Shredder with dust removing device

A paper shredder and dust technology, which is applied in the field of paper shredders with a dust removal device, can solve the problems of manual cleaning and increase user inconvenience, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

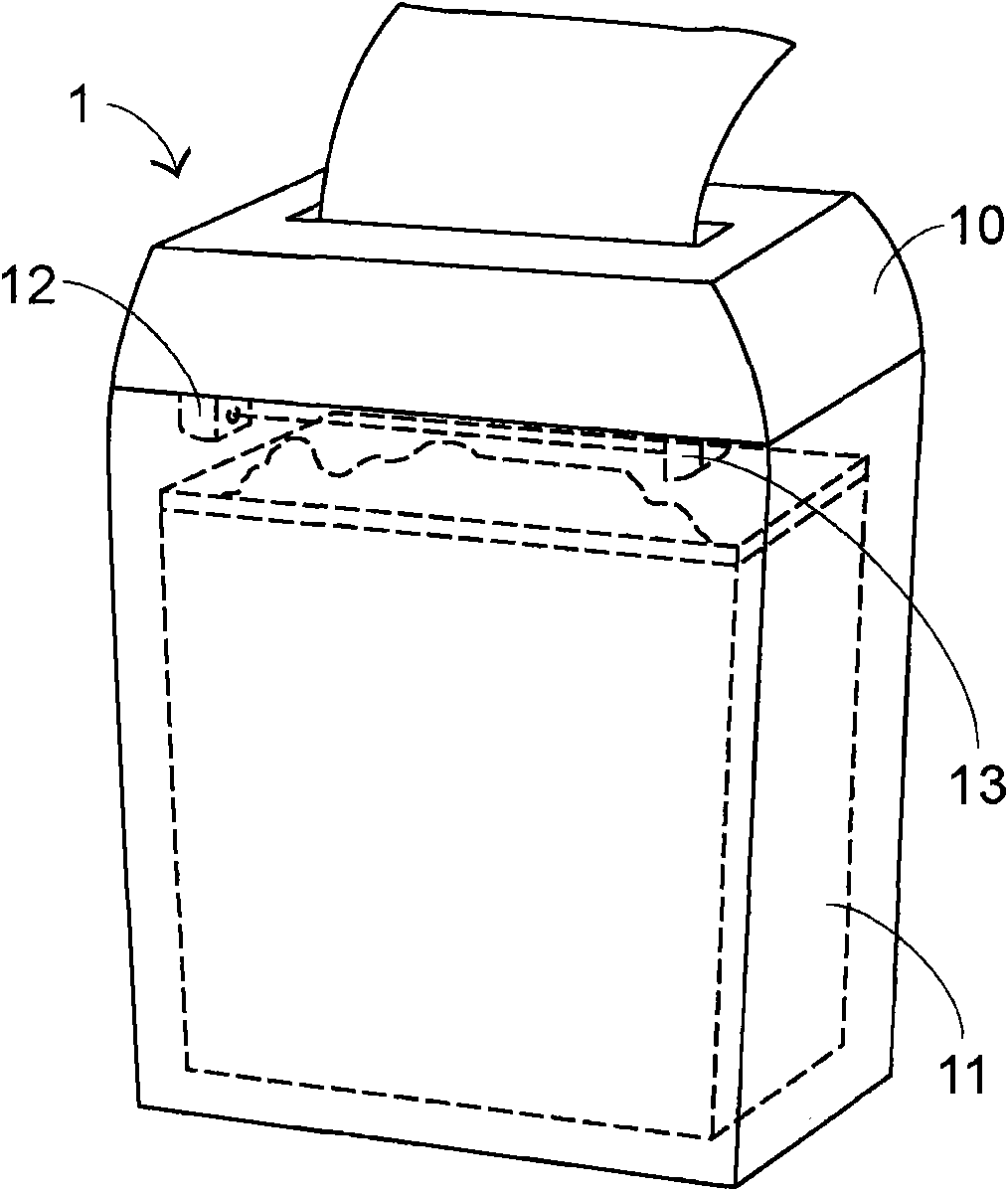

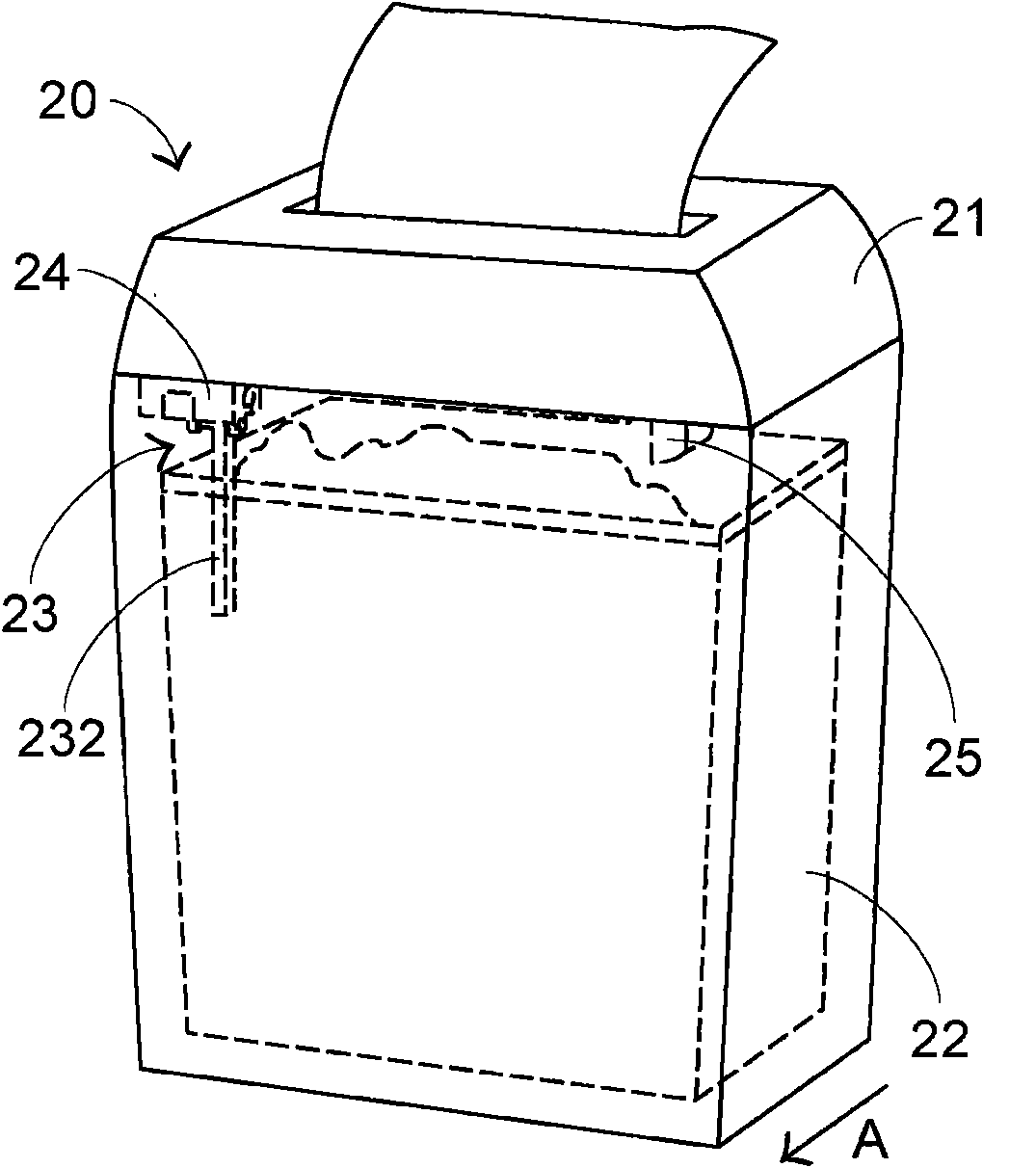

[0039] see figure 2 , which is a schematic diagram of a paper shredder with a dust removal device according to the present invention. figure 2 It shows that the shredder 20 of the present invention includes a shredder head 21 , a paper drum 22 , a sensing device and a dust removal device 23 . The paper tube 22 is used to contain shredded paper, and the sensing device is used to sense the status of the paper tube 22 being full of paper, including a sensor emitting part 24 and a sensor receiving part 25 .

