Patents

Literature

58 results about "Full paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

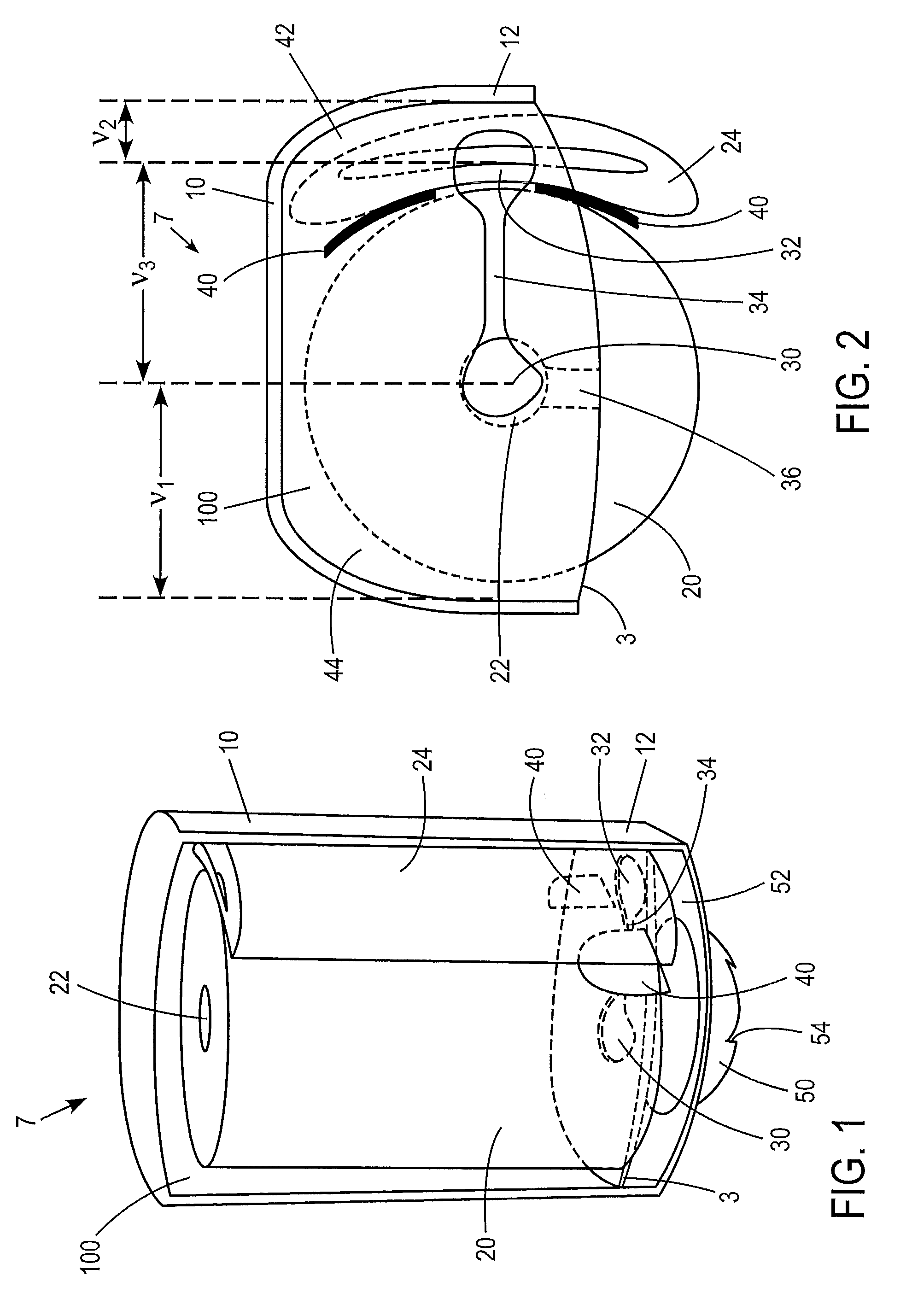

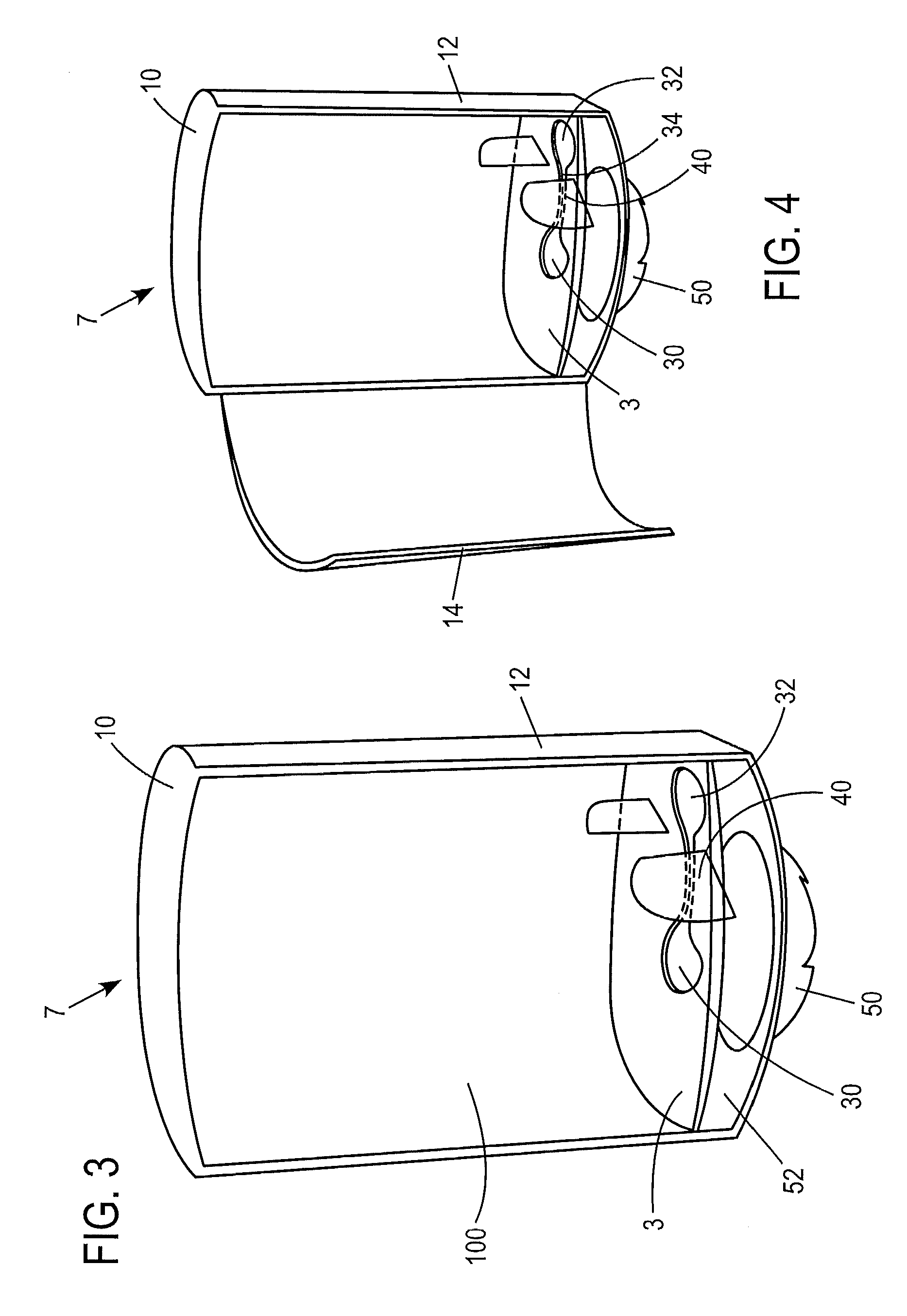

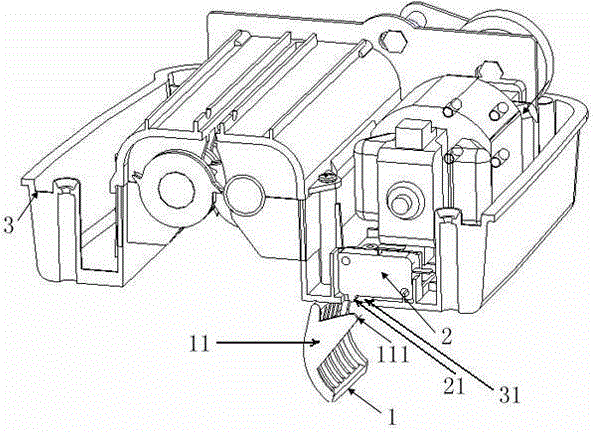

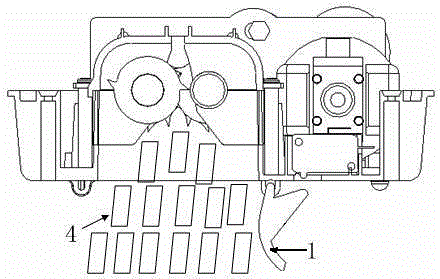

Sheet product dispenser

ActiveUS20170290473A1Reduce wasteEasy to switchDomestic applicationsMechanical engineeringFacial tissue

