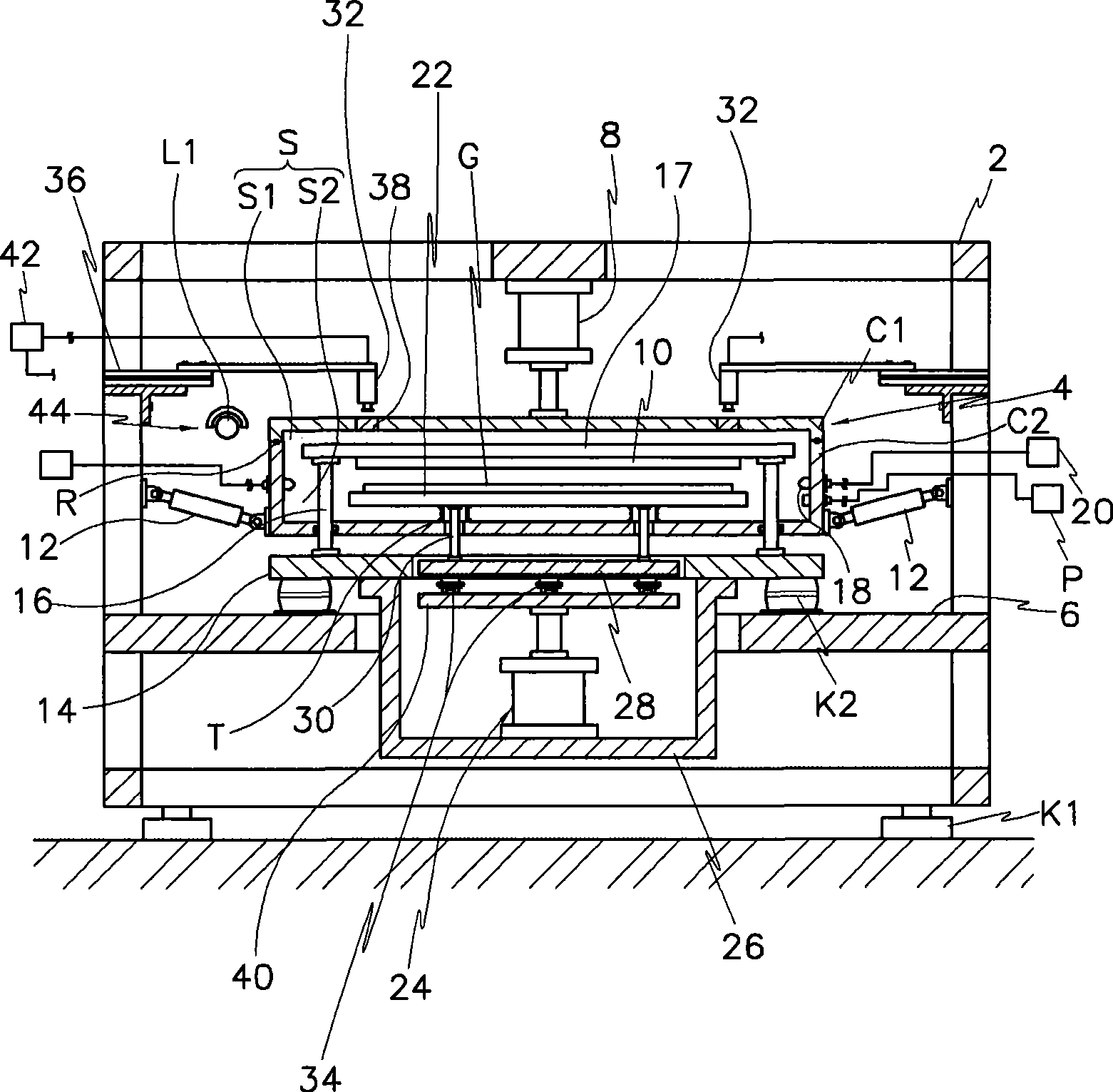

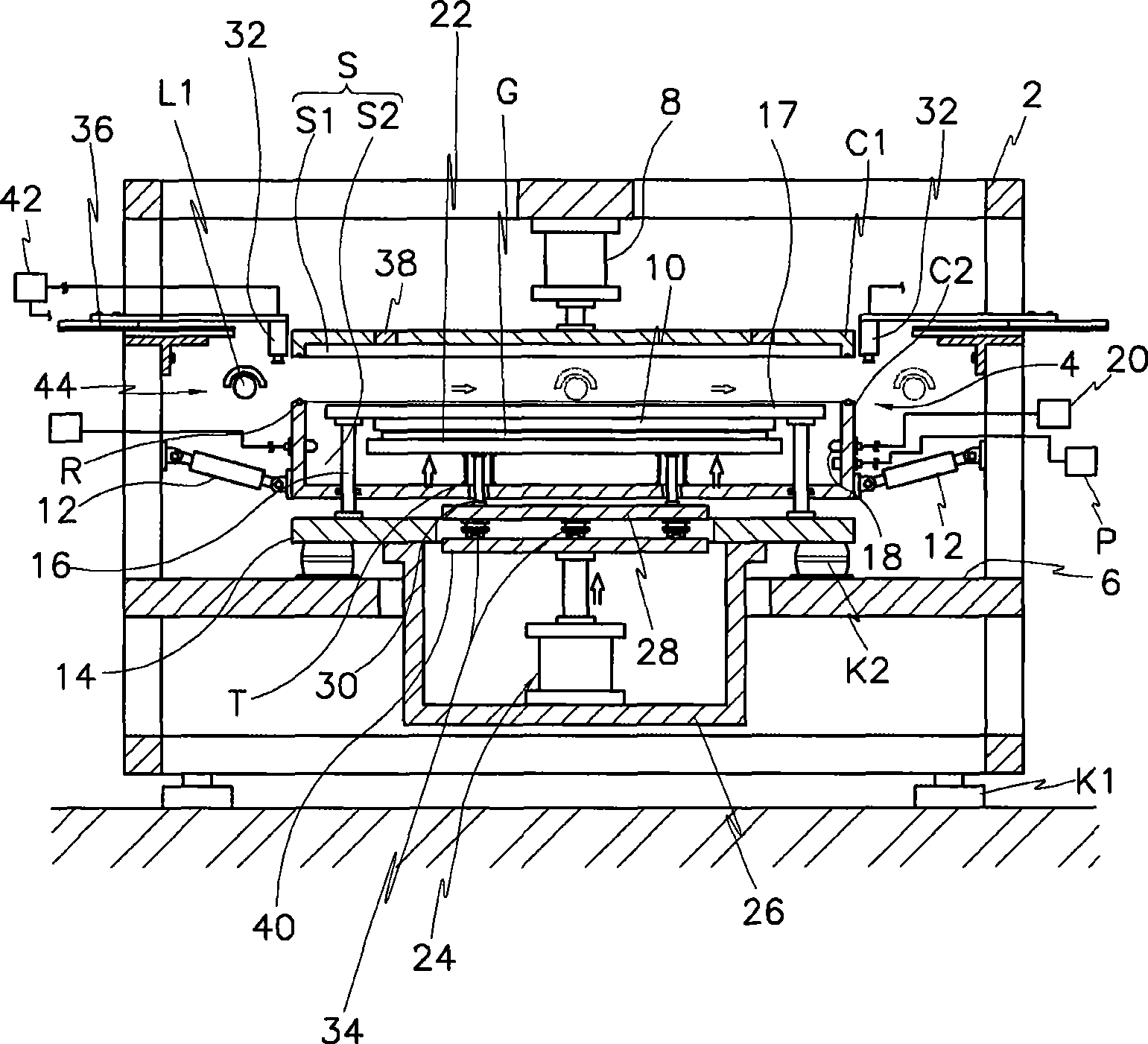

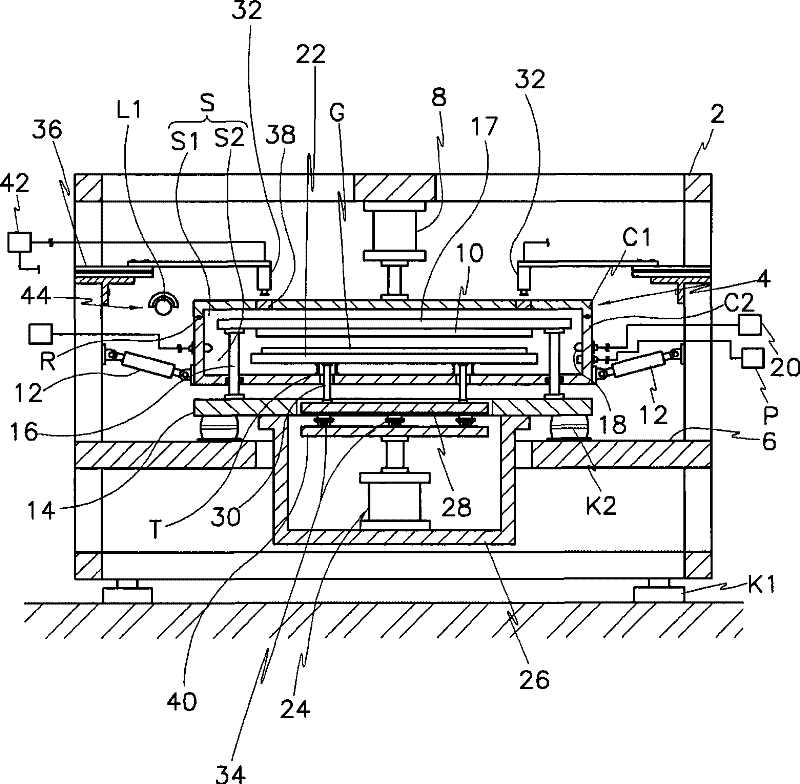

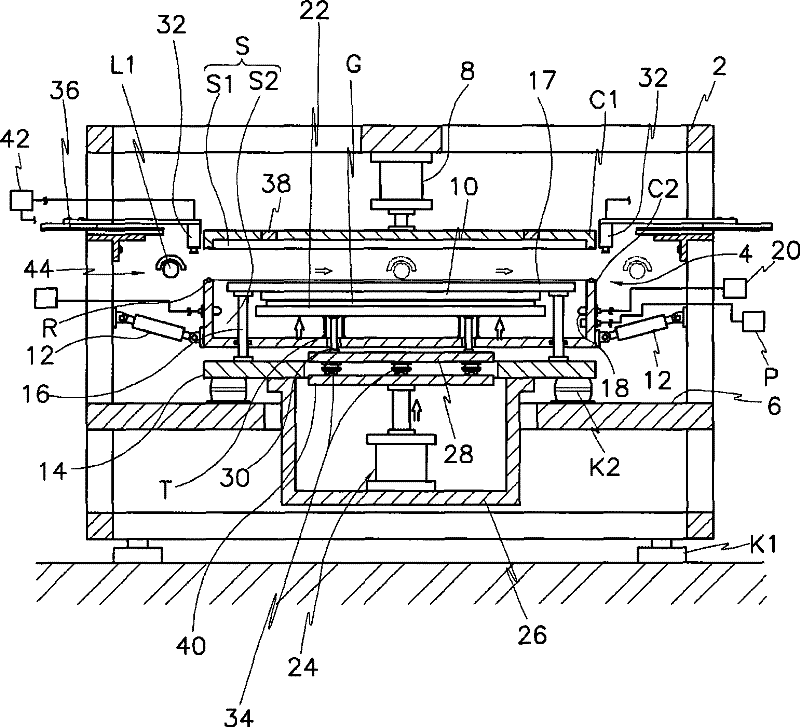

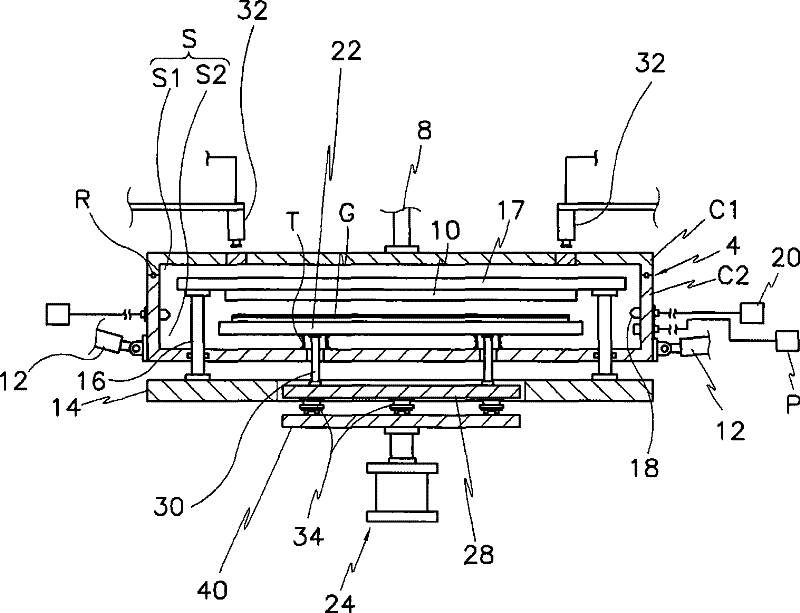

InactiveCN101398619ASmall sizeEasy to load and unloadPhotomechanical apparatusSemiconductor/solid-state device manufacturingFlat panel displayClosed space

The present invention discloses an impression device which can form an etching area and a non-etching area on a substrate used by flat panel display element with a simple mode. The device comprises the following components: a frame; a chamber which is provided with a first chamber casing and a second chamber casing that are set one an upper position and a lower position on the frame and form an openable closing space through combining operation or separation operation; a soft mould which is provided with a pattern surface that is used for differentiating the etching area and non-etching area and is positioned in the closed space of chamber; an objective table which is provided with a loading surface that is used for loading the substrate and moves up-and-down relatively to the soft mould in the closed space of chamber; and a hardening mechanism which moves from one side to the other side of objective table and simultaneously irradiates ultraviolet.