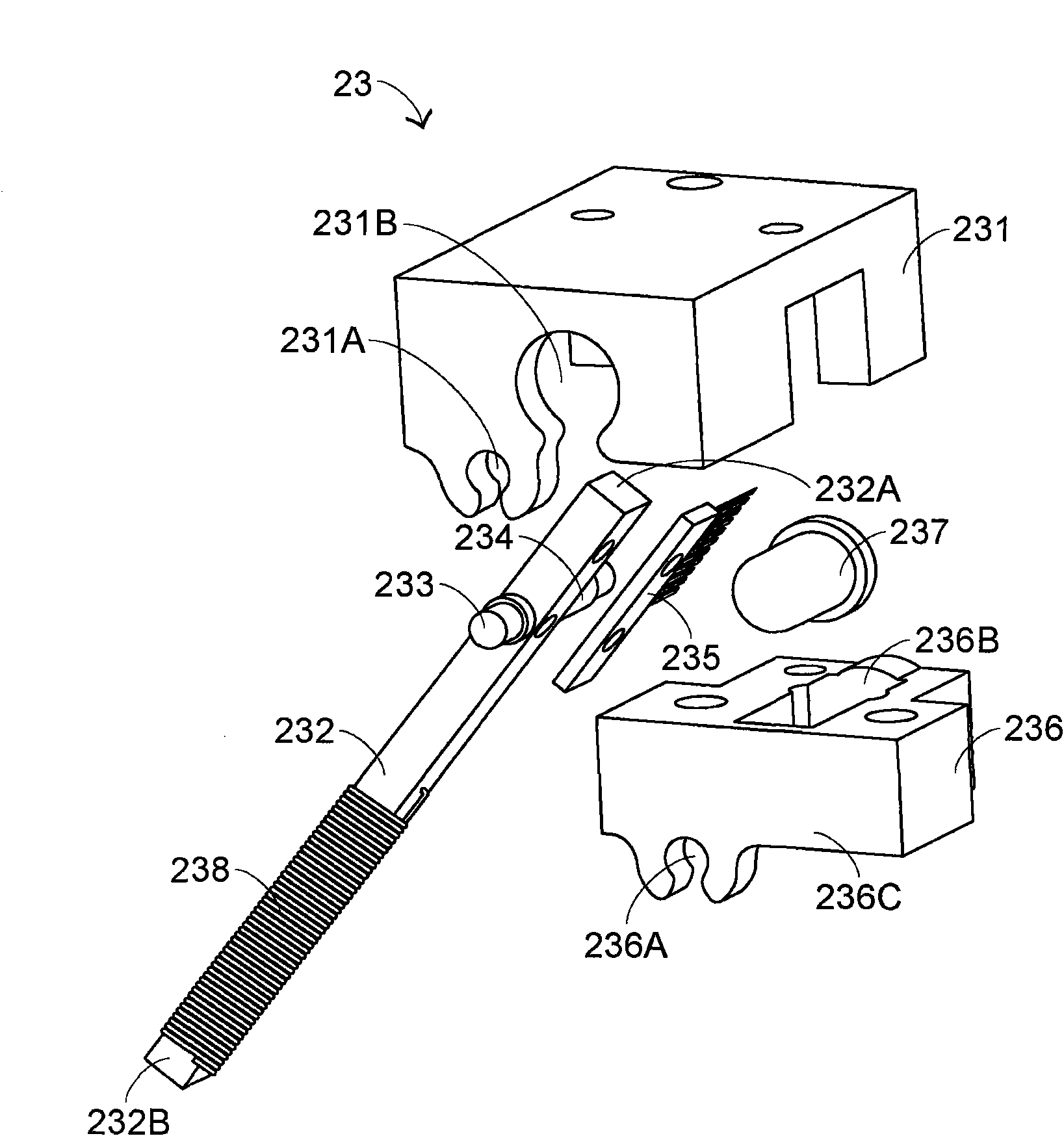

[0040] The dust removal device 23 of the present invention is used for cleaning the surface of the sensing device, and it can be installed adjacent to the above-mentioned sensor emitting part 24 (such as figure 2 shown) or adjacent to the above-mentioned sensor receiving part 25, to remove the dust on the surface of the sensing device. Although in figure 2 Only a single dust removal device 23 is set in the paper shredder of the present invention, but another dust remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com