Corrugated board full paper barrel

A technology of corrugated cardboard and paper barrels, applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of overlapping mechanized production at joints, difficulty in beautifying decoration and color printing patterns, and easy looseness of carton packaging, etc. , Convenient mechanized production, good overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

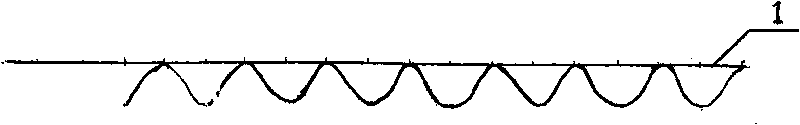

[0021] figure 1 Among them, one end of the single-sided corrugated cardboard 1 used for intersecting bonding is removed along the longitudinal direction of the corrugation by removing one and a half corrugations to form a flat plate with a width of about 15 mm.

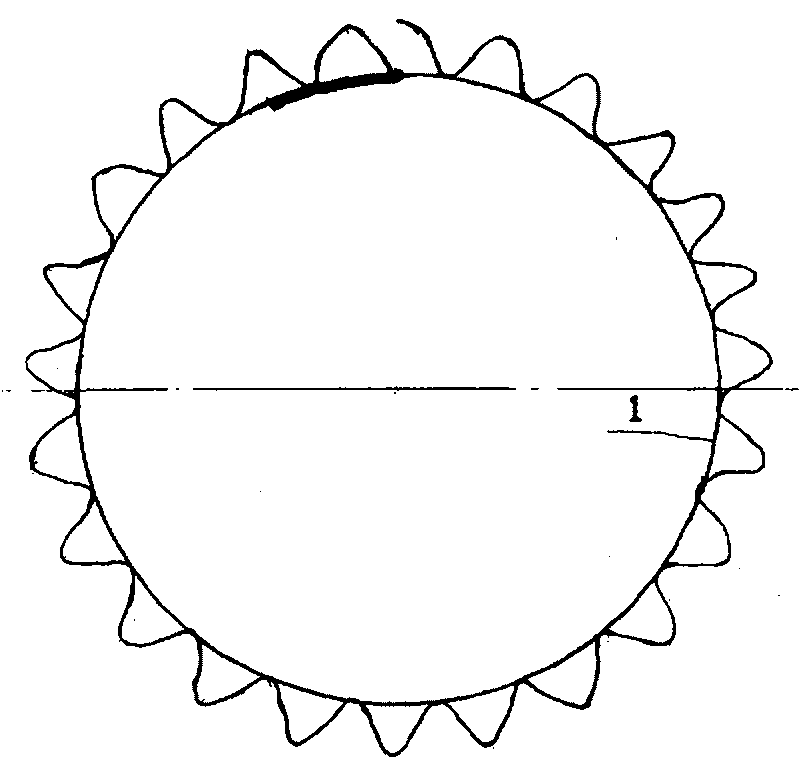

[0022] figure 2 Among them, the flat end of the single-face corrugated cardboard 1 intersects with the other end of the single-face corrugated cardboard 1 to form a cylindrical shape with corrugated outwards.

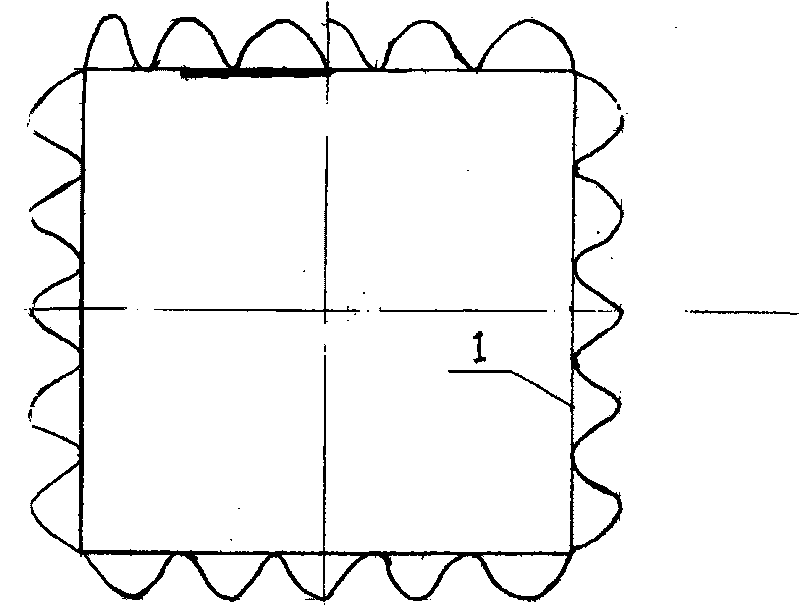

[0023] image 3 Among them, the flat end of the single-faced corrugated cardboard 1 intersects with the other end of the single-faced corrugated cardboard 1 to form a square tube with corrugated outwards.

[0024] Figure 4 Among them, face paper 2 is adhered to the outside of the corrugation of the tubular single-faced corrugated cardboard 1 to form a barrel body 3 of one tile and two cow corrugated cardboards.

[0025] Figure 5 In this method, an adhesive is applied to the top of the corrugation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com