Owner:WEIHAI DMS OPTICAL ELECTROMECHANICAL CO LTD

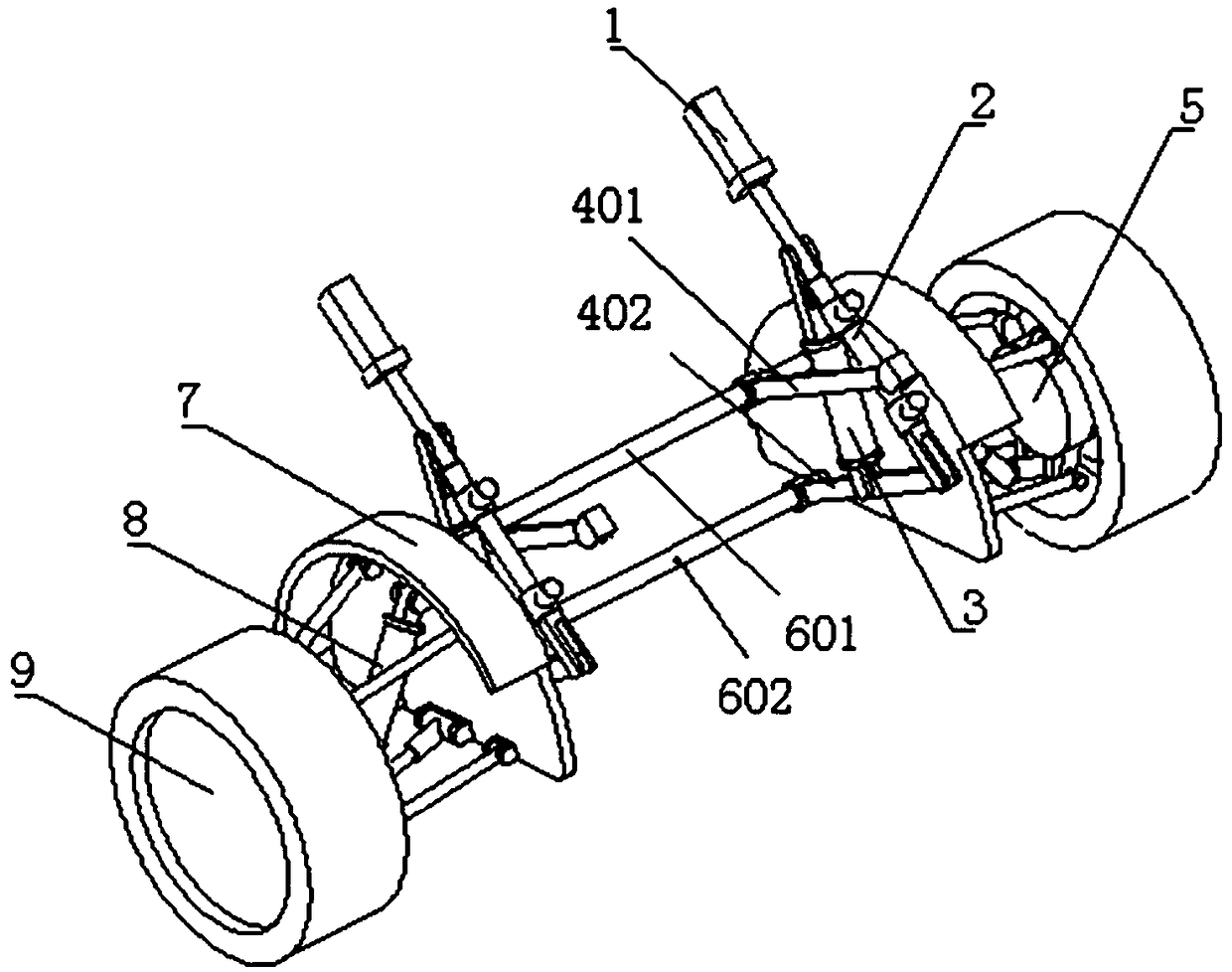

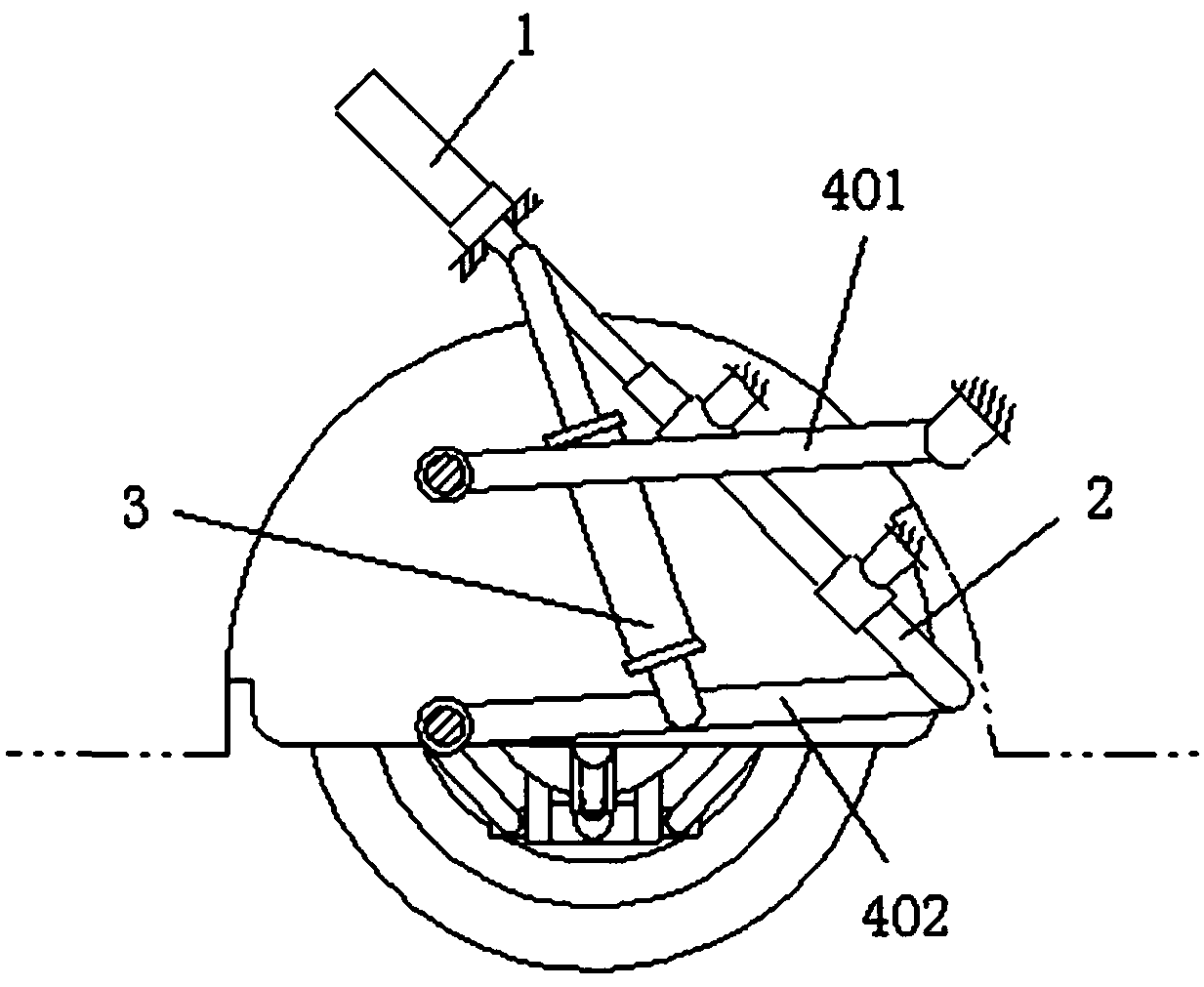

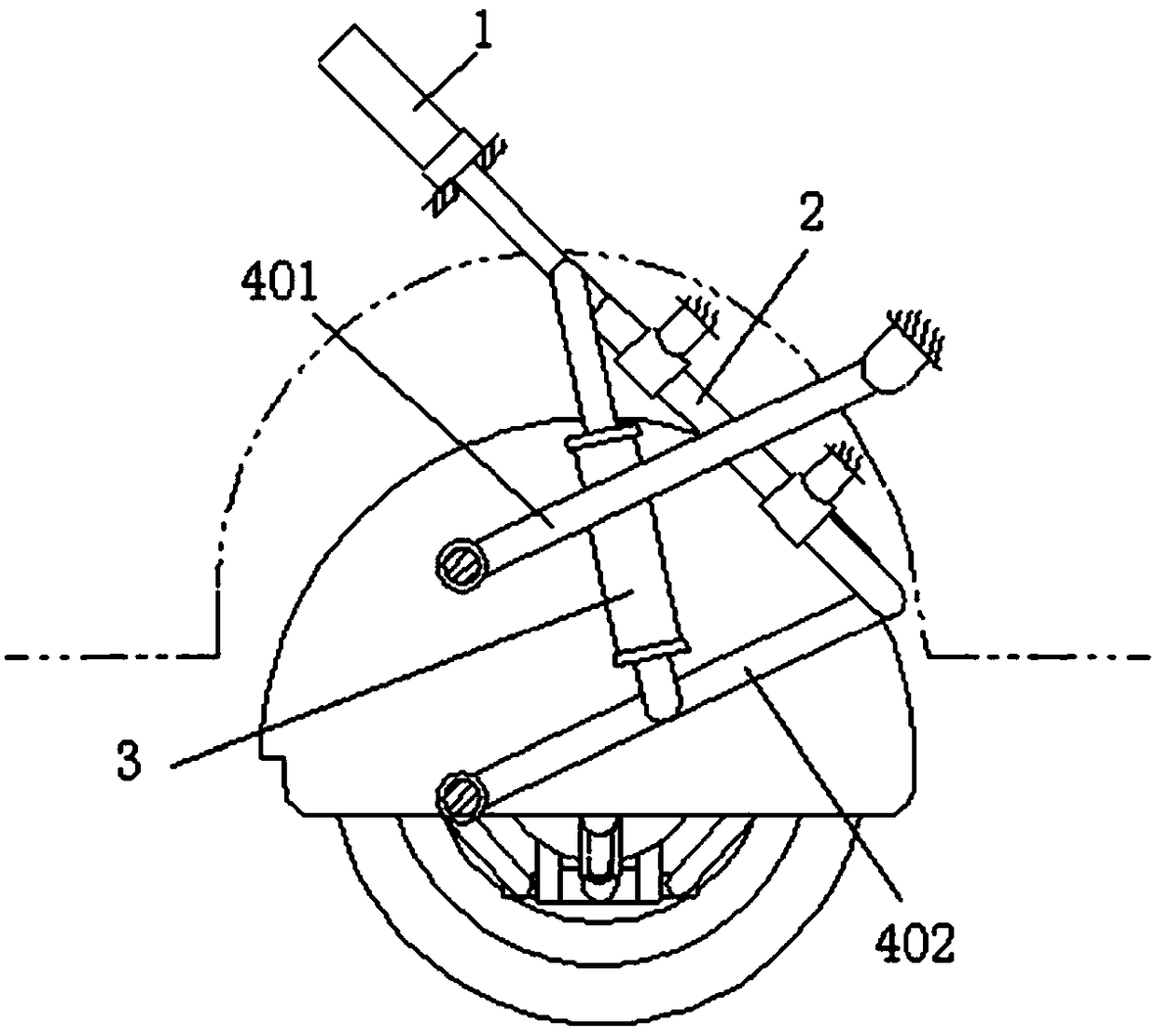

Damping device for aerocar and operation method thereof

ActiveCN109353177APut down smoothlySmooth recoveryInterconnection systemsResilient suspensionsHydraulic cylinderVehicle frame

The invention discloses a damping device for an aerocar and an operation method thereof. The damping device comprises independent suspensions, joint parts, a beam and secondary suspensions; the innersides of the two joint parts are fixedly arranged at the two ends of the beam respectively; each independent suspension comprises a first damper and a plurality of connecting rods; each secondary suspension comprises a hydraulic cylinder, a fixed arm, a second damper and a longitudinal arm; cylinder bodies of the hydraulic cylinders and the fixed arms are fixedly connected with a car frame of theaerocar; extending ends of pushing rods of the hydraulic cylinders are slidingly arranged in sliding rails of the fixed arms; one end of an upper longitudinal arm body is hinged onto the car frame ofthe aerocar, and the other end of the upper longitudinal arm body is hinged onto an upper beam body; one end of a lower longitudinal arm body is hinged to the lower end of the fixed arm, and the otherend of the lower longitudinal arm body is hinged onto a lower beam body. By means of the damping device for the aerocar and the operation method thereof, the damping requirement of normal car drivingof the aerocar can be met, and the impacting damping requirement when the aerocar is landed can also be met.

Owner:CHANGAN UNIV

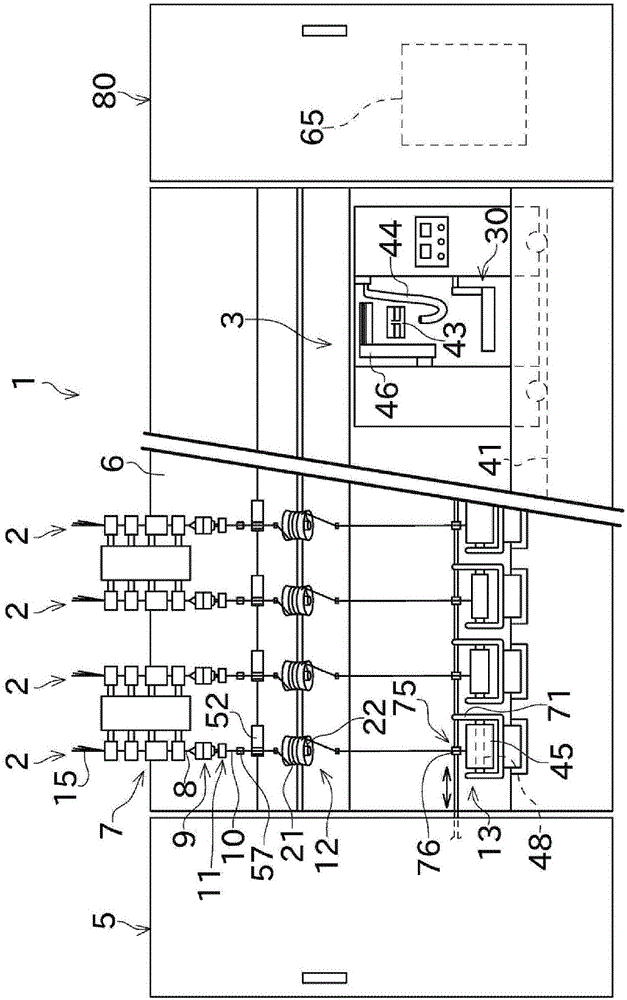

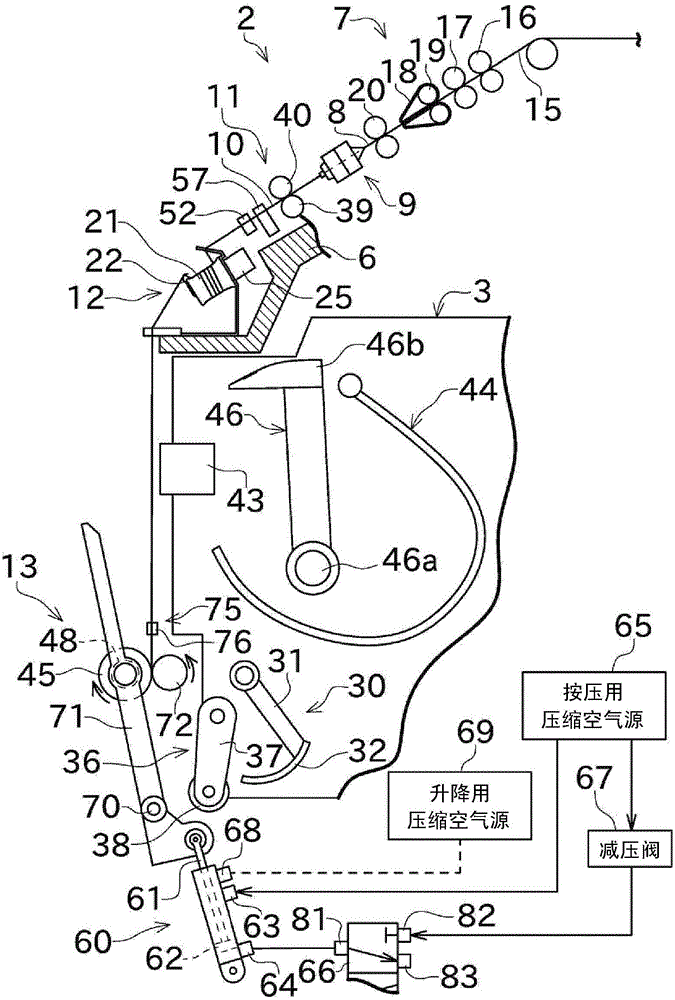

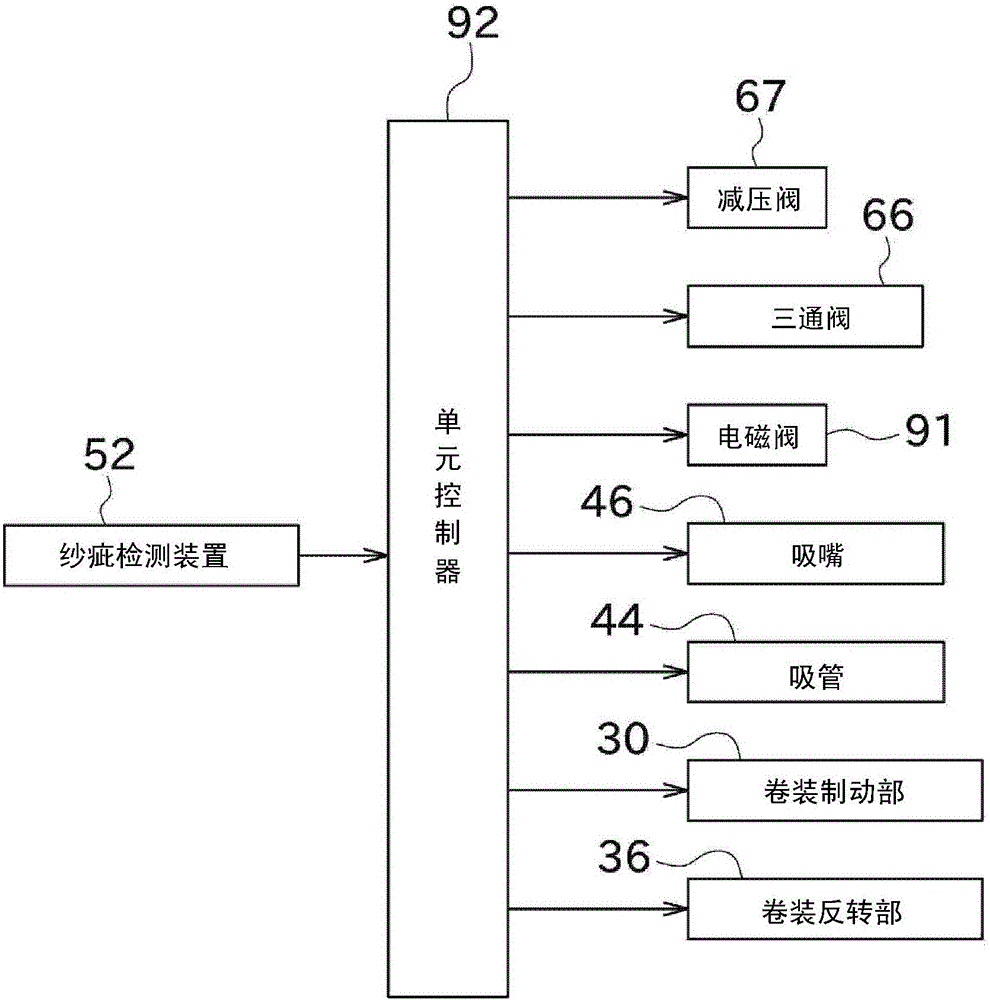

Textile machine

An object is to surely catch a yarn end of a package (45) when performing yarn joining and the like. A suction mouth (46) catches a yarn end of a package (45), a cradle arm (71) rotatably and movably supports the package so as to be movable in a separating direction, and an air cylinder (60) drives the cradle arm to move the package in the separating direction. A unit controller (92) controls, after causing the suction mouth to contact the surface of the package, the air cylinder to move the package in the separating direction. The unit controller provides a control so that the suction mouth catches the yarn end in the state in which the surface of the package and the suction mouth are separated from each other.

Owner:MURATA MASCH LTD

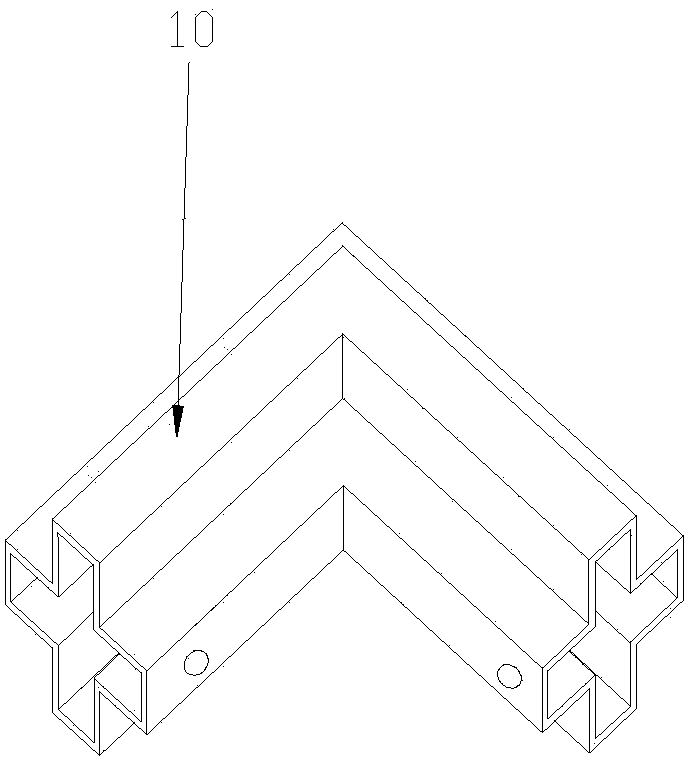

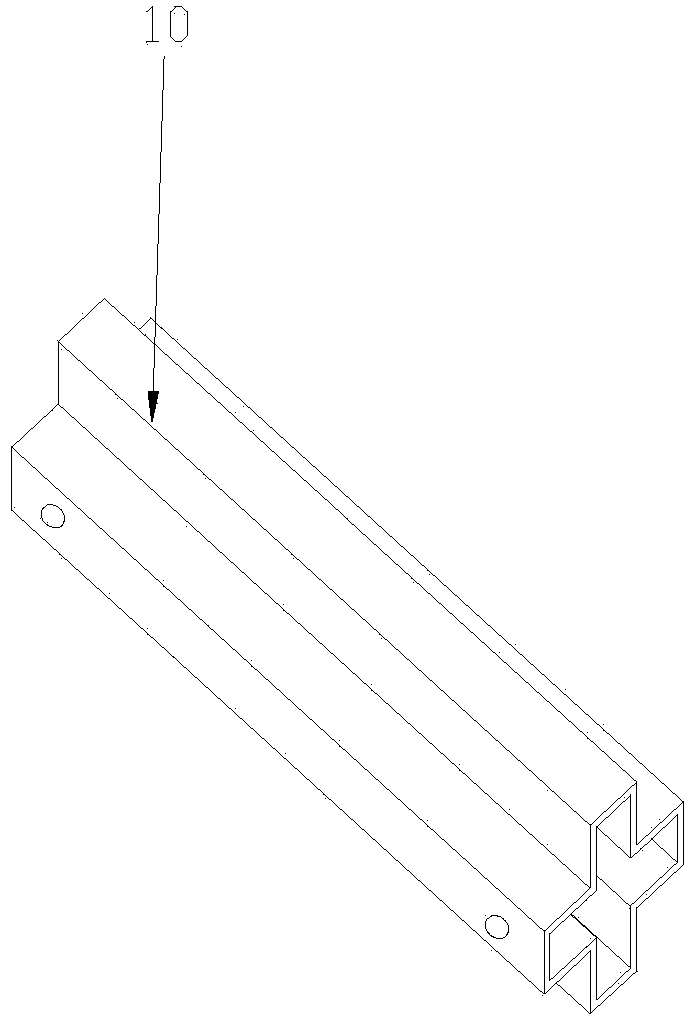

Connective building material and combined part used therewith

ActiveCN104251248AFirm standing supportStand firmCeilingsElongated constructional elementsGusset plateLap joint

The invention relates to connective building material comprising at least one protruding tube. The outer end of each protruding tube is provided with a hollow hole; the longitudinal section of the hollow hole is cross shaped. Each protruding tube comprises an upper protrusion, a left protrusion, a right protrusion and a lower protrusion. Two sides of each upper protrusion are connected with one side of the corresponding left protrusion and one side of the corresponding right protrusion, respectively. Two sides of each protrusion are connected with the other side of the corresponding left protrusion and the other side of the corresponding right protrusion, respectively. A first lap joint position is formed between each upper protrusion and the corresponding left protrusion; a second lap joint position is formed between each upper protrusion and the corresponding the right protrusion; a third lap joint position is formed between each lower protrusion and the corresponding left protrusion; a fourth lap joint position is formed between each lower protrusion and the corresponding right protrusion. The connective building material is applicable to mesh ceilings, and field installation time is greatly shortened. The connective material is also applicable to wardrobes, assembly is facilitated, support layers can be fastened via gusset plates, and greater weight can be supported. The connective building material is applicable to assembled desks, and the assembled desks can be quickly assembled. The connective building material is also applicable to partition walls, and a room can be quickly partitioned.

