Noiseless chain

A technology of silent chain and inner connecting plate, applied in the direction of transmission chain, metal material coating process, coating, etc., can solve the problems of aggravation, materials are easy to stick to each other and wear, and achieve the effect of improving oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

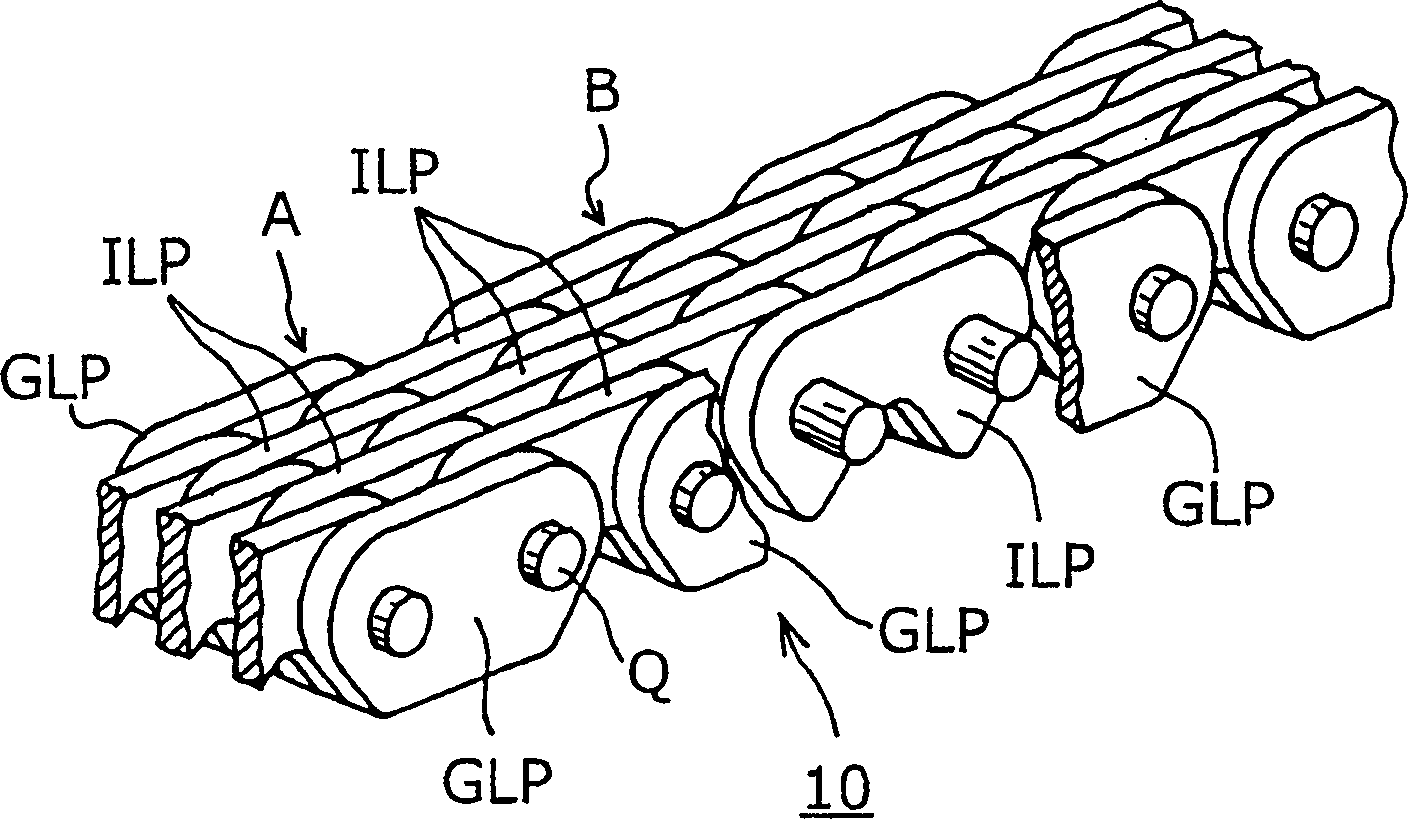

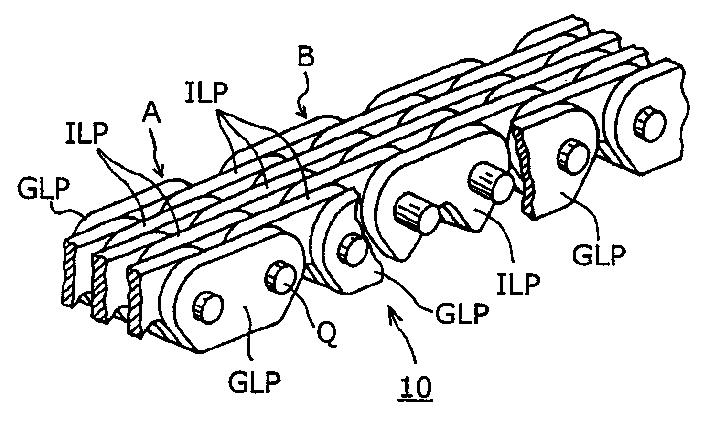

[0023] will now refer to figure 1 and 2 Embodiments of the invention are described based on Examples 1 and 2.

[0024] figure 1 is a perspective view showing an example of the silent chain of the present invention. The silent chain 10 has three rows of inner webs ILP with meshing teeth and located in the engagement arrangement A and four rows of guide webs GLP in the guide arrangement B. In addition, the connecting pin Q is fixedly fitted in the pin hole of the guide connecting plate GLP, and the connecting pin Q is loosely fitted in the pin hole of the inner connecting plate ILP. figure 1 In order to show the internal structure of the silent chain, the two central guide plates GLP on the proximal side are cut away. should pay attention figure 1 represents an example of a silent chain with four rows of guide lugs and three rows of inner lugs, but if a silent chain with inner lugs and more guides than the inner lugs is used and the guide lugs are in the outermost row The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com