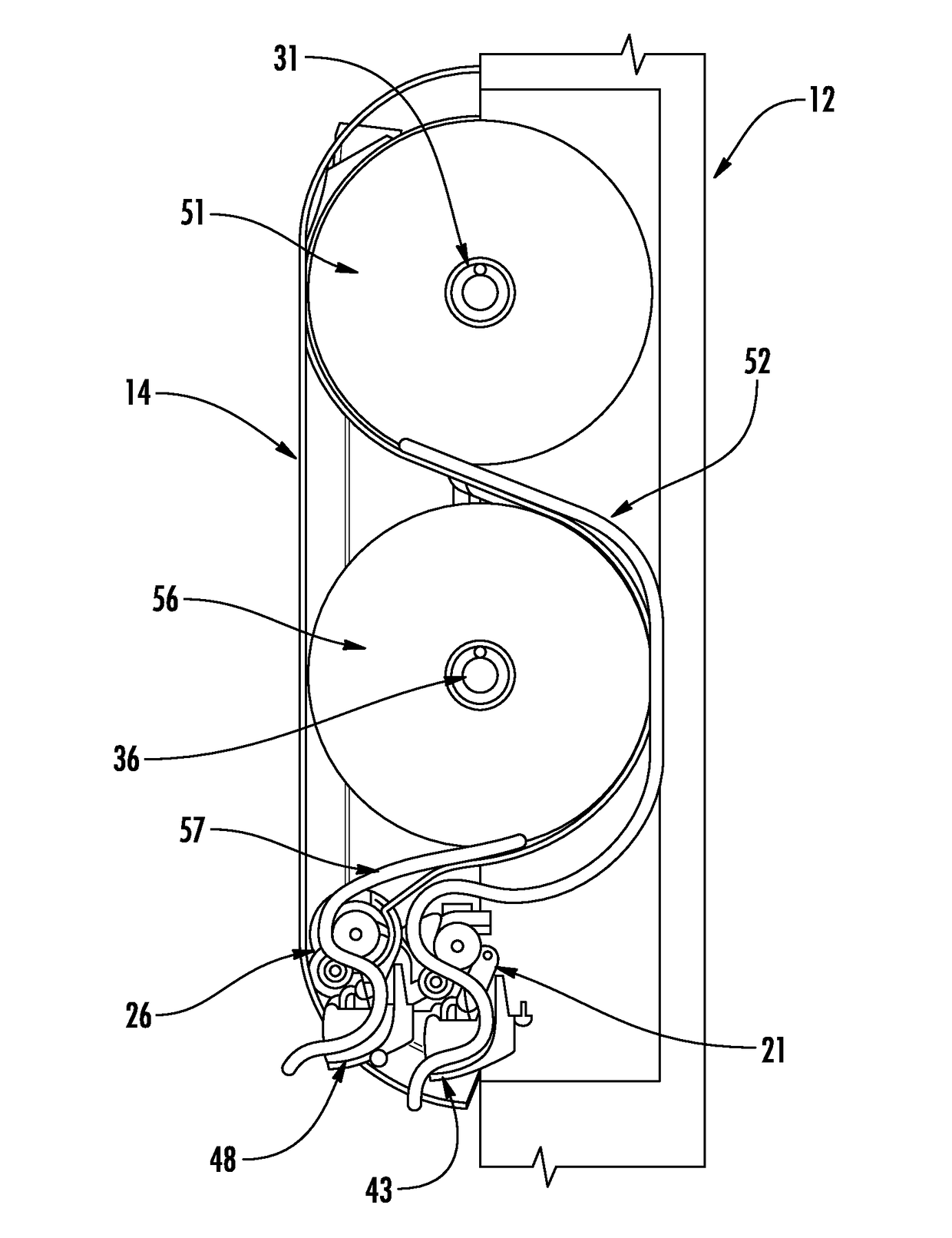

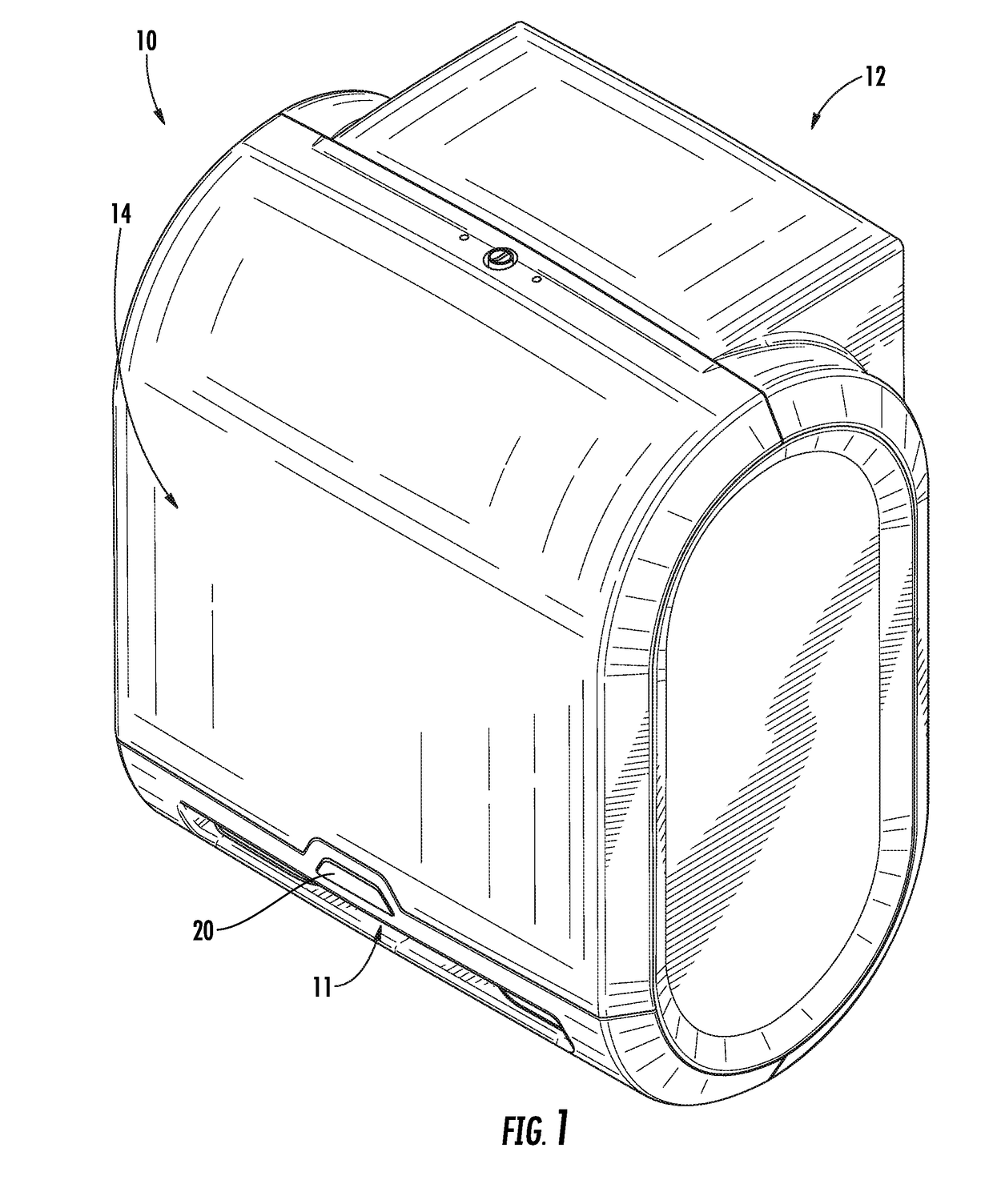

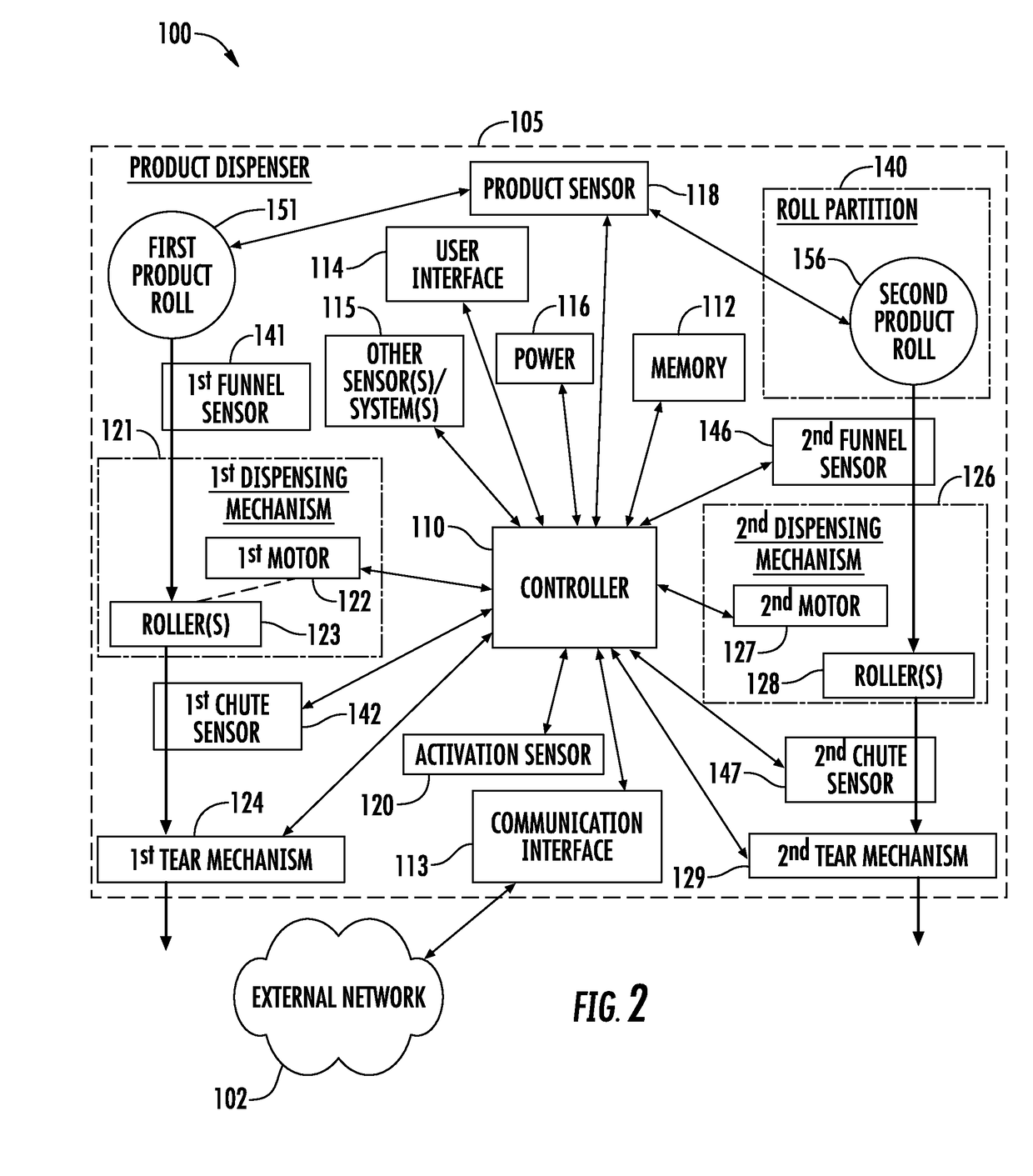

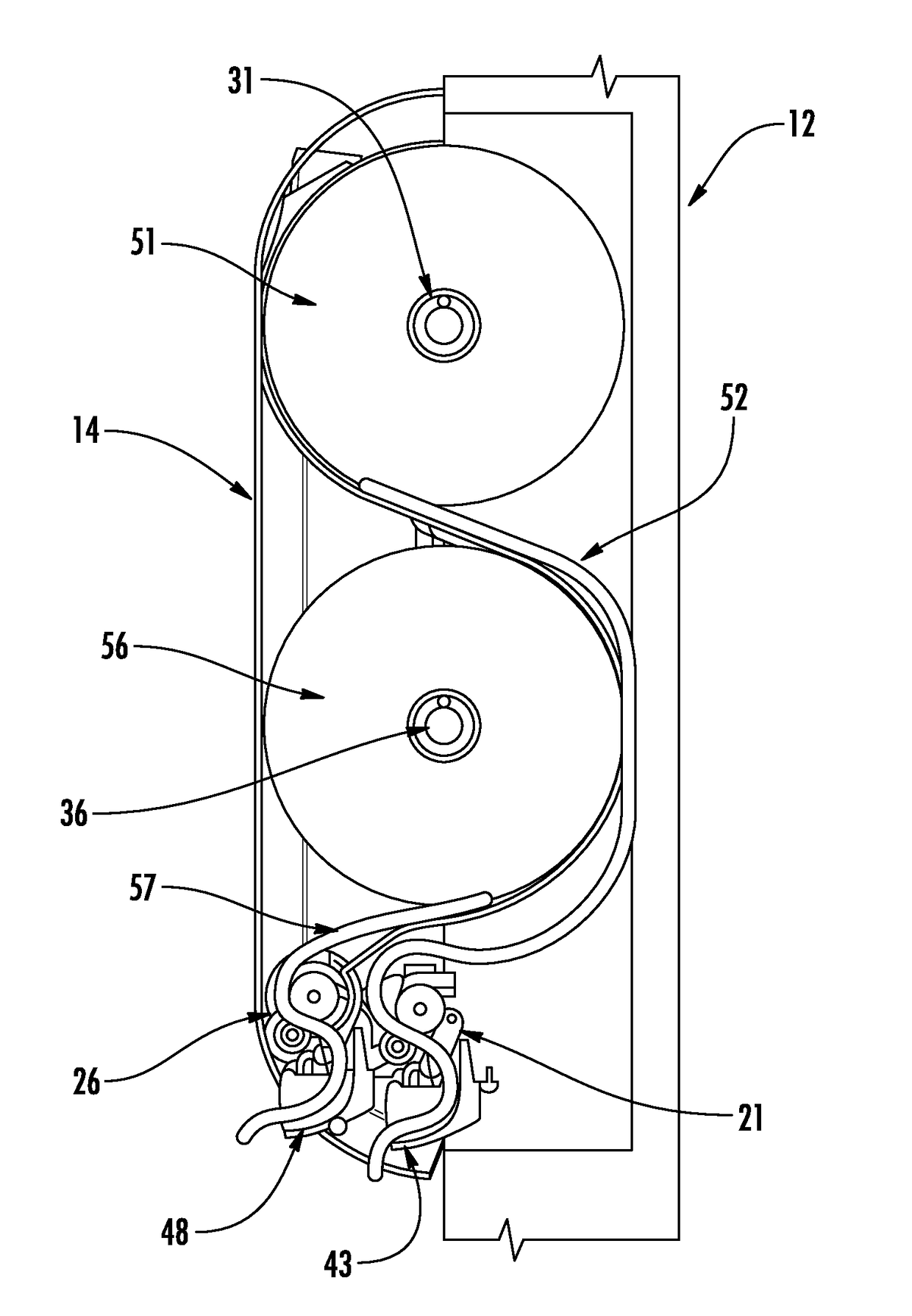

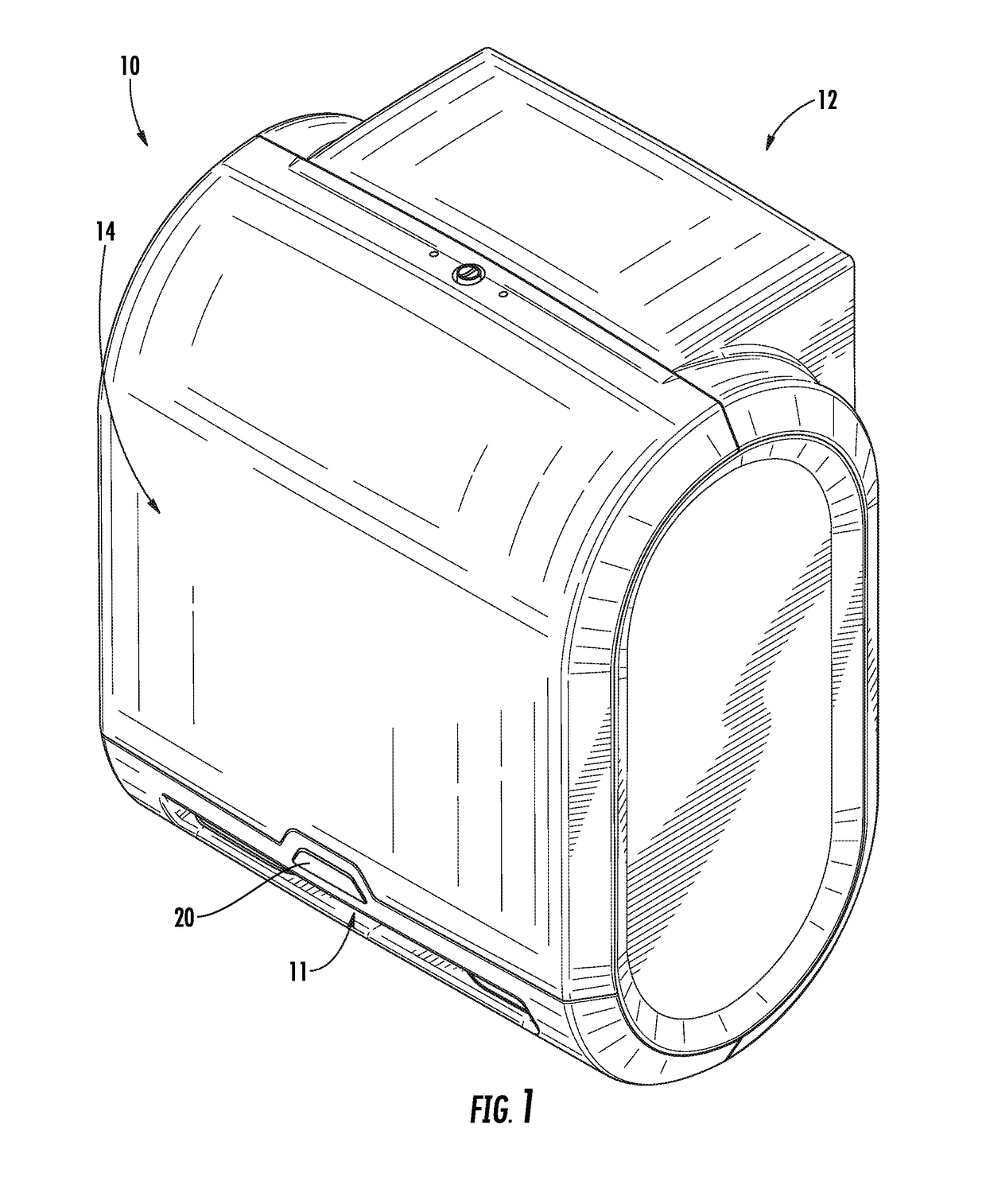

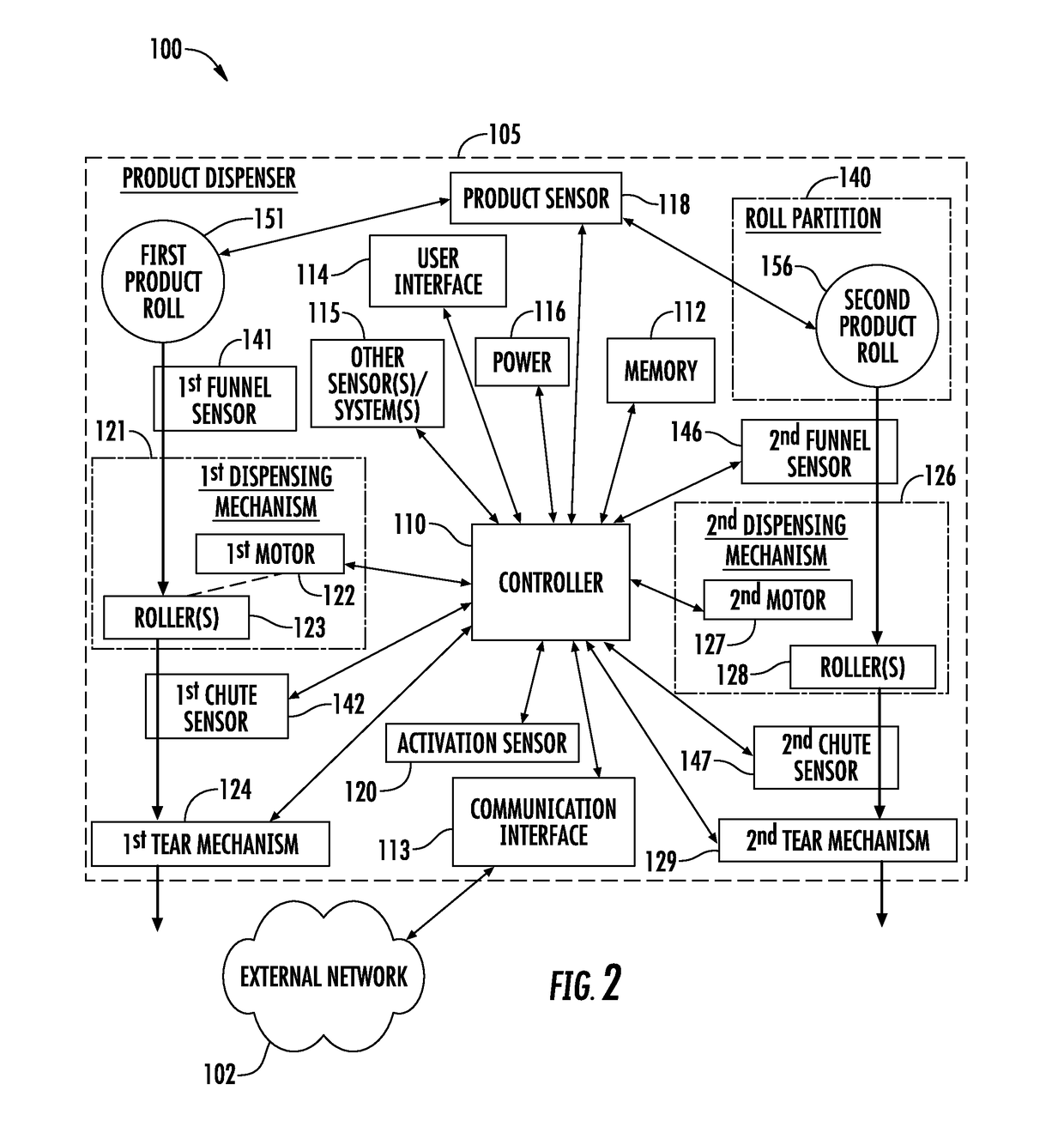

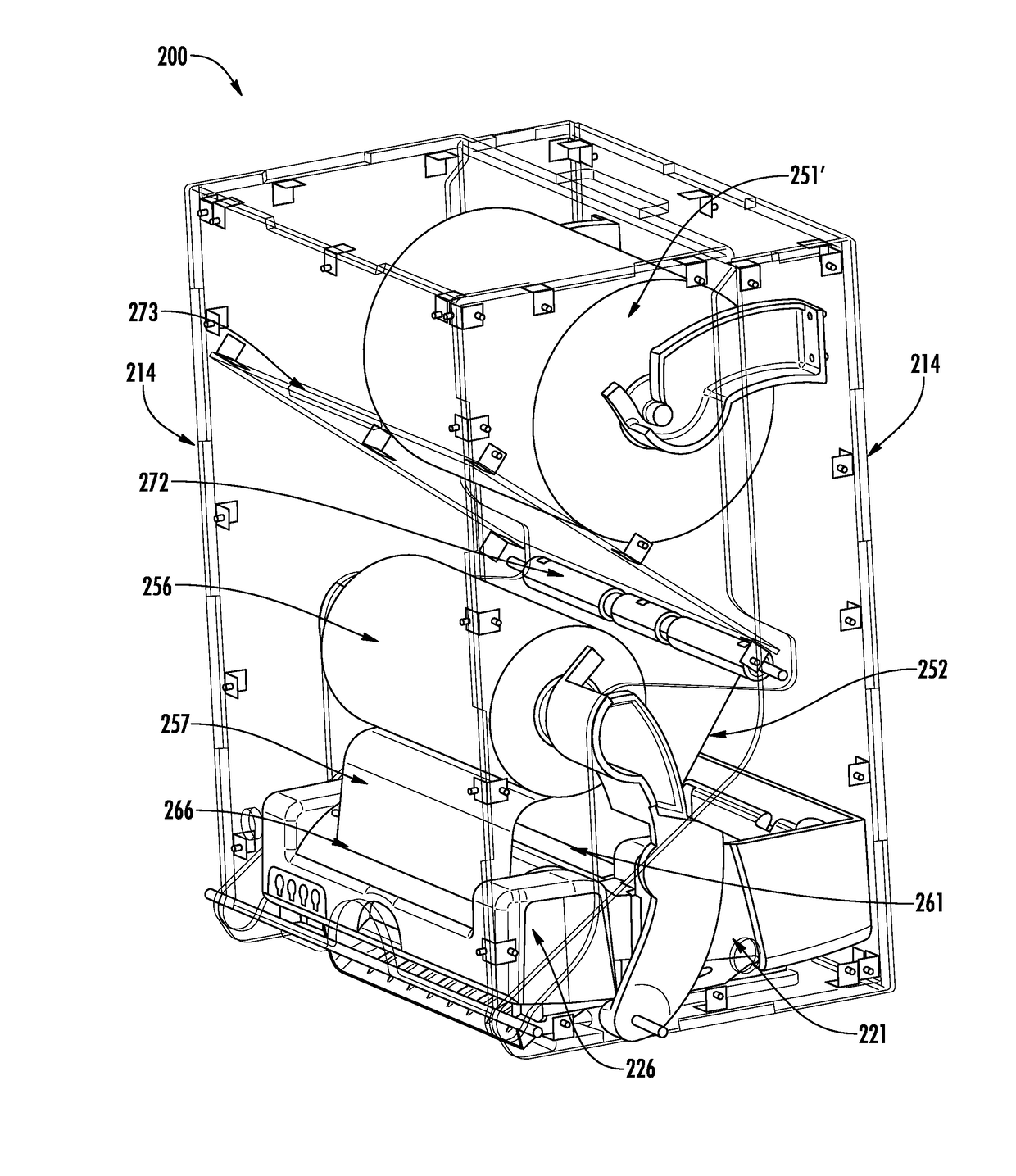

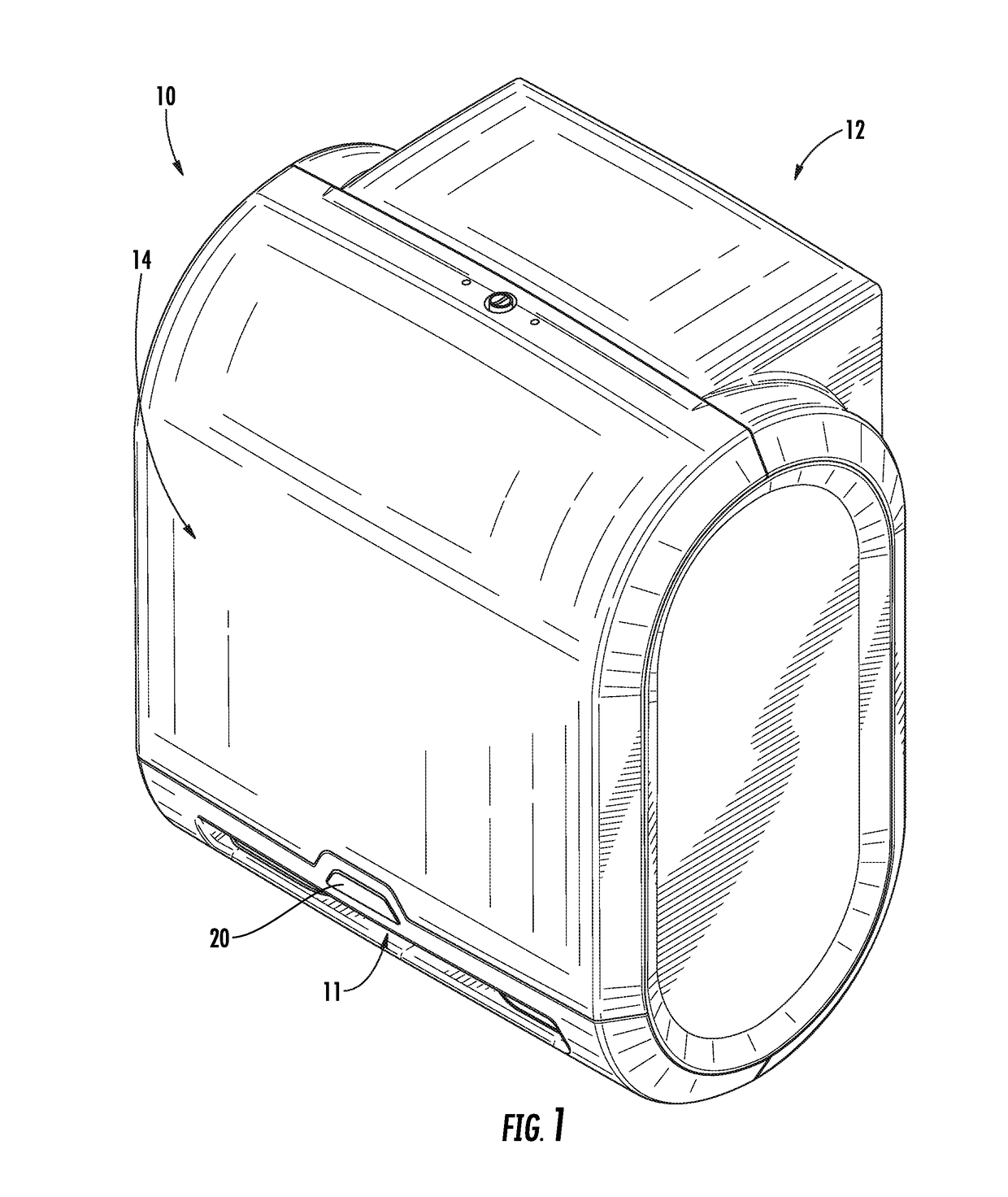

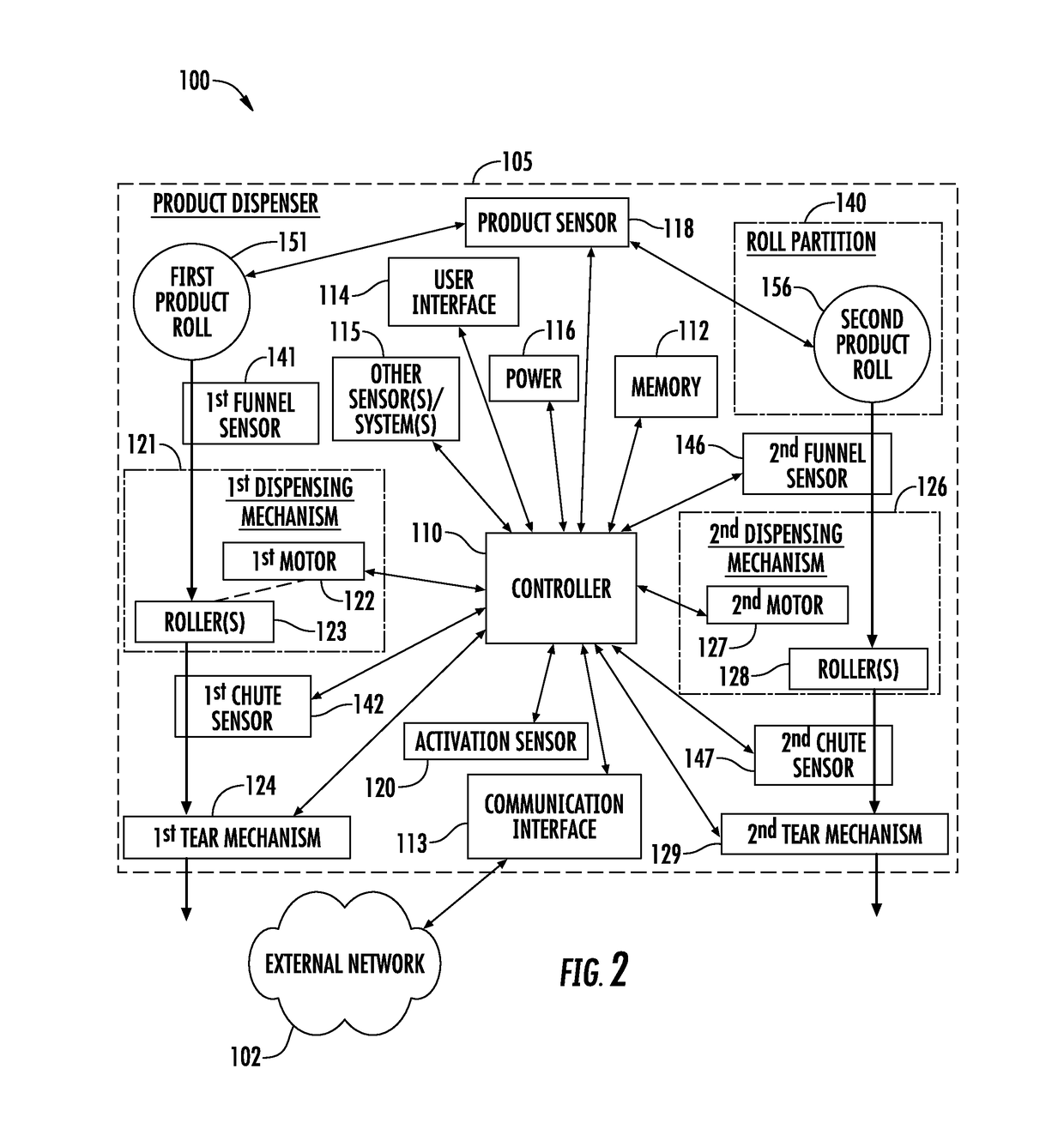

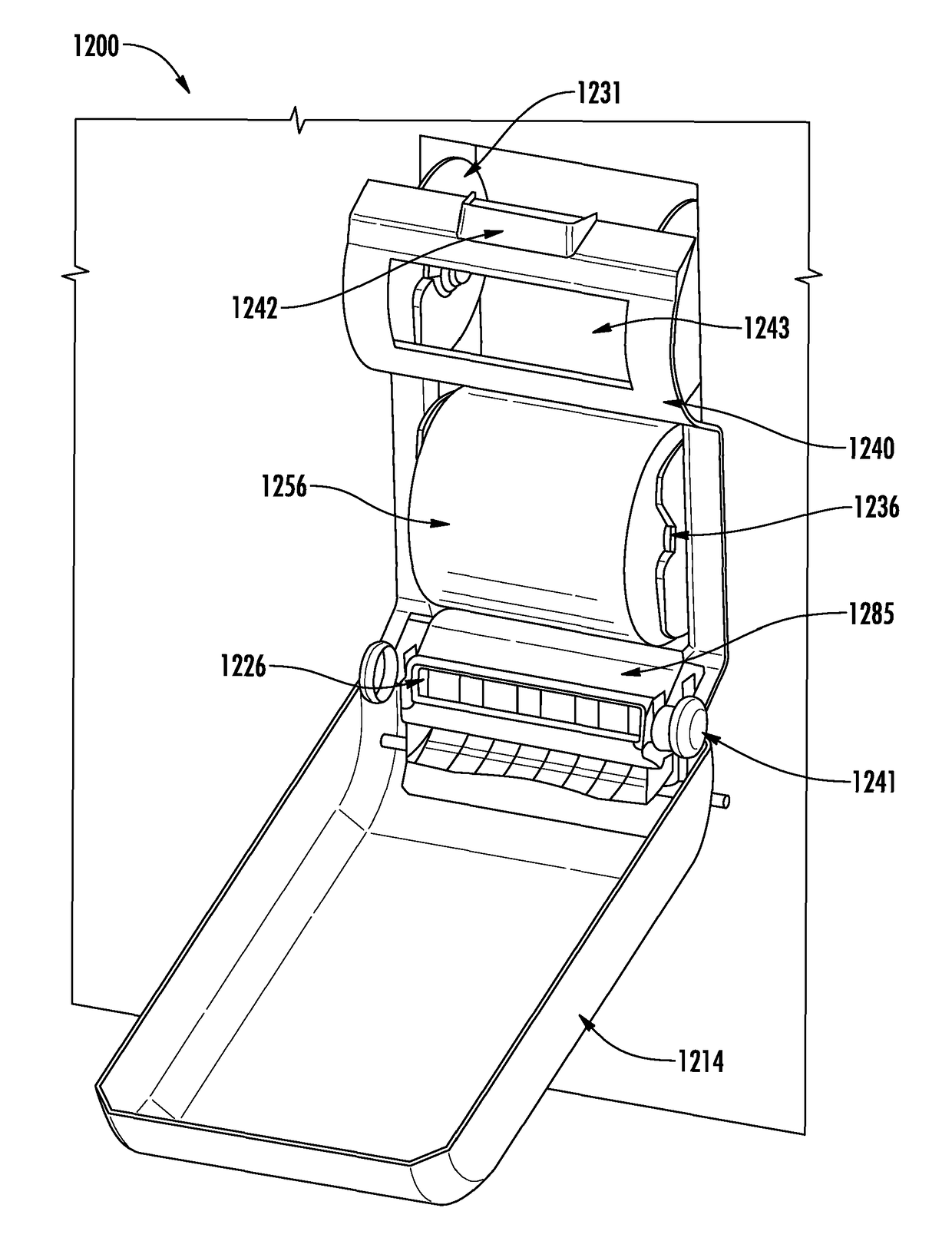

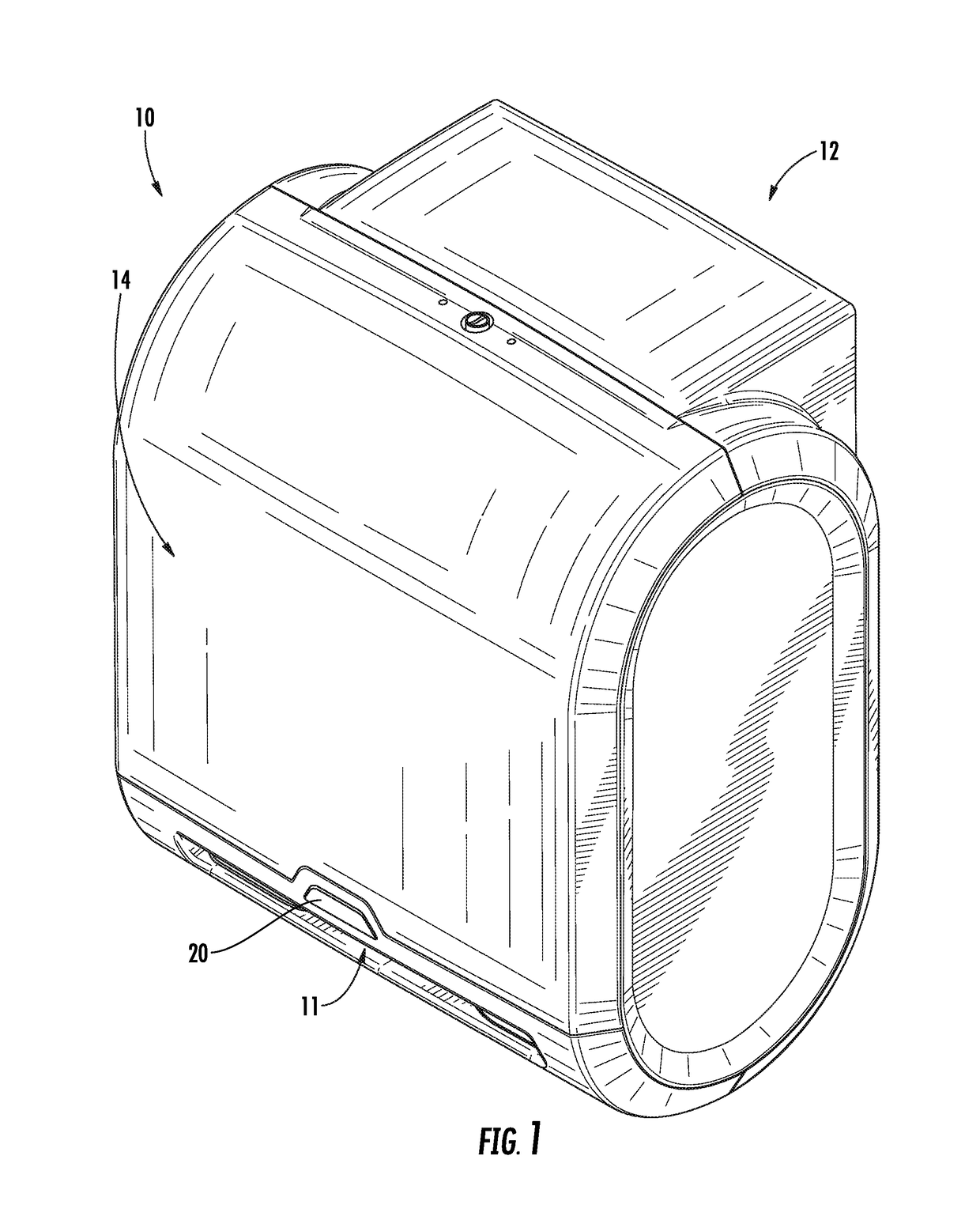

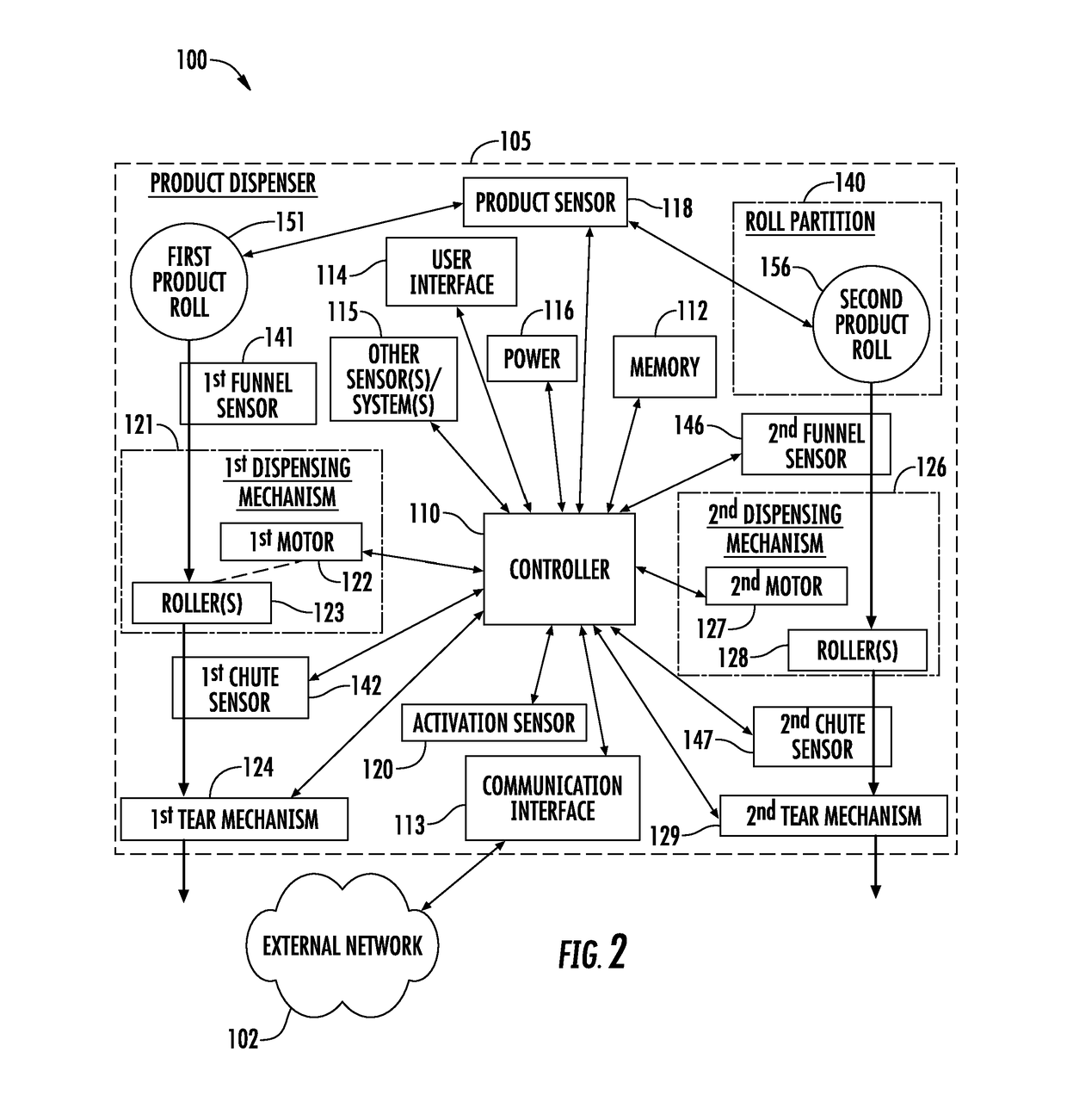

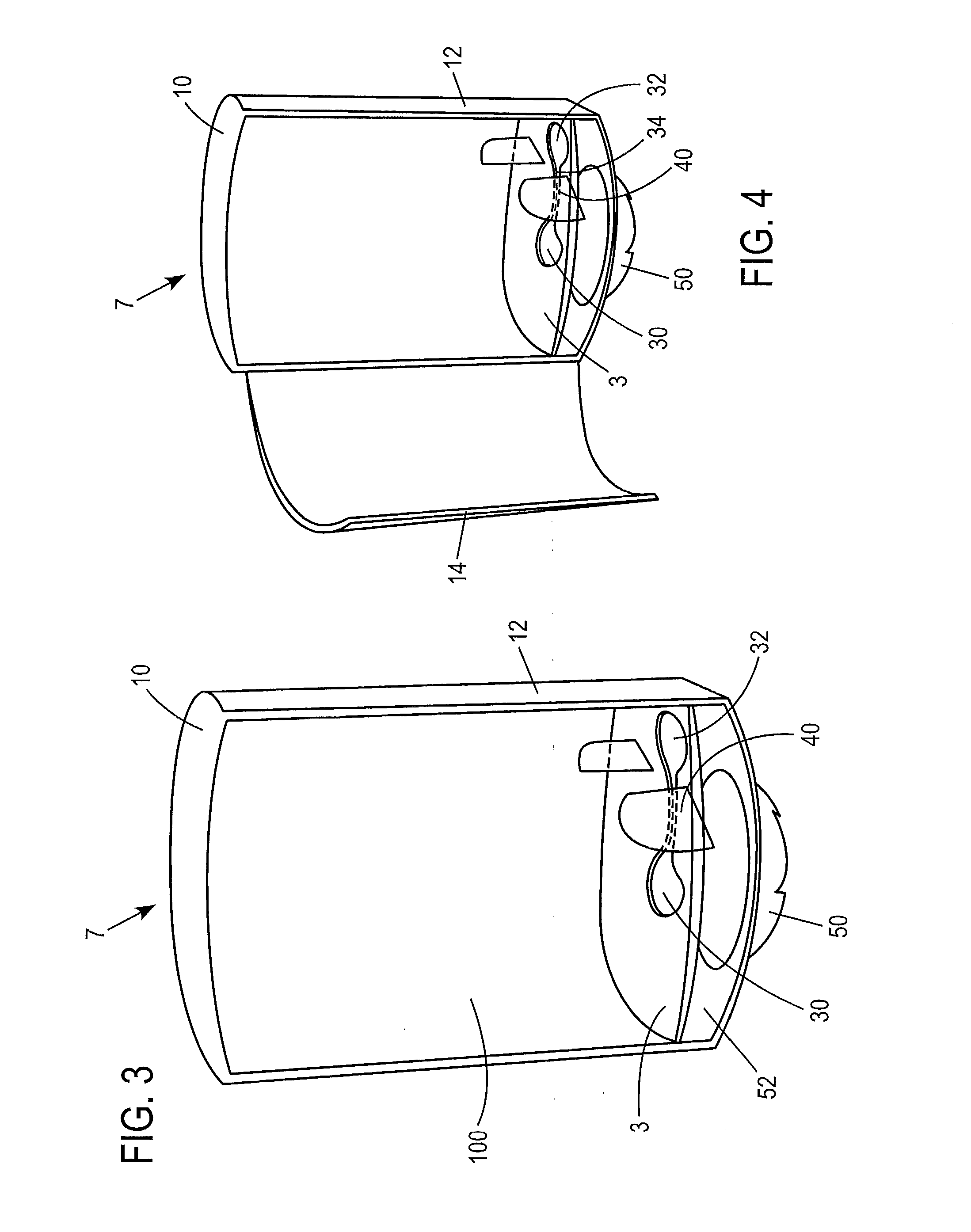

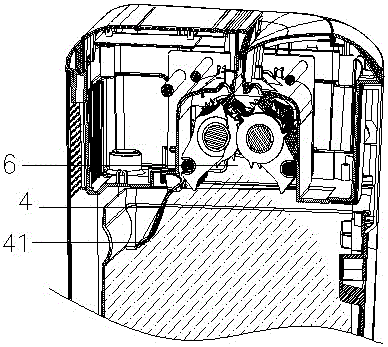

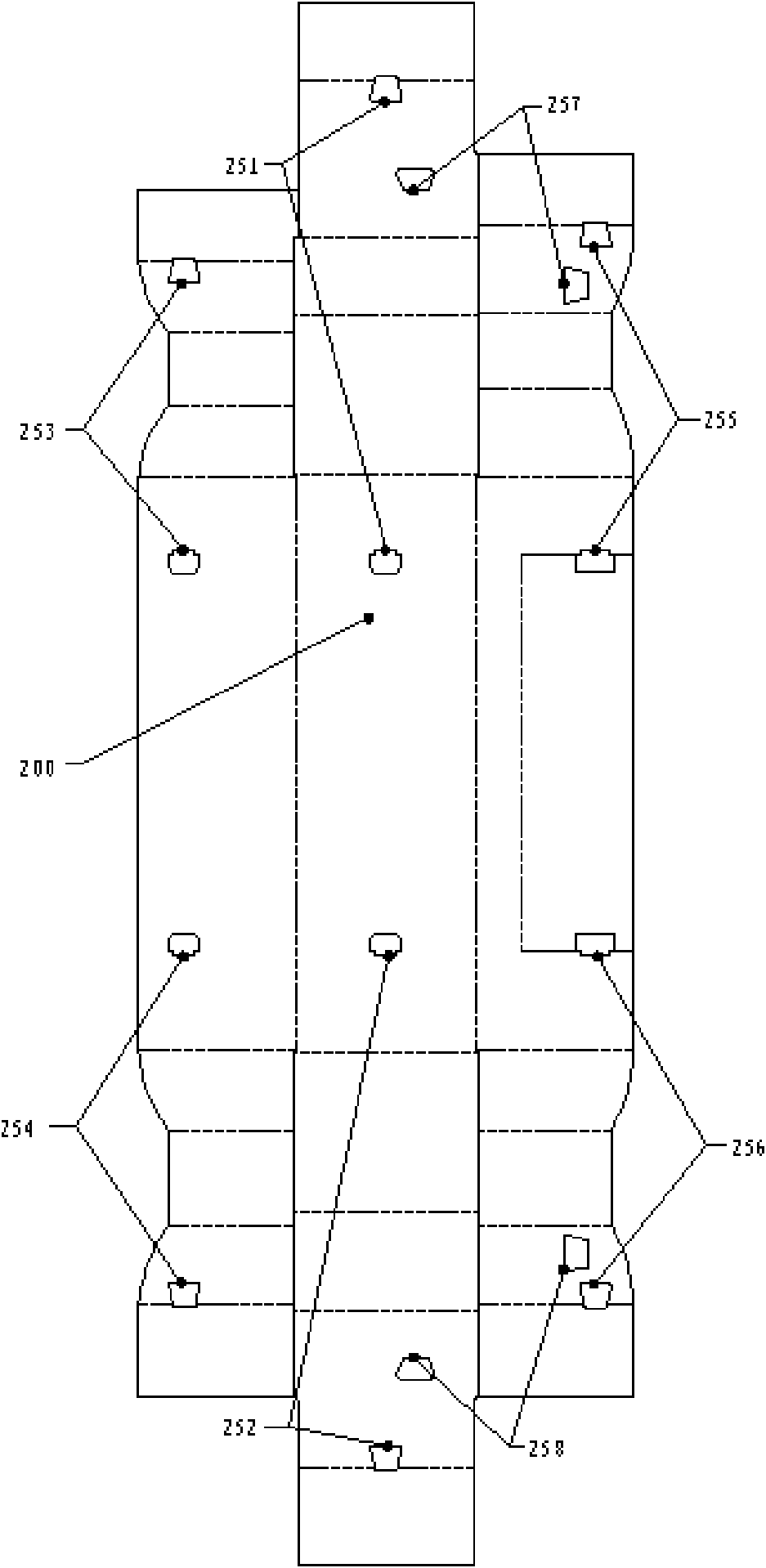

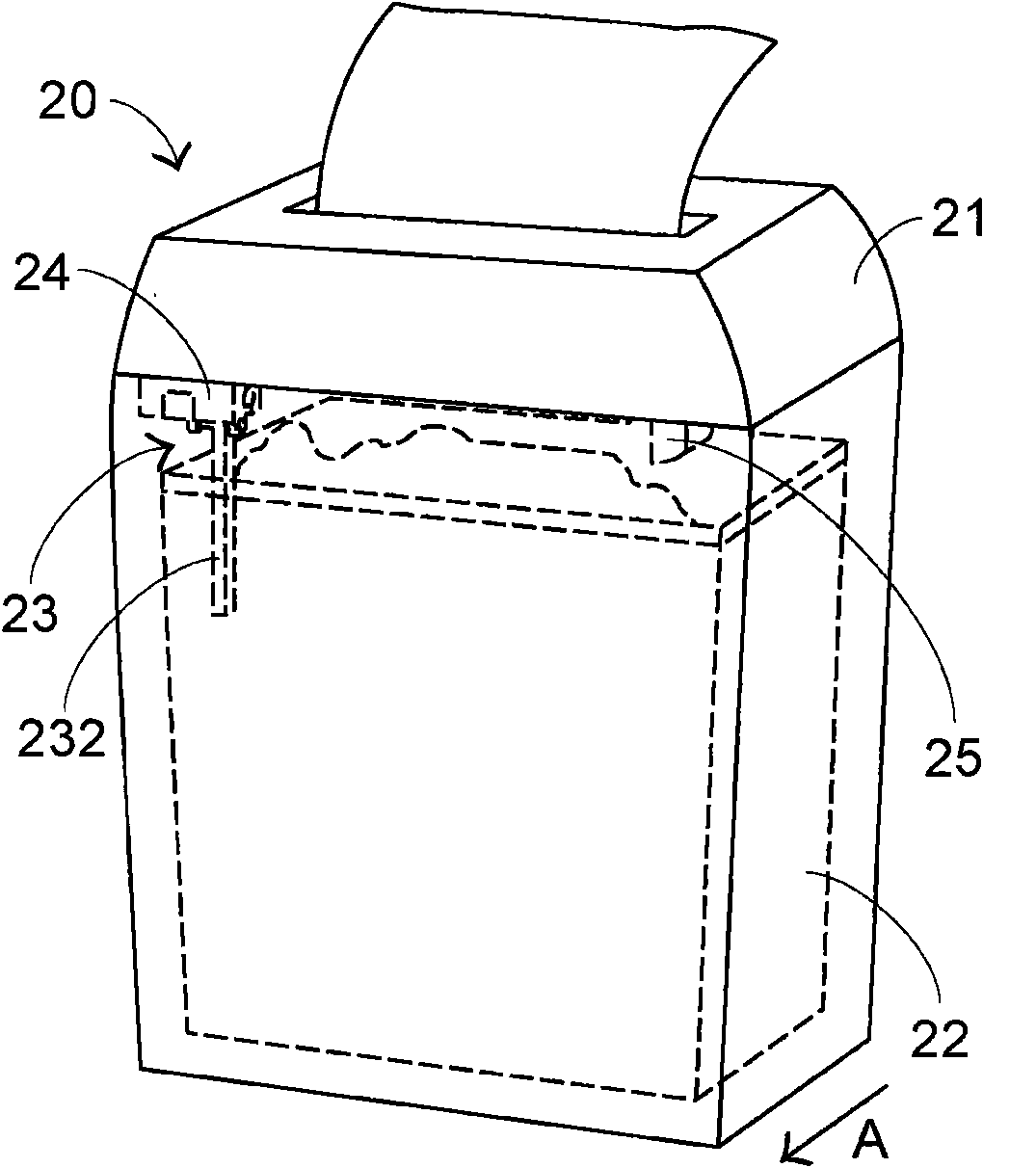

Some example product dispensers that accommodate two full paper towel rolls are provided herein. The product dispenser may employ separate dispensing mechanisms for each product roll and may include roll holders that articulate out from the housing to facilitate easy loading and access to replacement and loading of the other product roll. A roll partition may be utilized to separate the web paths of the two product rolls and enable rotation of front roll holders. Example funnel covers and nip covers can aid with intuitive installation. Example roll holders with retention mechanisms help prevent unintentional dropping of the installed product roll. Other beneficial features include utilizing motor operation sensing to dispense a desired sheet length, automatic / assisted loading into the dispensing mechanism, automatic switching between dispensing of product rolls, and always dispensing from the smaller product roll first. Many other features / structures of example product dispensers are also described herein.

Owner:GPCP IP HLDG LLC

Sheet product dispenser

ActiveUS20170290471A1Reduce wasteEasy to switchDomestic applicationsEngineeringMechanical engineering

Some example product dispensers that accommodate two full paper towel rolls are provided herein. The product dispenser may employ separate dispensing mechanisms for each product roll and may include roll holders that articulate out from the housing to facilitate easy loading and access to replacement and loading of the other product roll. A roll partition may be utilized to separate the web paths of the two product rolls and enable rotation of front roll holders. Example funnel covers and nip covers can aid with intuitive installation. Example roll holders with retention mechanisms help prevent unintentional dropping of the installed product roll. Other beneficial features include utilizing motor operation sensing to dispense a desired sheet length, automatic / assisted loading into the dispensing mechanism, automatic switching between dispensing of product rolls, and always dispensing from the smaller product roll first. Many other features / structures of example product dispensers are also described herein.

Owner:GPCP IP HLDG LLC

Sheet product dispenser

Some example product dispensers that accommodate two full paper towel rolls are provided herein. The product dispenser may employ separate dispensing mechanisms for each product roll and may include roll holders that articulate out from the housing to facilitate easy loading and access to replacement and loading of the other product roll. A roll partition may be utilized to separate the web paths of the two product rolls and enable rotation of front roll holders. Example funnel covers and nip covers can aid with intuitive installation. Example roll holders with retention mechanisms help prevent unintentional dropping of the installed product roll. Other beneficial features include utilizing motor operation sensing to dispense a desired sheet length, automatic / assisted loading into the dispensing mechanism, automatic switching between dispensing of product rolls, and always dispensing from the smaller product roll first. Many other features / structures of example product dispensers are also described herein.