Owner:PUTIAN COURTYARD CULTURE MEDIA

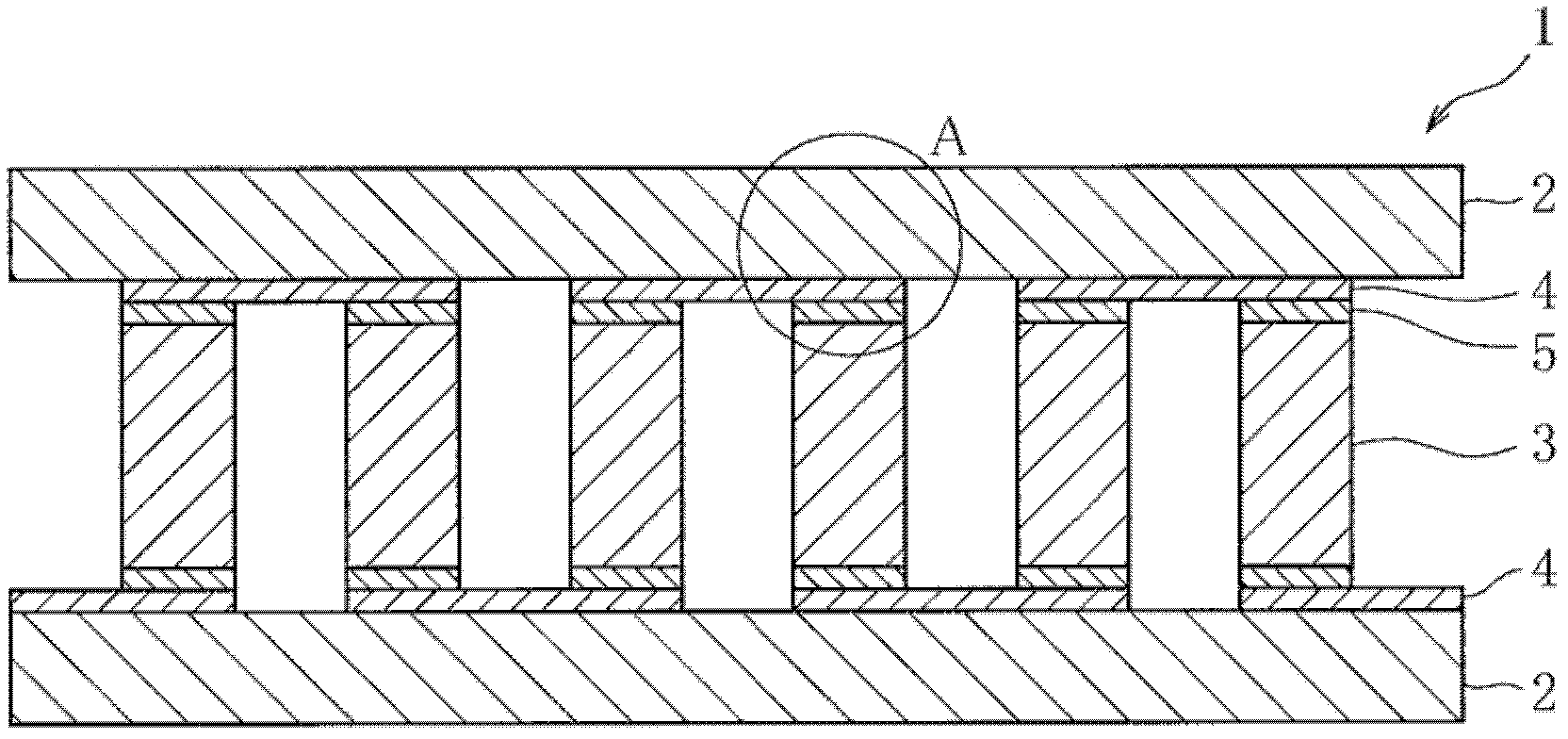

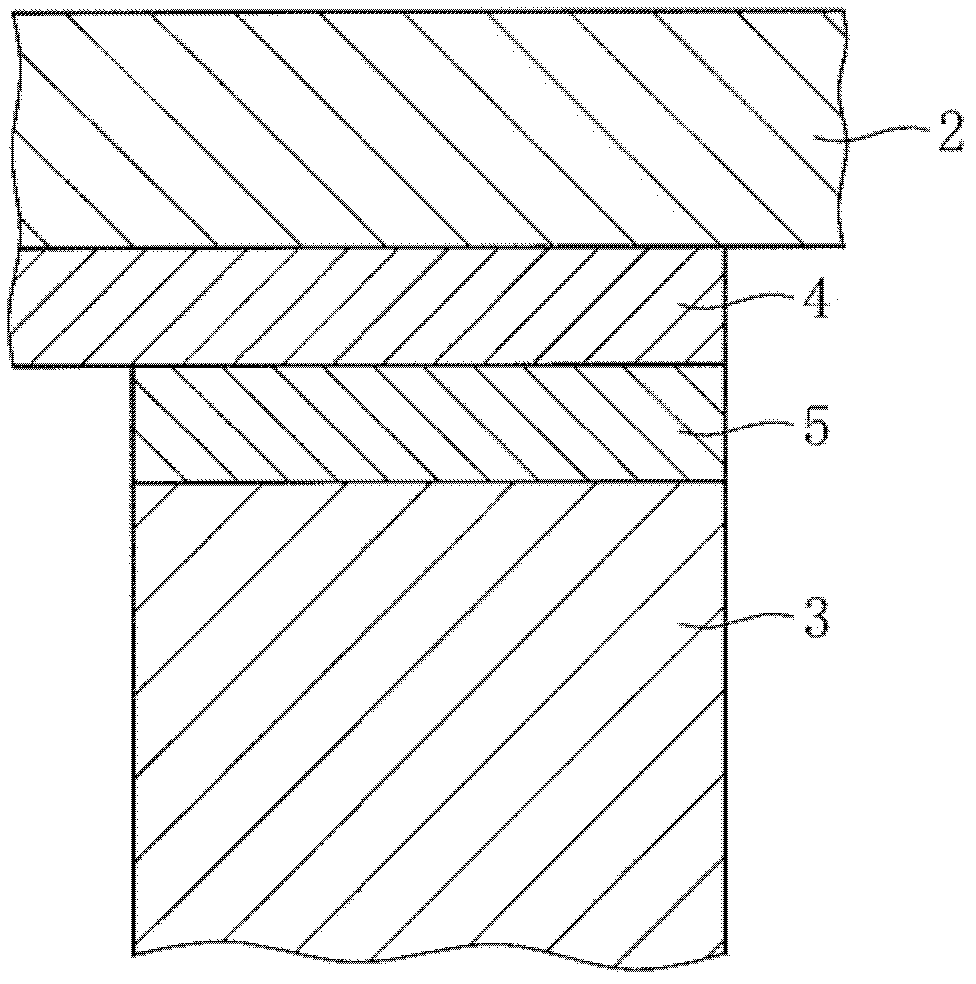

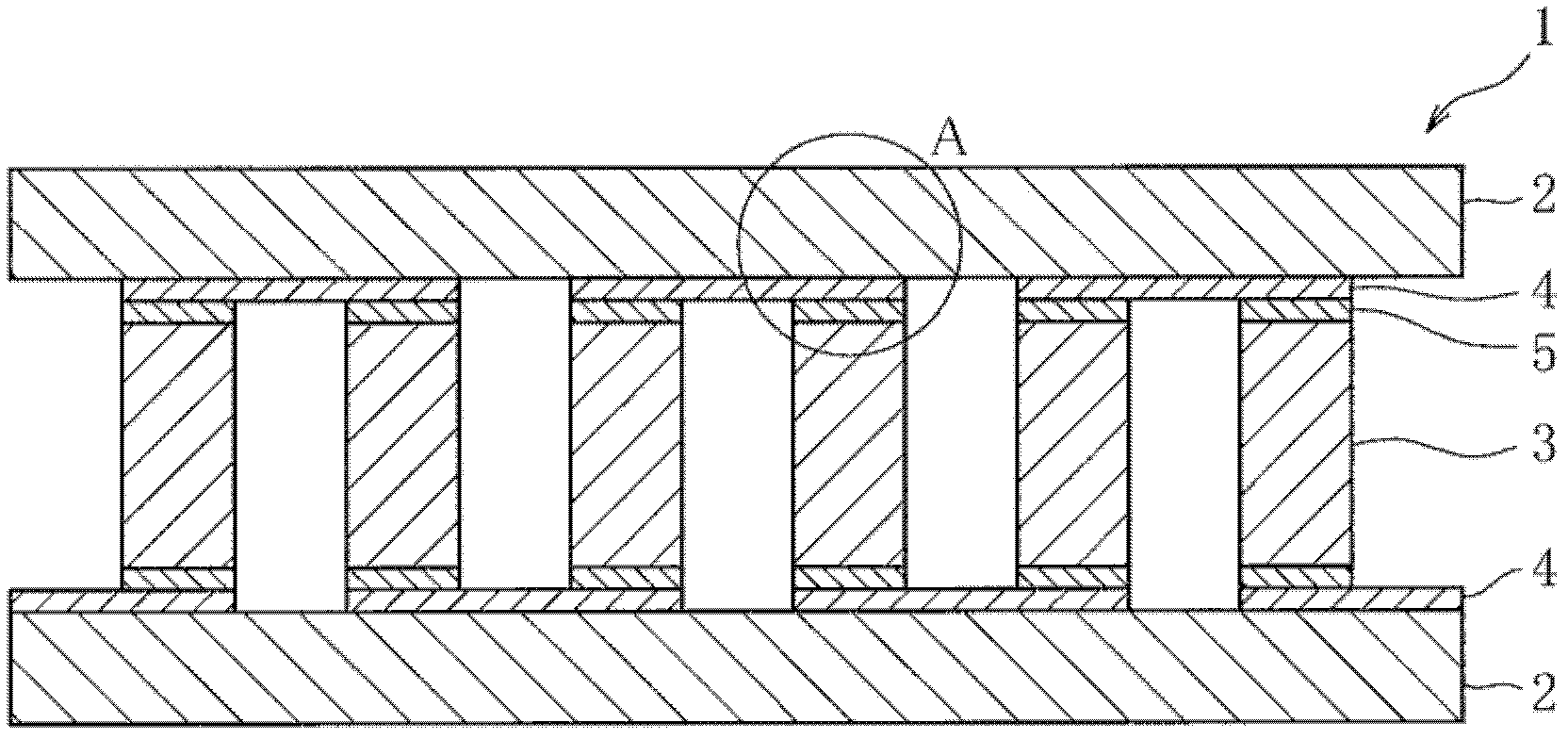

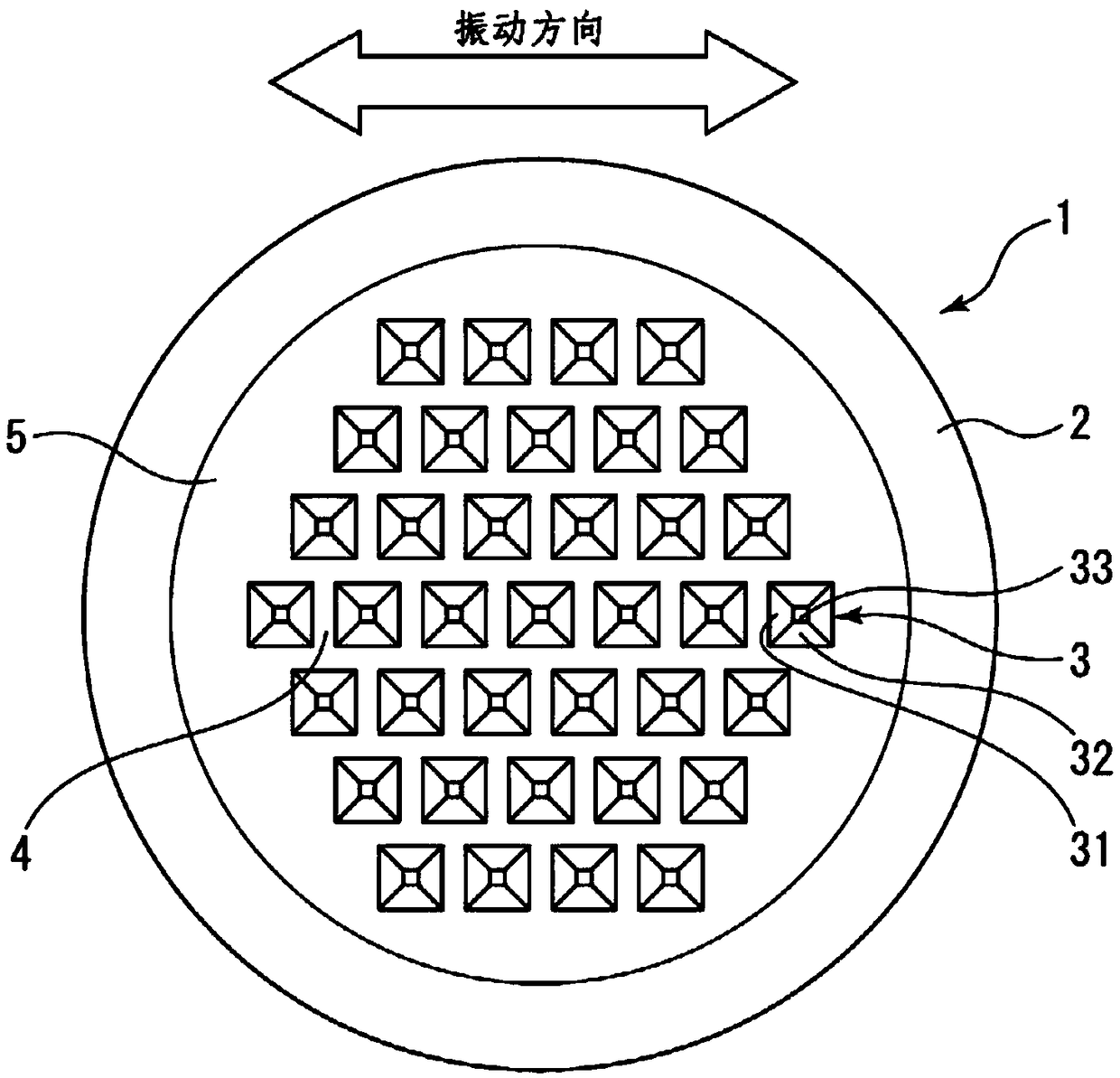

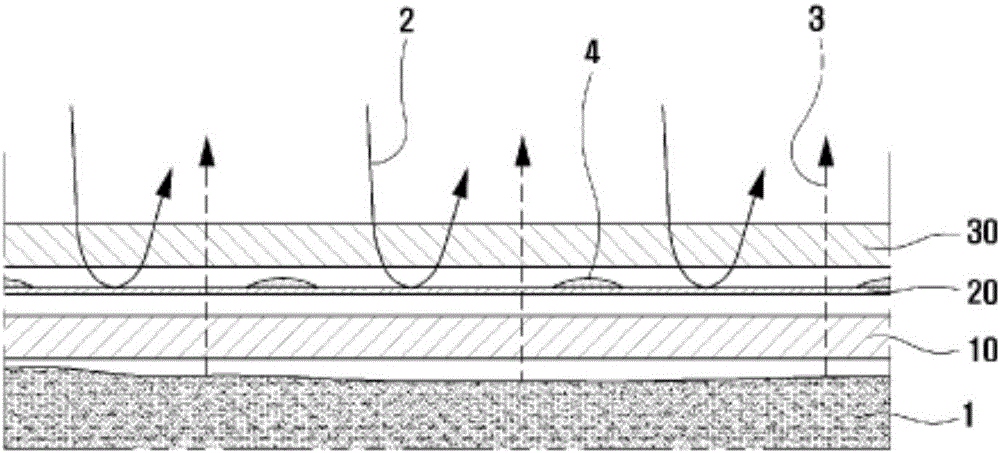

Method of producing thermoelectric conversion device

InactiveCN102422448AManufacturing without hindranceJoint smoothThermoelectric device manufacture/treatmentElectrostatic generators/motorsOptoelectronicsMetal powder

A method of producing a thermoelectric conversion device, provided with: a step of disposing electrodes (4) respectively to opposing surfaces of a pair of current-pressure applying members (2) which face each other; a step of interposing a plurality of members of thermoelectric conversion material (3) between the electrodes (4); and a step of bonding the electrodes (4) to the thermoelectric conversion material (3) by applying pressure to the electrodes (4) and thermoelectric conversion material (3) with the current-pressure applying member (2) while applying current to the electrodes (4) and the thermoelectric conversion material (3). The method of producing a thermoelectric conversion device is further provided with a step of forming intermediate layers (5), which include conductive metal powder and have plasticity, between the electrodes (4) and the thermoelectric conversion material (3).

