Paper shredder mechanical full paper mechanism

A paper shredder and mechanical technology, applied in the direction of grain processing, etc., can solve the problems of inflexible use, unsimple structure, and easily damaged shredder cutters, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

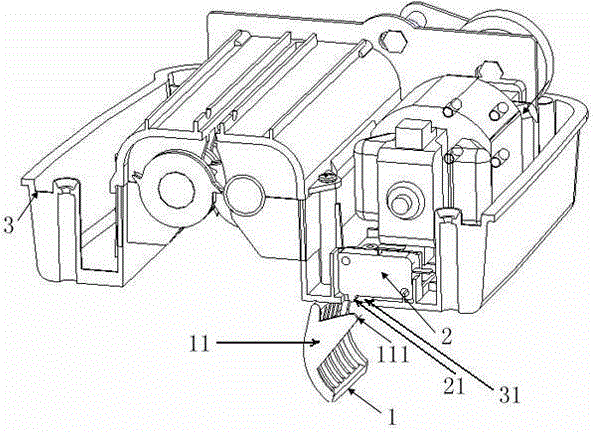

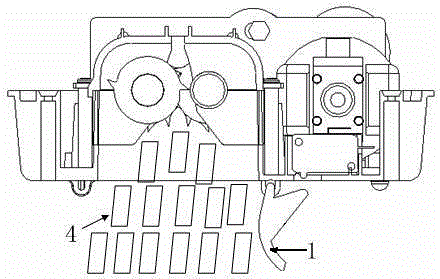

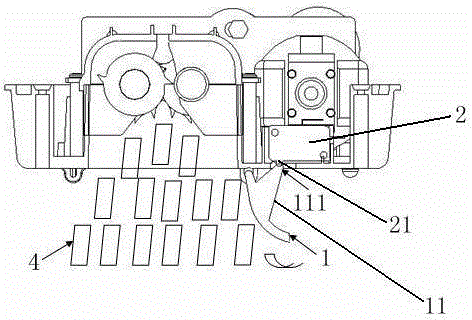

[0024] see figure 1 , the paper shredder mechanical full paper mechanism of the present embodiment includes:

[0025] The pressure plate 1 is arranged on the outside of the shredder core below the lower cover 3 of the shredder, and is flush with the direction of the knife axis of the shredder core. One end of the pressure plate 1 is pivotally connected to the lower cover 3 of the shredder, and the pivotally connected For example, the other end of the pressing plate 1 can swing freely through the connecting shaft; in other embodiments of the present invention, the pressing plate may not be flush with the direction of the cutter axis of the shredder core, but may be at a smaller angle;

[0026] The touch switch 2 is fixed on the lower cover 3 of the paper shredder, and the touch switch 2 is provided with a touch point 21 near the lower cover of the paper shredder. Preferably, in this embodiment, the touch switch 2 is a micro switch;

[0027] The pressing plate 1 is provided wit...

Embodiment 2

[0030] The difference between this embodiment and the first embodiment lies in that the actuating component provided on the pressing plate is an actuating lever.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com