Owner:GPCP IP HLDG LLC

Sheet product dispenser

ActiveUS9999326B2Reduce wasteEasy to switchDomestic applicationsArticle separationEngineeringMechanical engineering

Some example product dispensers that accommodate two full paper towel rolls are provided herein. The product dispenser may employ separate dispensing mechanisms for each product roll and may include roll holders that articulate out from the housing to facilitate easy loading and access to replacement and loading of the other product roll. A roll partition may be utilized to separate the web paths of the two product rolls and enable rotation of front roll holders. Example funnel covers and nip covers can aid with intuitive installation. Example roll holders with retention mechanisms help prevent unintentional dropping of the installed product roll. Other beneficial features include utilizing motor operation sensing to dispense a desired sheet length, automatic / assisted loading into the dispensing mechanism, automatic switching between dispensing of product rolls, and always dispensing from the smaller product roll first. Many other features / structures of example product dispensers are also described herein.

Owner:GPCP IP HLDG LLC

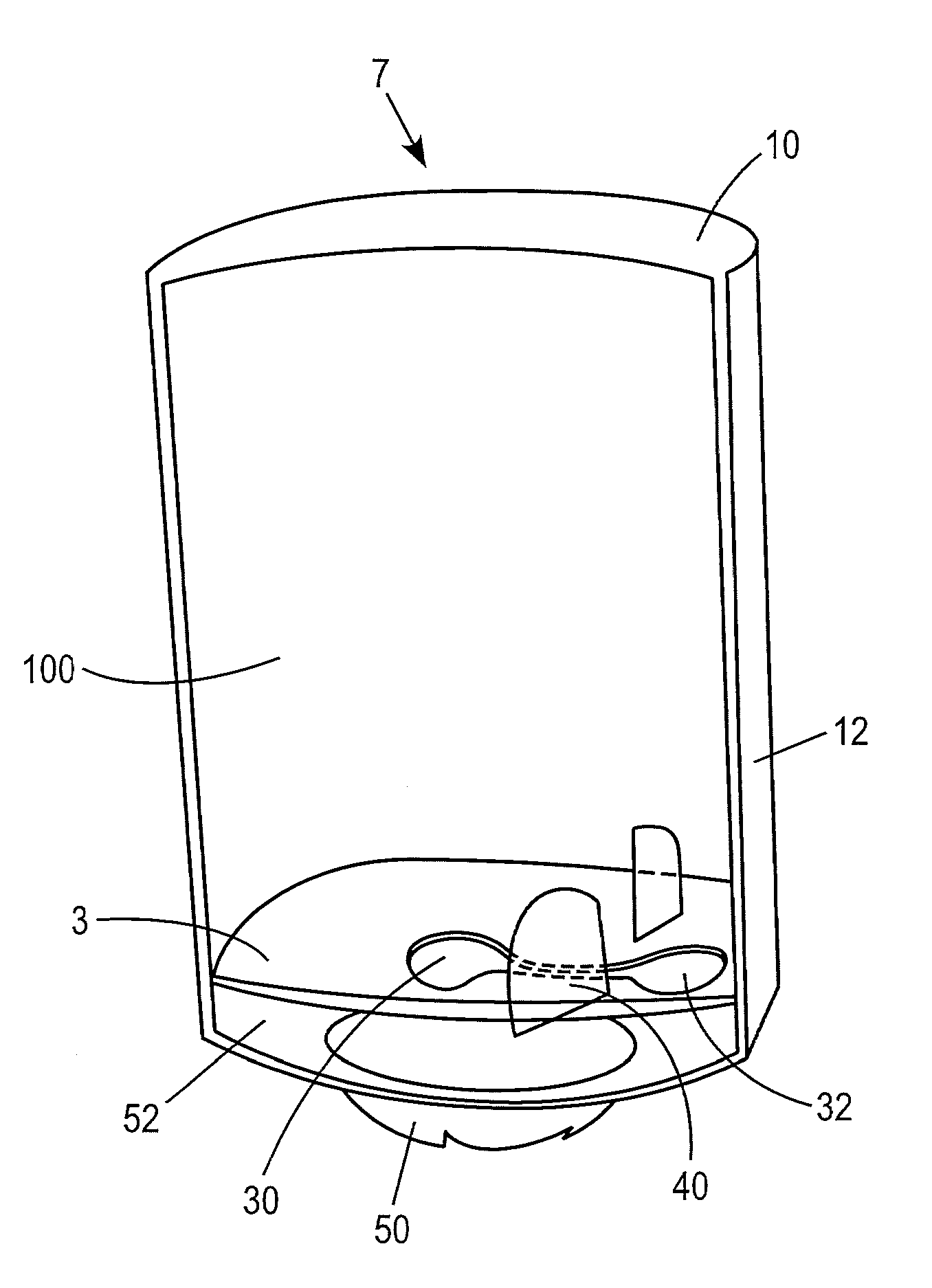

Dispenser for dispensing paper from center-feed tissue paper rolls

InactiveUS20120256037A1Improves serviceability and reliabilityFilament handlingDomestic applicationsSpray nozzleTissue paper

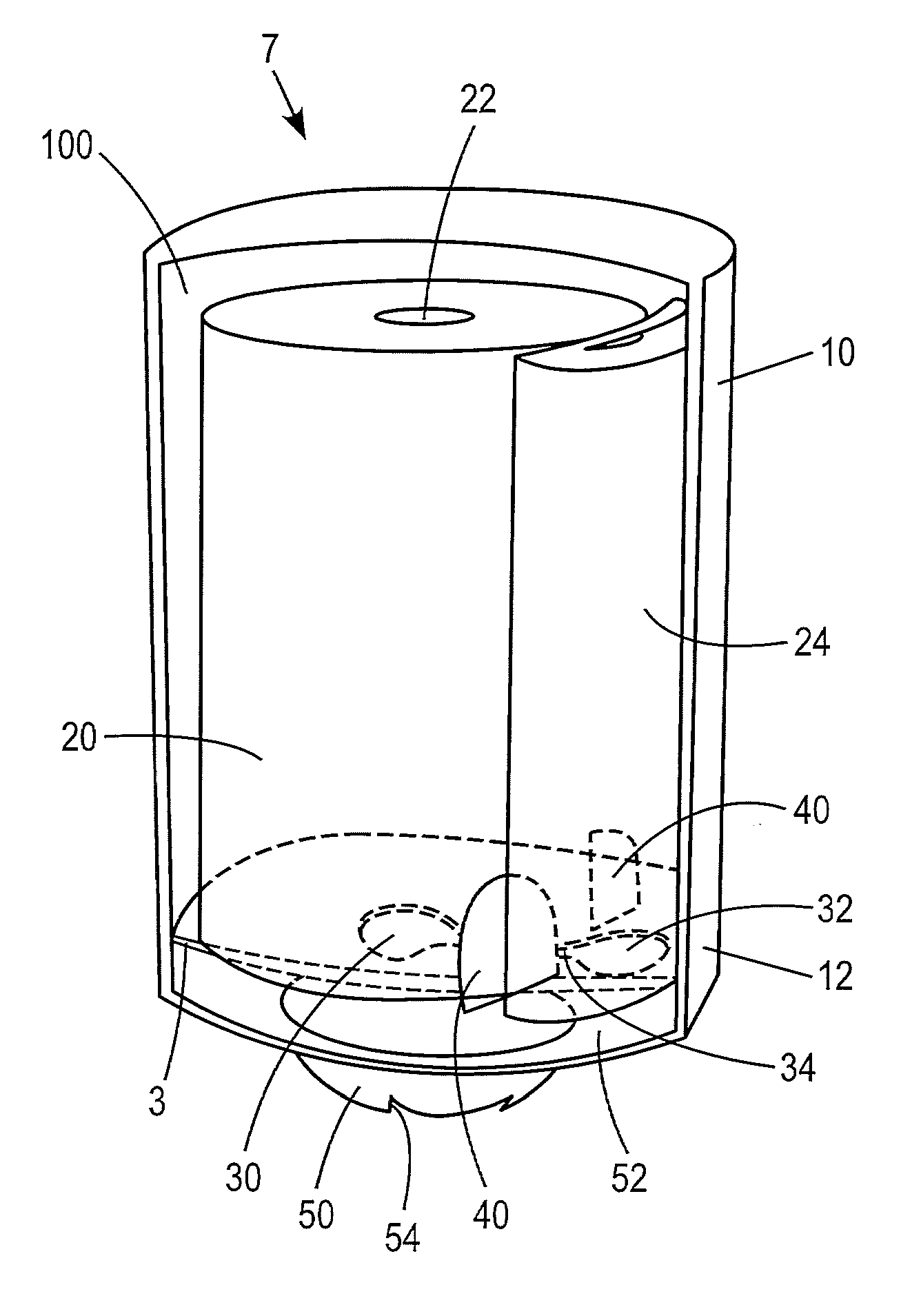

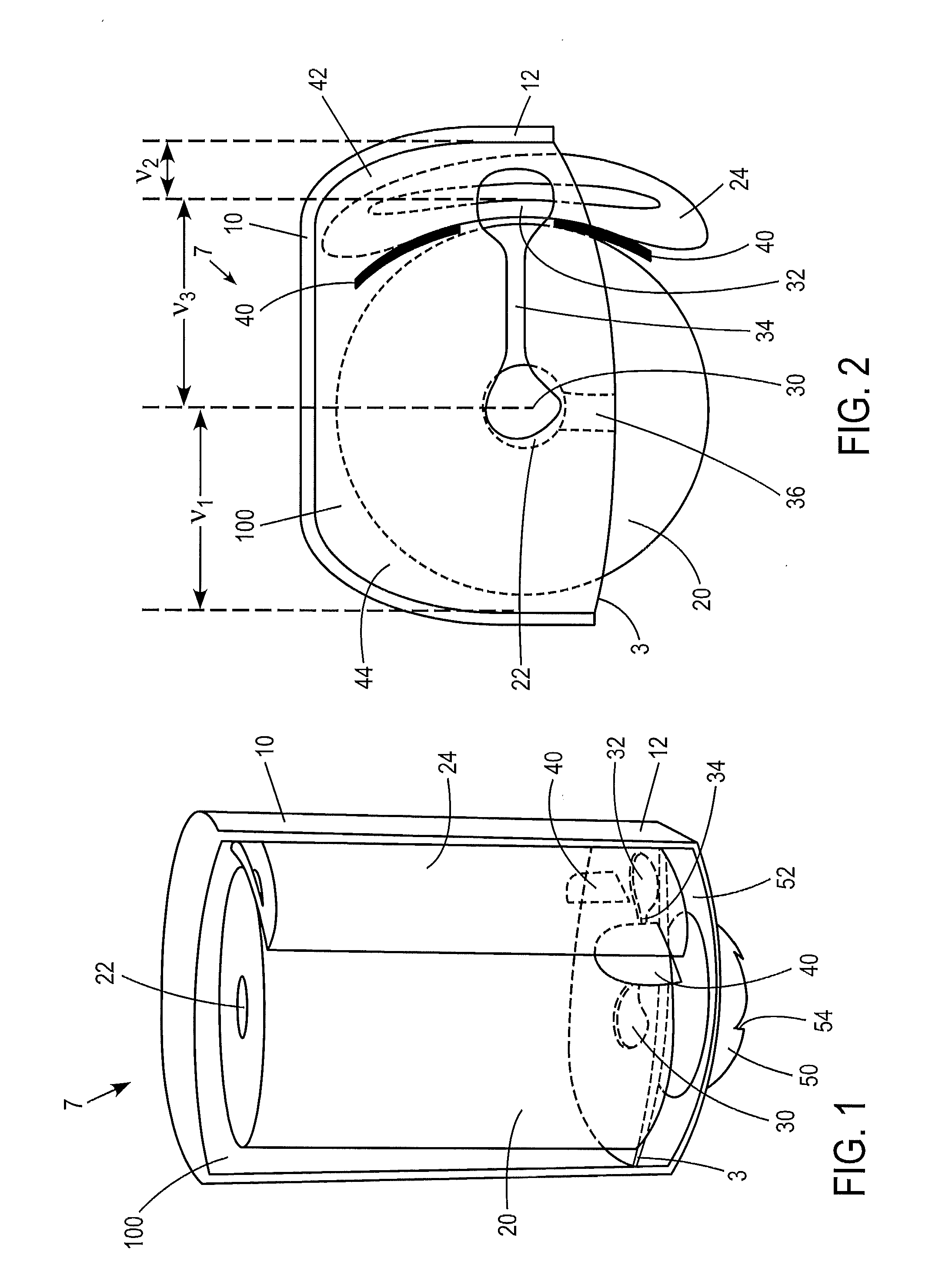

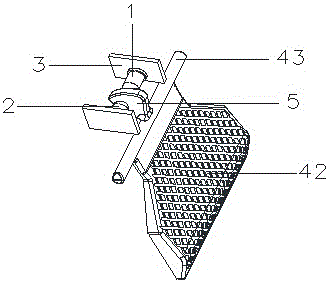

A dispenser for dispensing paper from center-feed tissue paper rolls, the dispenser having a housing with a receiving portion for receiving two center-feed rolls, one of which is a full paper roll and the other one an almost used-up paper roll squeezed into the form of a sickle to make the dispenser less bulky. The two rolls dispense through separate openings, which may be linked to a common dispensing nozzle spaced apart from the openings.

Owner:SCA HYGIENE PROD AB

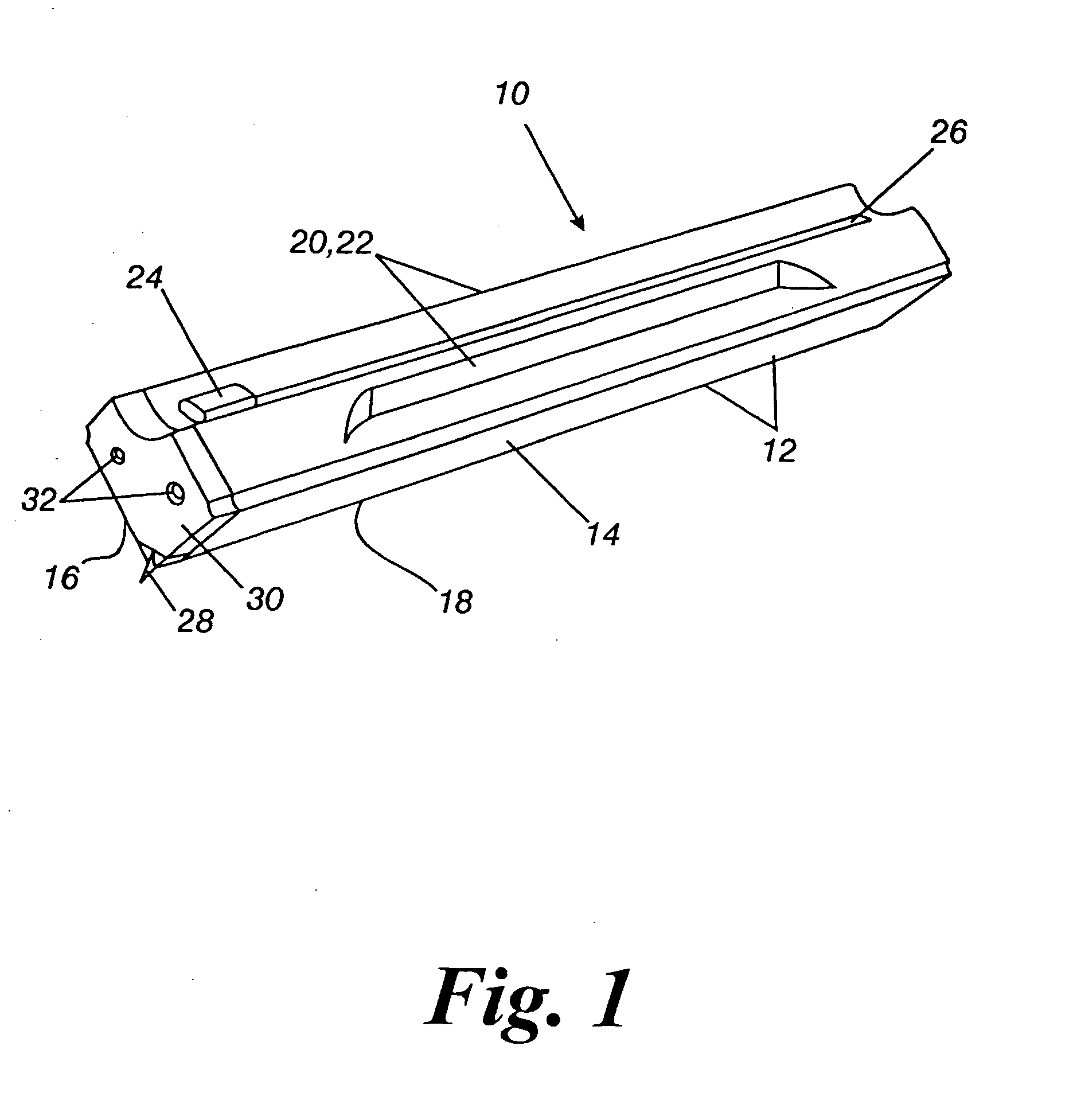

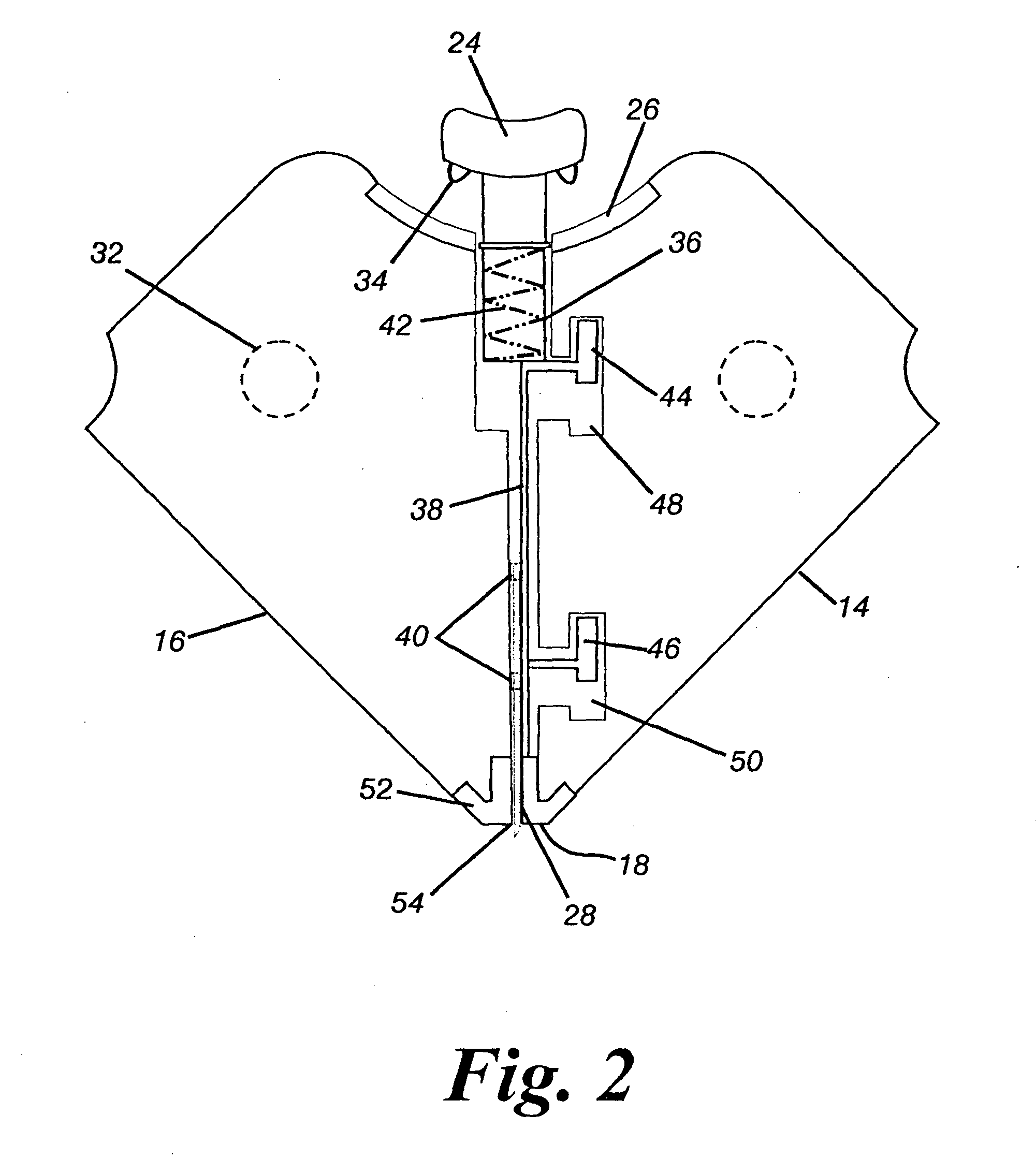

Handheld scoring device and method for scoring flexible sheet material

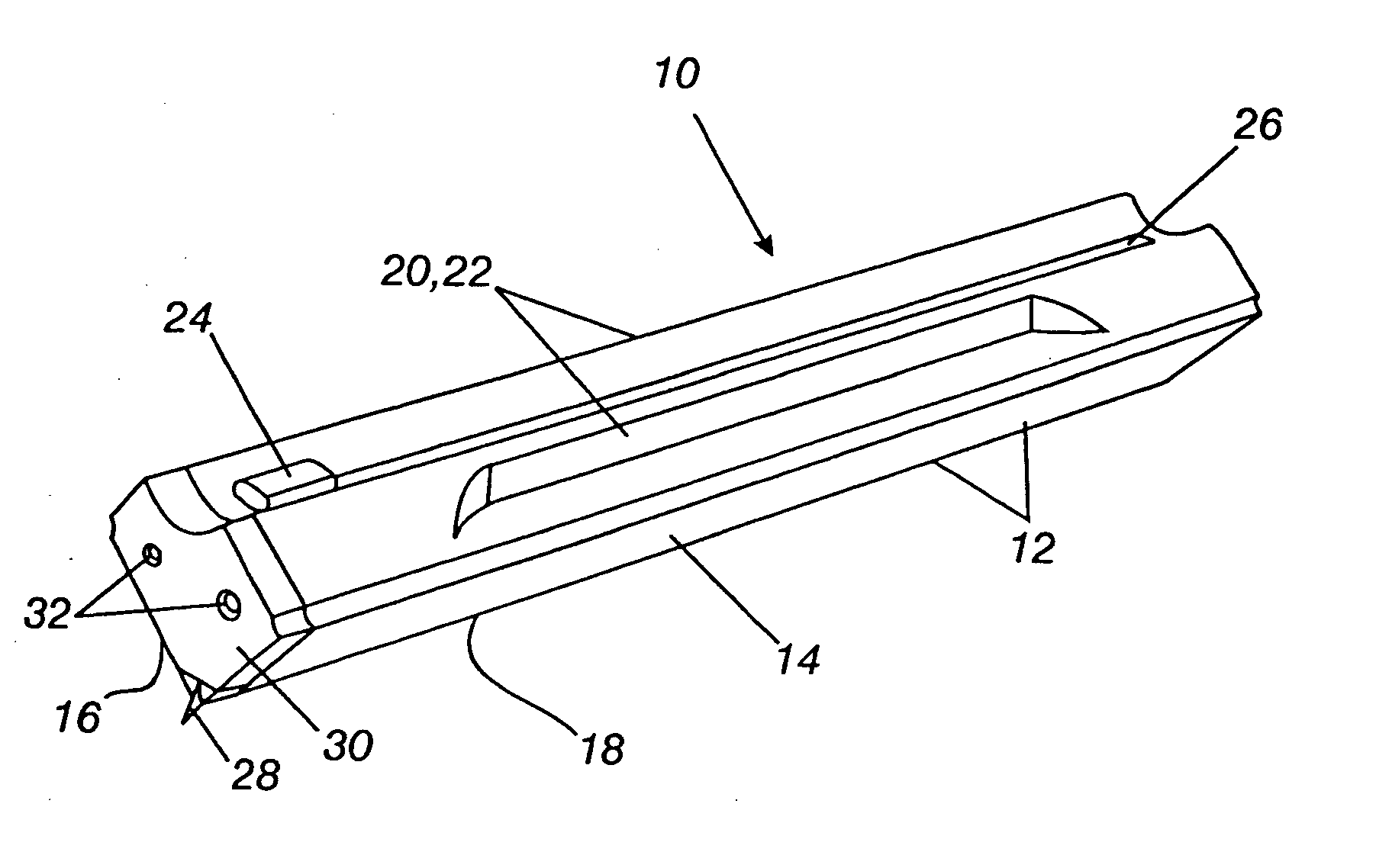

InactiveUS20050016352A1Easy to cutEasy to makeMetal working apparatusMetal-working hand toolsHand heldImproved method

An improved method and apparatus for the cutting of inside 90-degree corners such as cabinet lining, wallpaper and the like is provided. The invention fits snugly into a 90-degree corner, and an internally contained razor blade depresses enough to cut the paper product desired. Sheet, film, or foil material is positioned or applied over the corner. The cutting device is then inserted firmly into the corner, and slide button 24 slid along a track in order to cut the paper the full length of the cutting device. If the length of the desired cut should exceed the cutting length of the device, the device can simply be moved, and the process repeated until the full piece of paper is cut.