Owner:ATSUMITEC CO LTD +1

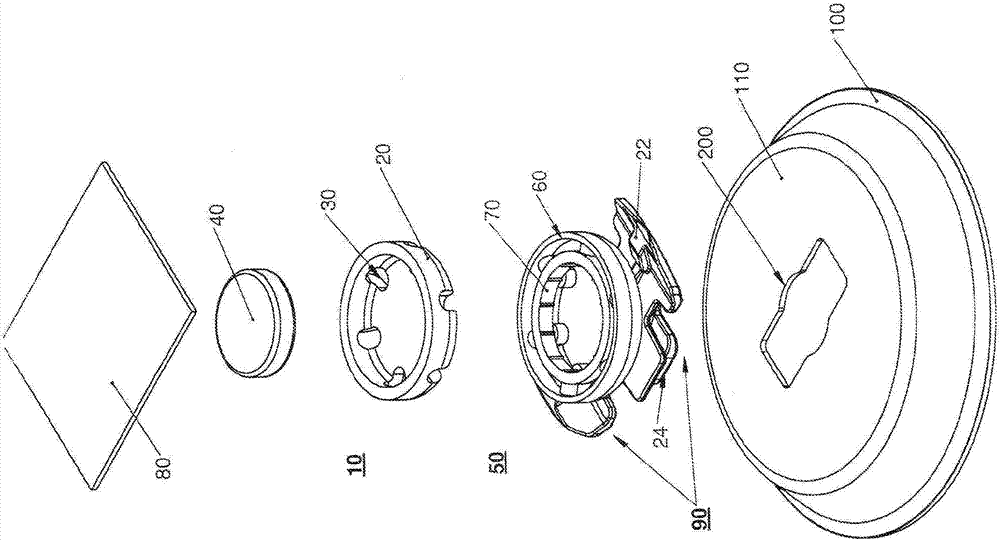

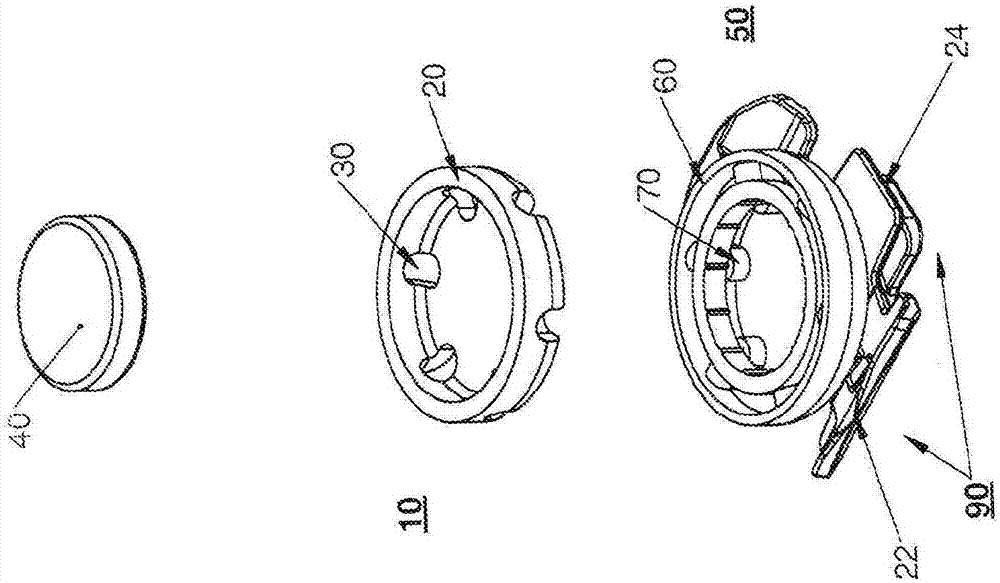

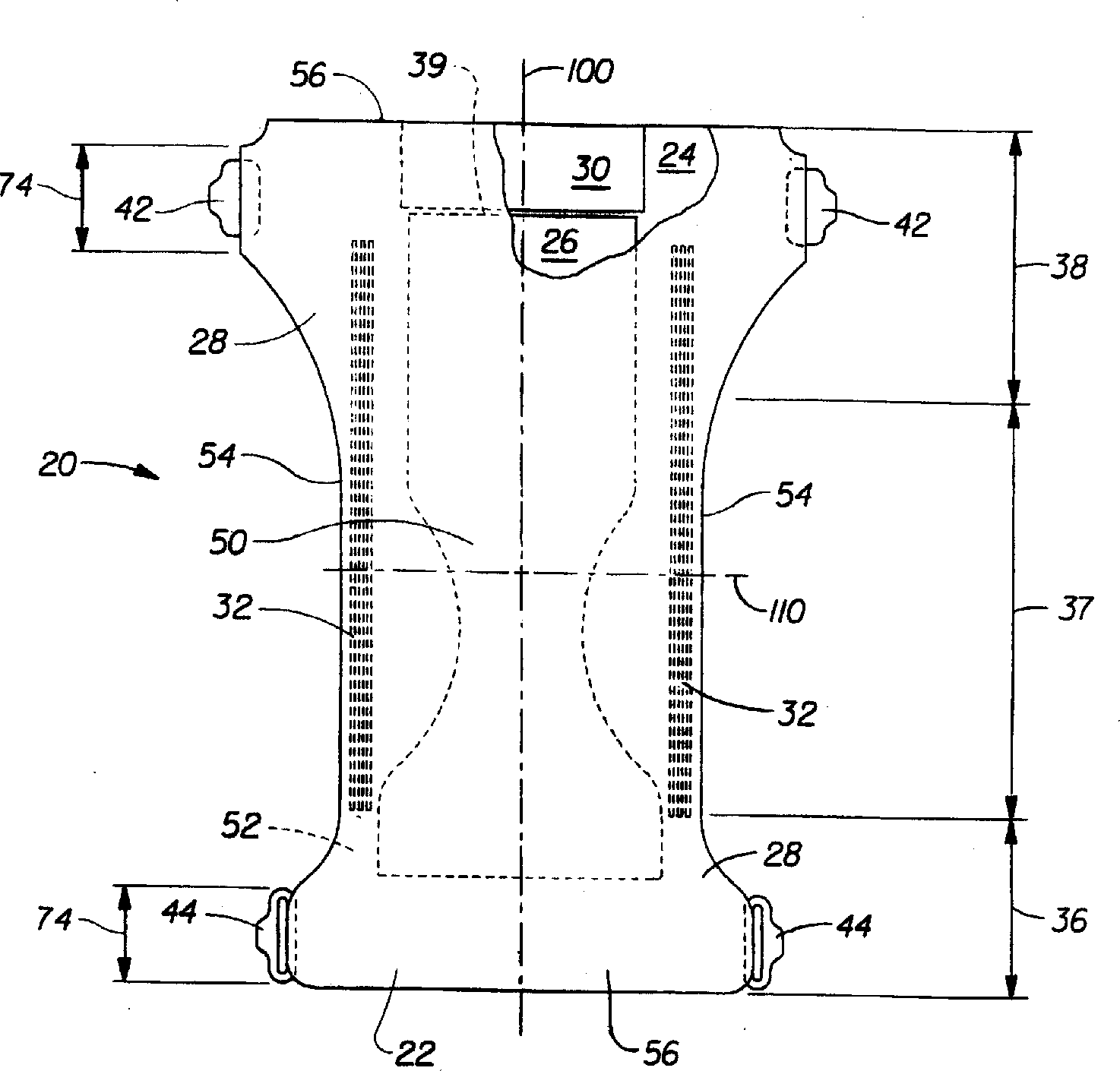

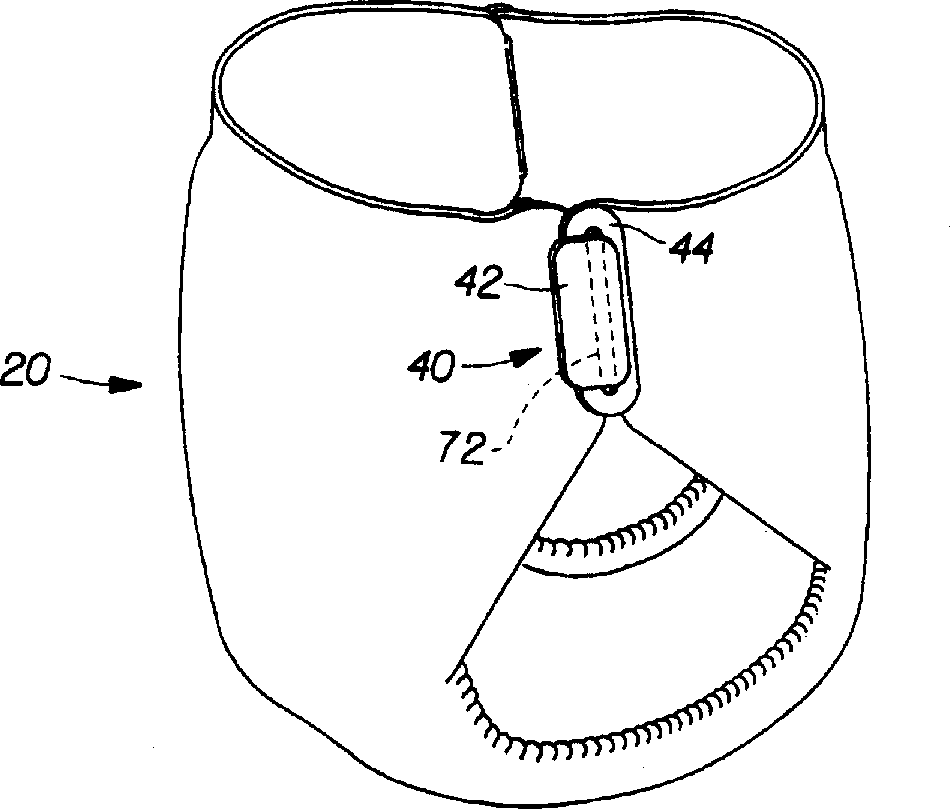

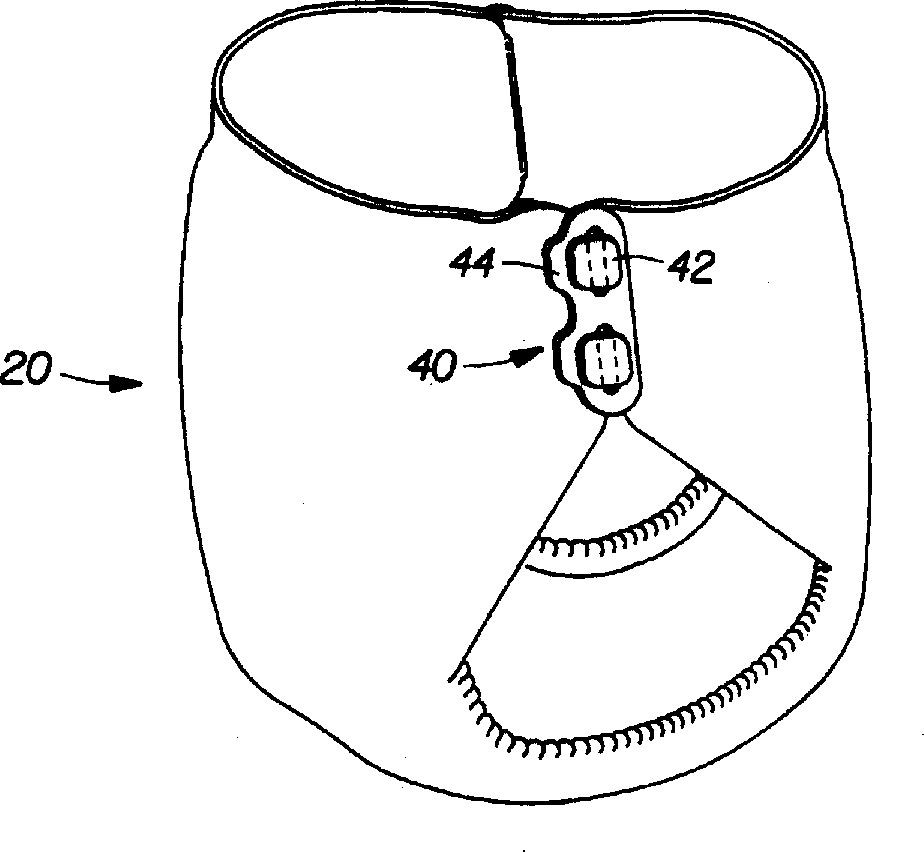

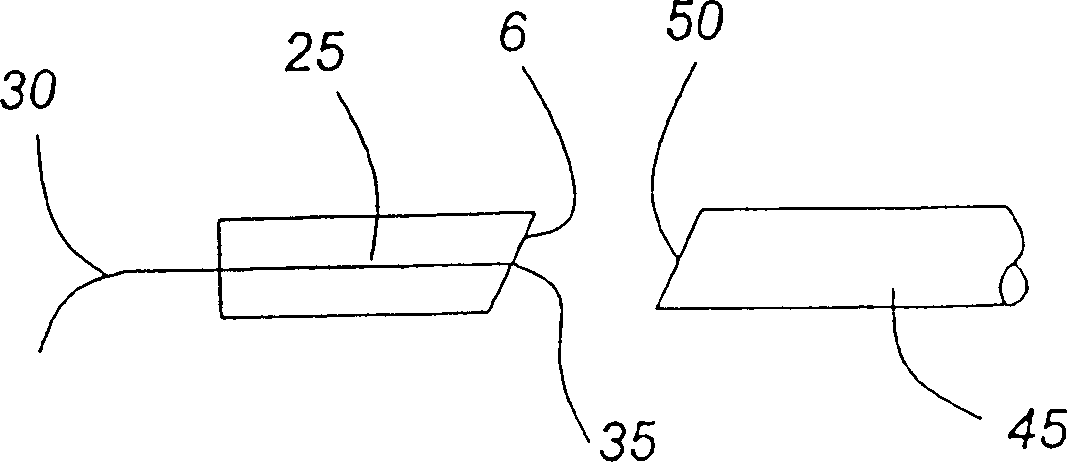

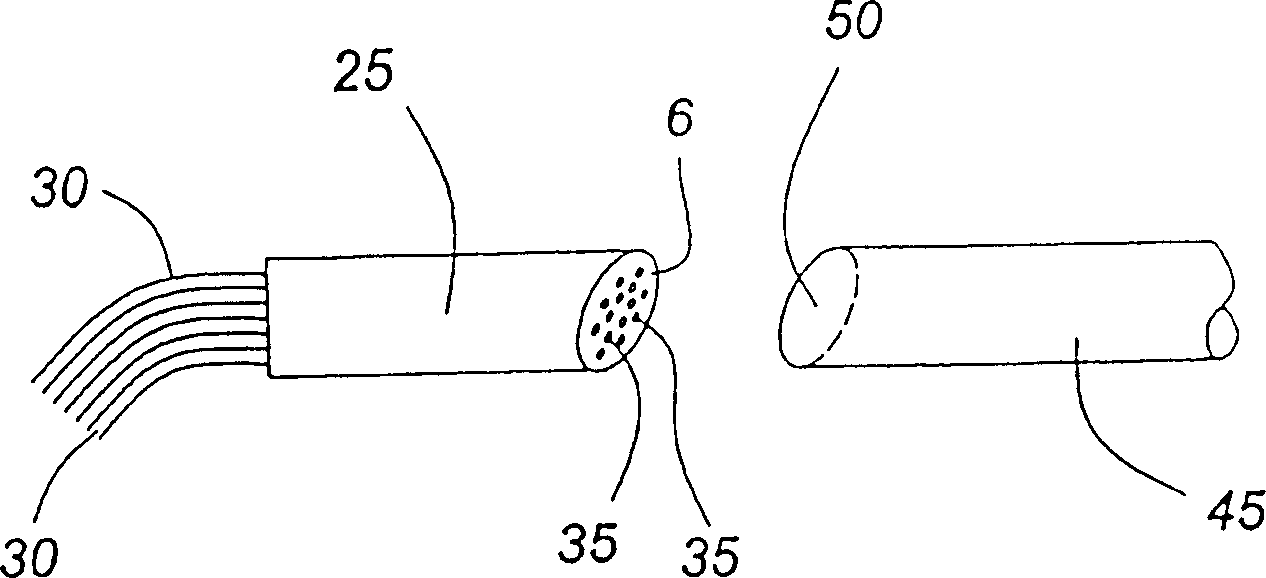

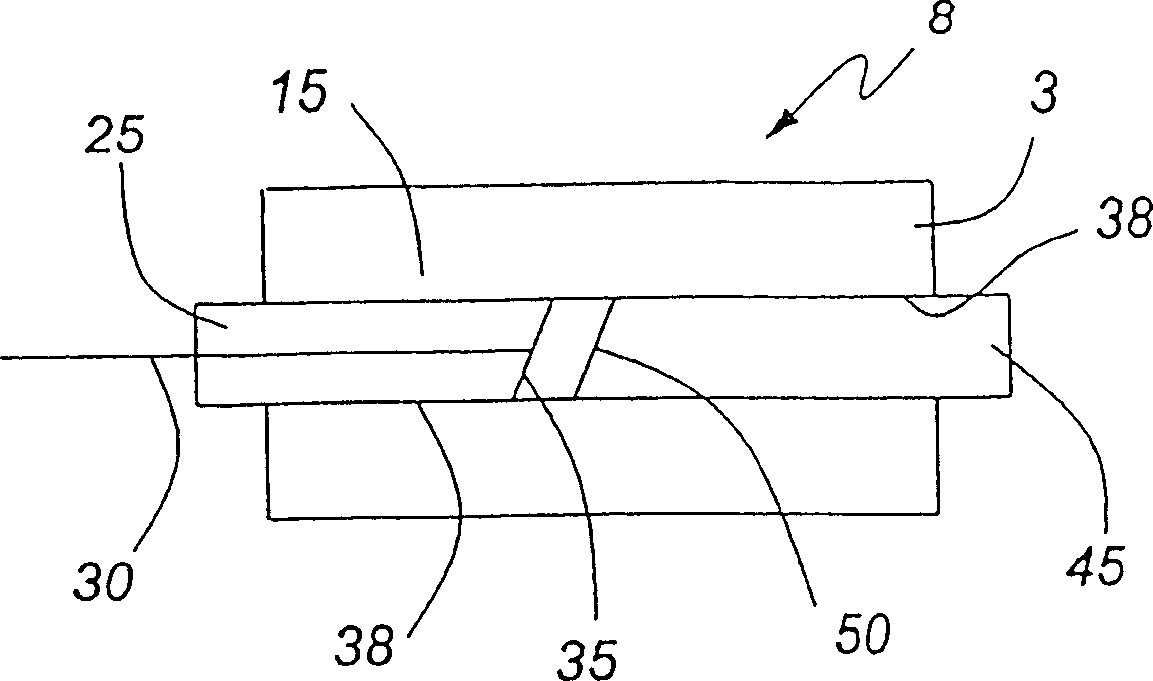

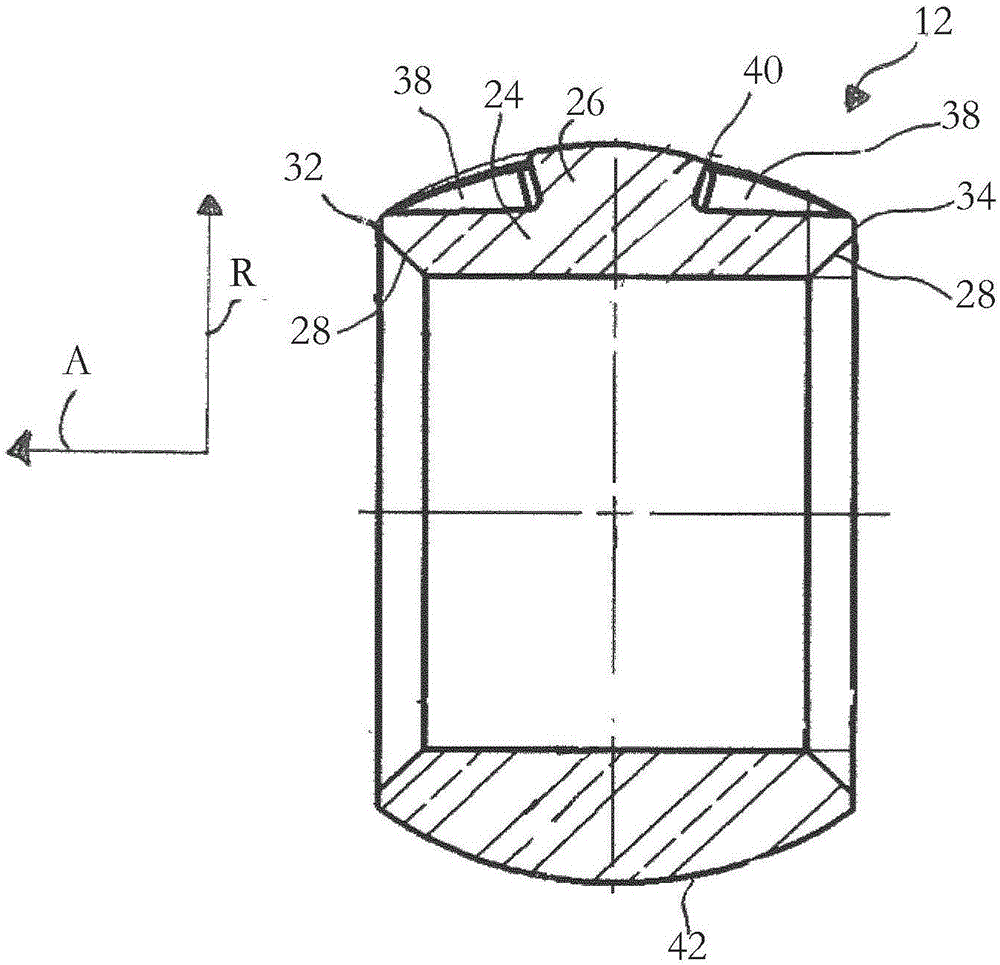

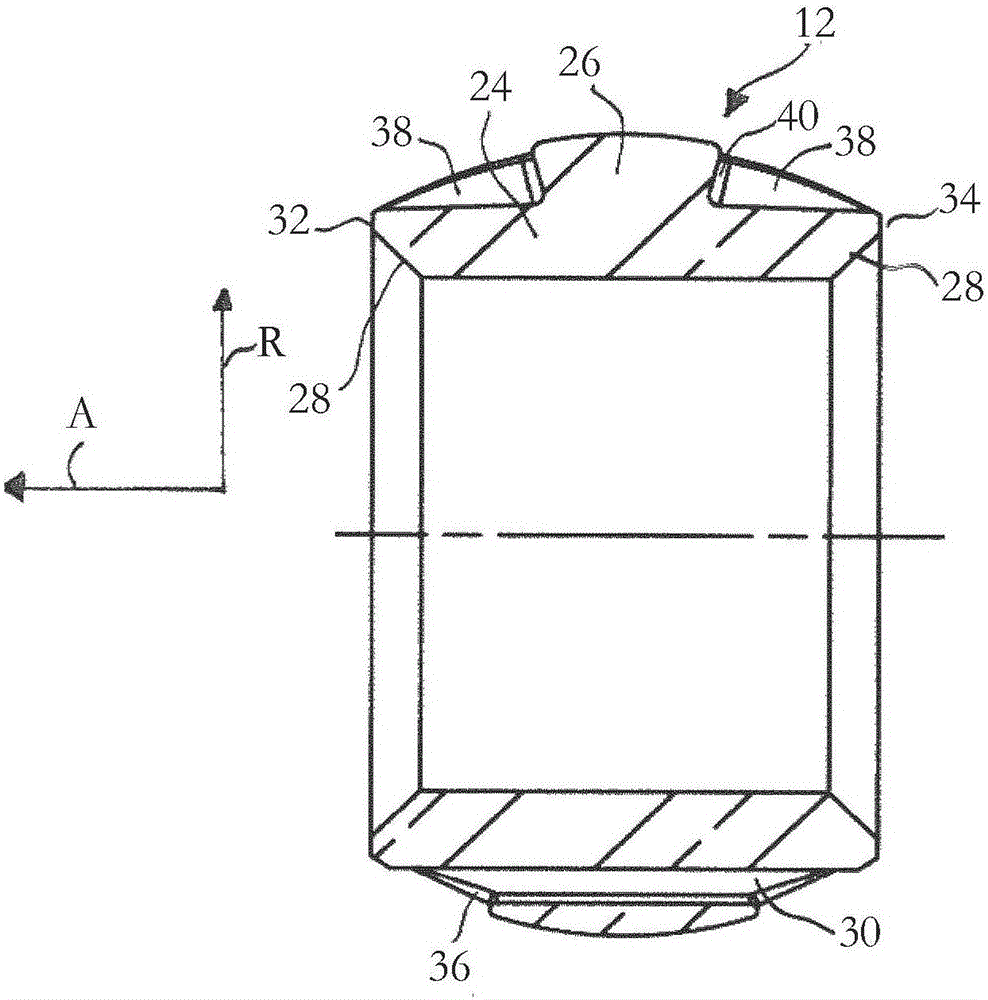

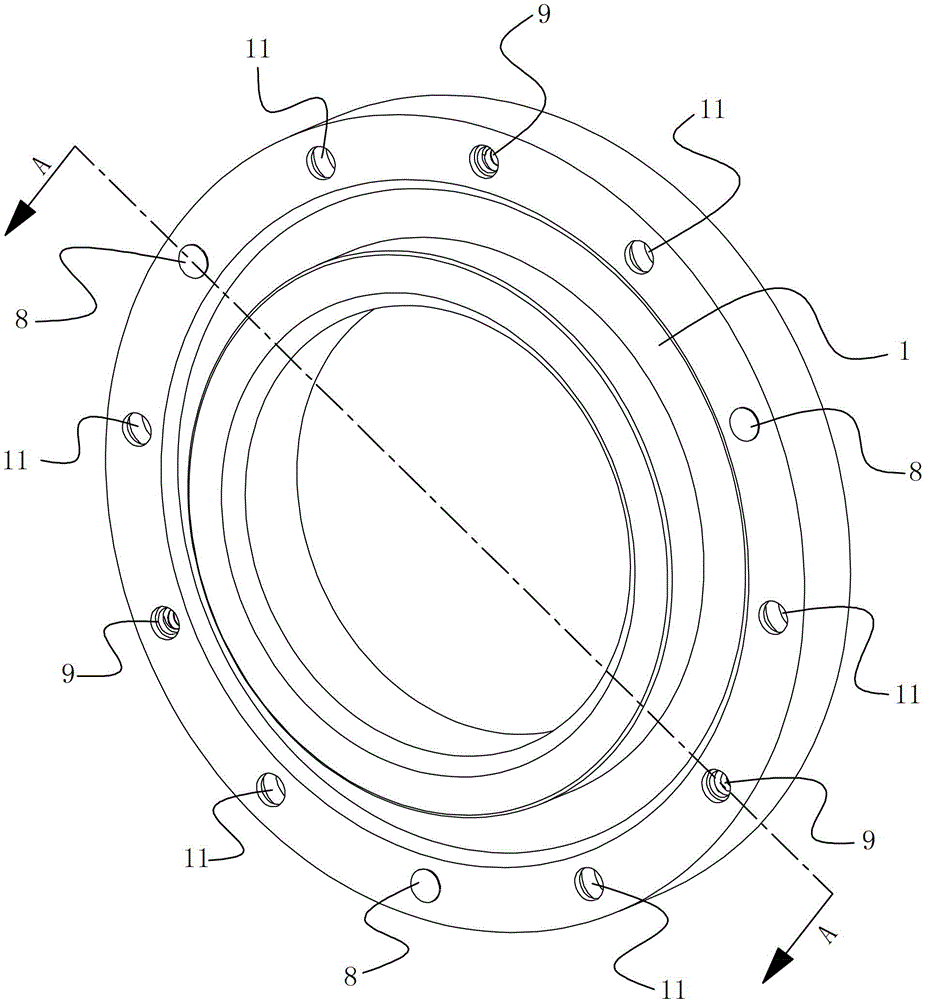

Absorbent article fastening device

Owner:THE PROCTER & GAMBLE COMPANY

Waterproof and dustproof quick plug and working method thereof

ActiveCN107240792ARealize automatic plugging and unpluggingPrevent inflowCoupling device engaging/disengagingCouplings bases/casesSeparated stateControl line

The present invention discloses a waterproof and dustproof quick plug and a working method thereof. The waterproof and dustproof quick plug comprises a female joint and a male joint. The female joint is arranged on a quick replacement tray. The male joint is arranged on a quick replacement chuck. The female joint is provided with a copper contact head. The male joint is provided with a probe matched with the copper contact head. The copper contact head and the probe are respectively connected with a control line and are sealed by silica gel. Due to the arrangement of the quick replacement tray and the quick replacement chuck, the automatic plugging of the male joint and the female joint is realized. The quick replacement chuck is provided with a nozzle for cleaning the male joint and the female joint. Due to the arrangement of the quick replacement tray and the quick replacement chuck, the automatic plugging of the male joint and the female joint is realized. Meanwhile, the quick replacement chuck is provided with the nozzle for cleaning purpose. Therefore, the functions of automatic plugging, automatic switching-on and automatic switching-off are realized. Residual water stains on the surface of a mechanism are prevented from flowing into the plug, so that the plug is dustproof and waterproof in the separated state.

