Axial elastic optimization structure for automobile clutch driven disc

An optimized structure and clutch technology, which is applied in clutches, friction clutches, mechanically driven clutches, etc., can solve the problems of aggravating torque fluctuations in the starting stage and aggravating the shaking during starting, so as to reduce the axial elastic force value, smooth engagement, and pressure evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

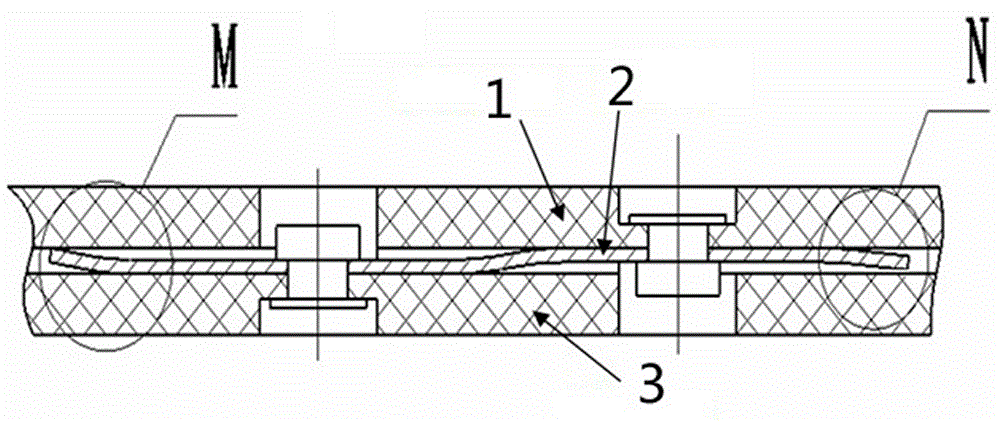

[0011] refer to figure 1 , the present invention is an automobile clutch driven plate axial elastic optimization structure, which is to assemble a wave plate 2 of a new structure between the first friction plate 1 and the second friction plate 3 of the existing clutch driven plate, and the wave plate 2 The M terminal edge is in contact with the first friction plate 1, and the N terminal edge of the corrugated plate 2 is not in contact with the friction plate, and is in a suspended state. When the clutch is engaged, the axial resistance of the first friction plate 1 and the second friction plate 3 on the wave plate 2 is small, thereby effectively reducing the axial elasticity value of the driven plate and making the clutch engagement process more supple and stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com