Owner:MCCORKLE RICKY J

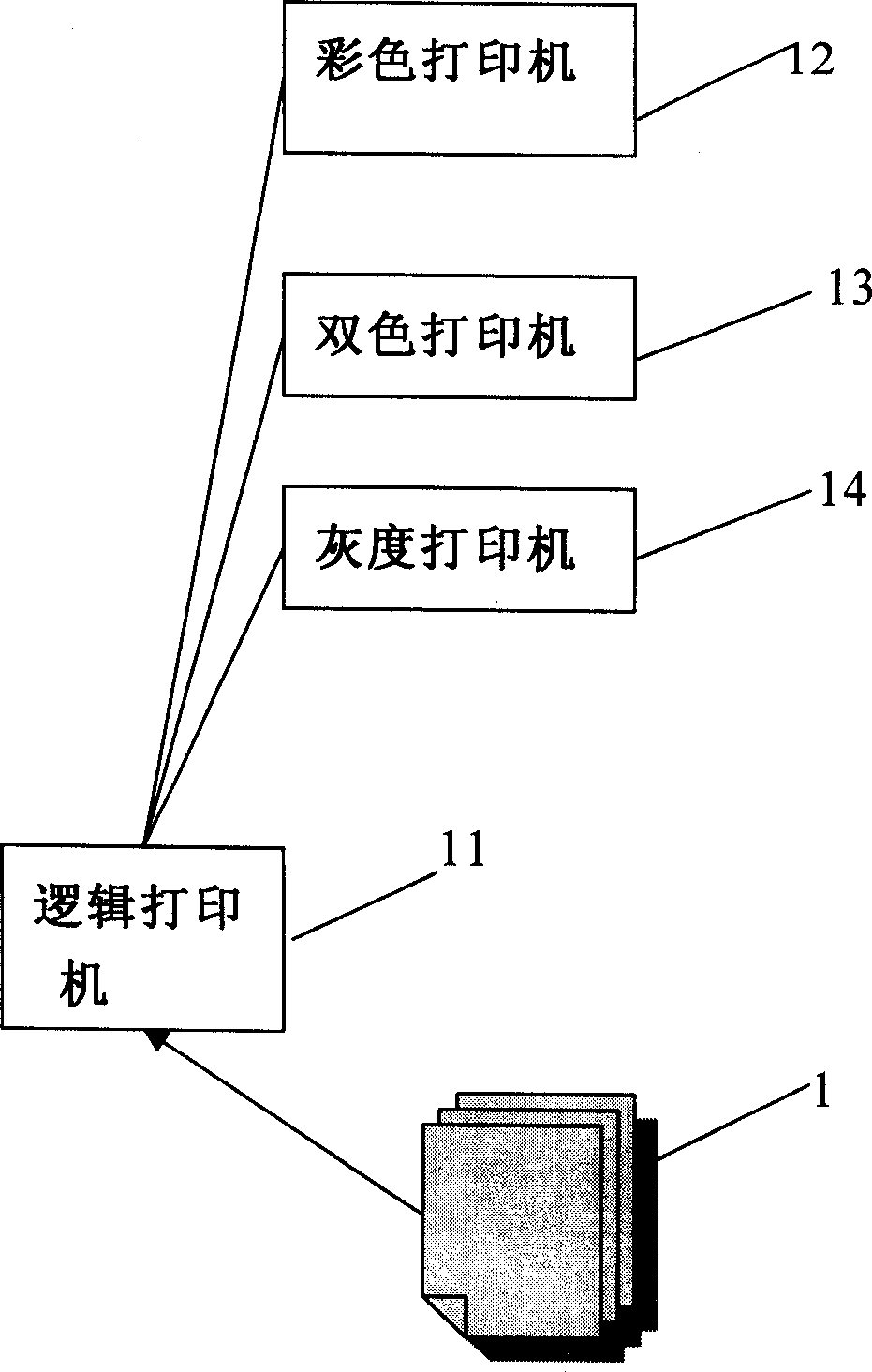

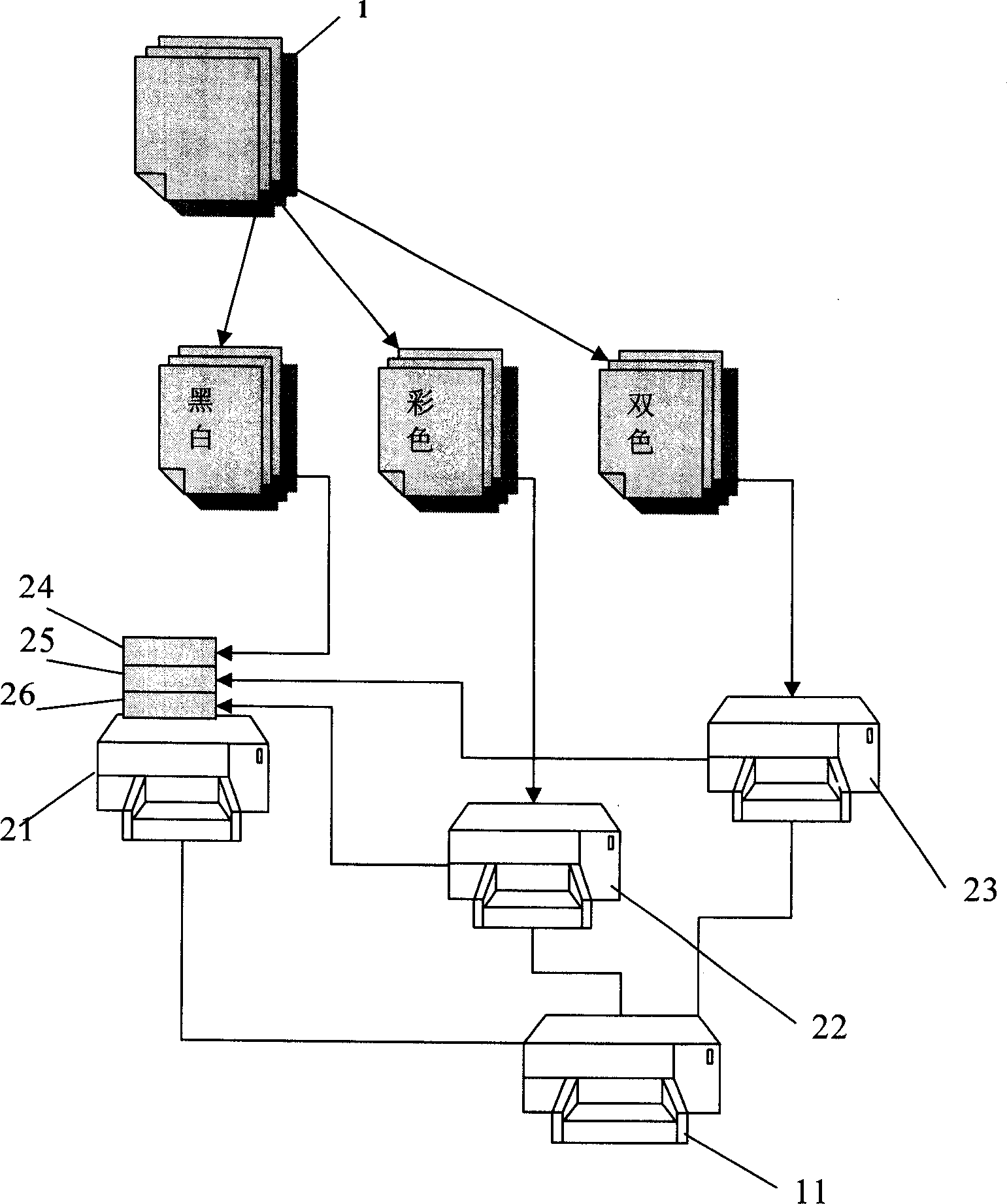

Method for completing full paper output in color mode based self-adaptive way

ActiveCN1908888AIncrease the output speedReduce output costVisual presentation using printersDigital output to print unitsDigital printingSelf adaptive

The related output method for multiple files comprises: deciding page color mode by software, auto setting inset box for special page, and outputting the whole file for one time by multiple printers. This invention reduces cost, improves output accuracy, and has wide application in digital printing.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

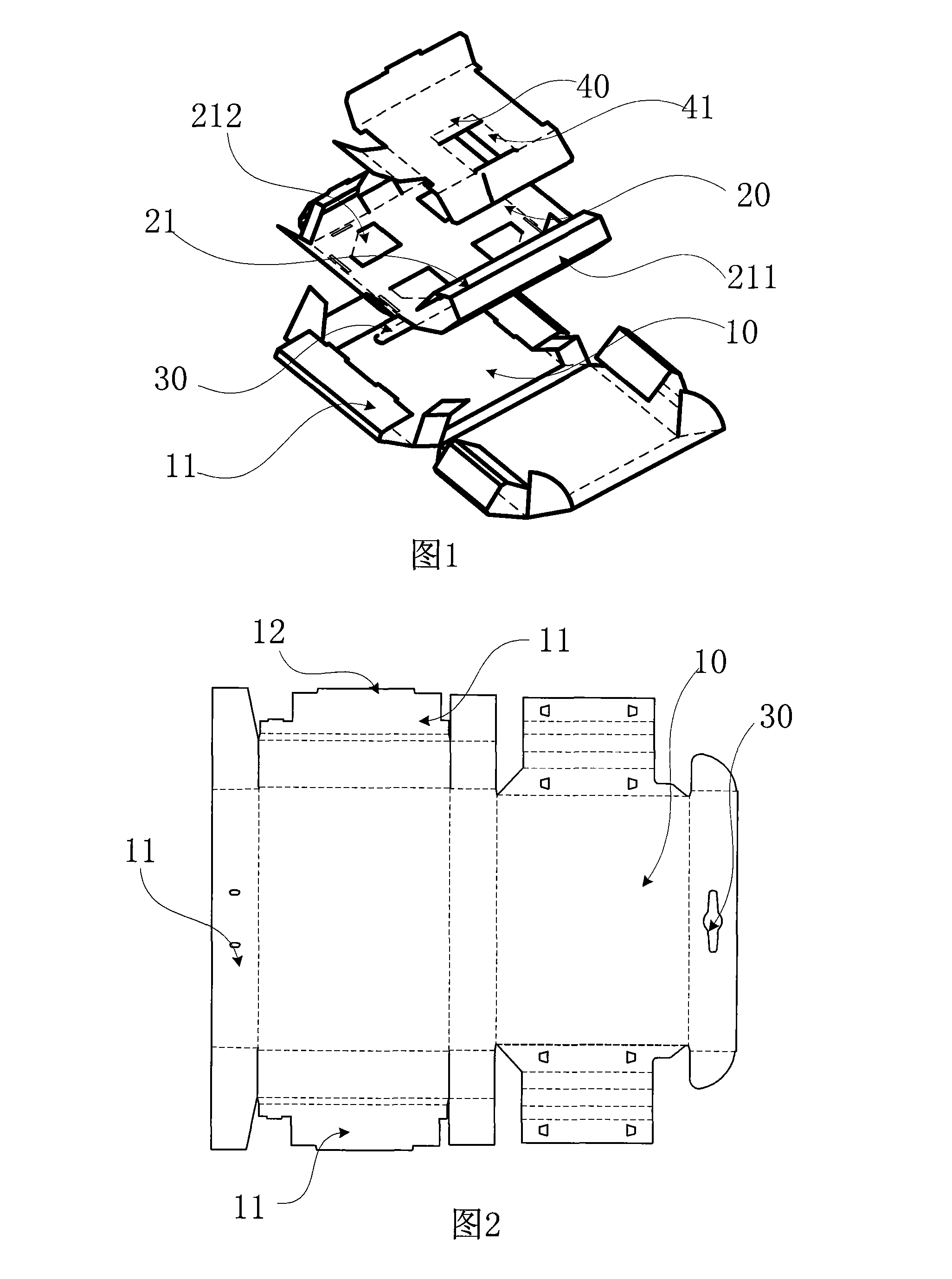

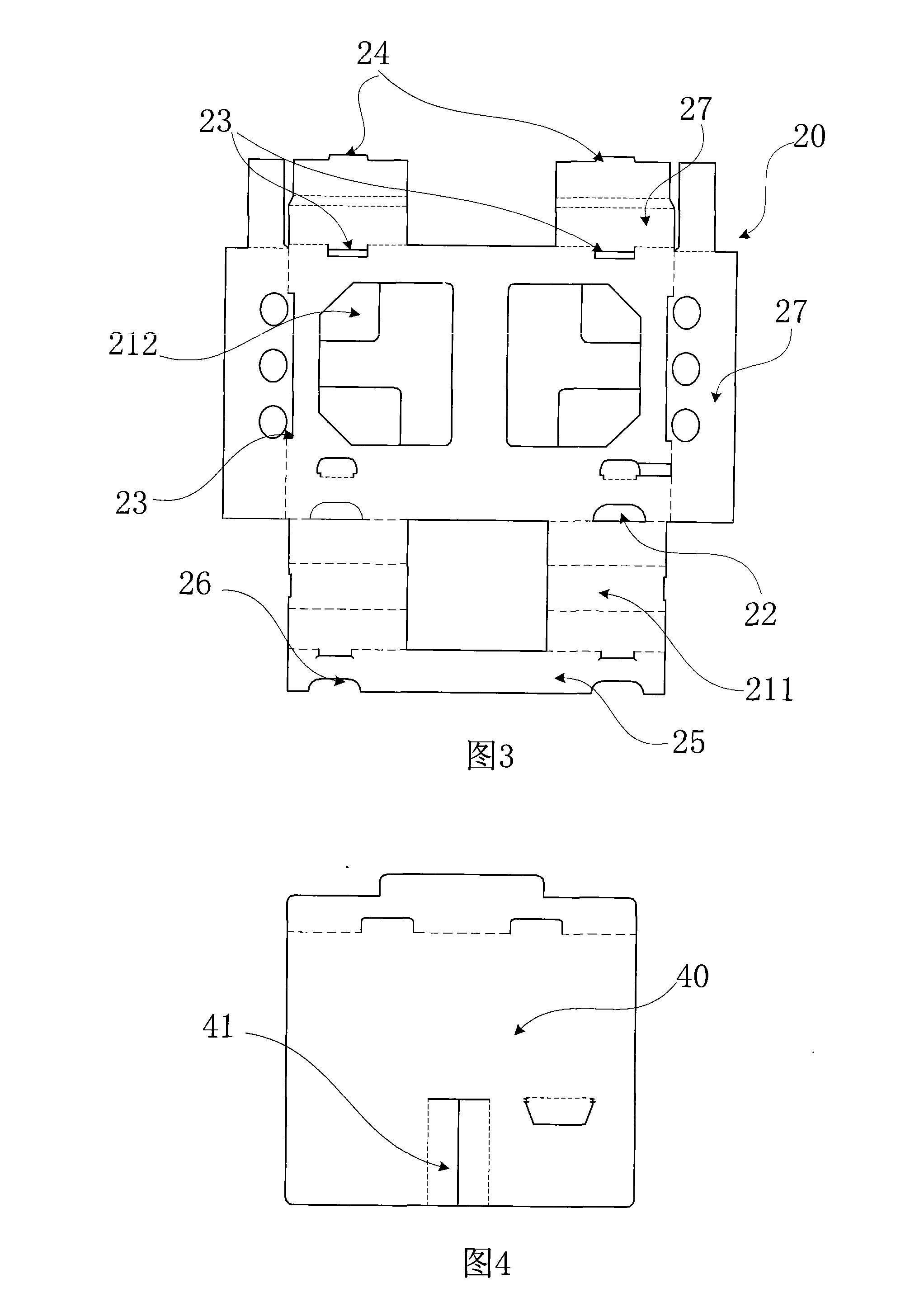

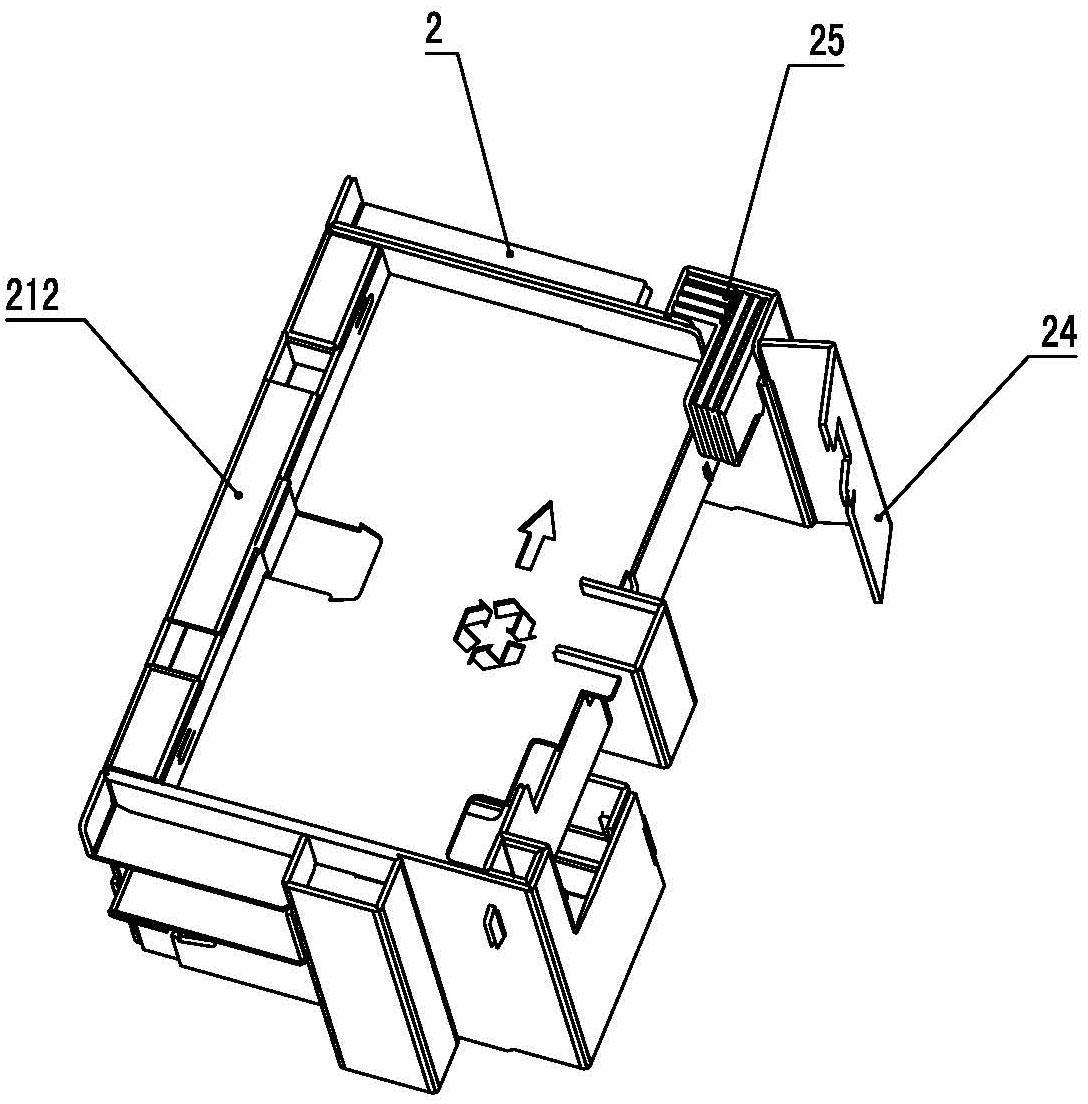

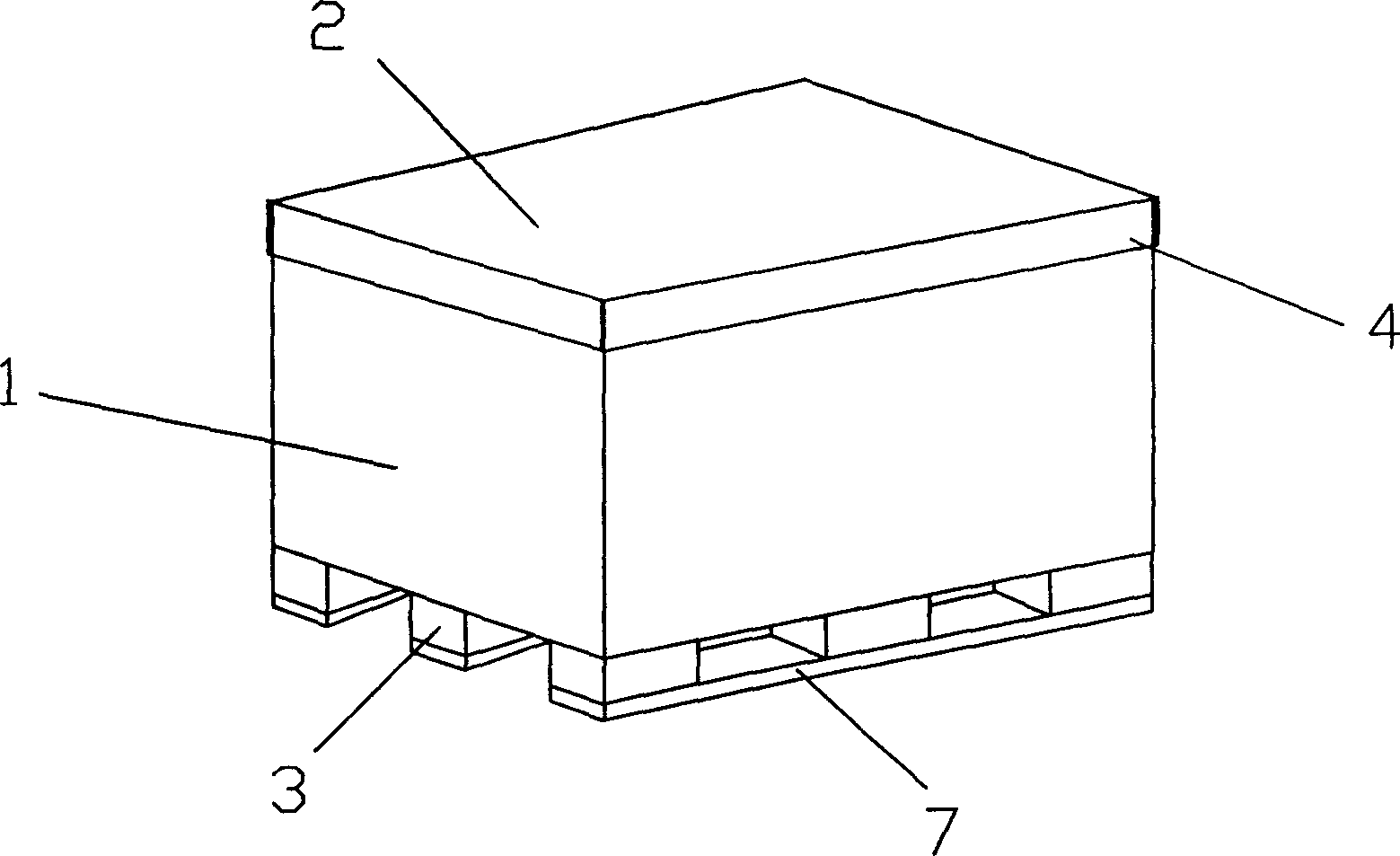

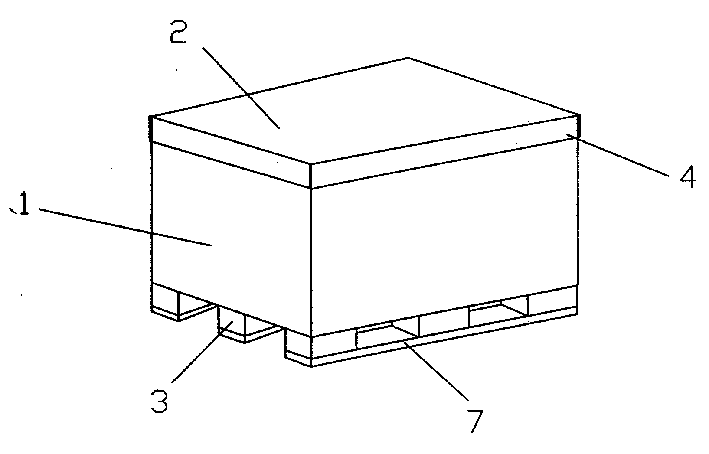

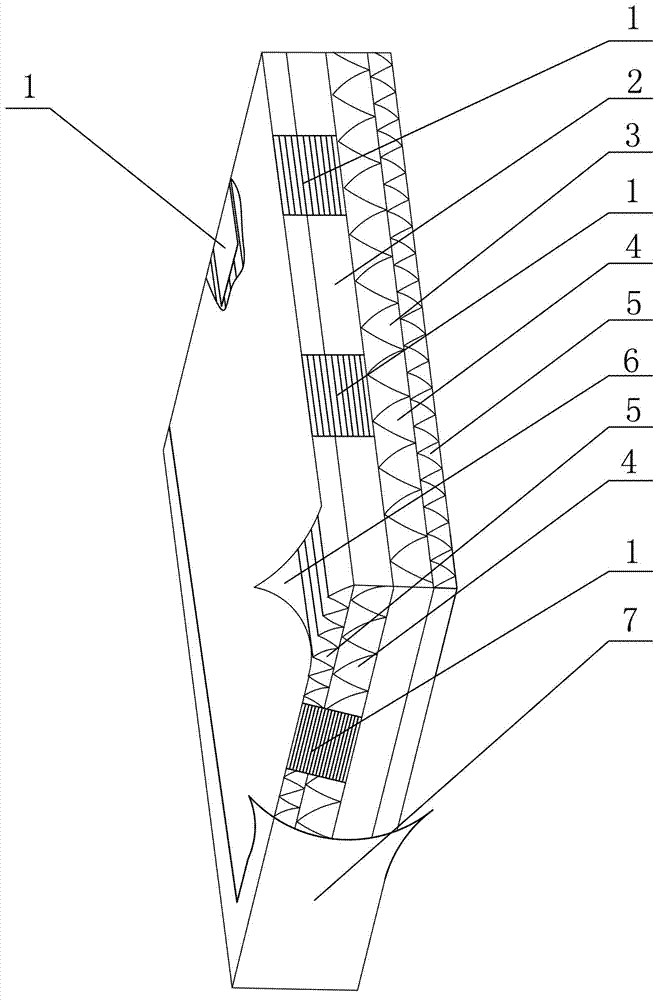

Full paper packaging box of flat panel display and manufacturing method thereof

InactiveCN101513779AReduce shockSave folding actionBoxes/cartons making machineryRigid containersCardboardDisplay device