Owner:西安精雕精密机械工程有限公司

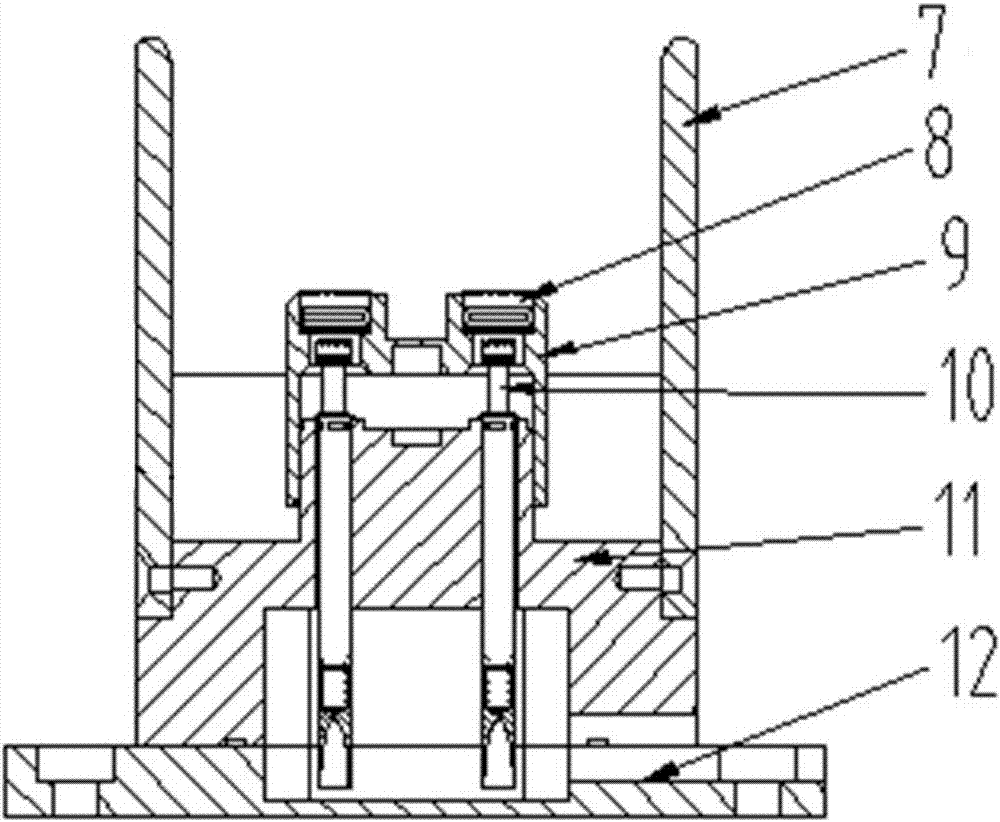

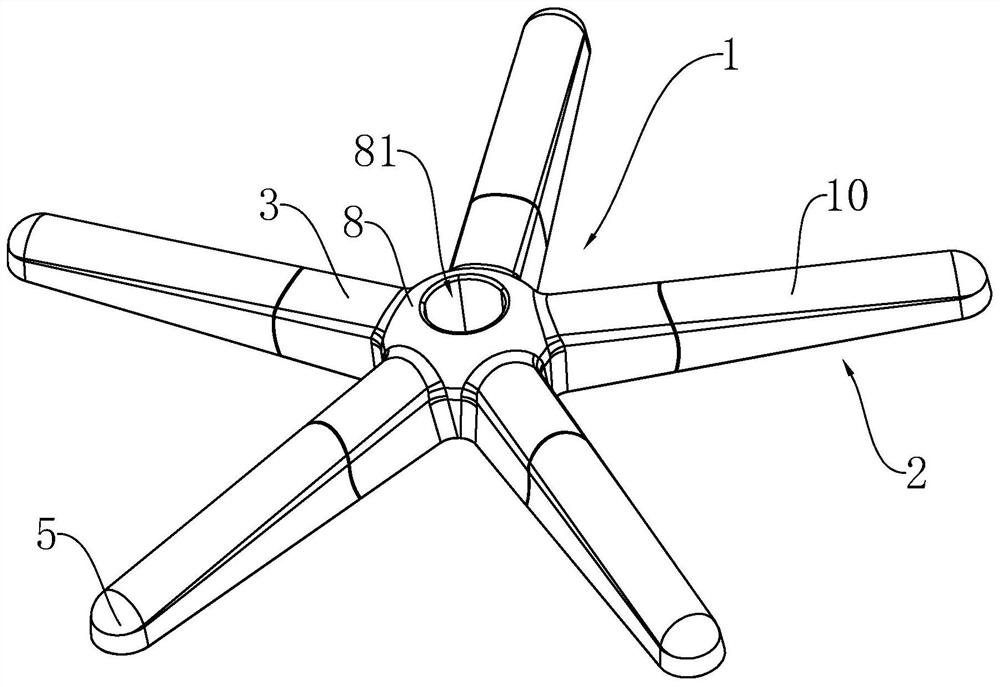

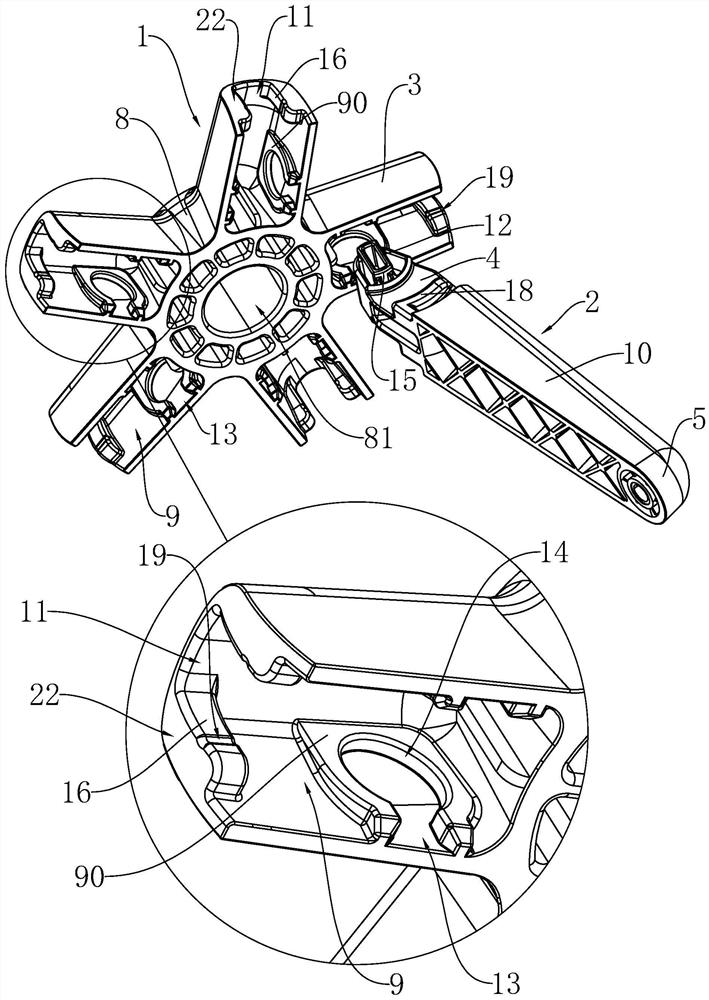

Detachable chair leg

PendingCN113116071ARealize disassemblyImprove applicabilityDismountable chairsFoldable chairsPhysical medicine and rehabilitationMedicine

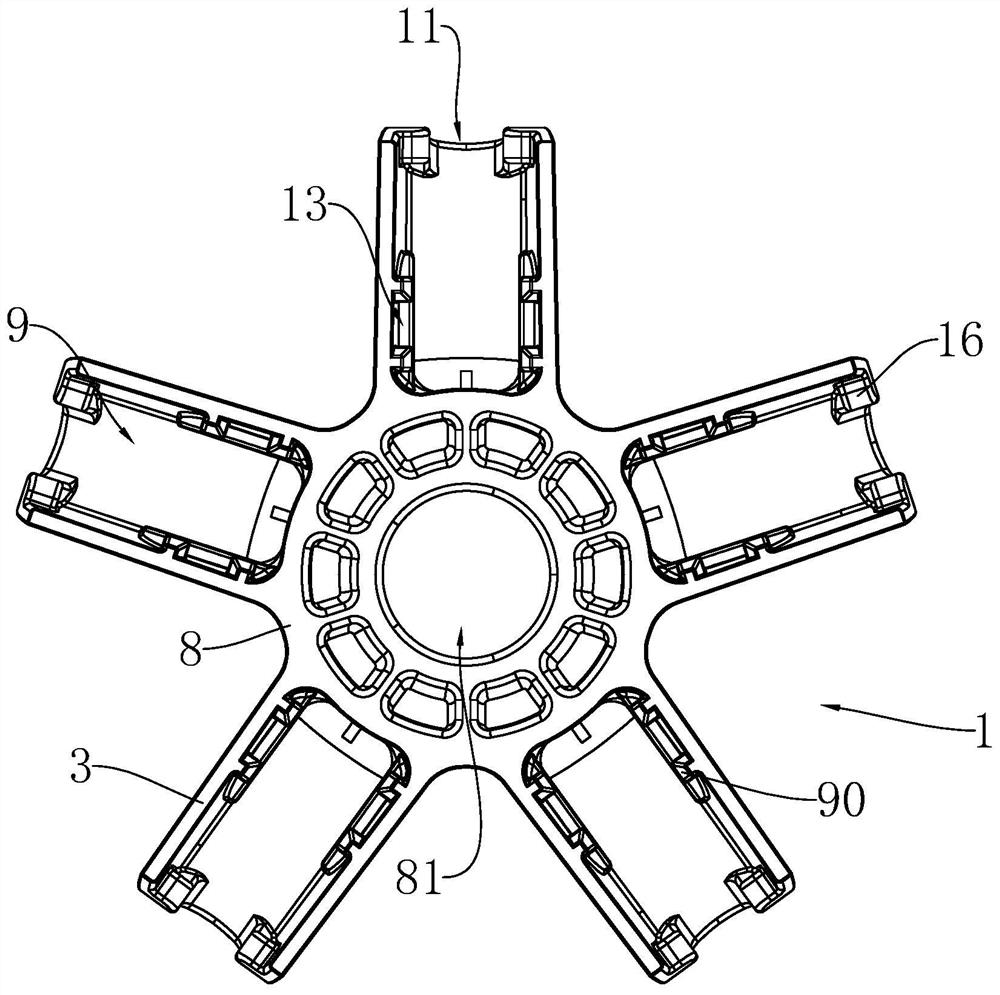

The invention discloses a detachable chair leg which comprises a connecting seat and a plurality of supporting legs radially arranged on the connecting seat, and the connecting seat comprises mounting parts uniformly arranged at intervals in the circumferential direction; each supporting leg comprises an access part located at the end; the access part is mounted in the mounting part, and the supporting legs are detachably connected to the connecting seat; an insertion rotating structure and a fixed limiting structure are arranged between the access part and the mounting part, and the insertion rotating structure is configured to enable the access part and the mounting part to be matched in an insertion manner and rotationally connected; the fixed limiting structure is configured to relatively fix the access part and the mounting part and prevent the access part and the mounting part from being separated; compared with the prior art, the connecting seatand the supporting leg are inserted through the insertion rotating structure and are in rotating fit, then the supporting leg is rotated till the fixing limiting structure enables the connecting seat and the supporting leg to be relatively fixed, and assembling is easy and convenient; the shape of the connecting seat is not limited, and the number of the supporting legs can be selected at will as long as the supporting legs are detachably connected with the connecting seat and the seat can be stably supported.

