Optical coupling

An optical coupling and optical axis technology, applied in the field of optical coupling systems, can solve the problems of difficult to establish spacing and alignment, and achieve the effect of uniform bonding and reliable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

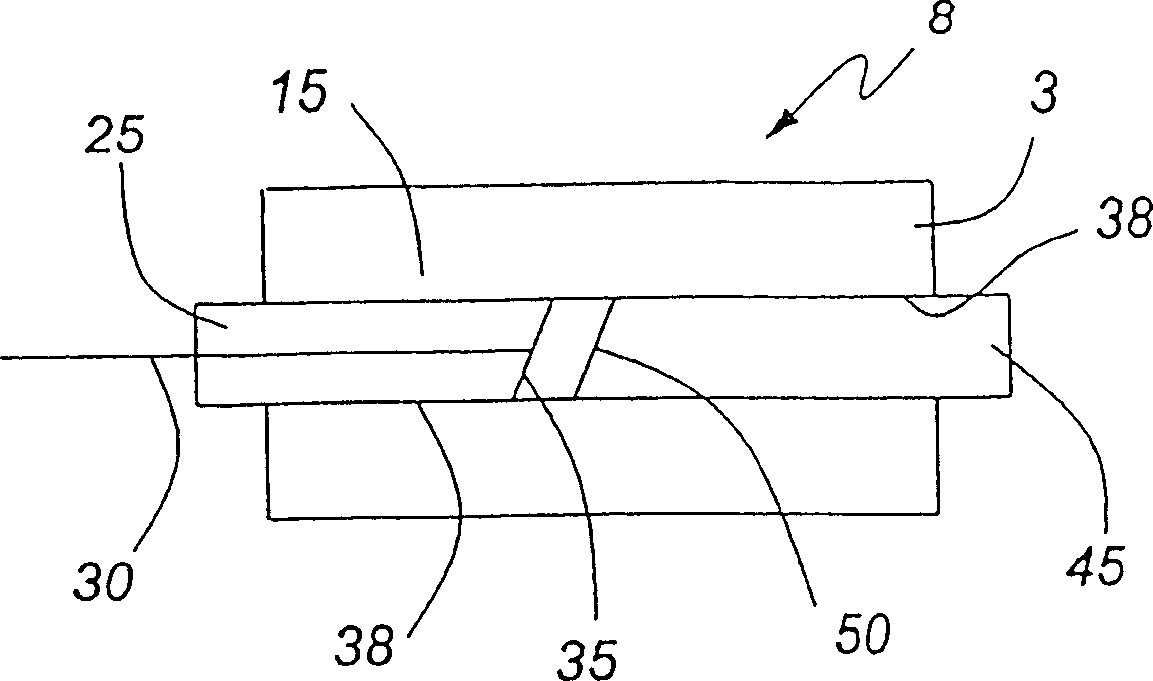

[0035]An optical coupling is provided, ideally using two ferrules with complementary end faces to provide optical coupling between an optical fiber and a lens spaced from each other. The coupling described here does not require adhesives in the optical path and provides considerable flexibility in the optical alignment of the fiber to the lens while providing a reliable and stable joint.