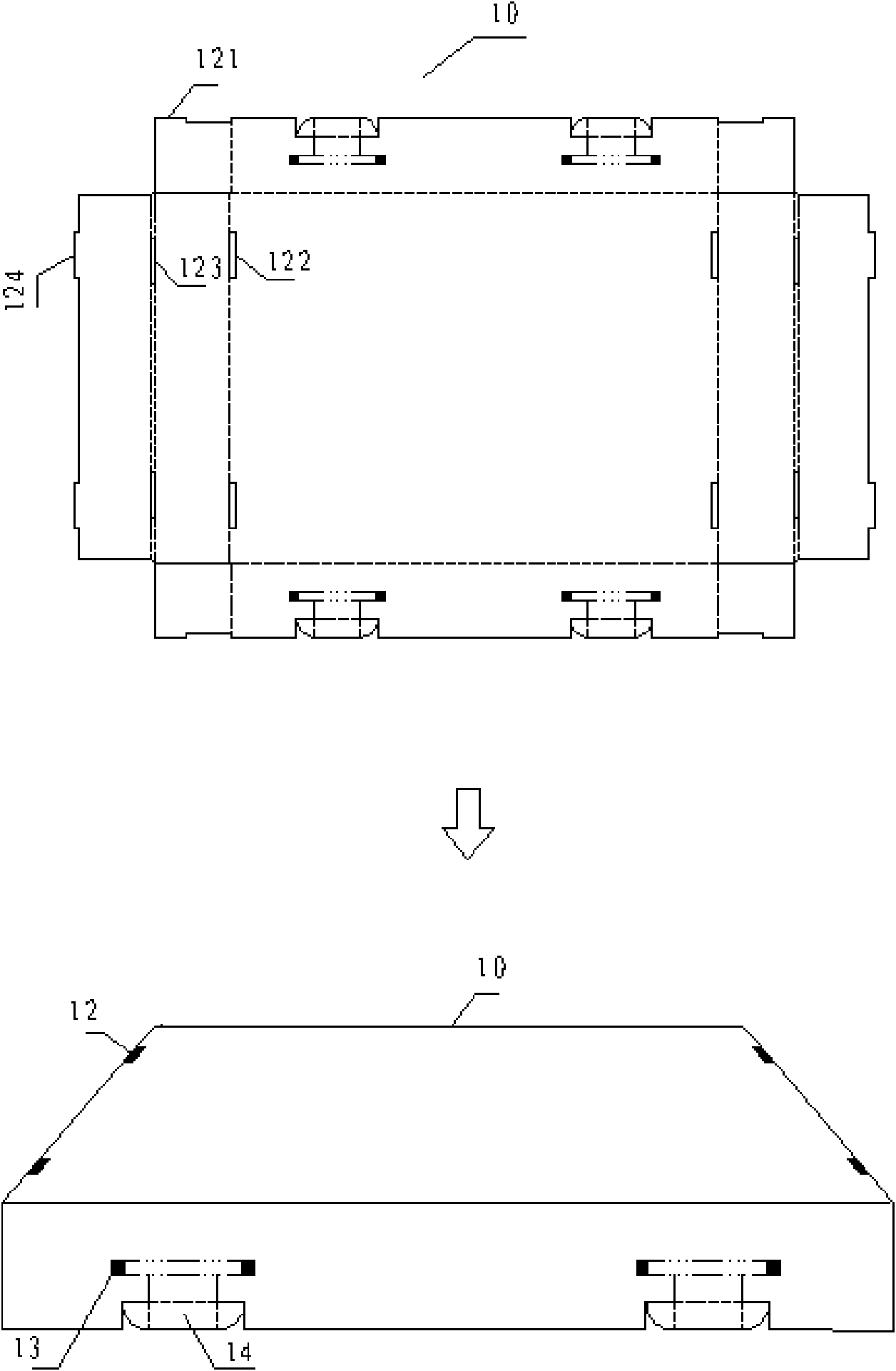

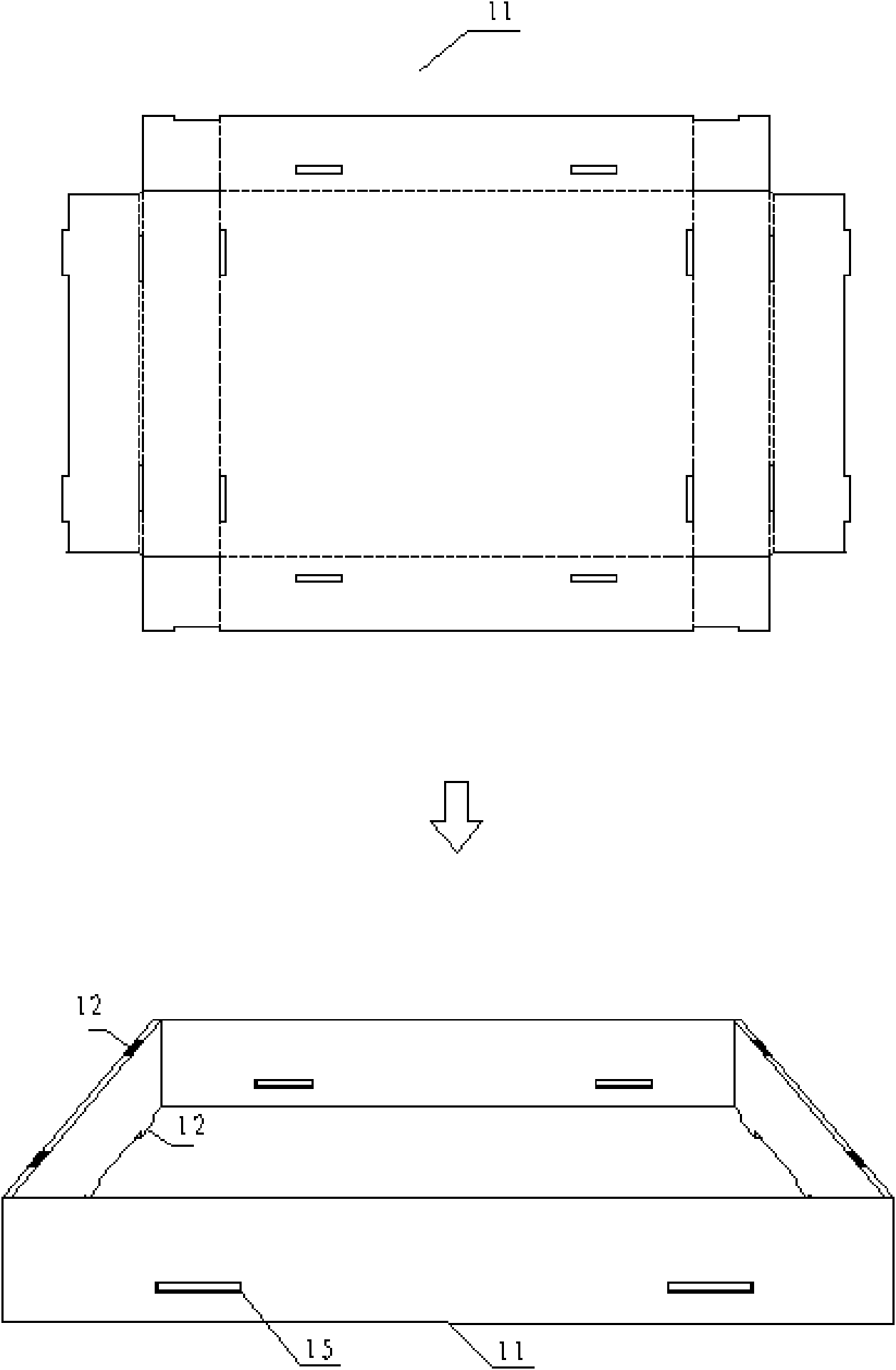

The present invention provides a full paper packaging box of flat panel display and a manufacturing method thereof, wherein the full paper packaging box of flat panel display comprises a box body (10) which is shaped by folding fastening, a base linear board (20) and a top-layer linear board (40). The top-layer linear board (40) is folded with a block part (41). The base linear board (20) is partially folded to a projected limiting stop catch (21). The box body (10) is provided with a handle opening (30). The packaging box of the invention is manufactured with full paper material, wherein the support of side wall of box body, the inner separation linear, etc. are equally obtained by overlapping the body of box body and the inner linear board. Simultaneously, a handle is installed according to the client requirement. Not only can the using of full paper material be guaranteed, but also the packaging box can be shaped in one time in the manufacturing process of paper board. The expense for insulating linear material traditionally is saved. Simultaneously, the space taken in the transportation process can be reduced. The difficulty for folding and assembling the packaging is reduced.The buffering performance of periphery and corners are increased.

Owner:MYS GRP CO LTD

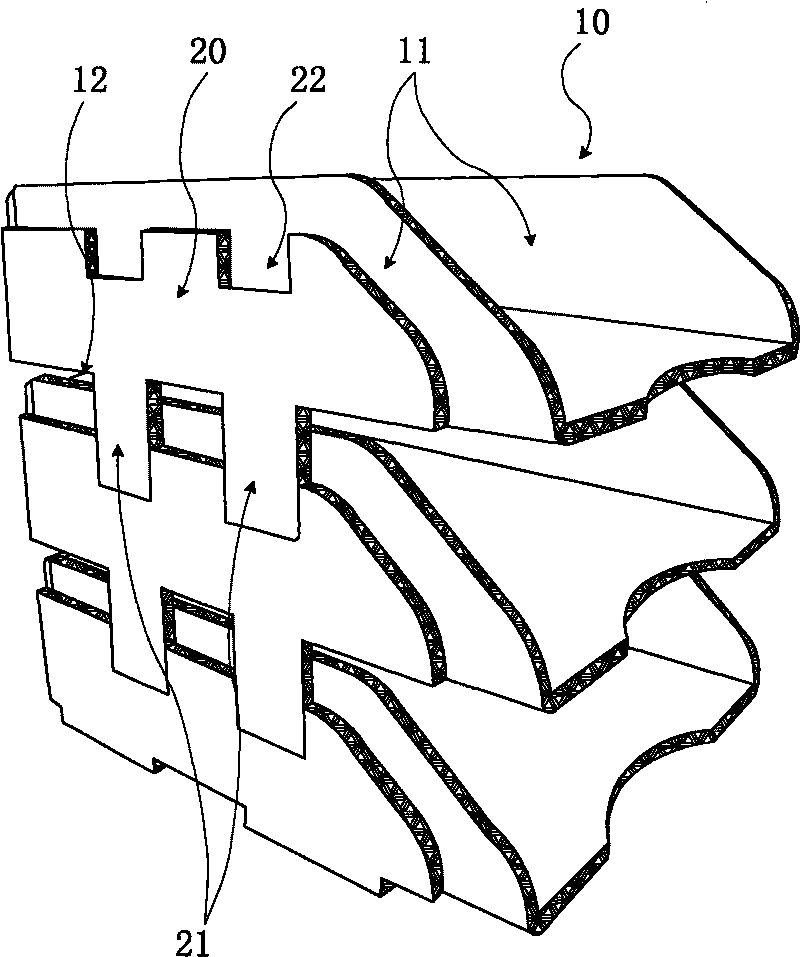

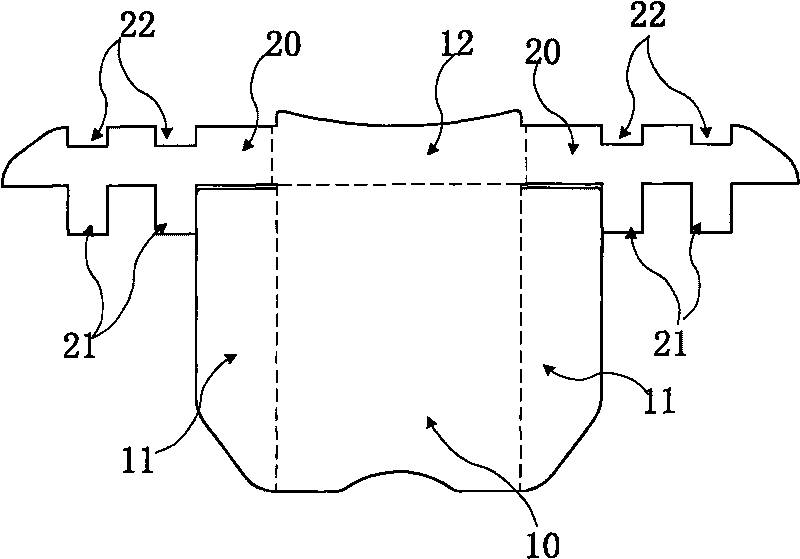

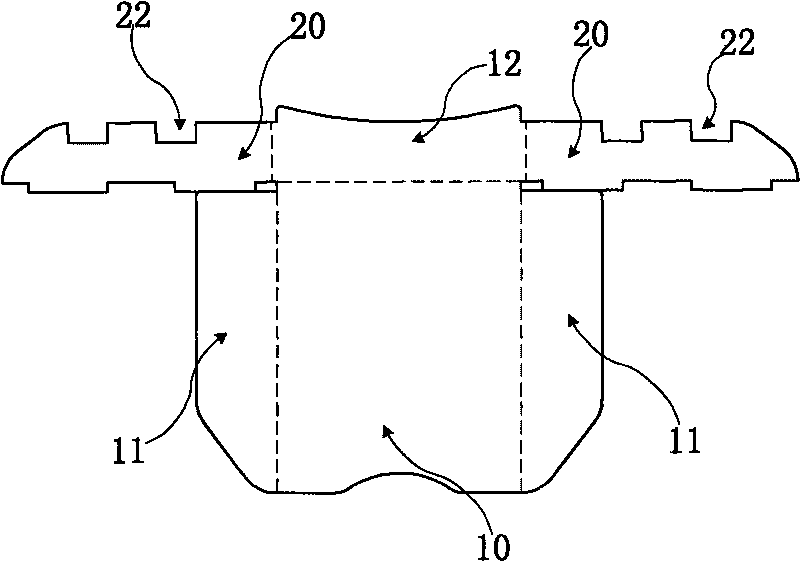

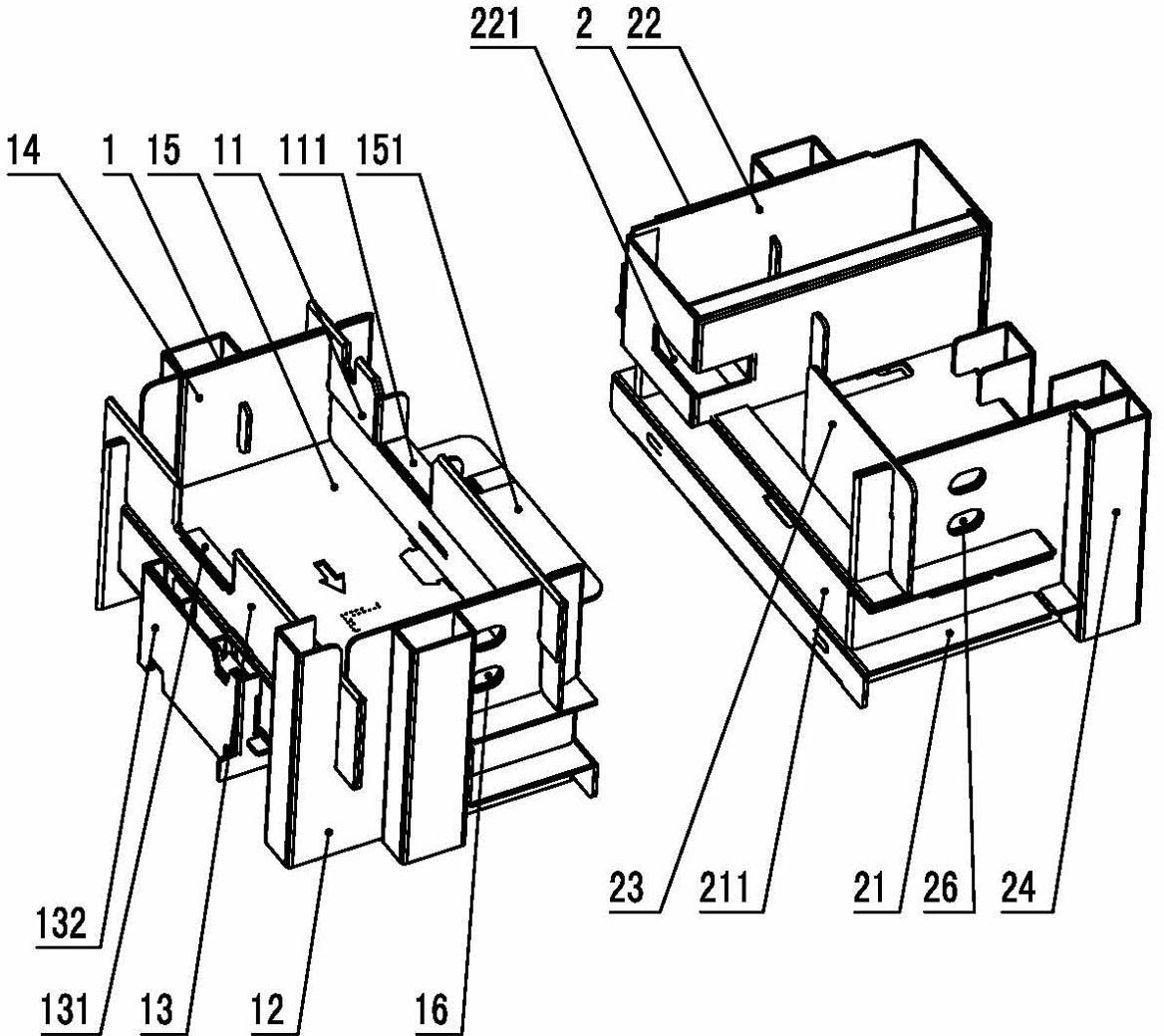

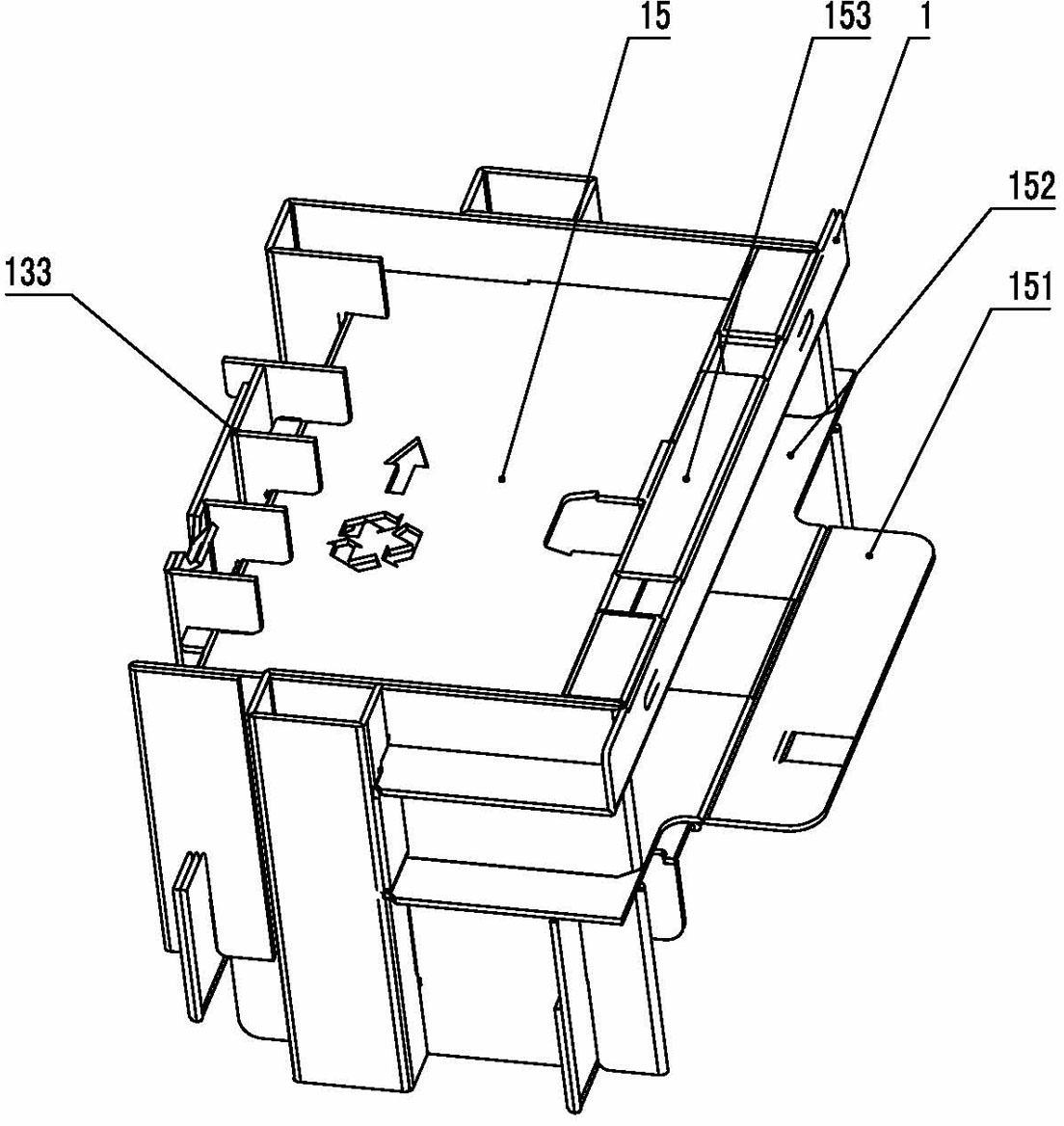

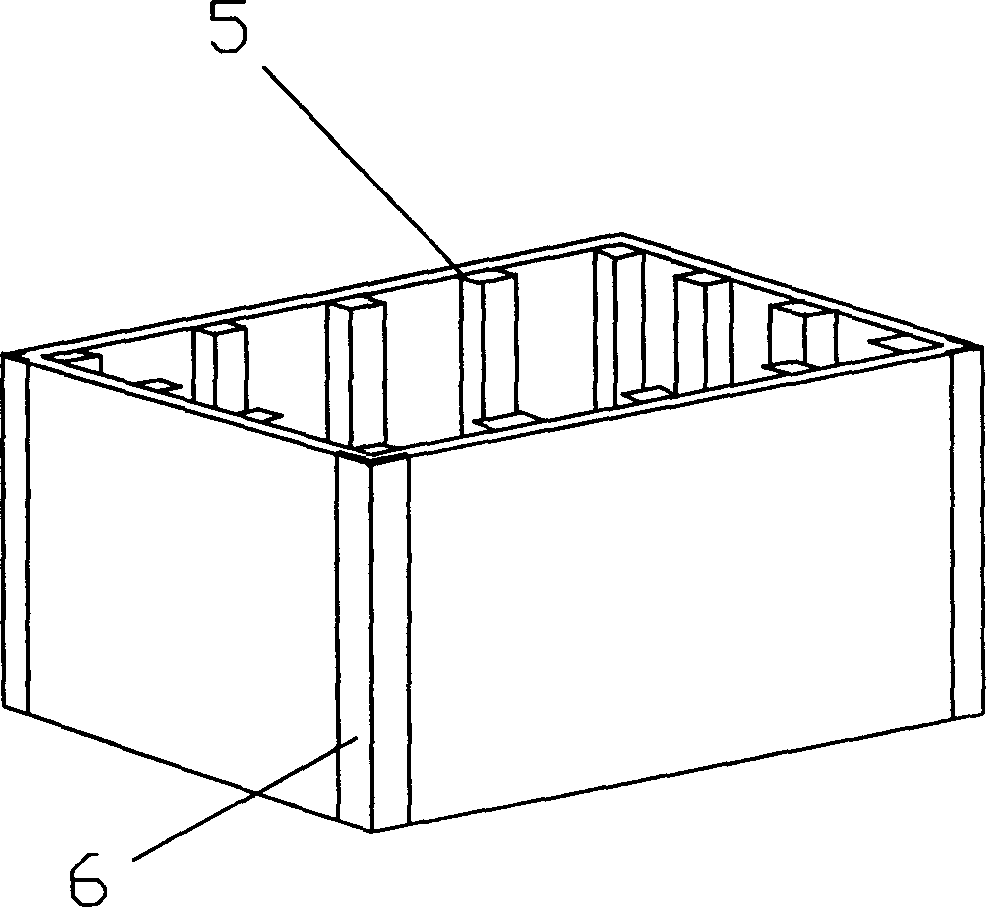

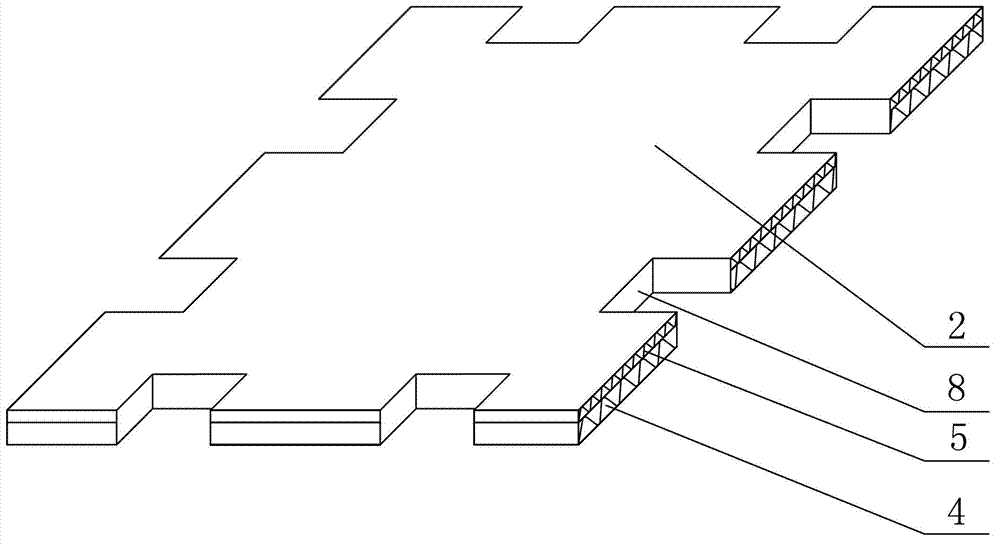

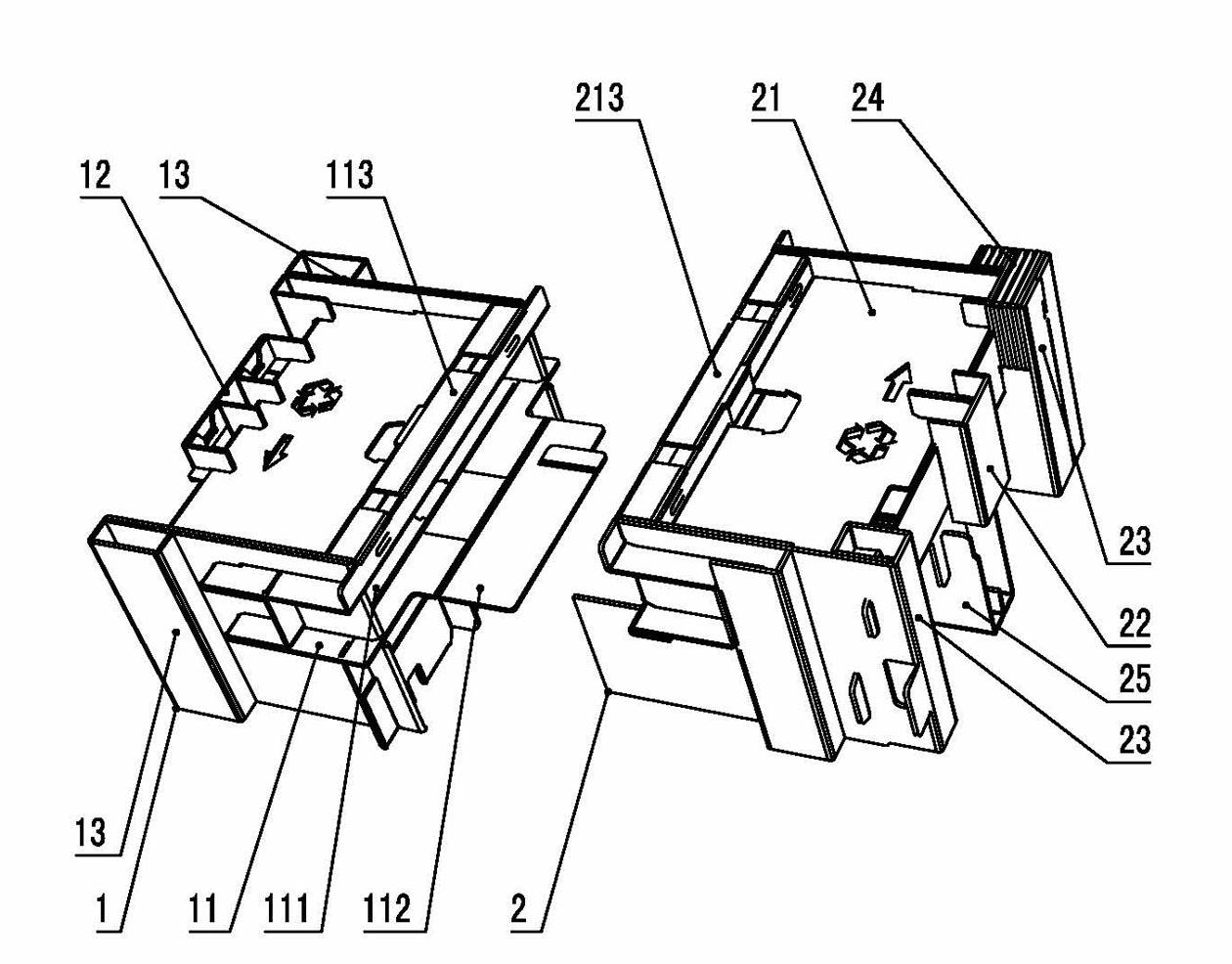

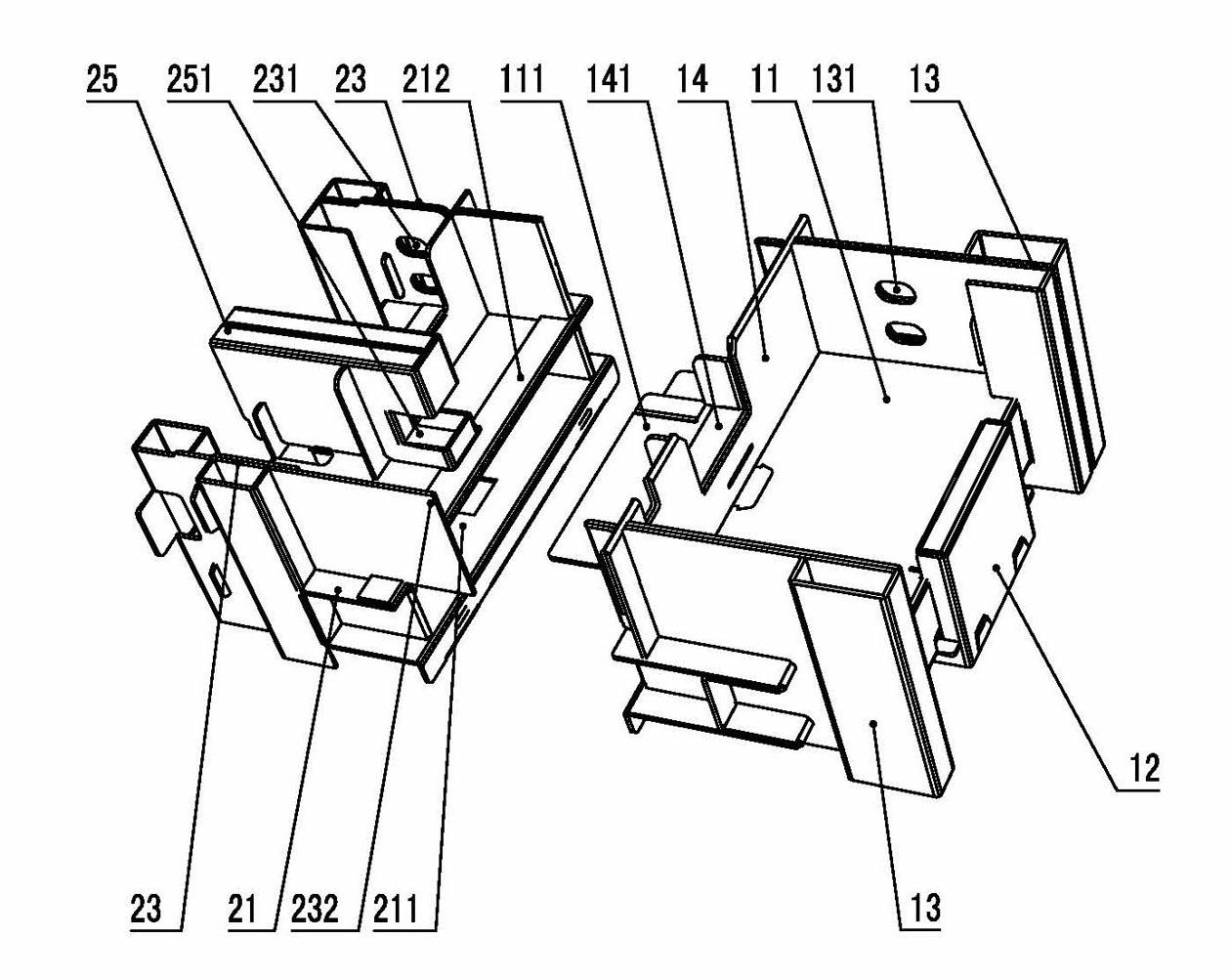

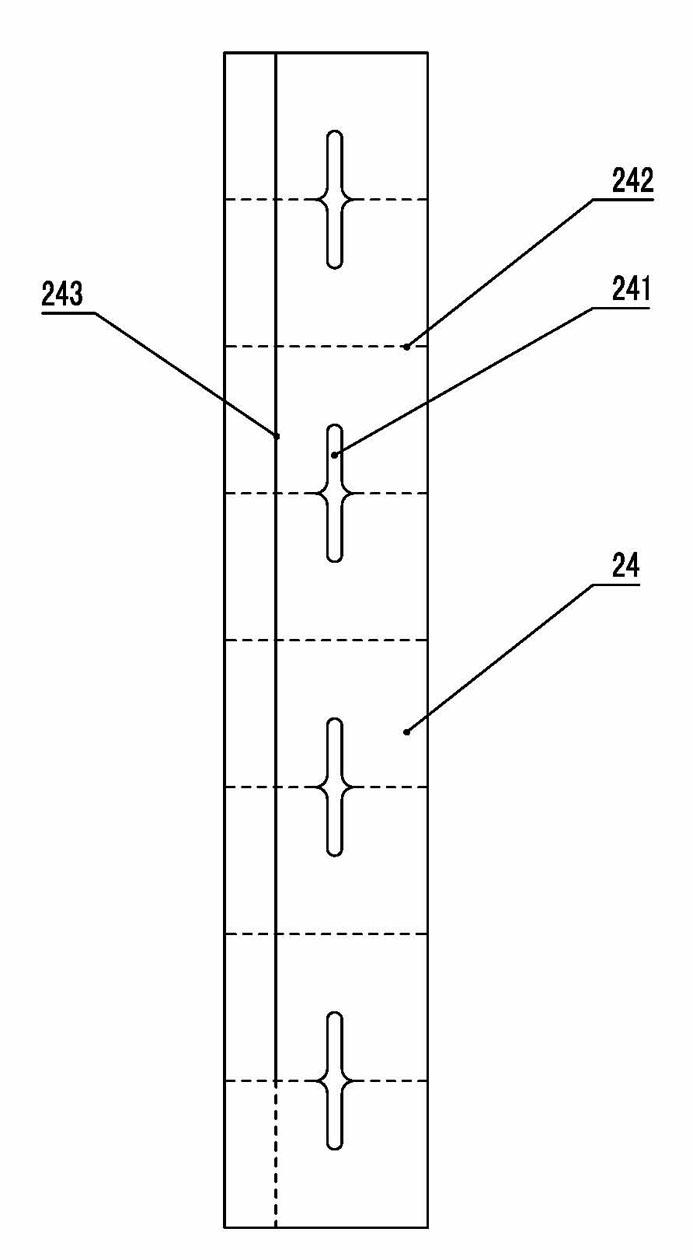

Full-paper multilayer document shelf and cutting and folding method thereof

InactiveCN101756527AAvoid influenceEasy to recycleBook cabinetsDismountable cabinetsPaper documentHeavy weight