Owner:UE FURNITURE CO LTD

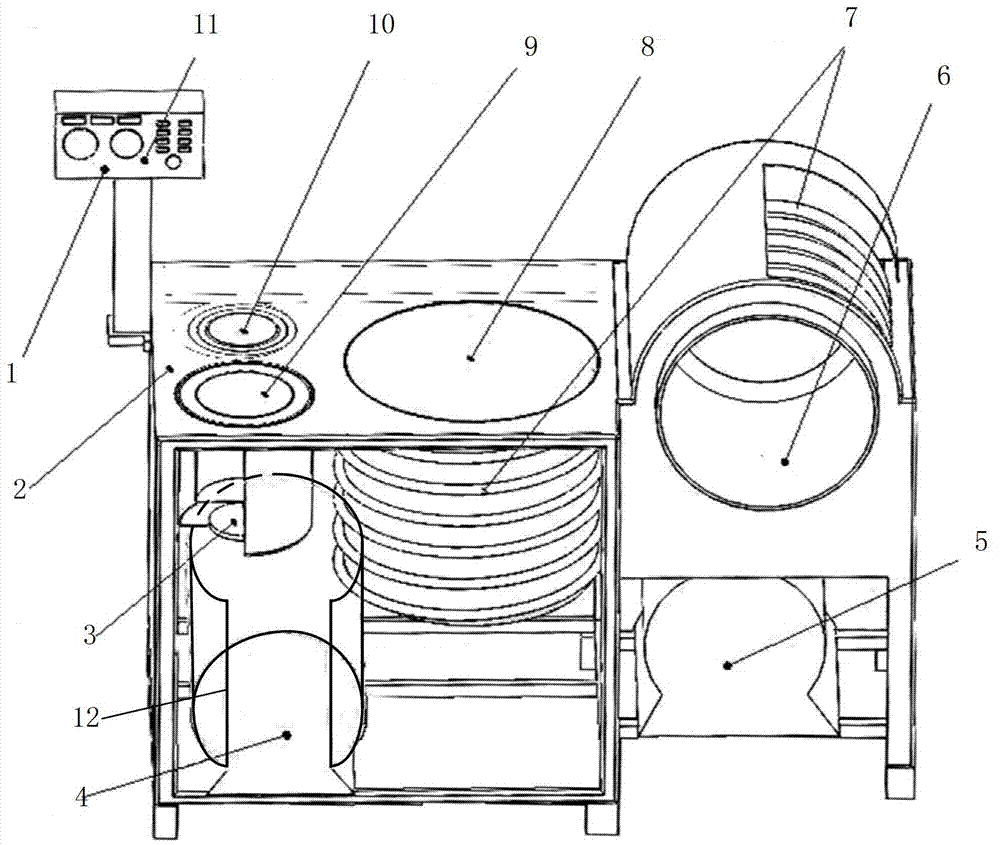

Production equipment of anti-infective bone graft material and preparation method

The invention discloses production equipment of an anti-infective bone graft material and a preparation method. The equipment comprises a bone grain preheating tank, a sol tank, a vacuum-pumping package tank, an ice water tank provided with a dispersing device, a rotary vacuum drying bin, a control panel, a vacuum pump and a refrigerating compressor region. According to the invention, gelatin antibiotics and active bones in either the appearances or the inner parts of products produced by the equipment and the process are jointed tightly and uniformly, and natural holes are filled with the gelatin antibiotics. The standardization of product production is realized, and mass production can be performed at a time so as to realize large-scale production of the products; bacteriostatic experiments in vitro and animal experiments prove that significant difference exists between the products produced by the method and the original products in the aspect of anti-infective properties; and the animal experiments and clinical applications prove that the bone repairing ability of the products produced by the new method is better than that of the products produced by the original method.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

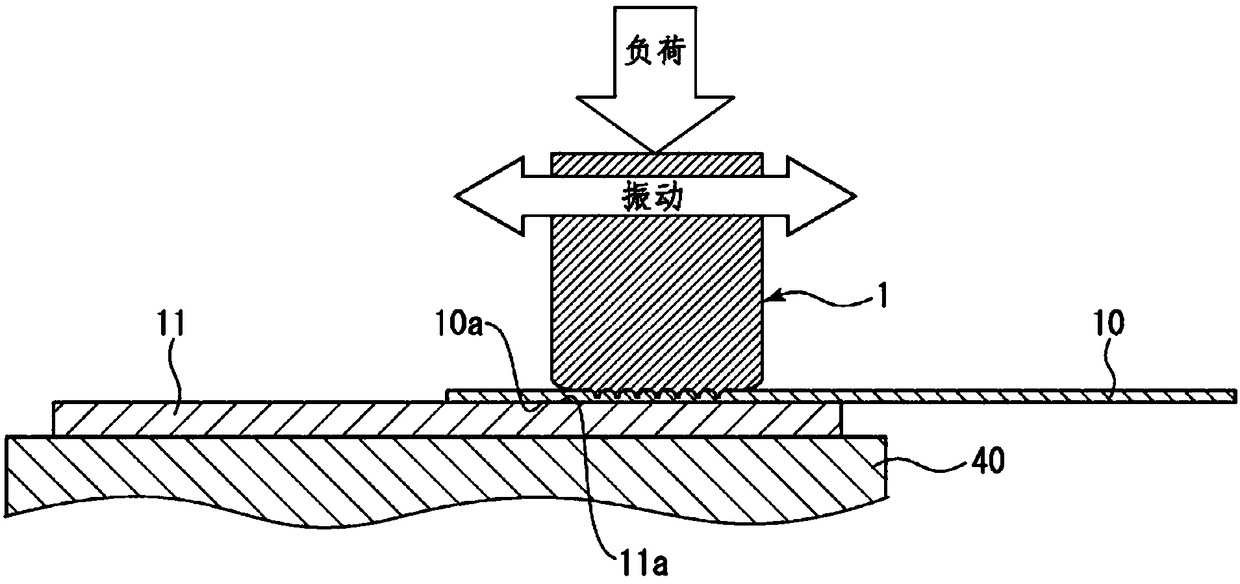

Ultrasonic bonding jig, ultrasonic bonding method, and bonding structure

InactiveCN109382580AImprove joint strengthJoint smoothSheet joiningNon-electric welding apparatusEngineeringUltrasonic bonding

