Speed changing box driving gear shifting through push-pull flexible shafts

A push-pull flexible shaft and gearbox technology, applied in the gearbox field, can solve problems such as ergonomics cannot be realized, and achieve the effects of smooth engagement, low resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

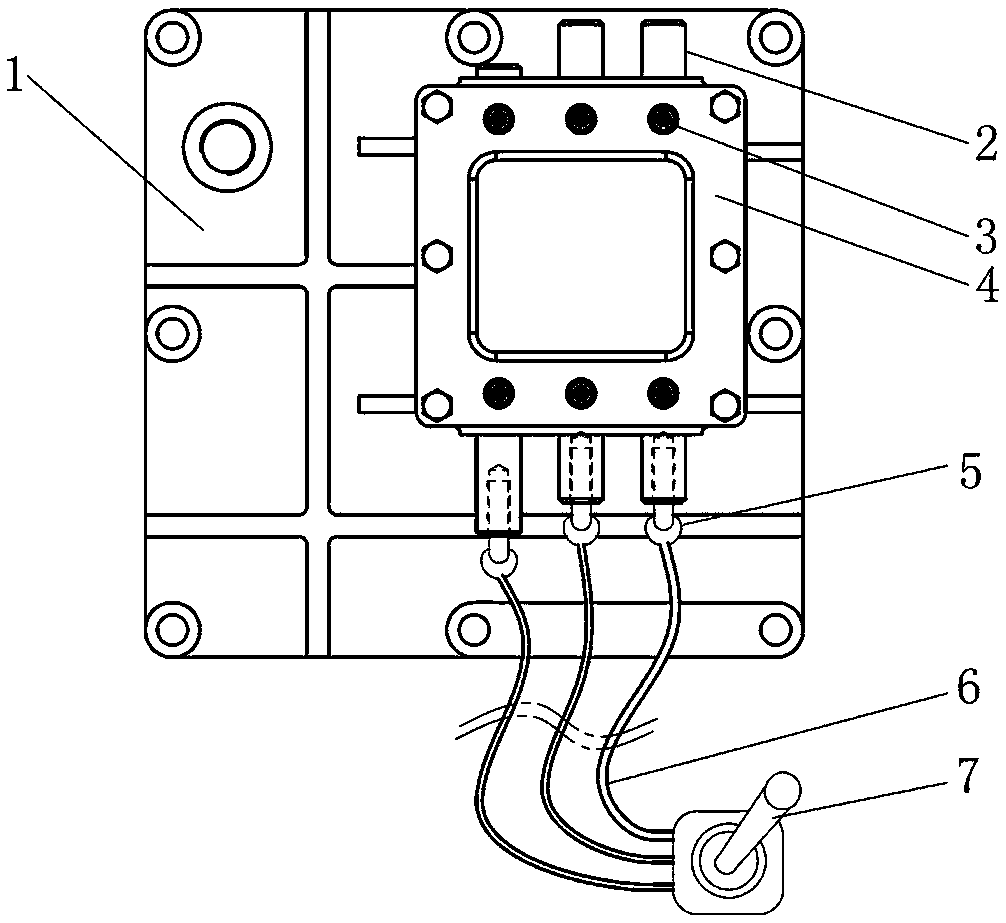

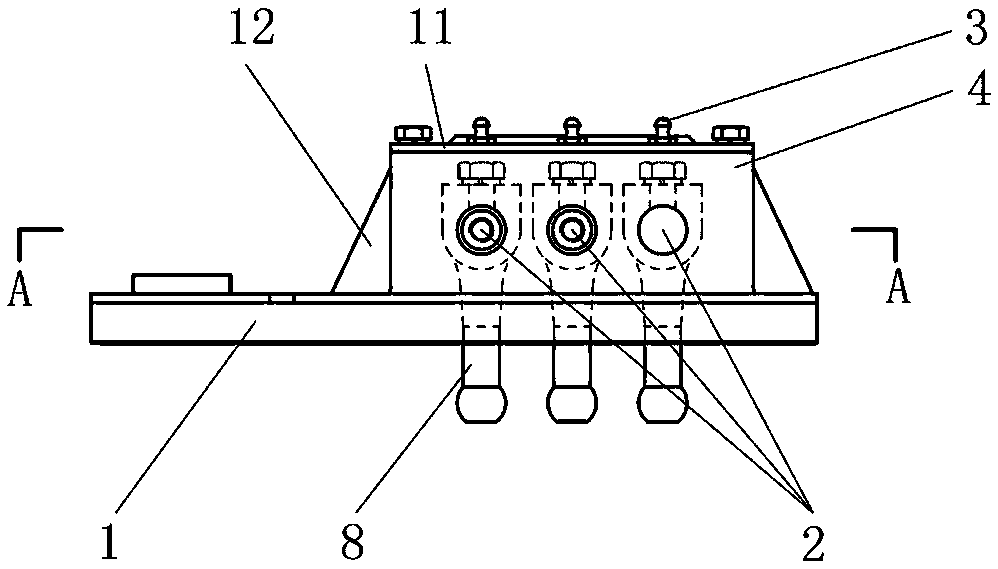

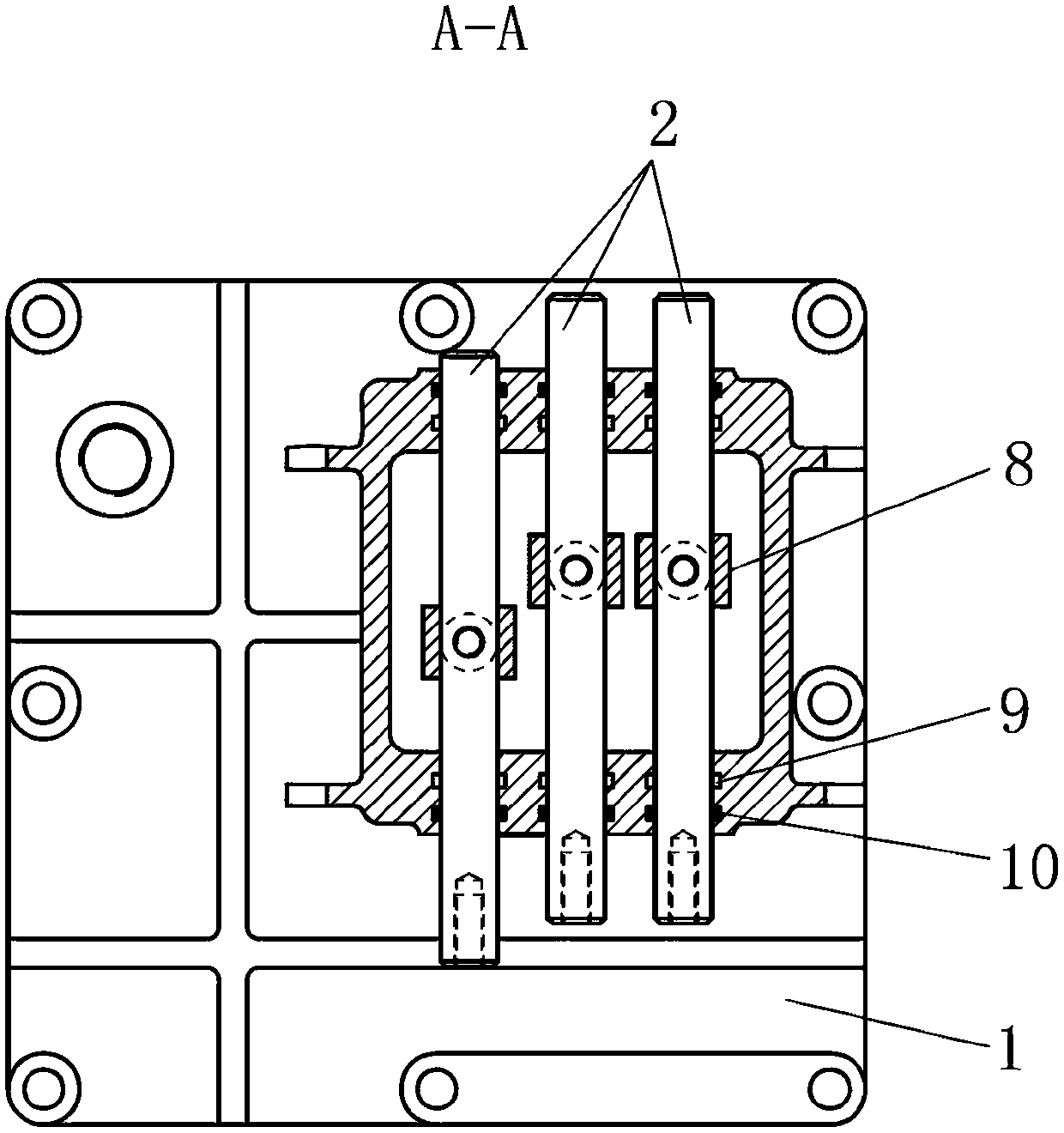

[0016] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3: A gearbox that utilizes a push-pull flexible shaft to drive shifting, including a gearbox body, a gear shaft in the gearbox body, a shift gear and a shift fork for shifting the shift gear. The upper cover of the gearbox body 1 A shift fork shaft box 4 is extended upwardly on the opening provided on the top, and more than one set of through holes are correspondingly arranged on the opposite side walls of the middle part of the shift fork shaft box 4, and a shift fork shaft 2 is pierced in each group of through holes. , the shift fork shaft 2 extending into the shift fork shaft box 4 is fixedly connected with a short shift lever 8, the lower end of the short shift lever 8 is connected with the shift fork that toggles the transmission gear, and the shift fork stretches out of the shift fork shaft case 4 One end of the shaft 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com