The invention discloses a full-paper multilayer document shelf unit which comprises a full-paper tray (10) provided with two lateral plates (11) and a rear lateral plate (12). Two peripheral plates (20) which are fixed into a whole with the two lateral plates (11) of the tray (10) are arranged at the two sides of the tray (10). Convex insertion plates (21) and concave slots (22) are respectively arranged in the upper and lower directions of the two peripheral plates (20), and are corresponding to each other in positions and shapes. A method for splicing a multilayer document shelf is that the insertion plates and the slots corresponding to two adjacent layers of document shelf units are spliced together and the two adjacent layers of document shelf units are superimposed so as to form the multilayer document shelf. Being convenient for recycling, the invention not only can avoid impact to the environment, but also can save large quantities of resources. In the aspects of manufacturing and using, the invention is simple as well as convenient in forming and can bear heavy weight; moreover, the number of layers can be increased or reduced at will.

Owner:MYS GRP CO LTD

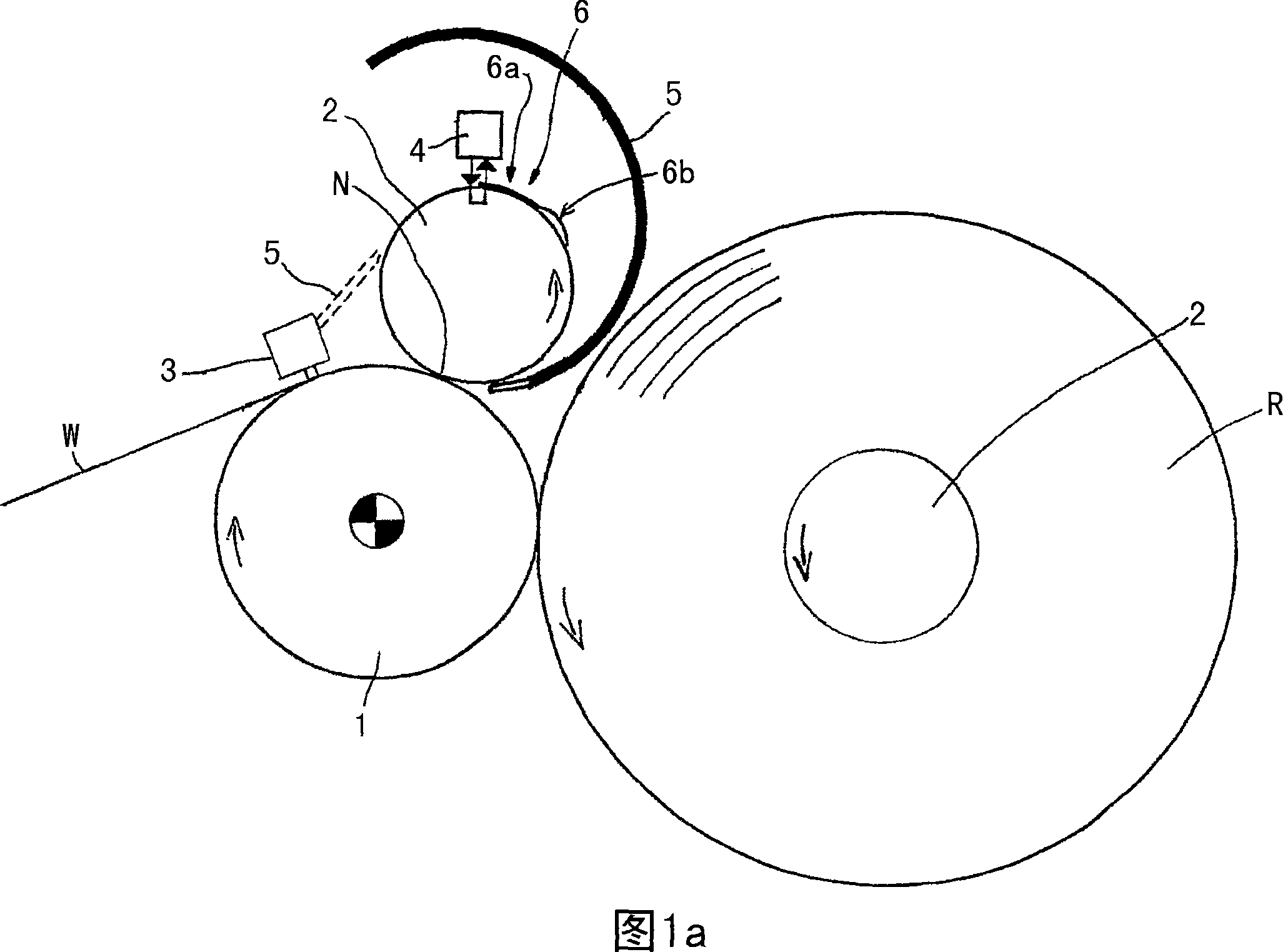

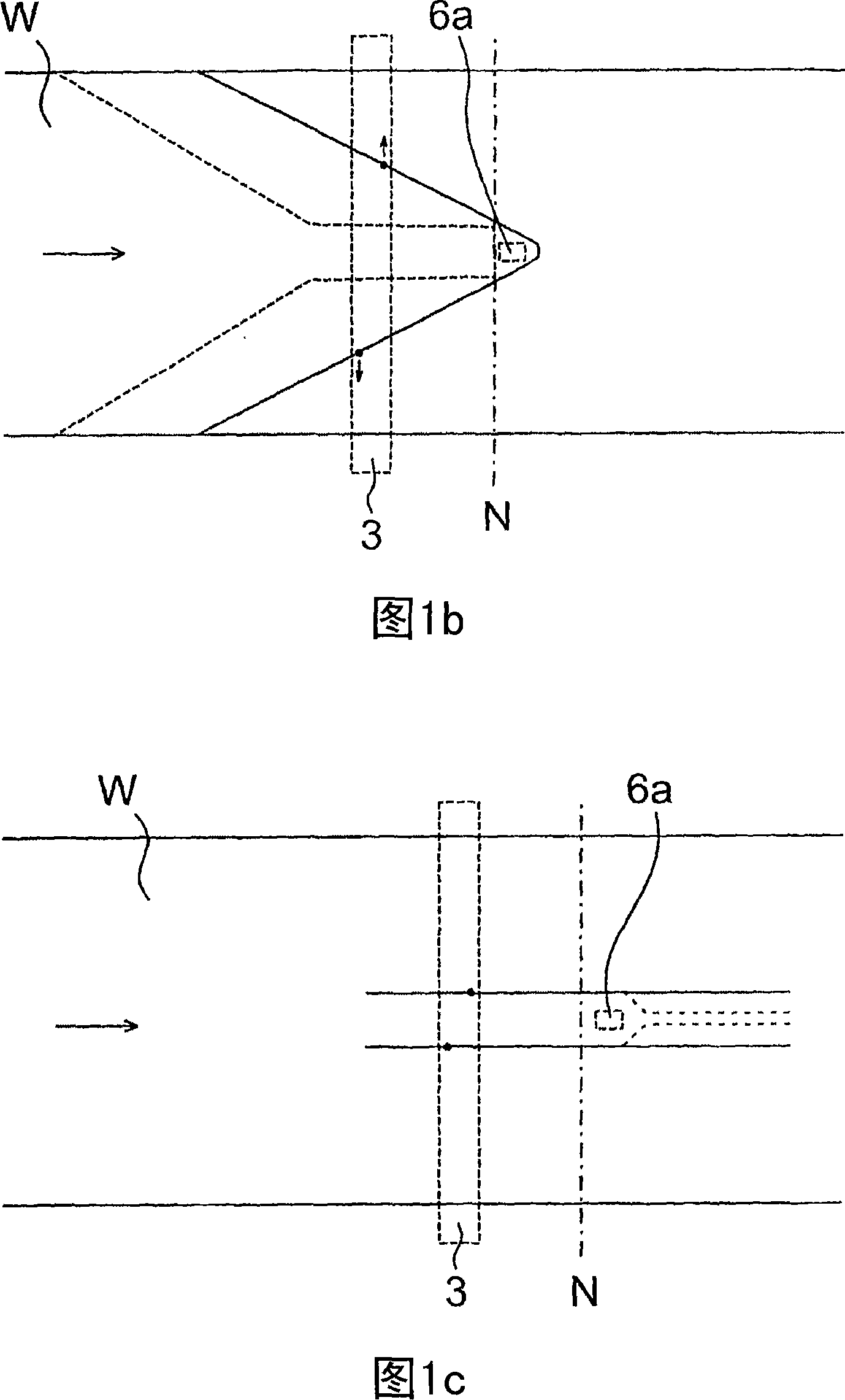

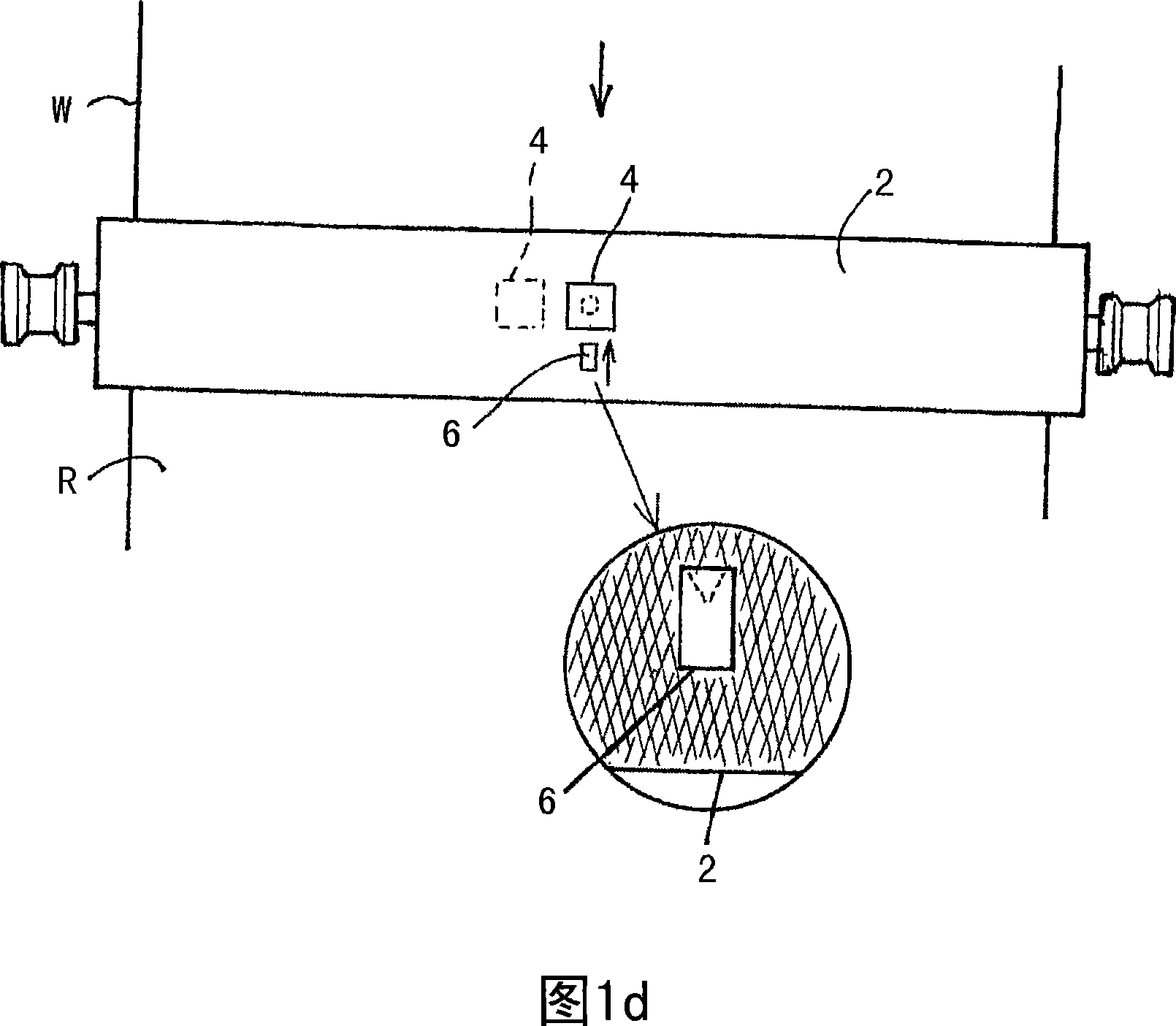

A method for changing a reel in a reeling process of a fiber material web and a reel change apparatus

During a roll change in the winding process of the fibrous material web, the fibrous material web (W) running onto a full roll is removed by adhering the web to the surface of a new winding core (2) Change to run around a new core (2) in roll change position. The web (W) adheres to the surface of the core (2) by changing the properties of the material located on the surface of the core (2). The material is a combination of an adhesive area (6a) on the core surface and a protective layer (6b) on top of the adhesive area, and the properties of the material are changed by removing the protective layer (6b).

Owner:METSO PAPER INC

Paper inside liner of packing case and packing case with same

ActiveCN102616464ASave spaceTake advantage ofContainers to prevent mechanical damageEngineeringMechanical engineering

Owner:MYS GRP CO LTD

Dispenser for dispensing paper from center-feed tissue paper rolls

InactiveUS8720813B2Improves serviceability and reliabilityProjector film strip handlingFilament handlingTissue paperFull paper

A dispenser for dispensing paper from center-feed tissue paper rolls, the dispenser having a housing with a receiving portion for receiving two center-feed rolls, one of which is a full paper roll and the other one an almost used-up paper roll squeezed into the form of a sickle to make the dispenser less bulky. The two rolls dispense through separate openings, which may be linked to a common dispensing nozzle spaced apart from the openings.

Owner:SCA HYGIENE PROD AB

Full-opening-pressure full-paper drum paper and method for preparing same

ActiveCN107100036AHigh strengthGood flexibilitySpecial paperPulp beating methodsFiberIntermediate frequency

The invention provides full-opening-pressure full-paper drum paper and a method for preparing the same. The method includes carrying out repulping, beating and bleaching and carrying out pulp mixing on fillers and chemical auxiliaries to obtain drum paper pulp; carrying out pulp fishing on the drum paper pulp; carrying out saturated steam treatment after pulp fishing is carried out; carrying out extruding dehydration. The full-opening-pressure full-paper drum paper and the method have the advantages that the surface quality of paper can be improved, and the tightness and the strength of the paper can be enhanced; vacuum drying is directly carried out at the low temperatures of 150-200 DEG C after pulp fishing forming is carried out, moisture in the paper can be removed, high-temperature and high-pressure treatment on the paper in drying procedures is omitted, fibers of the paper can be prevented from being damaged, accordingly, the strength and the flexibility of the obtained full-opening-pressure full-paper drum paper can be effectively improved, stereoscopic impression of human voice in intermediate frequencies can be enhanced, the voice is smooth and real, and the layering of low frequencies further can be enhanced; the generated voice is thick and solid and is free of noise or harshness, and tone is clear, natural and permeable.

Owner:梁胜祥

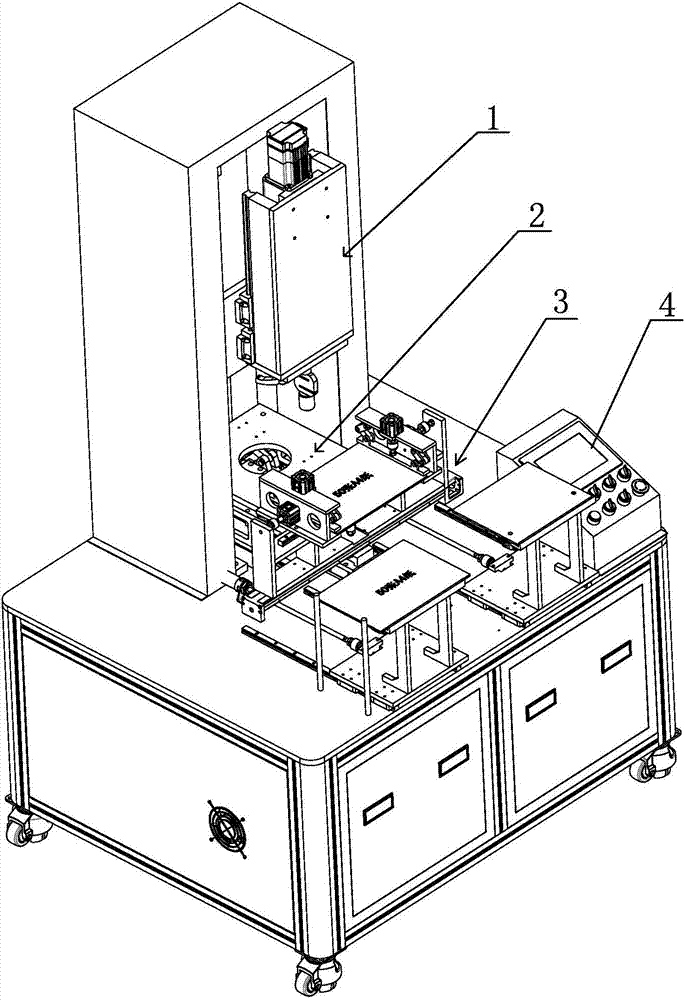

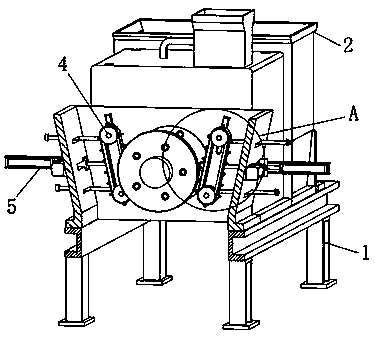

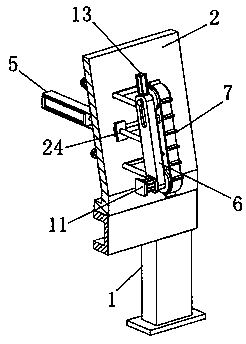

Bookbinding-type stationery comprehensive tester and test method thereof

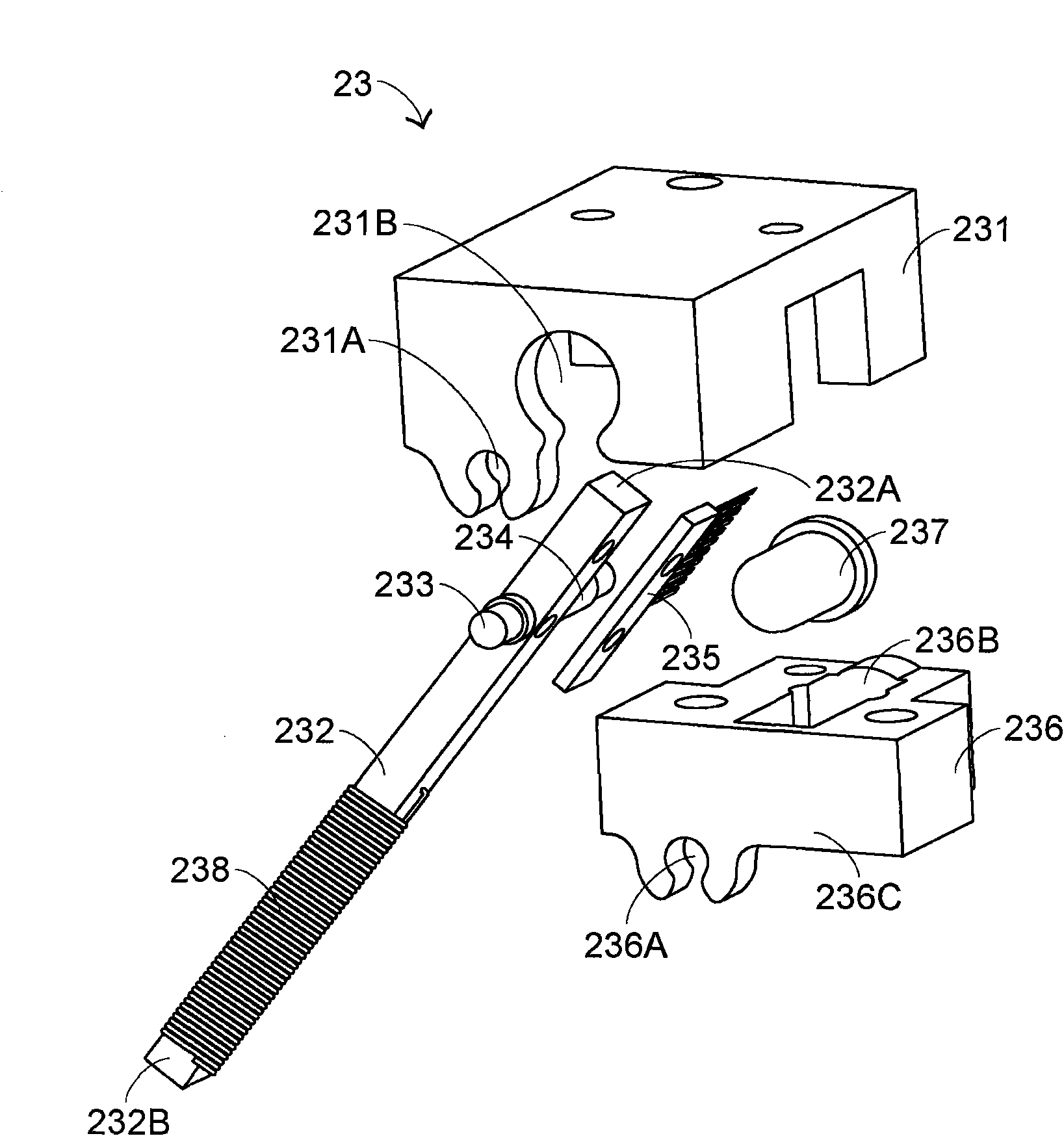

The invention discloses a bookbinding-type stationery comprehensive tester and a test method thereof. The tester is characterized in that the tester comprises a force applying and loading mechanism for applying pressure to a sample, a sample fixation mechanism arranged under the force applying and loading mechanism, a paper advance mechanism arranged in front of the sample fixation mechanism and a data output screen. The test method comprises the following steps: presetting magnitude of loading pressure and establishing a three-dimensional coordinate; feeding paper to a paper clamping device, and furthermore, feeding one side of the paper to a paper placing area of a stapler or a puncher; starting a first servo motor to enable an elastic loading head under a press lever to move downwards to apply a constant pressure to the stapler or the puncher so as to carry out stapling or punching operation until the whole piece of paper finishes stapling or punching; outputting the paper finishing stapling or punching through another paper feeding platform; and finally, repeating the steps above till finishing all test work of a sample to be tested through the stapler or the puncher to be tested. The advantage is that the tester is higher in mechanization, intelligence and automation.

Owner:国家文教用品质量监督检验中心

Full paper pallet box

A paper-transporting box is formed with a body, a cover and some supports under its bottom. The body is formed by: cutting paperboards with honeycomb or corrugated structure or composite paperboards, strengthening their edges, binding ribs on them, and binding together to obtain the body. The said ribs are of sectional paper pipes used to strengthen the paperboards. It cover is formed in same method. The supports are made of same materials to be bound on its bottom.