Owner:NIPPON MEKTRON LTD

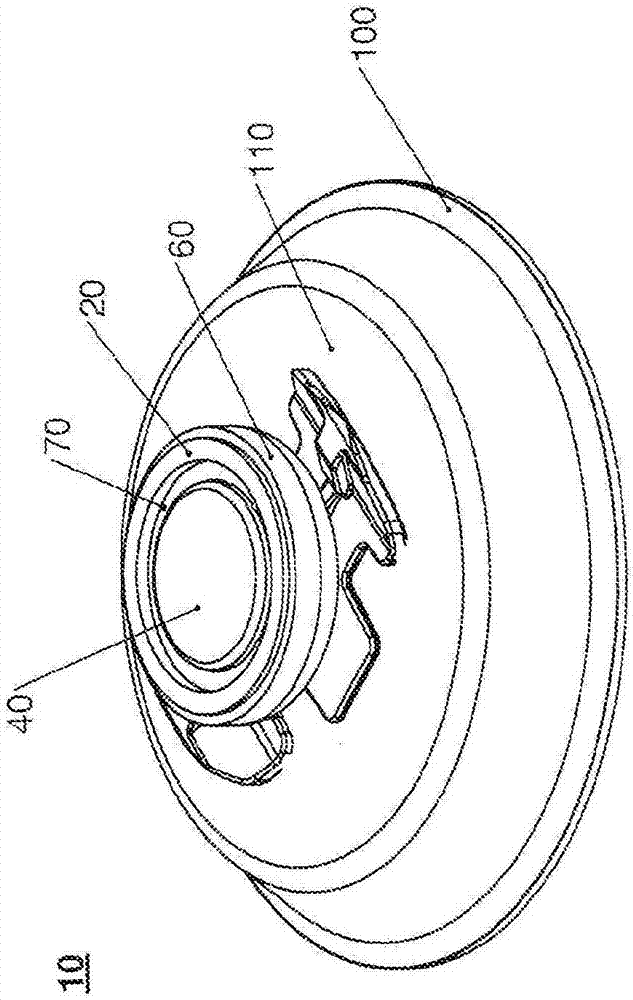

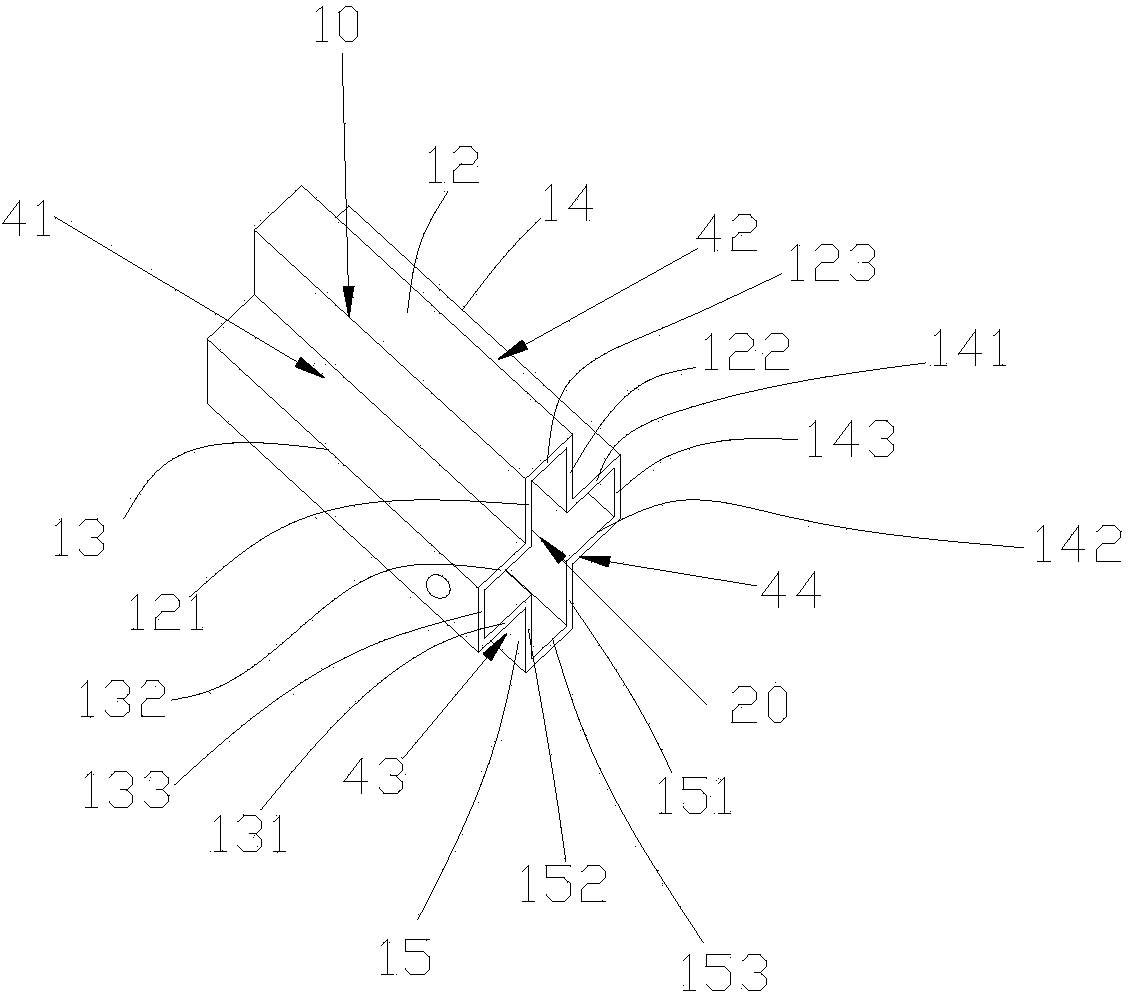

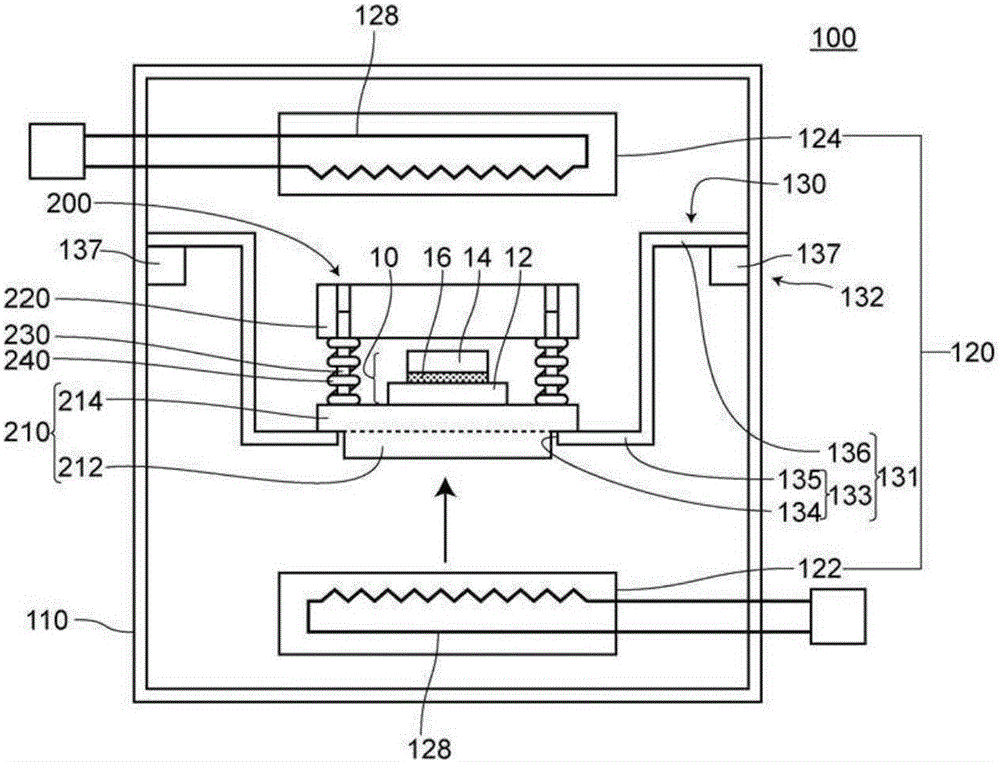

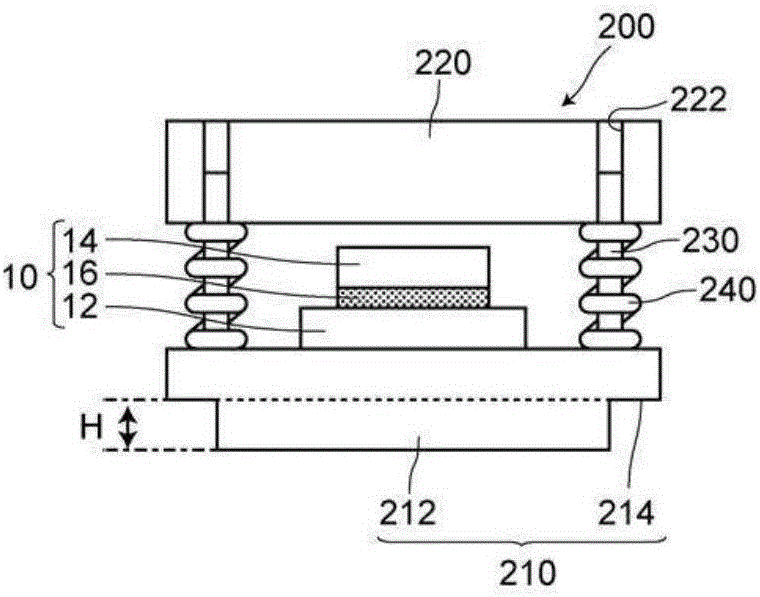

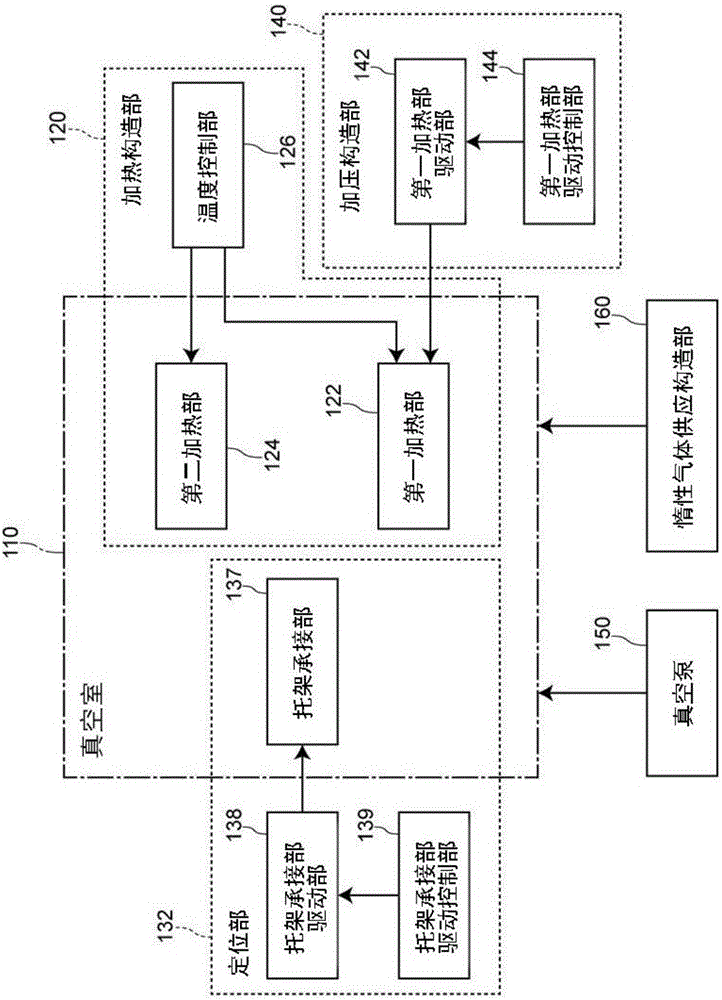

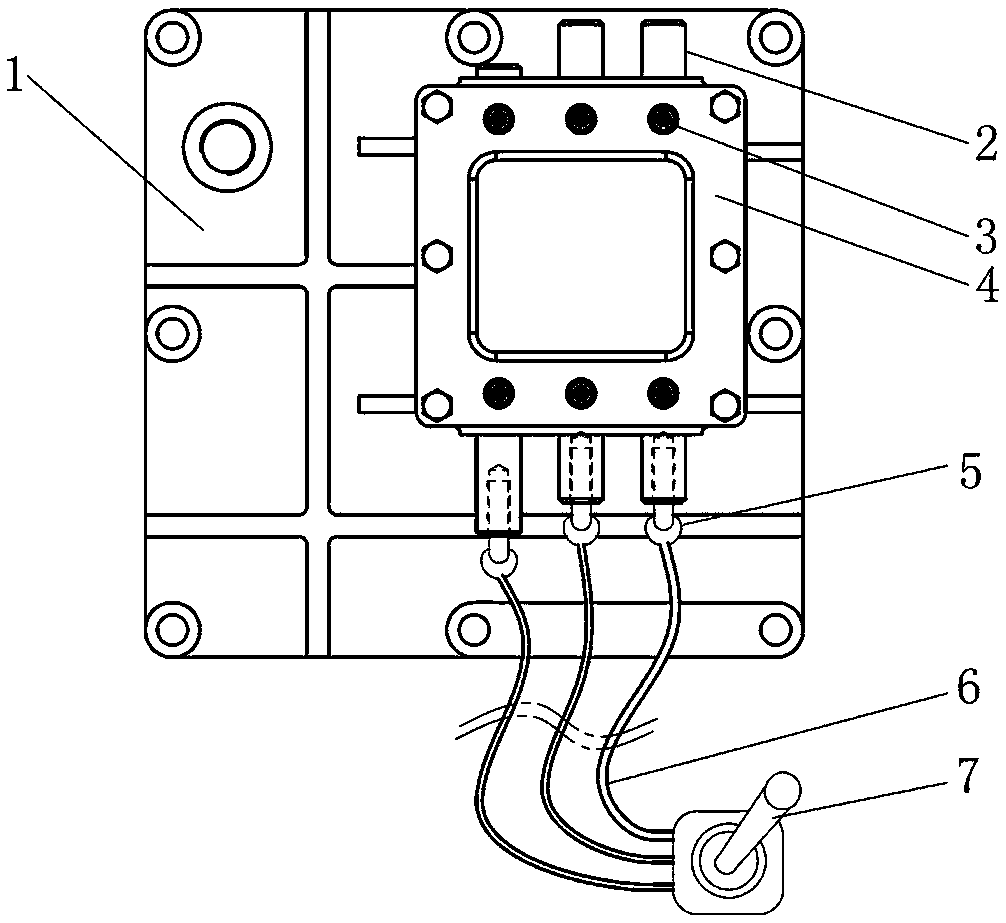

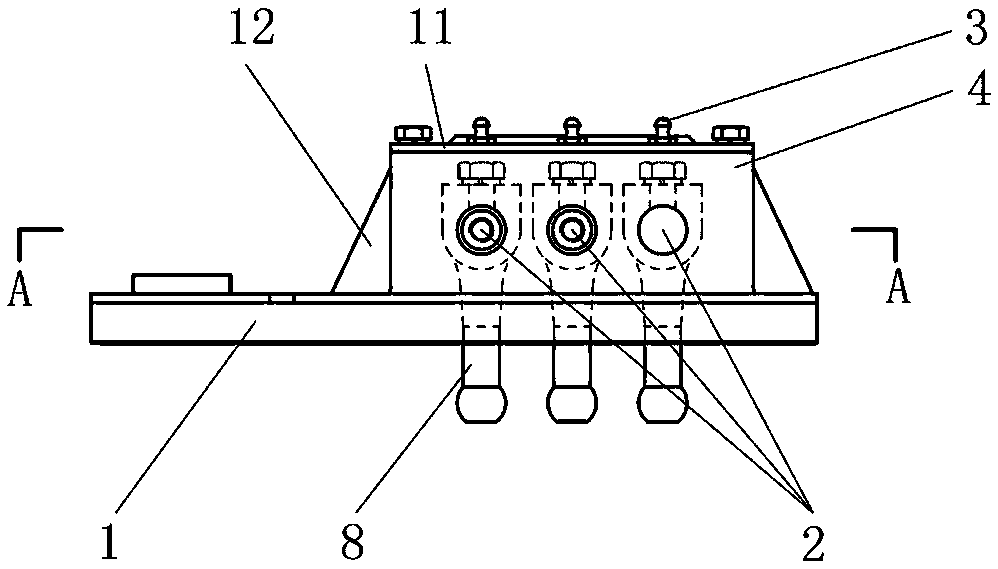

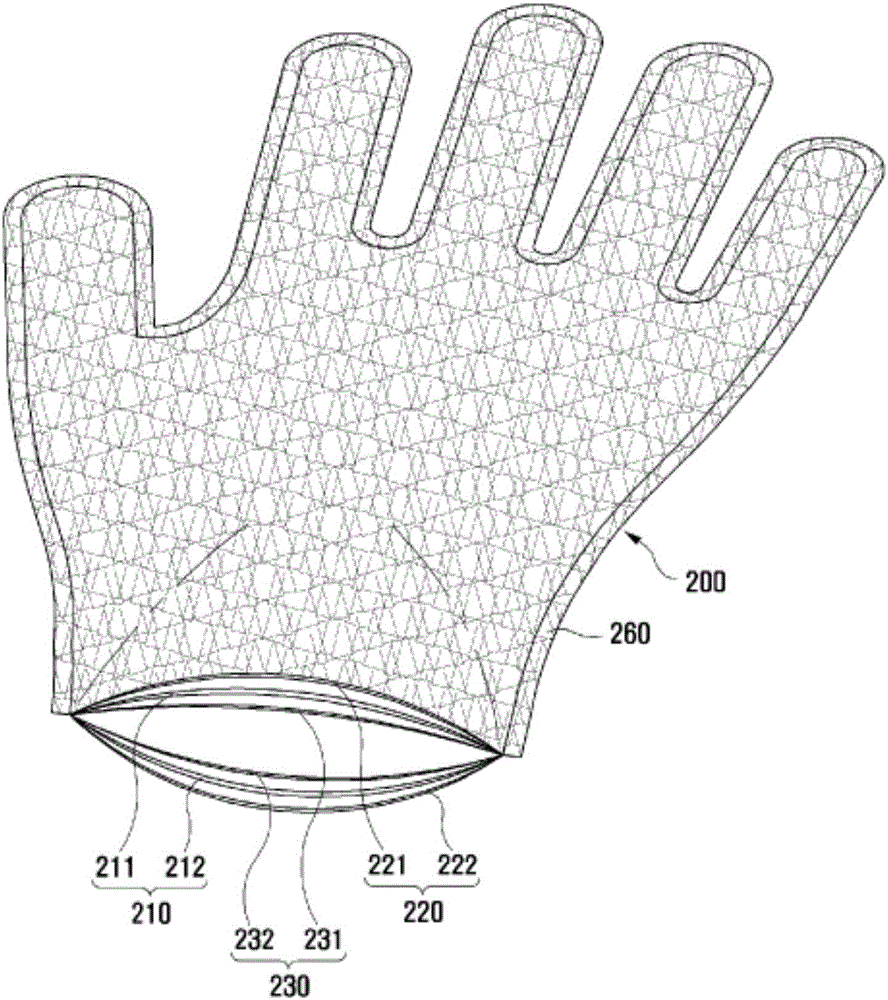

Bonding device, bonding method, and pressurization unit

InactiveCN106471611AAvoid conductionPrevent sintering reactionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal particle

This bonding device 100 is a bonding device that bonds a substrate 12 and an electronic component 14 together by heating, while pressurizing, a pressurization unit 200 including a first transmission member 210 and a second transmission member 220 that sandwich an assembly 10 in which the electronic component 14 is placed on the substrate 12 with a metal particle paste 16 therebetween and that transmit pressure and heat to the assembly, the bonding device comprising: a heating mechanism part 120 including a first heating part 122 and a second heating part 124 that are arranged at positions opposing one another; a positioning mechanism part 130 for positioning the pressurization unit 200 at a position within a space between the first heating part 122 and the second heating part 124 where the pressurization unit contacts neither the first heating part 122 nor the second heating part 124; and a pressurizing mechanism part 140 that pressurizes the pressurization unit 200 by moving the first heating part 122 and / or the second heating part 124. With this bonding device 100, the substrate 12 and the electronic component 14 can be bonded together with high bonding force.

Owner:SHINDENGEN ELECTRIC MFG CO LTD

Optical coupling

The present invention relates to an optical coupling between a first lens end and a second lens end, providing a reliable joint with a predetermined spacing and angular orientation. The optical coupling allows movement of the first lens end relative to the second lens in at least two alignment directions. Advantageously, the invention allows the first lens end to move relative to the second lens end in a direction perpendicular to the optical axis of the lens before the optical coupling is fixed. The first and second lenses are secured within separate sleeves and the sleeves are secured together. The first end and the second lens end are optically aligned prior to being fixed in place with each other.

Owner:LUMENTUM OPERATIONS LLC

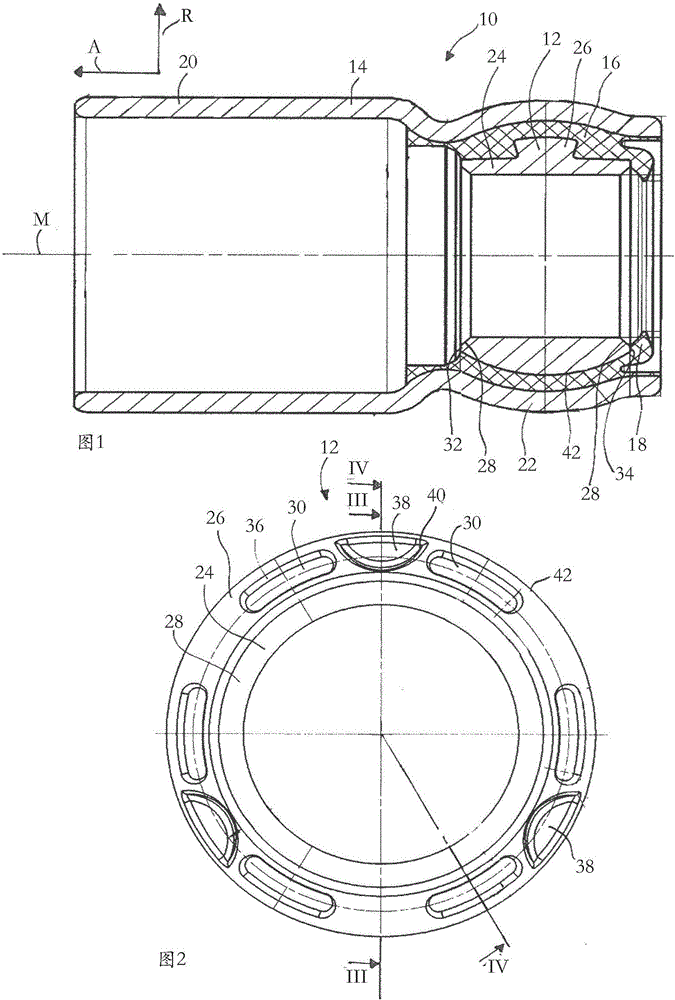

Centring sleeve for bearing and centring a shaft end

ActiveCN106460952AReduce manufacturing costAvoid liftingYielding couplingSpringsElastomerMechanical engineering

The invention relates to a centring sleeve (10) for bearing and centring a shaft end, comprising an inner bushing (12) and an outer bushing (14) that surrounds the inner bushing (12), wherein a spring element (16) is arranged between the inner bushing (12) and the outer bushing (14), said spring element (16) being provided with a sealing lip (18). According to the invention, in order to prevent a lifting of the sealing lip (18) in the case of high cardanic angles, the inner bushing (12) is provided with through openings (30) through which the elastomer passes, in order to create an interlocking connection between the spring element (16) and the inner bushing (12).

Owner:VIBRACOUSTIC SE

Speed changing box driving gear shifting through push-pull flexible shafts

InactiveCN109854718AOutstanding and Beneficial Technical EffectsEasy to operateGearboxesGear lubrication/coolingUniversal jointChange control

The invention belongs to the technical field of agricultural machines and relates to a speed changing box driving gear shifting through push-pull flexible shafts. The speed changing box comprises a speed changing box body, a gear shaft, a speed changing gear and shifting forks shifting the speed changing gear for gear shifting, and a shifting fork shaft box is arranged on an opening in an upward-extending mode, wherein the opening is formed in an upper cover of the speed changing box body; and one or more sets of through holes are correspondingly formed in the two opposite side walls of the middle of the shifting fork shaft box, a shifting fork shaft is arranged in each set of through holes in a penetrating mode, short shift rods are fixedly connected to the shifting fork shafts extendinginto the shifting fork shaft box, the lower ends of the short shift rods are connected with the shifting forks shifting the speed changing gear, universal joints capable of being connected with a speed changing control device are arranged at the ends, extending out of the shifting fork shaft box, of the shifting fork shafts, an annular oil groove is formed in the inner side of the inner wall of each through hole, an annular sealing groove is formed in the outer side of the inner wall of the through hole, a sealing ring is arranged in each annular sealing groove, a shifting fork box cover is arranged at the upper end of the shifting fork shaft box, and an oil injection nozzle communicating with each annular oil groove is formed in the shifting fork box cover. The speed changing box is suitable for being applied to the various agricultural machines.

Owner:ZHEJIANG HAITIAN MACHINERY

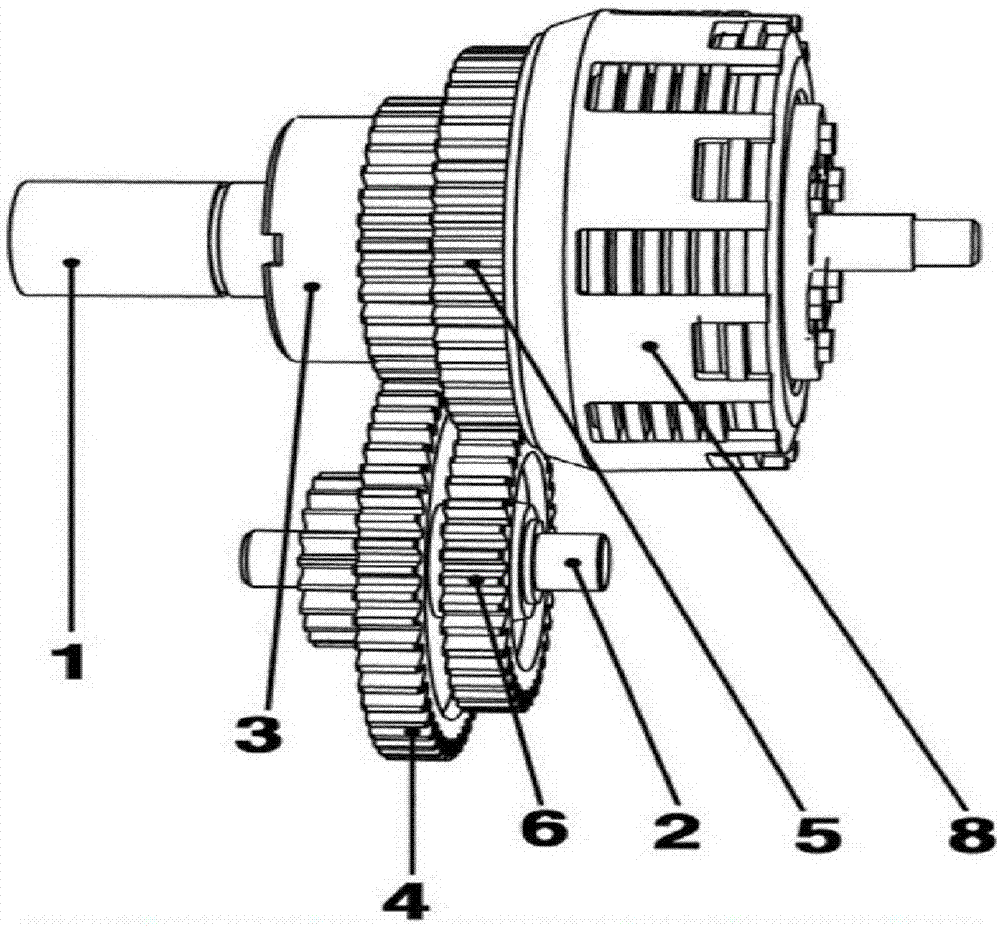

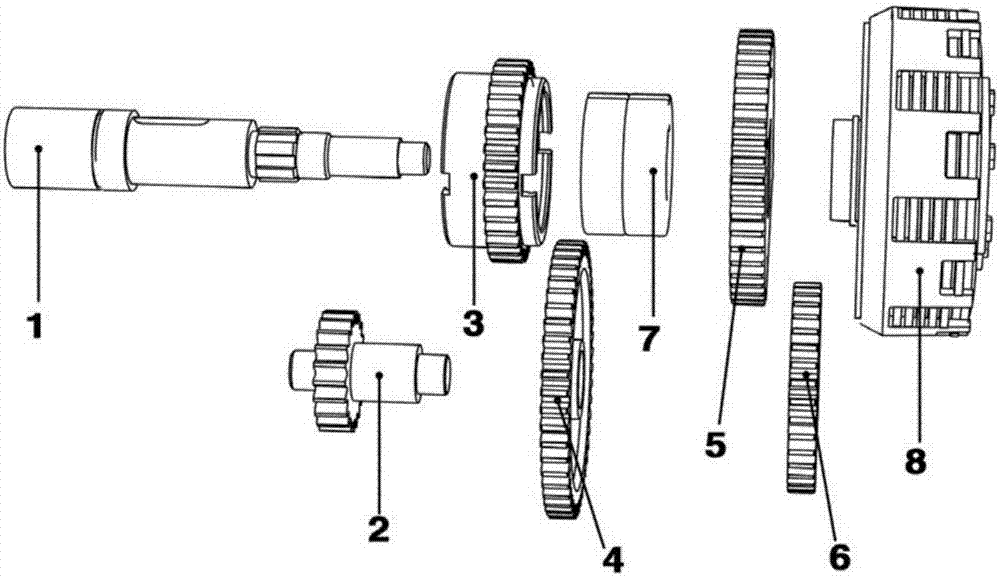

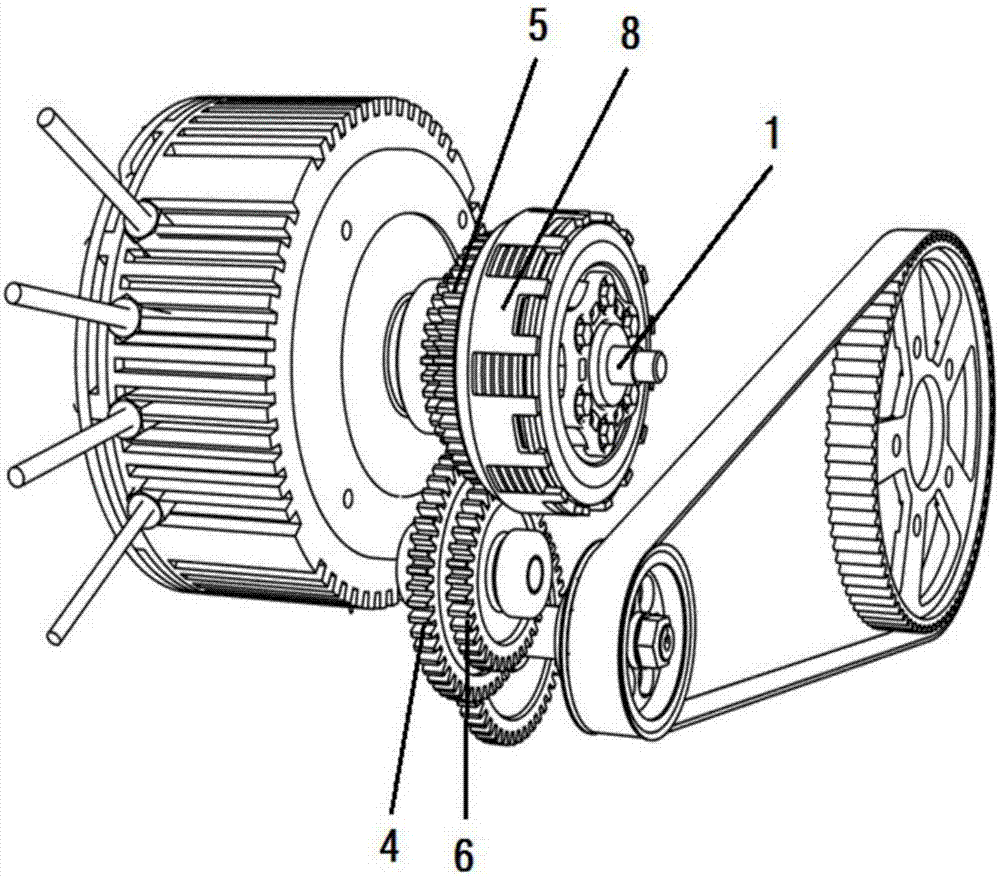

Multi-clutch gear shifting system special for motorcycle and use method of multi-clutch gear shifting system

InactiveCN107963177AReduce volumeReduce weightWheel based transmissionCycle actuatorsLow speedGear wheel

The invention discloses a special multi-clutch shifting system for motorcycles and a method for using the same, comprising: an input shaft, an output shaft, several groups of gear pairs meshing with each other; The secondary gear is set on the input shaft through the controllable clutch; several one-way clutches, the gears of each low-speed gear pair except the highest speed gear in several groups of the gear pairs pass through one of the one-way clutches. The clutch is sleeved on the input shaft. The present invention has a relatively simple overall structure, realizes a small-volume, low-weight shift system, can be used for motorcycles and mopeds, and is easy to produce and implement. Through the clutch, gear shifting without gaps can be realized, and automatic gear shifting and manual electronically controlled shifting can be realized without the operator having technical experience. At the same time, there is no gear impact in the shifting process, and the gears are shifted through the engagement of the clutch, which is smooth and prolongs the service life. Moreover, energy loss and calorific value are small during work.

Owner:重庆辉盛汽车零部件有限公司

Stamping apparatus

InactiveCN101398619BSmall sizeEasy loading and unloadingPhotomechanical apparatusSemiconductor/solid-state device manufacturingSimple modeEngineering

The present invention discloses an impression device which can form an etching area and a non-etching area on a substrate used by flat panel display element with a simple mode. The device comprises the following components: a frame; a chamber which is provided with a first chamber casing and a second chamber casing that are set one an upper position and a lower position on the frame and form an openable closing space through combining operation or separation operation; a soft mould which is provided with a pattern surface that is used for differentiating the etching area and non-etching area and is positioned in the closed space of chamber; an objective table which is provided with a loading surface that is used for loading the substrate and moves up-and-down relatively to the soft mould in the closed space of chamber; and a hardening mechanism which moves from one side to the other side of objective table and simultaneously irradiates ultraviolet.

Owner:WEIHAI DMS OPTICAL ELECTROMECHANICAL CO LTD

Automatic clutch for motorcycle

InactiveCN100516579CSimple structureGood automatic responseFriction clutchesFriction liningAxial displacementAbdominal cavity

The invention discloses an automatic coupler for vehicles, which comprises a front tray, a back tray, and a middle tray. The invention is characterized in that the central part of the left end of the middle tray is in wall shape and forms a cavity together with the wall of the back tray to restrict the axial displacement of a driven tray shaft arranged at the left side. An abdominal cavity of the middle tray is coaxially and uniformly hinged with 2 to 6 fly hammers which bear and transmit power. A hammer handle is arranged at the left part of the fly ball and a hammer body is arranged at the right part. The left end of the handle is provided with a pivoting hole which is hinged on the hinge base at the middle part of the left side of the middle tray. The right side of the hammer handle is also provided with a hole hinged with a connecting rod. The left side of the right part hammer body is provided with a pressing finger pressed at the right end of a clutch pressure plate. A cavity of the hammer body in the right part is provided with an offset piston and an offset piston spring. The spherical top end of the offset piston reciprocates on an orbit on a cavity wall of an inner hole of the middle tray. The high-speed centrifugal force of an engine leads a fly hammer group to be pressed and arranged in a clutch membrane group in the back tray and transmits power to an output tray connected with a gearbox. The invention has the advantages of simple structure, god self-moving responsiveness, regular joint, high transmission efficiency, long service life and proper cost.

