Damping piston for combined brake clutch

A technology of braking clutch and damping piston, applied in the direction of fluid drive clutch, non-mechanical drive clutch, clutch, etc., can solve the problems of insignificant positive effect, insufficient stability and reliability, and achieve smooth engagement, sufficient contact and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

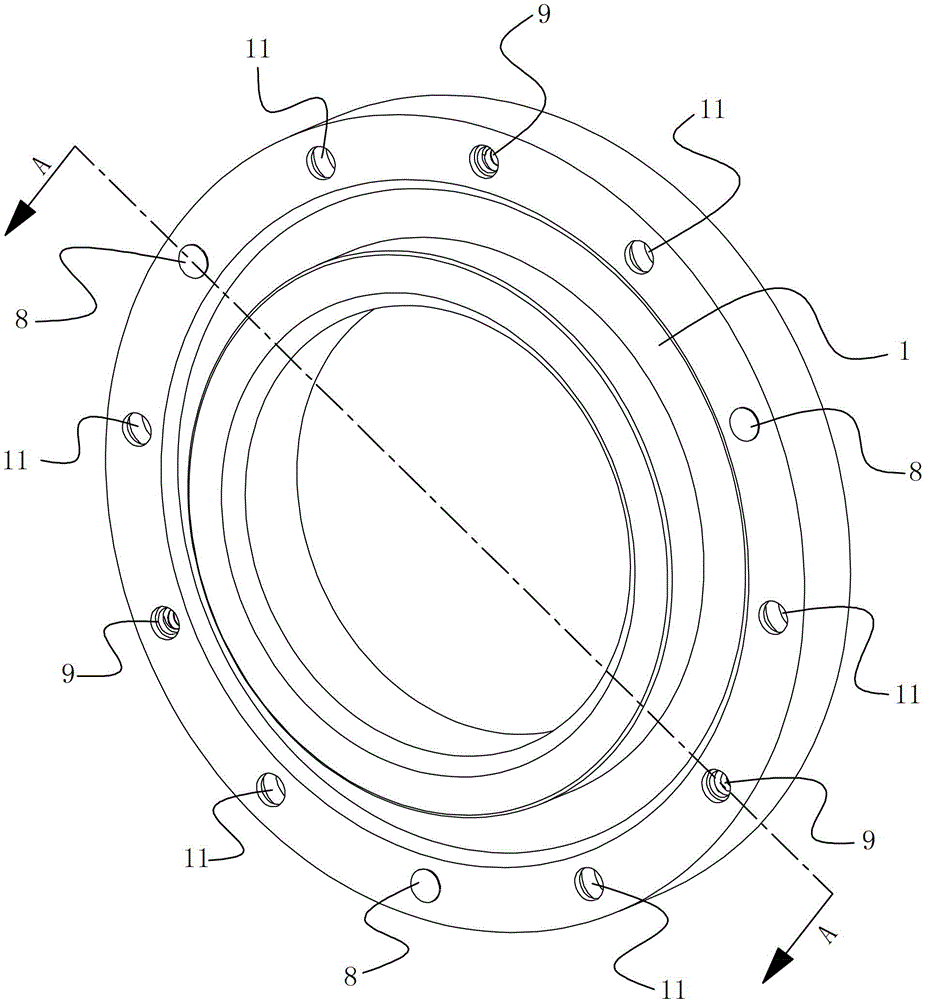

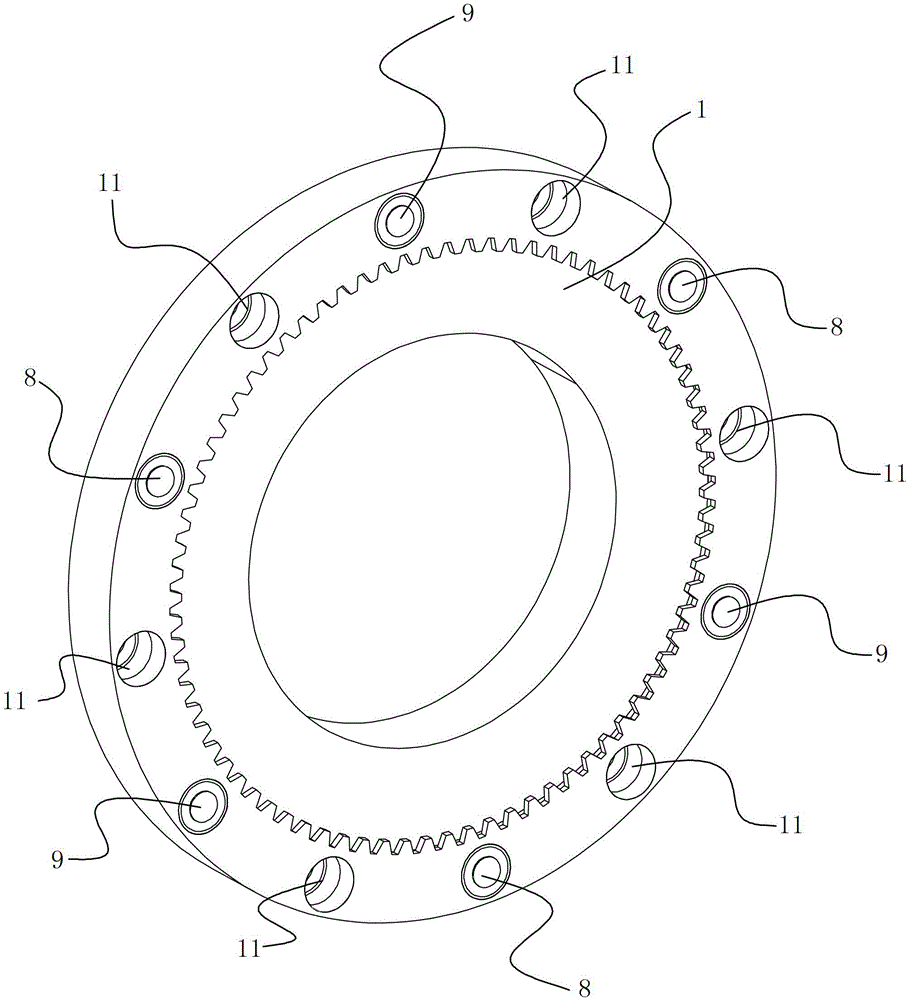

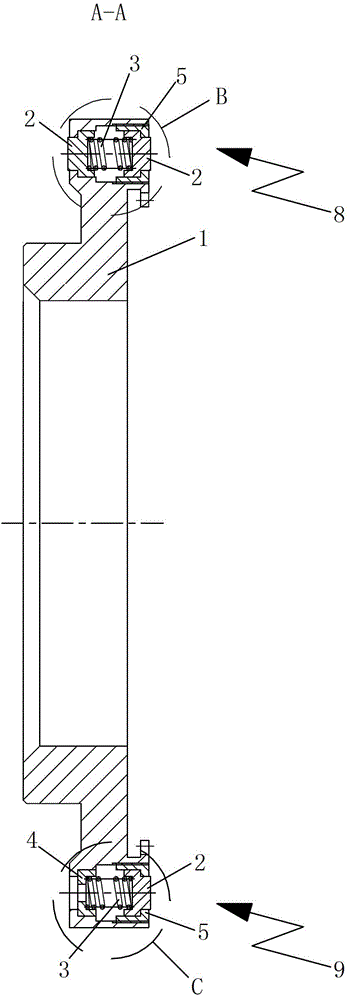

[0035] See Figure 1 to Figure 3, The damping piston for the combined brake clutch of this embodiment includes a piston body 1 , a two-way damping unit 8 and a one-way damping unit 9 . The piston body 1 is provided with 12 through mounting holes 11 equidistantly along the circumferential direction. There are three two-way damping units 8 and three one-way damping units 9 respectively, and the two-way damping units 8 and the one-way damping units 9 are symmetrically installed in the corresponding mounting holes 11 . And the two-way damping units 8 are arranged at equal intervals along the circumferential direction of the piston body 1 . Between the adjacent two-way shock absorbing unit 8 and one-way shock absorbing unit 9, there is an empty mounting hole 11 that does not install two-way shock absorbing unit 8 and one-way shock absorbing unit 9 (in the empty mounting hole 11, two-way shock absorbing unit 8 and one-way shock absorbing unit 9).

[0036] See Figure 6 1. The en...

Embodiment 2

[0043] See Figure 7 , the rest of the damping piston for the combined brake clutch of this embodiment is basically the same as that of Embodiment 1, the difference is that: the end of the mounting hole 11 close to the clutch end is provided with a first annular step 11-1, the mounting hole 11 One end close to the braking end is provided with an internal thread 11-2. The damping concave block 4 of the one-way damping unit 9 is against the second annular step 51, and the protrusion 21 of the damping protrusion 2 of the one-way damping unit 9 passes through the inner circle of the first annular step 11-1 and Extend the piston body 1.

Embodiment 3

[0045] The remainder of the damping piston for the combined brake clutch of this embodiment is basically the same as that of Embodiment 1, except that there are nine mounting holes 11 . There are three two-way damping units 8 and three one-way damping units 9 each, the three two-way damping units 8 are distributed in an equilateral triangle, and the three one-way damping units 9 are also distributed in an equilateral triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com