Owner:刘胜祥

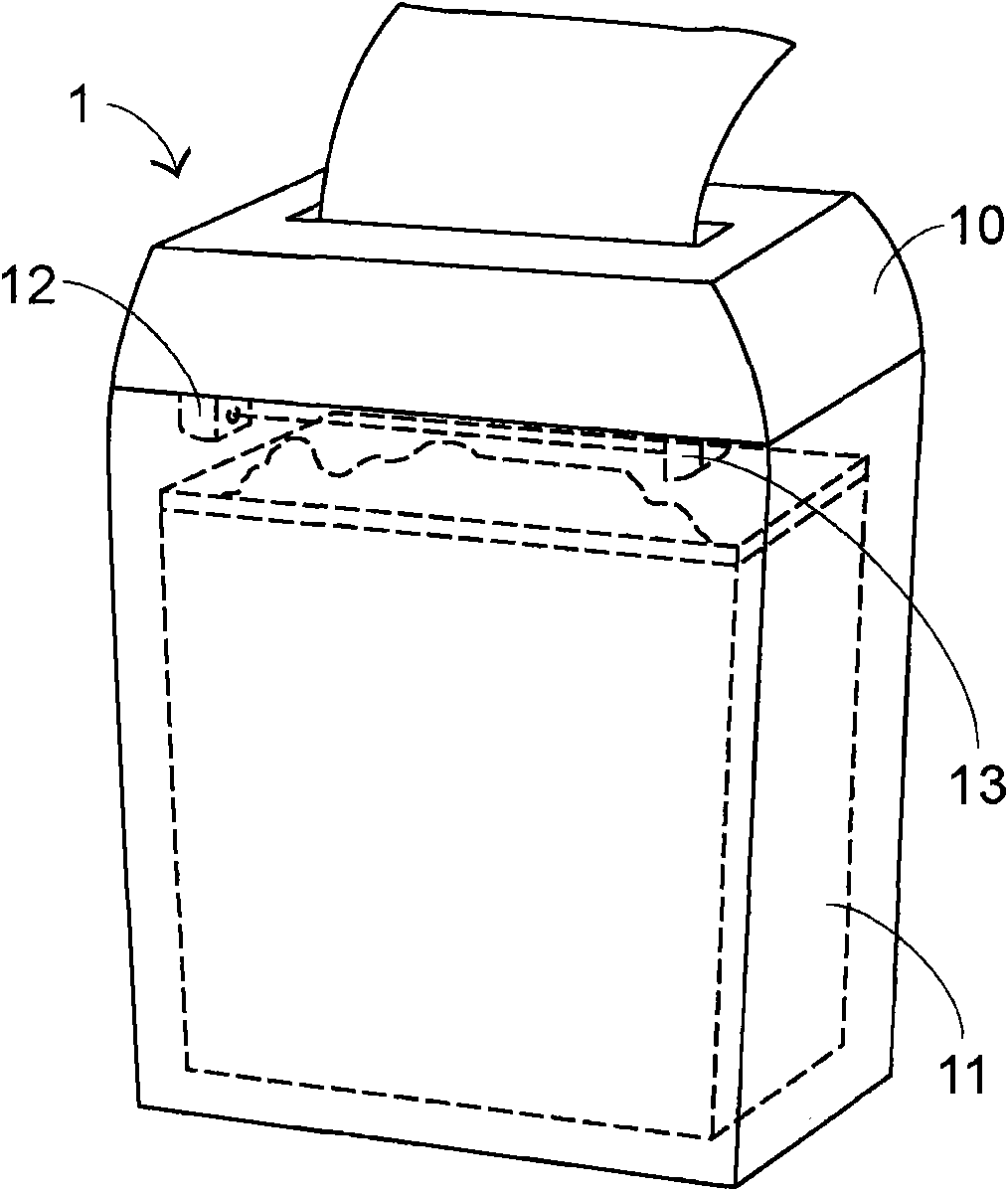

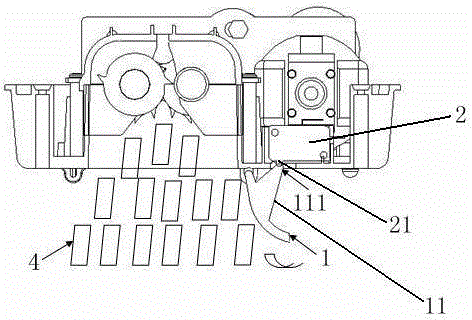

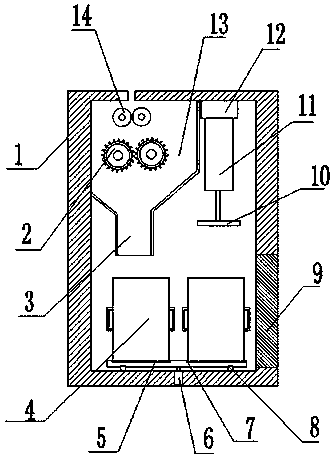

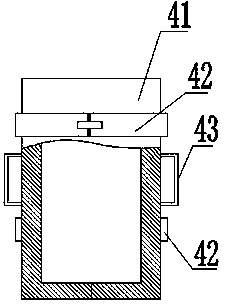

Full paper detection device for paper shredder

The invention relates to a full paper detection device for a paper shredder. The full paper detection device for the paper shredder comprises a receiving LED tube and an emitting LED tube which are arranged at a paper outlet of a lower cover of the paper shredder and are opposite in position. The receiving LED tube and the emitting LED tube are separately arranged on two parallel fixed plates, a full paper board is hinged to the paper outlet of the lower cover, a baffle plate between the receiving LED tube and the emitting LED tube is arranged upward on the top of the full paper board in a convex manner, and the receiving LED tube and the emitting LED tube are connected to an alarming circuit. Shredded paper of a garbage can in the paper shredder is continuously stacked and the height is more and more great, so that the shredded paper will push the full paper board to move, and the full paper board in the moving process will drive the baffle plate thereon to move to deviate from the original position; after the baffle plate moves to deviate from the original position, a signal emitted by the emitting LED tube can be received by the receiving LED tube; after the signal is communicated, the alarming circuit starts to alarm to remind full paper; by way of combining mechanical and electronic alarm, the full paper structure is simple and the cost is low, and moreover, parts are not damaged in the using process, so that the device is high in reliability.

Owner:DONGGUAN FUTAI ELECTRONICS

Flat-panel television packaging structure and processing method thereof

InactiveCN101654176AReduce usageIncrease attractivenessPackaging vehiclesContainers for machinesCardboardEnvironmental resistance

The invention discloses a flat-panel television packaging structure capable of improving the package recovery and a processing method thereof. The flat-panel television packaging structure comprises abox body and a buffer pad; a box bottom, a box cover and the buffer pad are in cross cutting and provided with at least one set of paper boards with self-lock structures which are folded to form; thebox cover is provided with a box unpacking strip which is in break point connection with the box cover, a buckle tongue connected to the box unpacking strip and a buckle hole which is arranged at thecorresponding position of the box bottom and used as a self-lock buckle structure to be connected with the box cover and the box bottom; and the formed buffer pad consists of at least two buffer bodies based on the same substrate, wherein at least one buffer body is provided with a hollow structure. The processing method of the flat-panel television packaging structure is used for formed mutually-matched self-lock buckle structures preset on the paper boards which are folded to form the box bottom and the box cover. The flat-panel television packaging structure has simple processing and forming, convenient package, good recovery and good safety for packing the box, accords with environment-friendly trend because of full paper package and is particularly suitable for packaging flat-panel televisions and analogs thereof.

Owner:SICHUAN PANOVASIC TECH

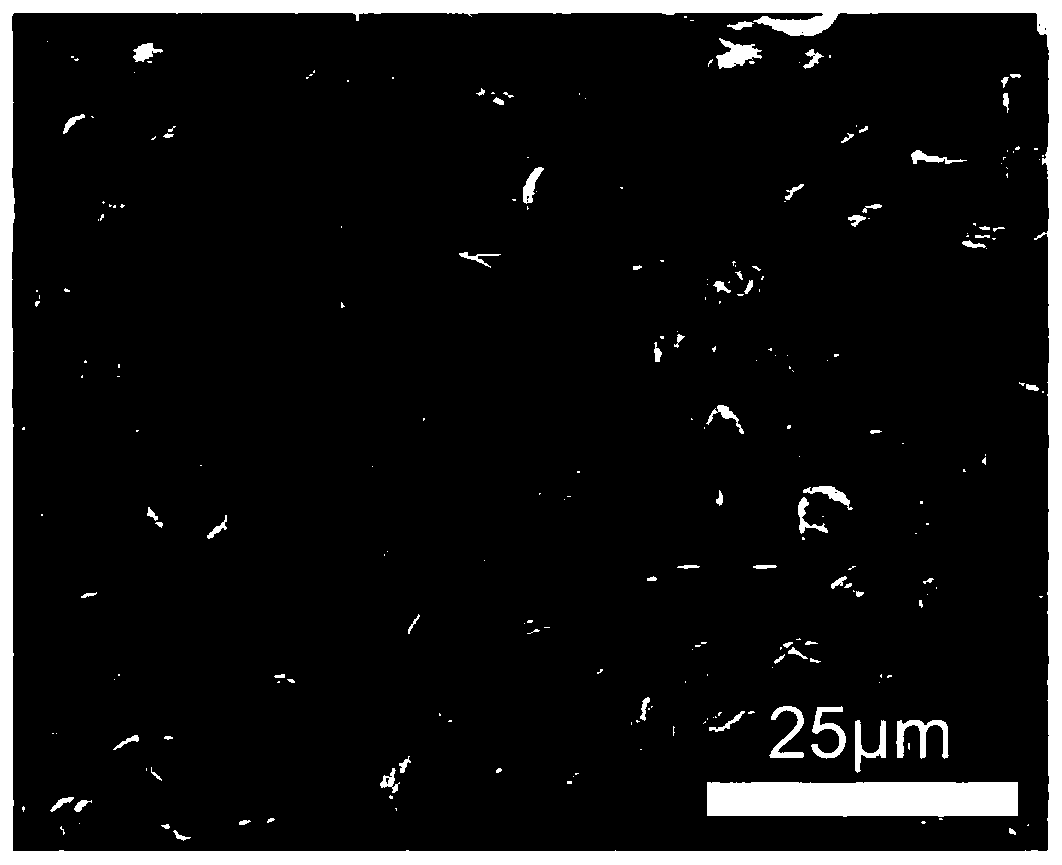

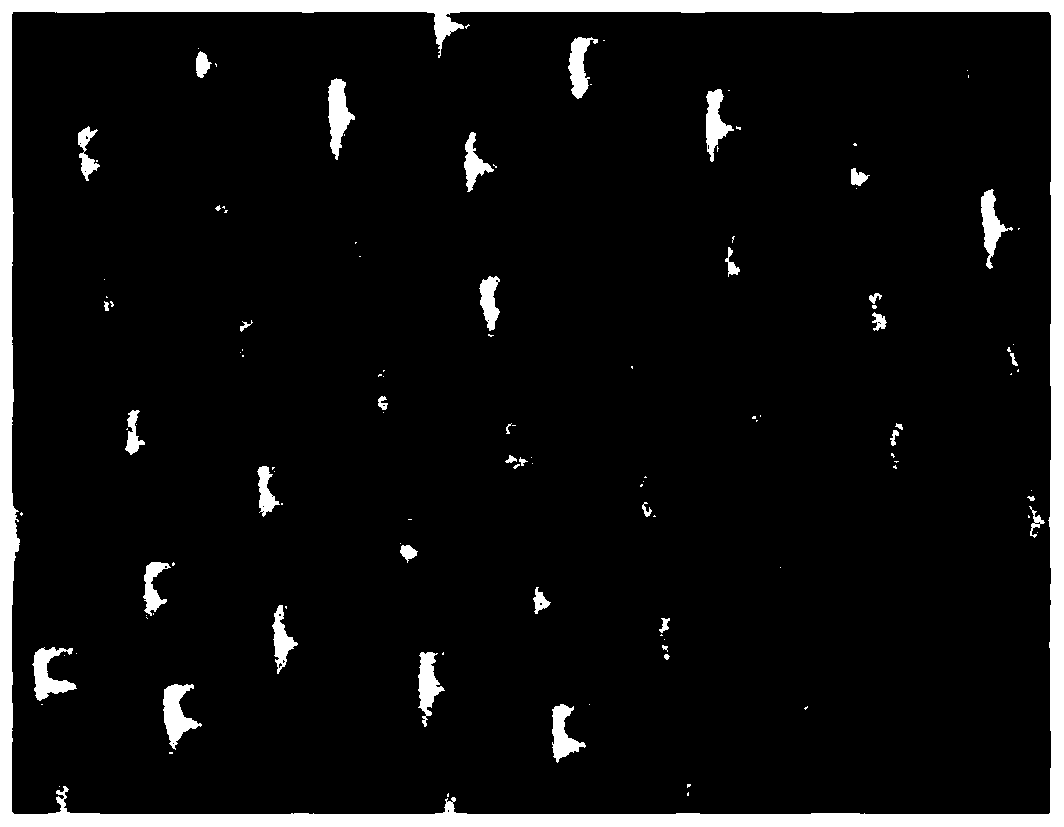

Full-paper base micro-lens array

The invention provides a full-paper base micro-lens array, and belongs to nano / micron micro-structure materials. The full-paper base micro-lens array comprises a substrate of cellulosic fiber and a plurality of micro lenses of the cellulosic fiber, the multiple micro lenses are periodically distributed on the surface of the substrate in an arrangement mode, and the micro lenses and the substrate are of an integrated structure. The cellulosic fiber is extracted from herbaceous plants or woody plants, and any external additives do not contained. Compared with traditional glassy micro lenses andresin micro lenses, the full-paper base micro-lens array has the characteristics of low cost, flexibility, green and environmental protection and the like, and can be widely applied to aspects such asimaging, displaying and sensors.

Owner:NANJING UNIV

Shredder with dust removing device

InactiveCN101773866ALow costAchieve the purpose of automatic cleaningGrain treatmentsEngineeringFull paper

The invention relates to a shredder with a dust removing device. The shredder with the dust removing device mainly comprises a shredder head, a bin, a sensing device, and the dust removing device, wherein the shredder head is used for cutting paper; the bin is arranged below the shredder head and used for accommodating scrap paper generated during cutting the paper; the sensing device is arranged at the shredder head and used for sensing the full paper state of the bin; the dust removing device is used for cleaning the sensing device and comprises a cover and an oscillating rod; and the cover is arranged outside the sensing device and one end of the oscillating rod is pivoted with the cover and the other end of the oscillating rod extends into the bin and comprises a cleaning component. When the bin is moved out of the shredder, the oscillating rod is oscillated to make the cleaning component remove the dust of the sensing device. The shredder not only has the advantage of low cost, but also has the advantage of automatic cleaning without increasing operation steps to users.

Owner:PRIMAX ELECTRONICS LTD

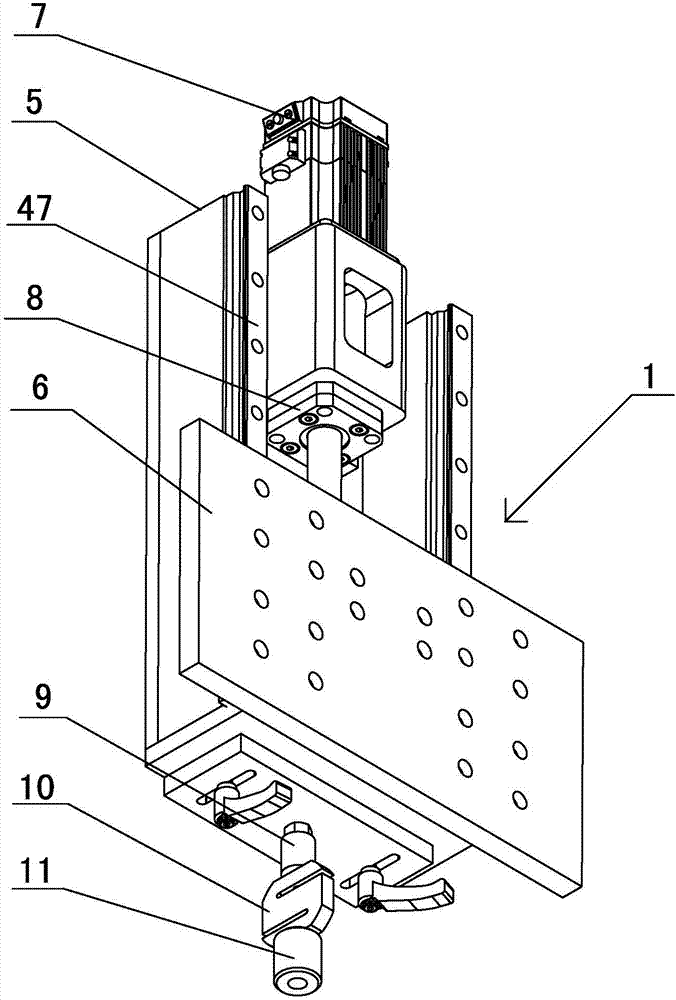

Paper advance mechanism for performance test of stapler or hole puncher and working process of paper advance mechanism

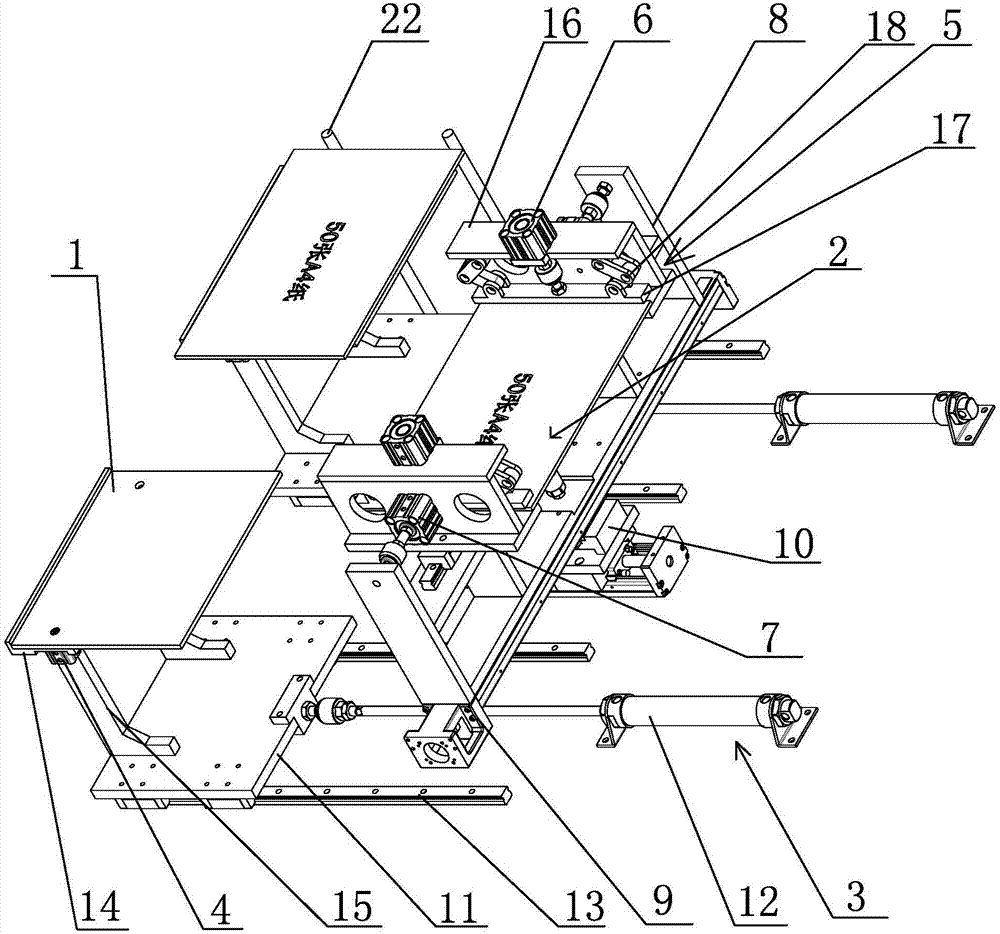

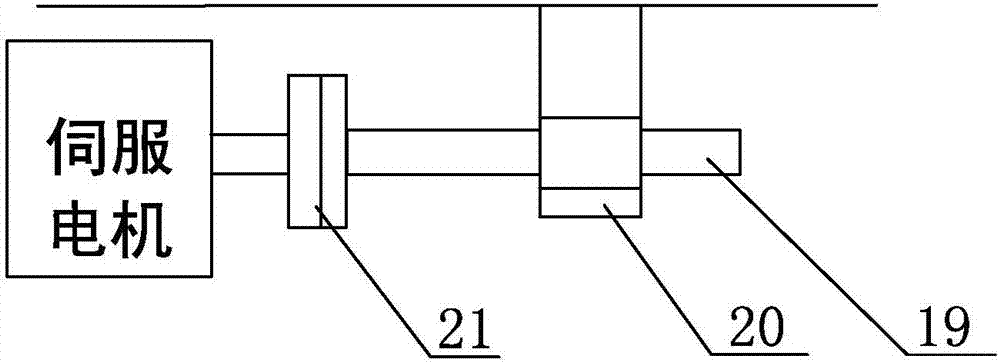

The invention discloses a paper advance mechanism for performance test of a stapler or a hole puncher and a working process of the paper advance mechanism. The paper advance mechanism is characterized in that the paper advance mechanism comprises two paper conveying platforms and a paper clamping device, the two paper conveying platforms are symmetrically distributed on the two sides in front of the paper clamping device, a Y-axis air cylinder driving mechanism and a Z-axis air cylinder driving mechanism are arranged below the paper conveying platforms, the paper clamping device comprises two paper clamping parts used for clamping the side edges of the paper, the tops of the paper clamping parts are provided with a paper clamping air cylinder driving mechanism, the side walls of the paper clamping parts are provided with a paper tensioning air cylinder driving mechanism, a first servo motor and a first screw transmission mechanism which are connected mutually are fixedly arranged at the bottom of a U-shaped bearing and connecting frame, a second servo motor and a second screw transmission mechanism which are connected mutually send paper into the paper clamping device and further send one sides of the paper into steps of binder holes of the stapler or the hole puncher; and the paper clamping device is controlled to move left to right till needle punching or hole punching work of the whole paper is completed, and the paper advance mechanism has the advantages of mechanization, intellectualization and the higher degree of automation.

Owner:国家文教用品质量监督检验中心

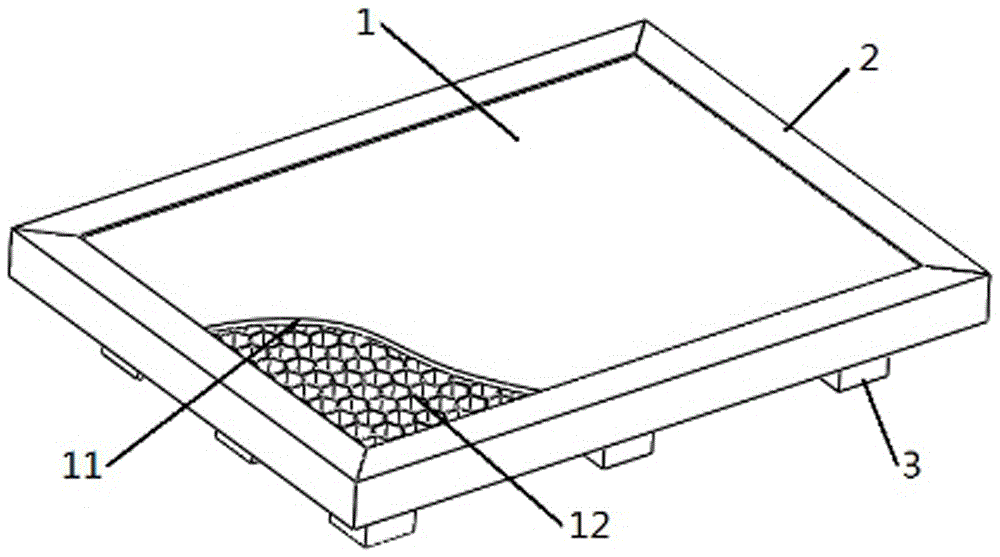

Paper pallet packaging cover board

InactiveCN102815439AReduce weightSimple production processPaper/cardboard layered productsRigid containersCardboardIn plane

The invention discloses a paper pallet packaging cover board. The paper pallet packaging cover board comprises a body, wherein the body comprises an upper board and a lower board, the upper board and the lower board respectively consist of at least two corrugated cardboards with different corrugated forms, and directions of the cardboards on the contact surface of the upper board and the lower board are crisscross. The paper pallet packaging cover board is characterized in that four side edges of the upper board are provided with packaging liners, and the packaging liners are formed by adhering a plurality of cardboards. The paper pallet packaging cover board has the advantages that the packaging liners are high in hardness and strength, a packaging band can be directly tied at the positions of the packaging liners when the paper pallet packaging cover board is used for packaging so as to avoid damage to paper. Moreover, the paper pallet packaging cover board adopts full-paper materials, thus being high in plane strength, good in bearing capacity, excellent in shockproof and buffering performance, light in weight, capable of realizing surface printing and being directly recovered, green and environment-friendly.

Owner:宁波亚洲纸管纸箱有限公司

Paper shredder mechanical full paper mechanism

The invention discloses a mechanical paper fill-up mechanism for a paper shredder. The mechanical paper fill-up mechanism for a paper shredder comprises: a pressing plate, which is arranged outside a paper shredder core below a paper shredder lower cover, and has one end pivotally connected to the paper shredder lower cover and the other end as a free end; and a touch switch, which is fixed on the paper shredder lower cover, with one side near the paper shredder lower cover being equipped with a touch point. One pressing plate side away from the paper shredder core is equipped with a touch component, and the paper shredder lower cover is provided with a through-hole enabling the touch component to touch the touch point of the touch switch. Driven by paper scraps in a waste paper bucket of the paper shredder, the pressing plate rotates around the joint of the paper shredder lower cover and itself, so that the touch component disposed on the pressing plate can touch the touch point of the touch switch to power off the paper shredder. With the characteristics of simple structure and convenient use, the mechanical paper fill-up mechanism for the paper shredder can sensitively detect the paper fill-up information in the waste paper bucket of the paper shredder and make the paper shredder shut down.

Owner:AURORA OFFICE EQUIP

Buffering paper internal liner and packaging box provided with same

The invention relates to a buffering paper internal liner and a packaging box provided with the same. The buffering paper internal liner provided by the invention comprises a left liner and a right liner, wherein the left liner comprises a left suspended liner, a first base buffering liner, a second base buffering liner and at least two left supporting leg liners; the left supporting leg liners, the first base buffering liner and the second base buffering liner are respectively vertical to the left suspended liner; the middle parts of the left supporting leg liners are grafted with the left suspended liner; the at least two left supporting leg liners are respectively arranged on front and back sides of the left suspended liner; and the first base buffering liner and the second base buffering liner are respectively grafted with left and right ends of the left suspended liner. The invention also provides a packaging box. The buffering paper internal liner provided by the invention has the beneficial effects of environmental friendliness due to adoption of full-paper packaging, smaller space required by package because the space is fully utilized, favorable buffering property and capability of passing a drop test.

