Full-paper base micro-lens array

A micro-lens array and micro-lens technology, applied in the directions of lenses, optics, instruments, etc., can solve the problems of insoluble, no thermoplasticity of paper, unsuitable micro-structure array, etc., and achieve low cost, good solvent resistance and heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Place the wet pure wood cellulose fiber paper on the closely arranged concave spherical microlens array template, then cover the paper with filter membrane and multi-layer filter paper in turn, apply a pressure of about 0.1-10MPa, and wait for 2 hours After the paper is completely dried and released from the mold, a densely arranged convex spherical microlens array can be obtained, the diameter of the structural unit is 500nm, and the period is 500nm.

Embodiment 2

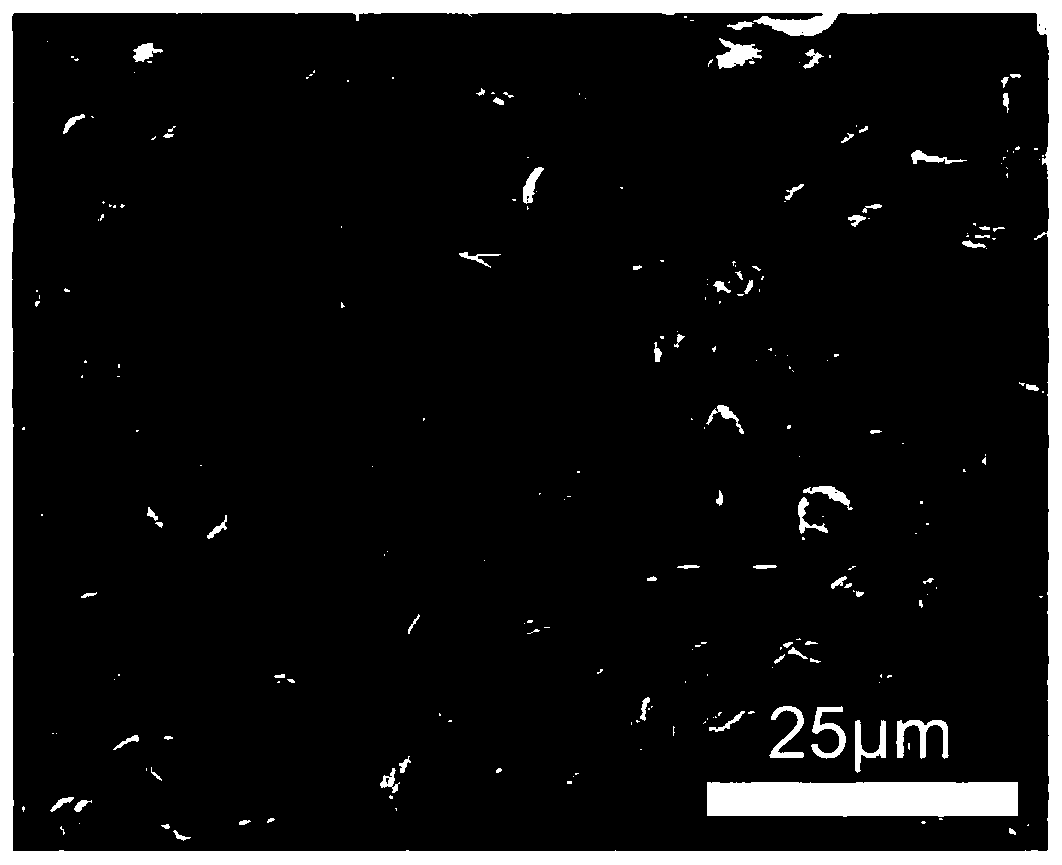

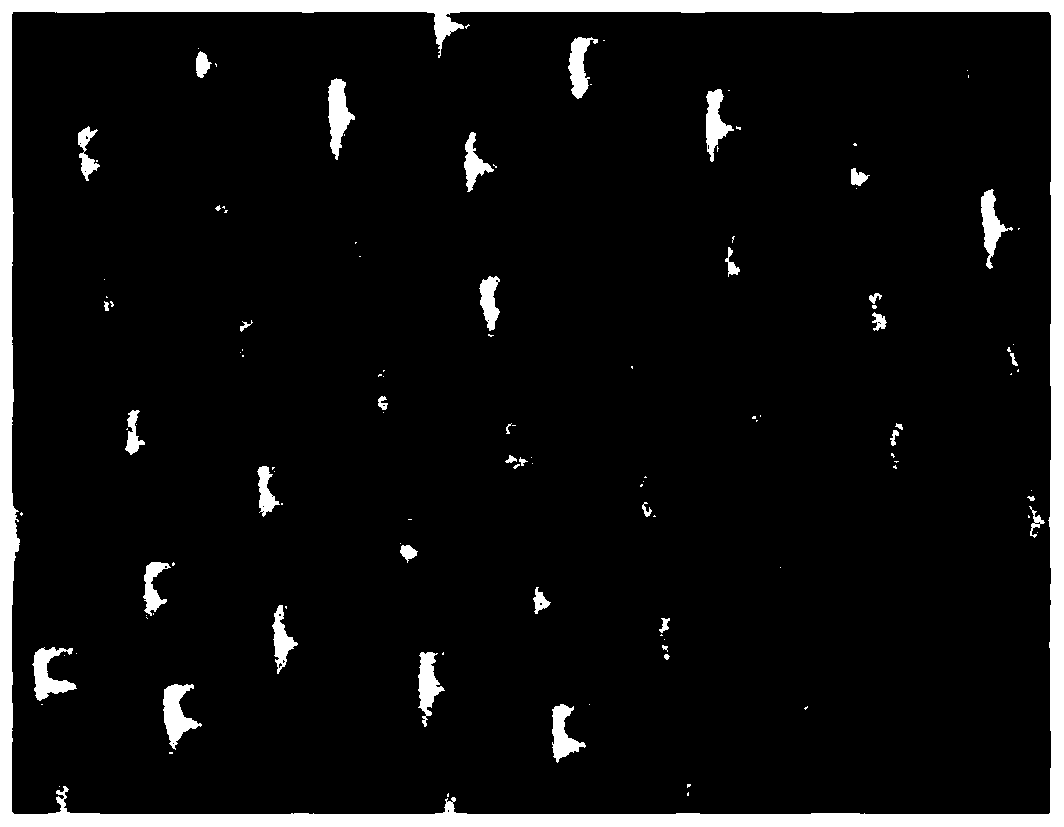

[0023] Place the wet pure wood cellulose fiber paper on the non-tightly arranged concave spherical microlens array template, and then cover the paper with filter membrane and multi-layer filter paper in turn, apply a pressure of about 0.1-10MPa, after 2 hours After the paper is completely dry and demolded, a non-closely arranged convex spherical microlens array can be obtained, the diameter of the structural unit is 6.5 μm, and the period is 6.5 μm.

Embodiment 3

[0025] Place the wet pure wood cellulose fiber paper on the non-closely arranged convex spherical microlens array template, and then cover the paper with filter membrane and multi-layer filter paper in turn, apply a pressure of about 0.1-10MPa, and after 2 hours After the paper is completely dry and demolded, a non-closely arranged concave spherical microlens array can be obtained, the diameter of the structural unit is 50 μm, and the period is 40 μm.

[0026] Example 3:

[0027] Place the wet pure bamboo cellulose fiber paper on the tightly arranged convex free-form surface microlens array template, and then cover the paper with filter membrane and multi-layer filter paper in sequence, apply about 0.1-10MPa pressure, after 2 Wait until the paper is completely dry, and after demolding, a microlens array with a tightly arranged concave free-form surface can be obtained. The diameter of the structural unit is 500 μm, and the period is 500 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com