Owner:江大建 +1

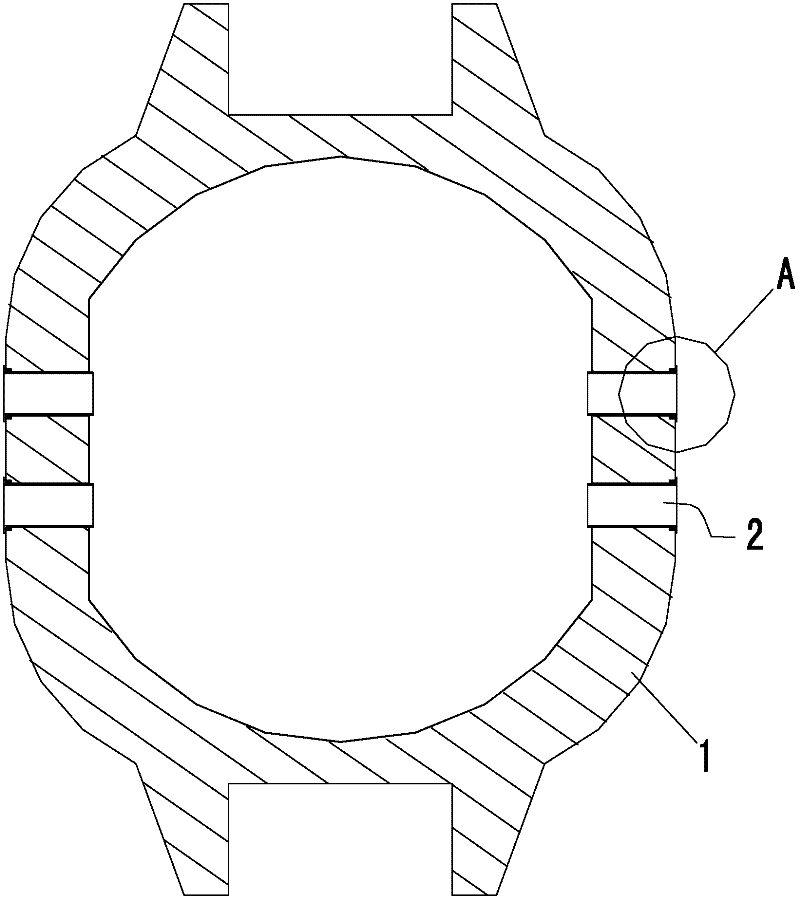

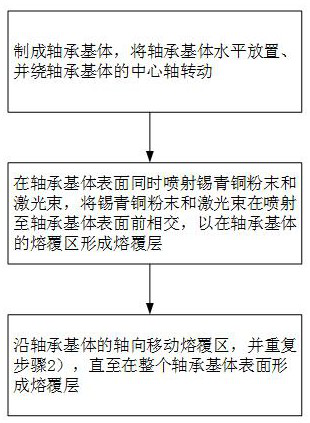

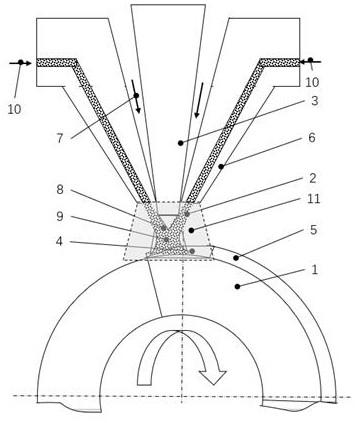

Manufacturing method of wind power sliding bearing

PendingCN113737176AImprove wear resistanceGuaranteed reliability and longevityMetallic material coating processesEngineeringStructural engineering

The invention provides a manufacturing method of a wind power sliding bearing. The manufacturing method comprises the following steps of: manufacturing a bearing base body, horizontally placing the manufactured bearing base body, and rotating the bearing base body around a central shaft of the bearing base body; simultaneously spraying tin bronze powder and a laser beam on the surface of the bearing base body, and enabling the tin bronze powder and the laser beam to be intersected before the tin bronze powder and the laser beam are sprayed to the surface of the bearing base body, so as to form a cladding layer in a cladding area of the bearing base body; and moving the cladding area along the axial direction of the bearing base body, and repeating the step 2) until the cladding layer is formed on the surface of the whole bearing base body. The manufacturing method has the advantages that the performance of the bearing is guaranteed, the cost is saved, the operation is convenient, and the like.

Owner:HUNAN CHONGDE IND TECH

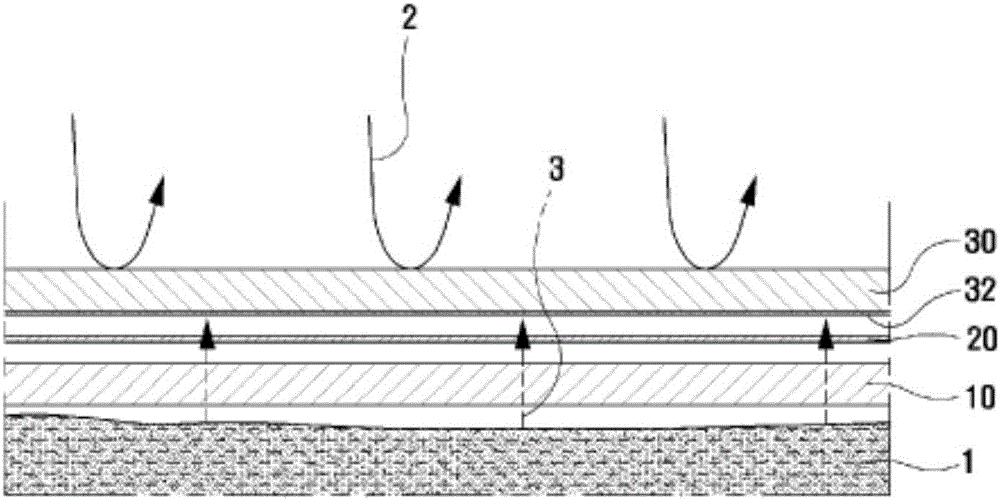

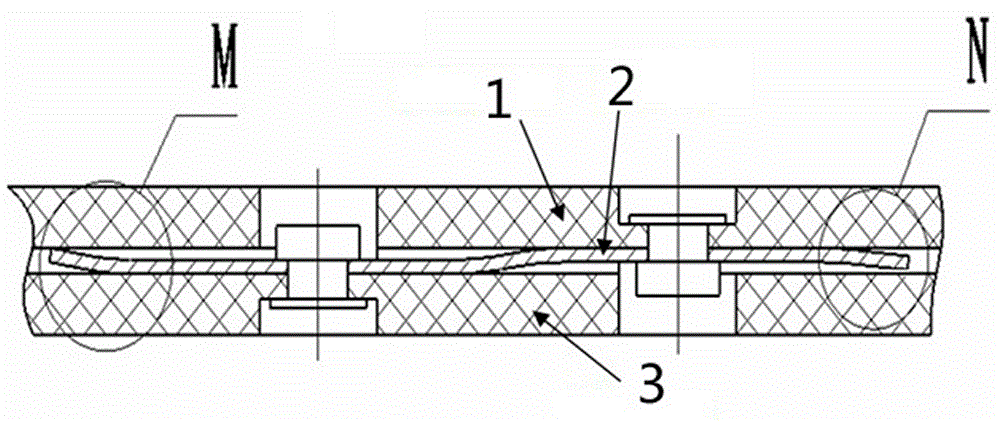

Glove intermediate membrane having moisture permeability and waterproof functions and to be simultaneously coupled to outer shell and inner liner, gloves using same, and manufacturing method therefor

ActiveCN106535687AJoint smoothThe manufacturing process is simple and simpleFibre treatmentGlovesMoisture permeabilityHeat fusion

The present invention relates to: a glove intermediate membrane having moisture permeability and waterproof functions; gloves using the same; and a manufacturing method therefor. The glove intermediate membrane is manufactured by overlapping and disposing a glove-shaped first intermediate membrane inserted between an inner liner and an outer shell of a glove and made of a first material having moisture permeability and waterproof functions, and a glove-shaped second intermediate membrane made of a second material having a melting point lower than that of the first material so as to be joined thereto, and then thermal bonding an edge part excluding a wrist part. In addition, a glove is manufactured by inserting an inner liner, the glove intermediate membrane described above and an outer shell on a mold one by one, and then thermal bonding the same. A glove manufactured thereby has permeability and waterproof functions and simultaneously has excellent grip, and manufacturing time can be reduced and manufacturing costs can be remarkably reduced since the manufacturing process thereof is simple.

Owner:株式会社世芝

Preparation method of high-performance automobile asbestos-free clutch facing

InactiveCN108679131ANo pollution in the processHigh strengthFriction liningActuatorsAdhesive cementRubber material

The invention discloses a preparation method of a high-performance automobile asbestos-free clutch facing. The preparation method comprises the following steps: S1, dipping of asbestos-free wire (cloth) in resin; S2, preparation of a rubber material, specifically, 1, selection of raw materials; 2, rubber mastication; 3, ingredient filler adding and mixing; and 4, adhesive cement beating; S3, adhesive dipping; S4, blank reeling, hot press molding and heat treatment; and S5, grinding processing, inspection and packing. The preparation method is simple in process, has high strength and high wearresistance, meets various performance indexes which should be achieved during transmission of an automobile when used, is safe to use, comfortable and stable, harmless to human bodies and pollution-free to the environment, and is stable in friction coefficient, low in wear rate and light in specific gravity while energy is saved and consumption is reduced, and when the high-performance automobileasbestos-free clutch facing is used, smooth reunion and small impact are implemented.

Owner:来安县隆华摩擦材料有限公司

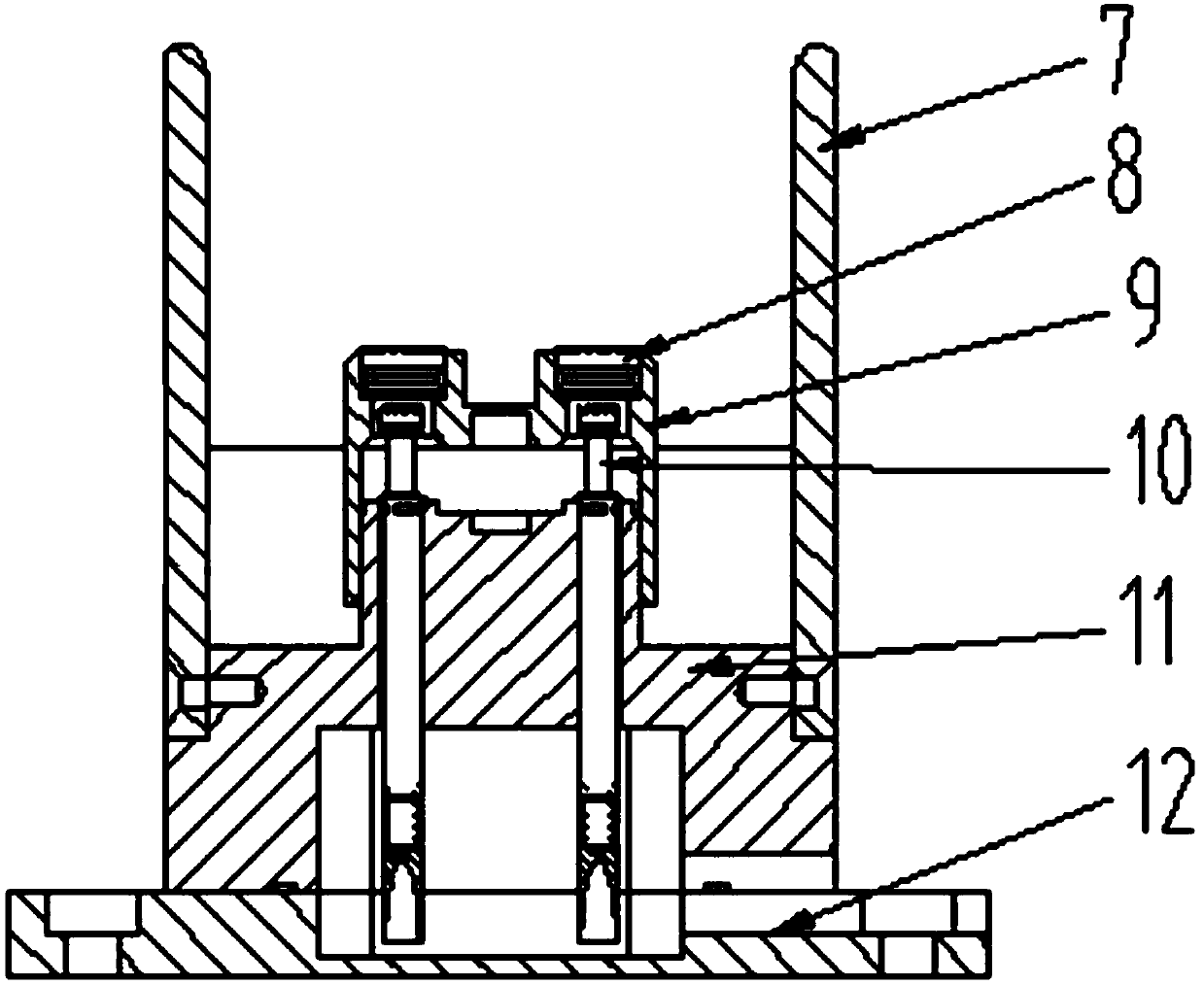

Damping piston for combined brake clutch

ActiveCN103335032BImprove featuresExtended service lifeSpringsFluid actuated clutchesJoints noiseControl theory

The invention relates to a damping piston for a combined type brake clutch. The damping piston comprises a piston body, a plurality of bi-directional damping units and a plurality of single-way damping units, wherein a plurality of penetrating installing holes are formed in the piston body along a circumferential direction at equal intervals; and each bi-directional damping unit and each single-way damping unit are respectively arranged in the corresponding installing hole. According to the damping piston for the combined type braking clutch, according to different force situations of two sides of the piston, stable and reliable damping units are arranged so as to damp the two sides of the piston at different degrees, so that the joint process of the clutch can be smooth and uniform, and the joint noise can be effectively reduced.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

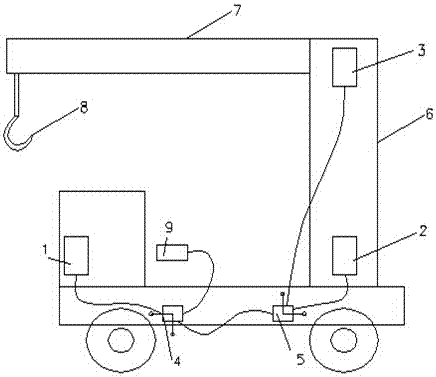

Long-distance multi-control clutch control system for oil field workover vehicle

ActiveCN105501054BNot affected by deformationReduce frictional resistanceAuxillary drivesControl systemTruck

Owner:SINO TRUK JINAN POWER

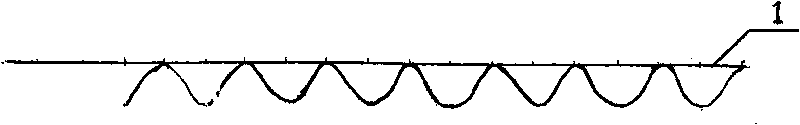

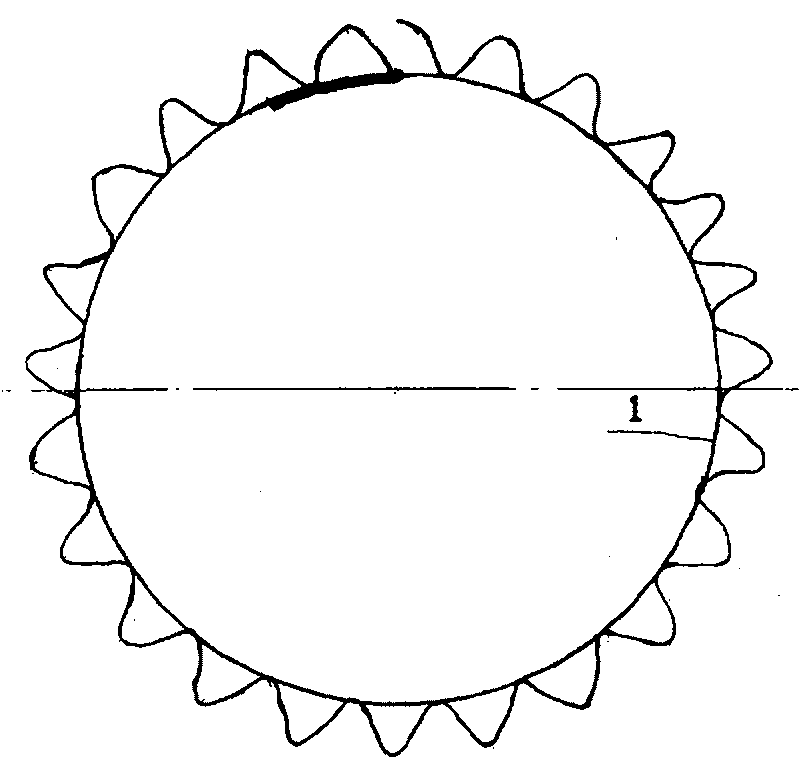

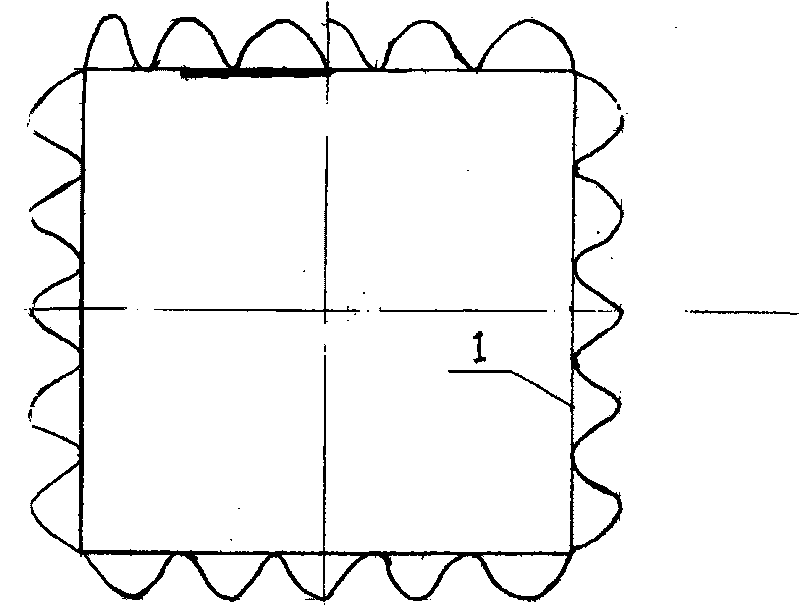

Axial elastic optimization structure for automobile clutch driven disc

The invention discloses an axial elastic optimization structure for an automobile clutch driven disc. The axial elastic optimization structure comprises the clutch driven disc and is characterized in that a waveform piece is arranged between friction plates of the clutch driven disc; the waveform piece is composed of two waveforms, the edge of one waveform makes contact with the friction plates, and the edge of the other waveform does not make contact with the friction plates. An axial elastic value of the driven disc during clutch engagement is decreased by improving the structure of the waveform piece, so that the compressing force of the driven disc and the friction transmission torque are increased smoothly during clutch engagement, and engagement is smooth. A clutch driven disc assembly is simple in structure and good in manufacturability.

Owner:GUILIN FUDA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com