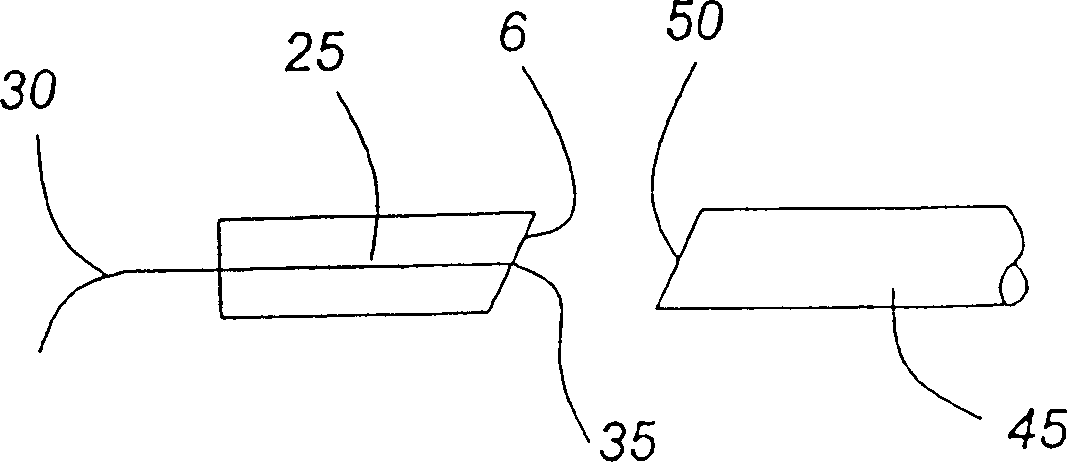

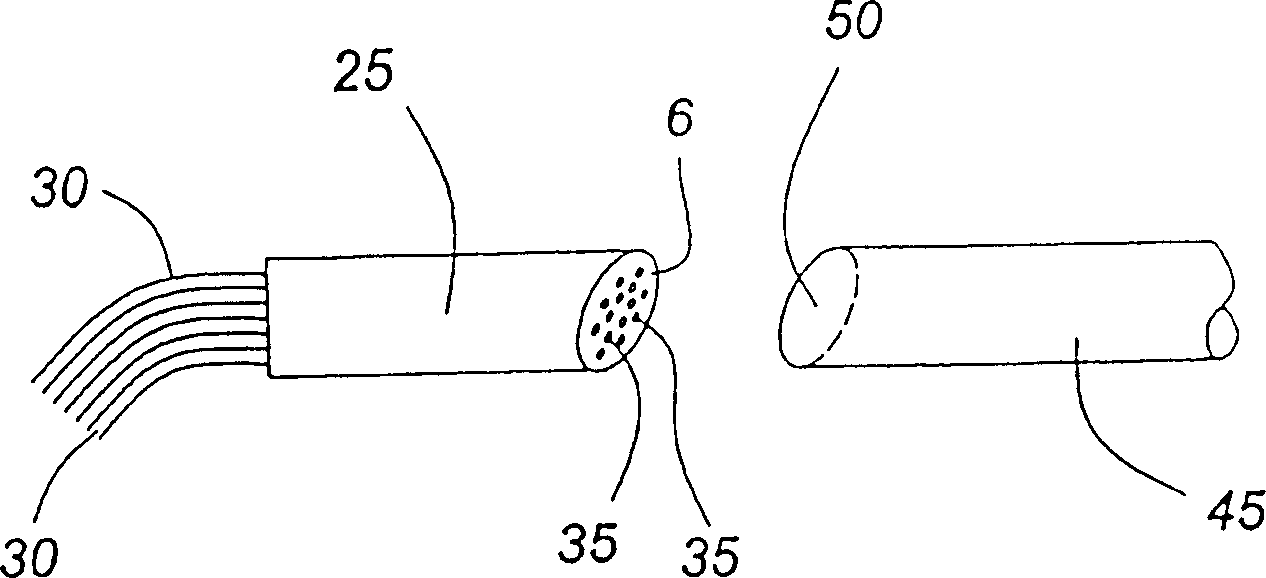

[0036] Referring to FIG. 1 , there is shown a cross-sectional side view of known elements to be optically coupled, namely an optical fiber 30 and a lens 45 . The lens 45 is used for guiding a beam of light into the optical fiber and / or for receiving a beam of light from the optical fiber 30 . Optical fiber 30 is contained within a fiber optic tube / ferrule 25 which supports and secures optical fiber 30 thereto. The fiber tube 25 has an end 6 and the optical fiber 30 has an end 35 . The ends are polished flush. Ends 35 and 50 are polished to the same complementary non-right angle. For simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com