Owner:MYS GRP CO LTD

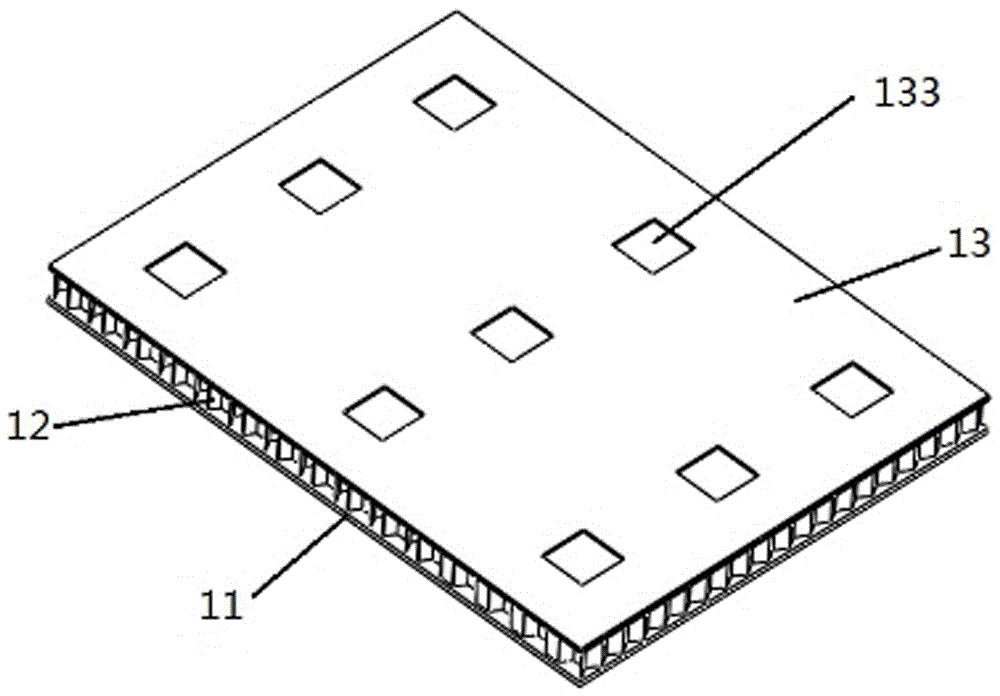

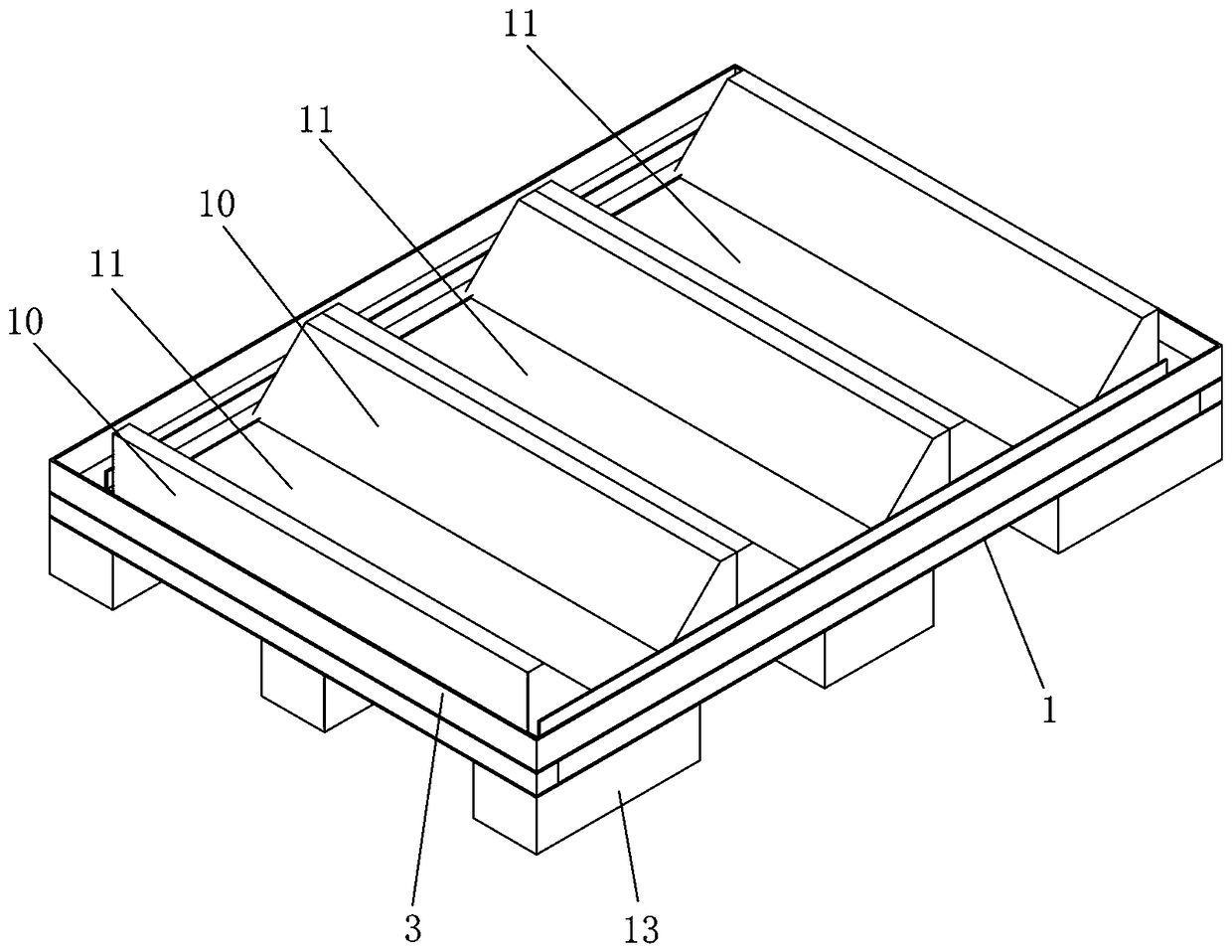

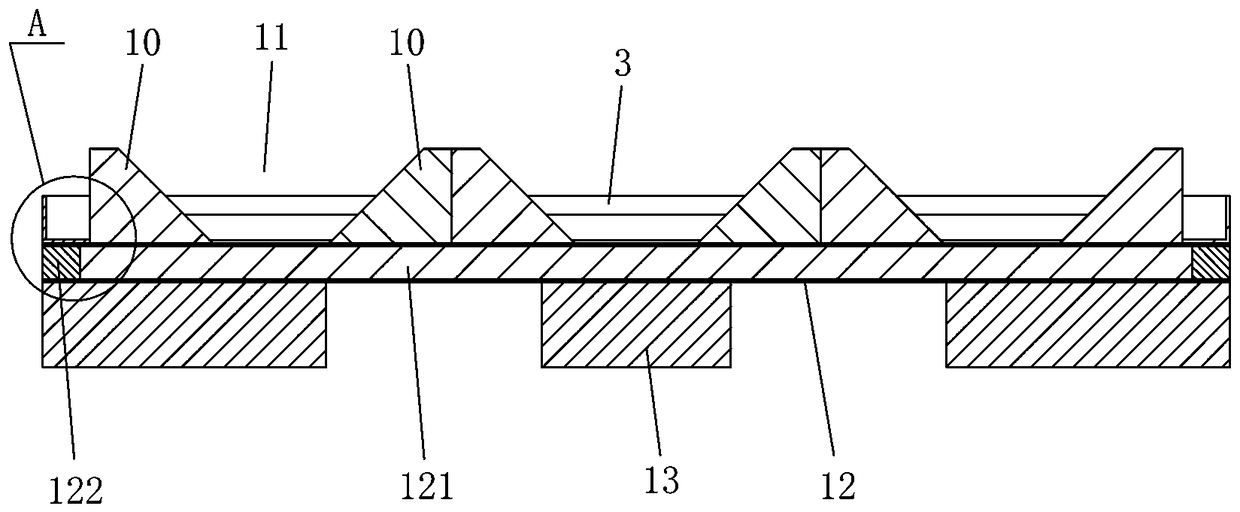

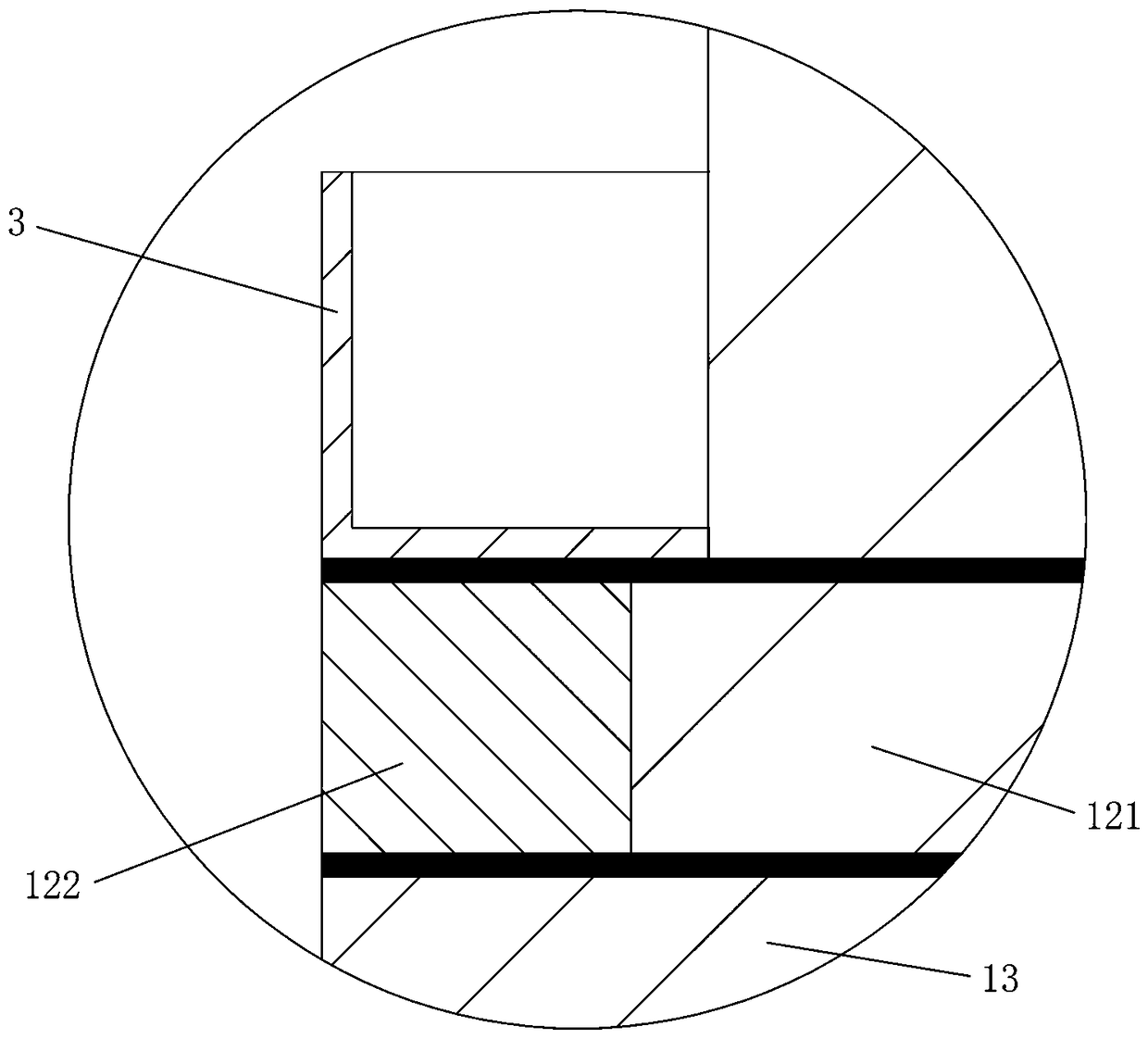

Footing embedded type full-paper combined heavy-load tray and forming method thereof

InactiveCN105730823AReduce weightHigh bonding strengthRigid containersCardboardPulp and paper industry

The invention relates to the field of design and preparation of logistical packing containers, and discloses a footing embedded type full-paper combined heavy-load tray and a forming method thereof. The footing embedded type full-paper combined heavy-load tray comprises a plank, paper angle beads and footings, wherein the plank comprises a top plate, a core plate and a bottom plate, which are superposed in sequence; the bottom plate comprises a first flat bottom plate and a slotted flat bottom plate, which are superposed in sequence; through slots which are consistent with the cross sections of the footings in the aspect of size are formed in the slotted flat bottom plate; the first flat bottom plate and the slotted flat bottom plate are superposed at the through slots to form a grooves; the footings are installed in the grooves and extend out from the slotted flat bottom plate; and the paper angle beads is connected with the side surfaces of the plank in a cladding manner. The footing embedded type full-paper combined heavy-load tray is formed by full-paper parts, so that the tray can be recycled and reused or completely degraded in nature while the strength is improved; and the tray is simple in structure.

Owner:HUNAN UNIV OF TECH

Paper shredder

The invention discloses a paper shredder. The paper shredder comprises a paper shredder housing; a partition plate is arranged inside the paper shredder housing and is used for dividing the inside ofthe housing into a crushing chamber and a paper scrap collection chamber; the bottom of the crushing chamber is provided with a paper scrap outlet; a placing seat is arranged inside the paper scrap collection chamber; the placing seat is provided with two paper scrap collection buckets; an inlet of one collection bucket rightly faces the paper scrap outlet; a compression mechanism is arranged above the other paper scrap collection bucket; a pressing plate of the compression mechanism can extend into the paper scrap collection bucket; the placing seat is of a circular structure of which the center is connected with a stepping motor which is arranged on the bottom of the housing; and the stepping motor rotates to drive the two paper scrap collection buckets to be exchanged in position. The paper shredder disclosed by the invention is provided with the two paper scrap collection buckets; the two paper scrap collection buckets can be driven to rotate by the stepping motor so as to be exchanged in position; after one paper scrap collection bucket is full, the full paper scrap collection bucket is fed to the compression mechanism by virtue of rotation so that the paper scraps can be compressed; and thus paper scrap collection and paper scrap compression can be simultaneously implemented.

Owner:陆应根

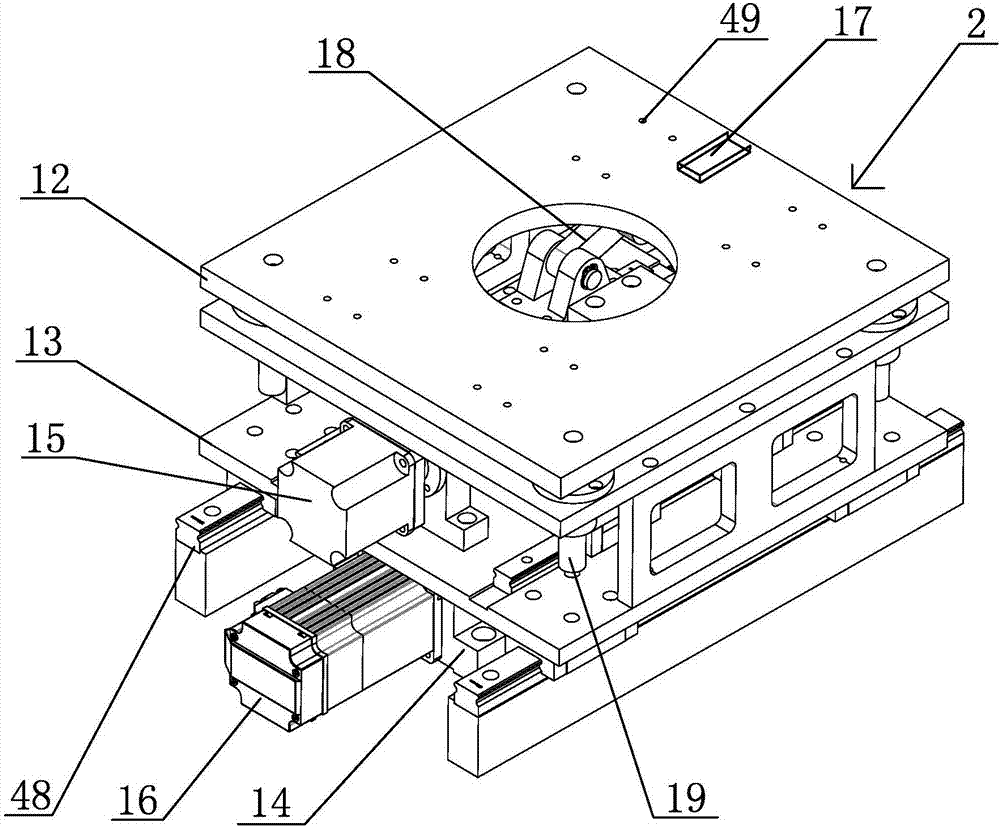

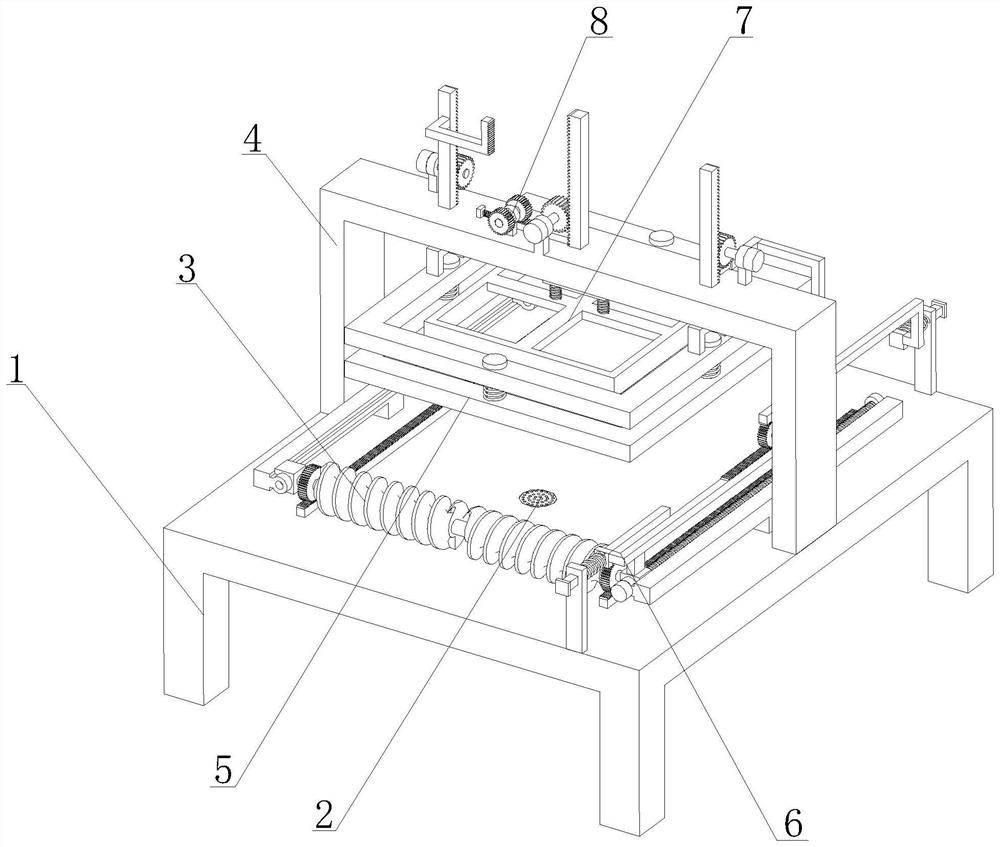

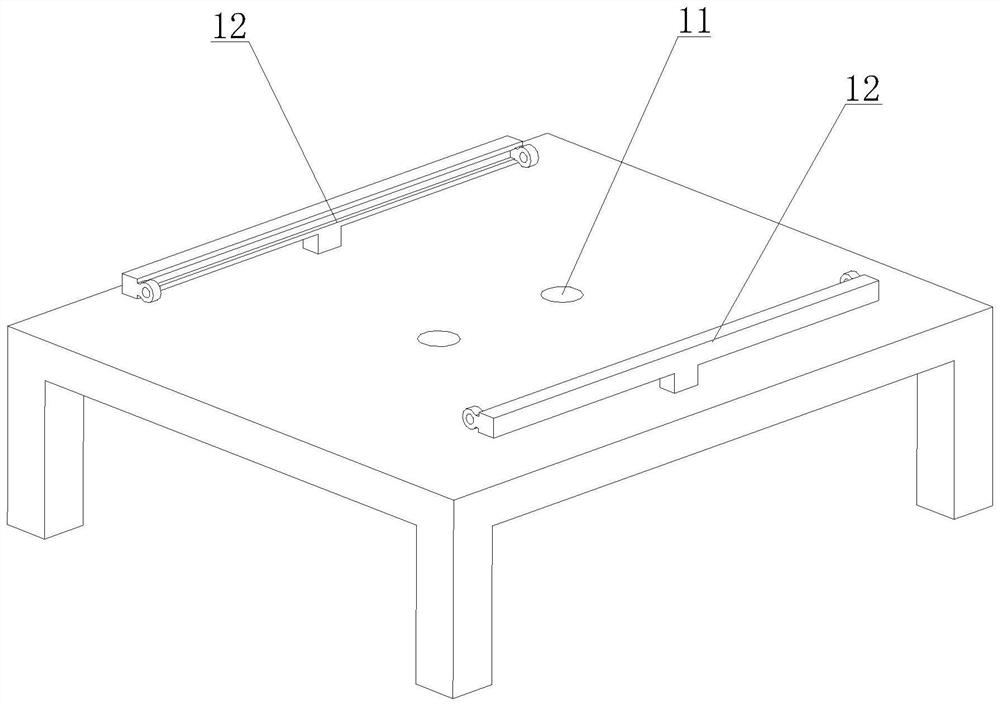

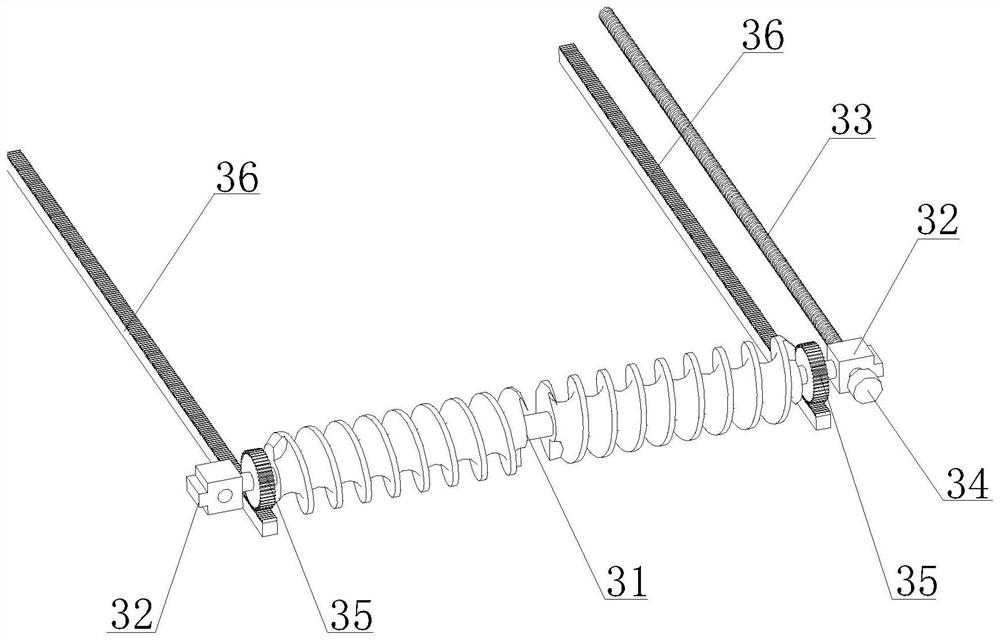

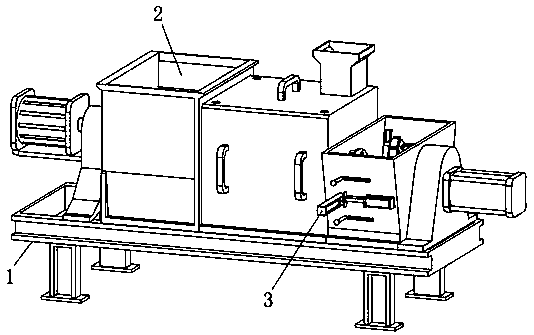

Positioning and leveling device for paper slitting and using method of positioning and leveling device

PendingCN114393631AAvoid interferenceAvoid the influence of slitting accuracyMechanical working/deformationMetal working apparatusAugerEngineering

The invention discloses a positioning and leveling device for paper slitting and a using method of the positioning and leveling device, and belongs to the field of paper slitting. The invention discloses a positioning and leveling device for paper slitting. The positioning and leveling device comprises a workbench, a leveling mechanism, a mounting frame, a pressing mechanism and a clamping mechanism, the leveling mechanism is arranged on the workbench, the leveling roller capable of sliding and rotating at the same time is arranged in the leveling mechanism to level a whole piece of paper, and the first auger and the second auger which are coaxial and opposite in rotation direction are arranged in the leveling roller to level the paper from two directions perpendicular to each other, so that the leveling effect is guaranteed; the pressing mechanism is arranged on the mounting frame to press and fix paper on the workbench so as to guarantee the slitting quality, the clamping mechanism is arranged to control the pressing time of the pressing mechanism, and the situation that a pressing plate is pressed downwards to interfere with a leveling roller, and consequently the structure of the device is damaged is avoided; the using method of the positioning and leveling device for paper slitting comprises the steps of feeding, leveling, pressing, slitting and material taking.

Owner:JI LONG MACHINERY CO LTD

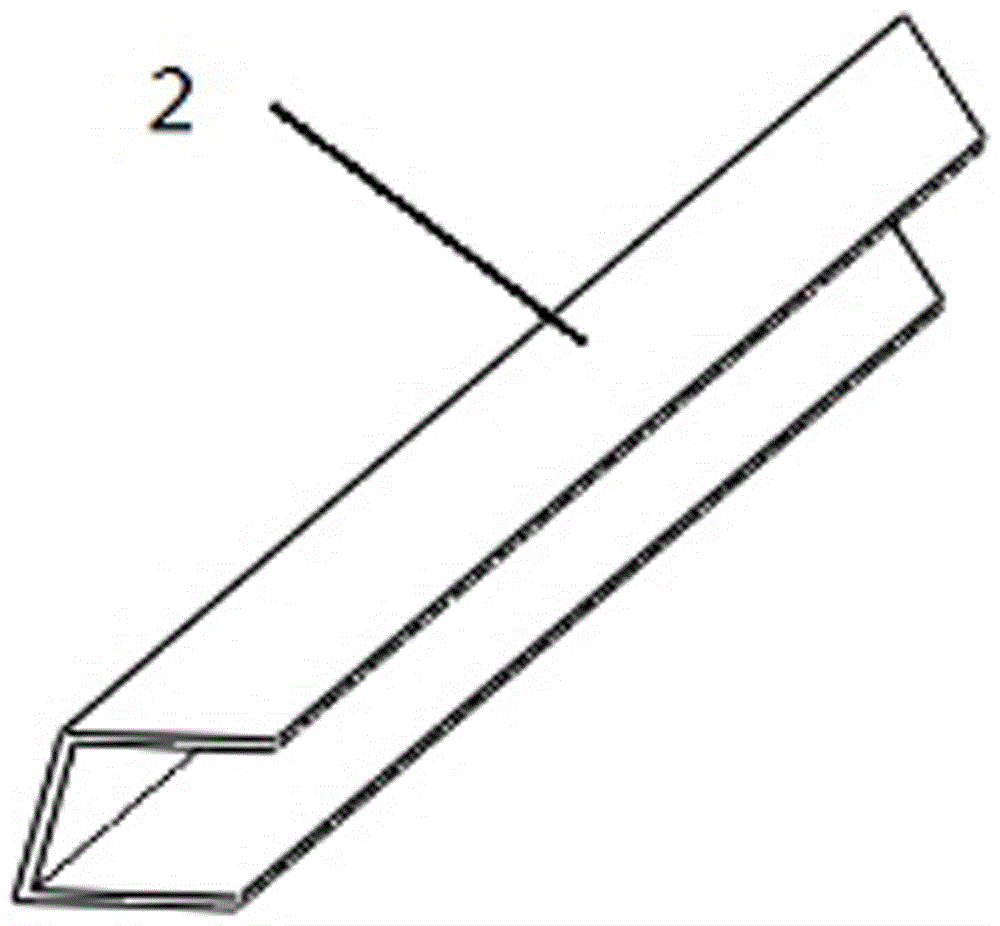

Full paper type horizontal coiled material packaging box

PendingCN108190196ASimple structureEasy to manufactureContainers for annular articlesPaper basedPulp and paper industry

The invention discloses a full paper type horizontal coiled material packaging box. The full paper type horizontal coiled material packaging box comprises a paper base support and a paper box cover. The paper box cover is provided with an inner cavity of which one end is open. The paper box cover is arranged on the paper base support, and a closed space used for containing coiled materials is formed between the paper box cover and the paper base support. The paper base support is provided with a plurality of first positioning grooves used for holding the coiled materials and preventing the coiled materials from rolling. The full paper type horizontal coiled material packaging box has the advantages that the packaging box is simple in structure, easy to manufacture, low in manufacturing cost and stable and reliable in positioning, and the coiled materials are convenient to pick and place.

Owner:HUNAN HUAWANG TECH

Decorative base paper production process and equipment utilizing diagonal stabilization technology

InactiveCN111235937AGuaranteed expansion rateGuaranteed uniformityPulp beating methodsSynthetic cellulose/non-cellulose material pulp/paperPaper productionProcess engineering

The invention discloses a decorative base paper production process utilizing a diagonal stabilization technology. The process comprises the steps of repulping, pulping, pulp mixing, net part forming,squeezing, drying, surface sizing, secondary drying, calendaring, coiling, slitting, inspecting and warehousing. According to the decorative base paper production process and equipment utilizing a diagonal stabilizing technology, 5%-10% of nylon fibers are added, a beating degree is controlled between 35-degree SR and 40-degree SR, the expansion rate of the decorative base paper during transfer printing and dipping is ensured, the expansion rate and the elasticity of the whole piece of a decorative base paper during natural use are also ensured, the overall form of the decorative base paper can be ensured after the decorative base paper is used outdoors for a long time, and meanwhile, accumulation and extrusion of dehydrated paper pulp are effectively avoided, the uniformity of paper pulpmoisture in the process is guaranteed, the problems of poor smoothness and poor moisture of a finished body paper are effectively avoided, normal and efficient paper pulp dehydration can be effectively prevented from being influenced, meanwhile, auxiliary cleaning can be conducted on the interiors of a discharging roller and a discharging end, and great convenience is achieved.

Owner:ZHEJIANG GRANDRICH PAPER

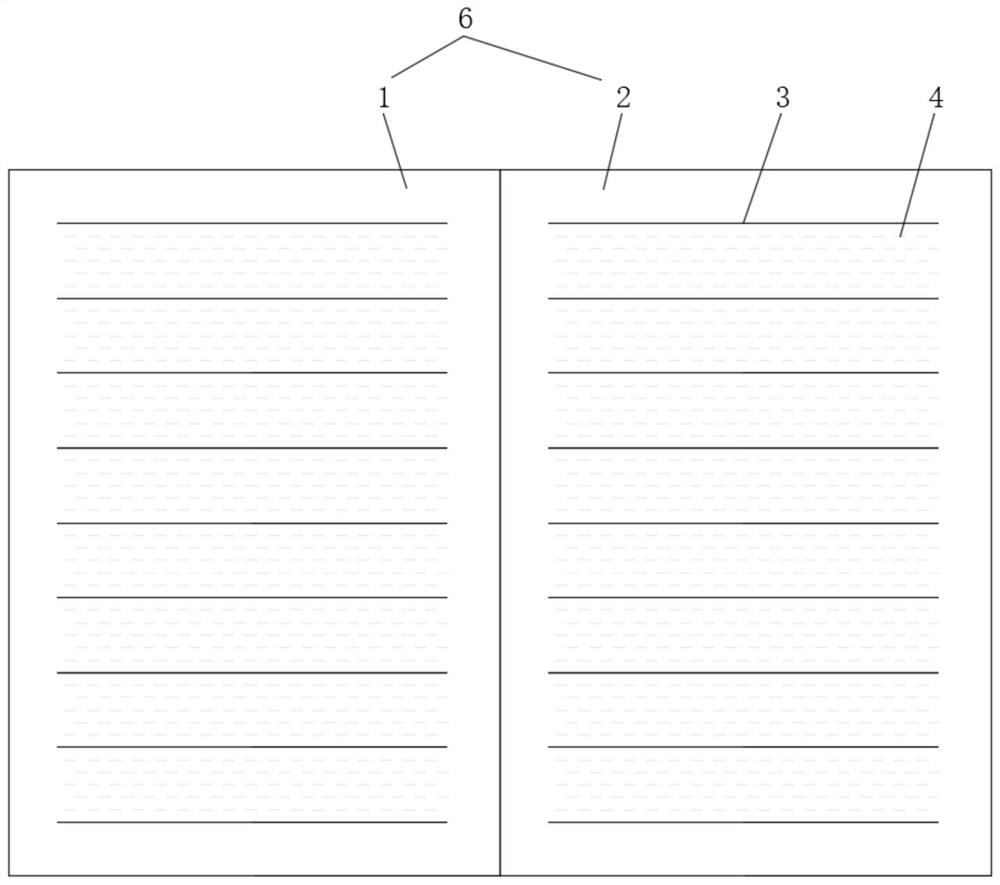

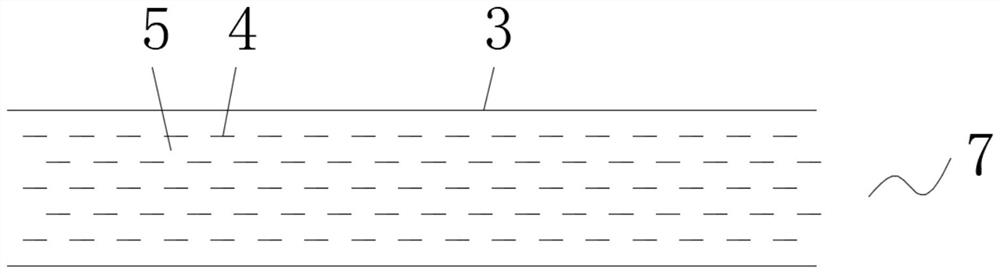

Myopia-preventing paper

InactiveCN112982016AReduce dosageAvoid eye fatigueCoatings with pigmentsSpecial paperOphthalmologyEngineering

The invention belongs to the technical field of myopia-preventing paper, and discloses myopia-preventing paper which comprises a myopia-preventing paper body. The myopia-preventing paper body comprises a myopia-preventing paper surface A and a myopia-preventing paper surface B. Ink coatings which are staggered up and down are printed on the myopia-preventing paper surface A and the myopia-preventing paper surface B. Gaps are reserved between the upper and lower adjacent rows of ink coatings printed on the myopia-preventing paper surface A, and the ink coatings on the myopia-preventing paper surface B are printed in the gaps. The ink coatings printed in an up-down staggered mode are adopted, the reflection factor is greatly lower than that of common paper, eye muscles move passively, eyestrain is prevented after long-time use, myopia is prevented, a brand new antibacterial water-based ink material technology is adopted for inner page printing of all products, and the antibacterial efficiency is high. By means of the ink coatings which are arranged in an up-down staggered mode, at least half of ink can be saved for the printing of the whole paper, a myopia prevention effect is achieved, and ink is saved.

Owner:山东峰威印务有限公司

Production method of composite paper

ActiveCN111074689AImprove adhesion strengthThere will be no "dust falling" phenomenonNatural cellulose pulp/paperSpecial paperPlant fibreViscose fiber

The invention discloses a production method of composite paper, which comprises the following steps: S1, grinding plant fibers into pulp, adding ES fibers or PE fibers into the pulp, and then preparing the pulp into plant fiber paper; S2, arranging viscose fibers or PET fibers on the surfaces of the two sides of the plant fiber paper through a carding machine, performing spunlace treatment to allow the plant fiber paper and the viscose fibers or PET fibers to be mutually and straightly wound so as to obtain wood pulp cloth; S3, drying the wood pulp cloth. Compared with the prior art, the method has the following beneficial effects: short scraps on the plant fibers are bonded and fixed on the whole piece of paper by utilizing the bonding and fixing effects after the ES fibers (or PE fibers)are melted and then solidified, so that the adhesion strength of the short scraps on the whole piece of paper is greatly improved, and a dust falling phenomenon does not occur when the paper is used.

Owner:항저우지노르인더스트리얼컴퍼니리미티드

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com