Footing embedded type full-paper combined heavy-load tray and forming method thereof

An embedded and footed technology, which is applied in the direction of rigid containers, containers, packaging, etc., can solve the problems that affect the popularization and use of paper pallets, unsatisfactory connection strength, and poor impact resistance, so as to reduce weight and load The effect of strong ability and impact resistance, reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

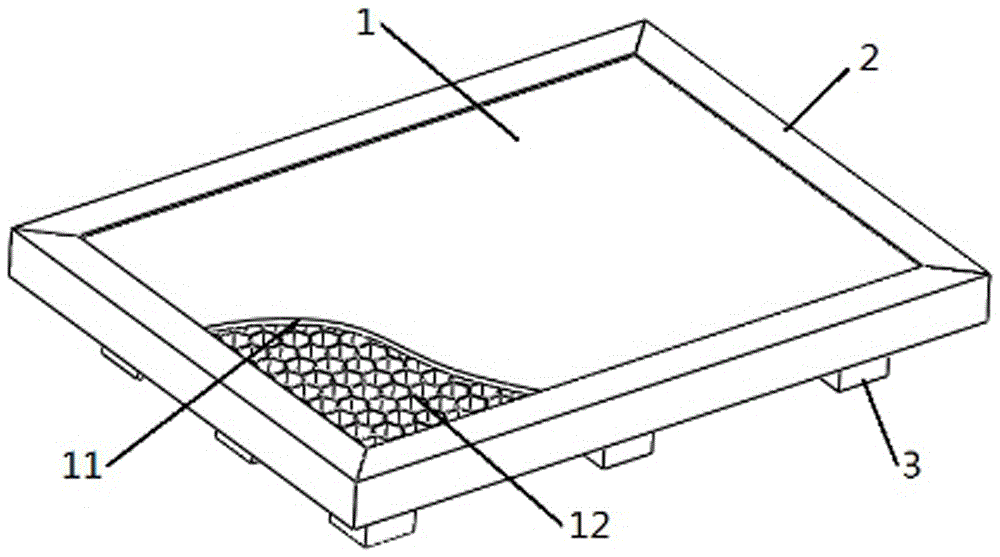

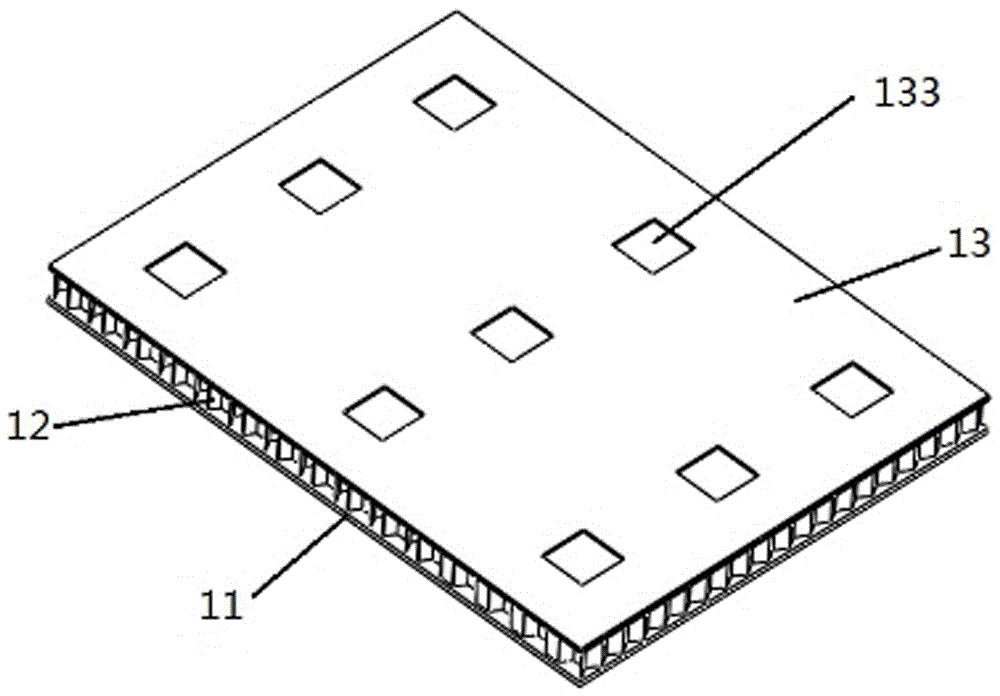

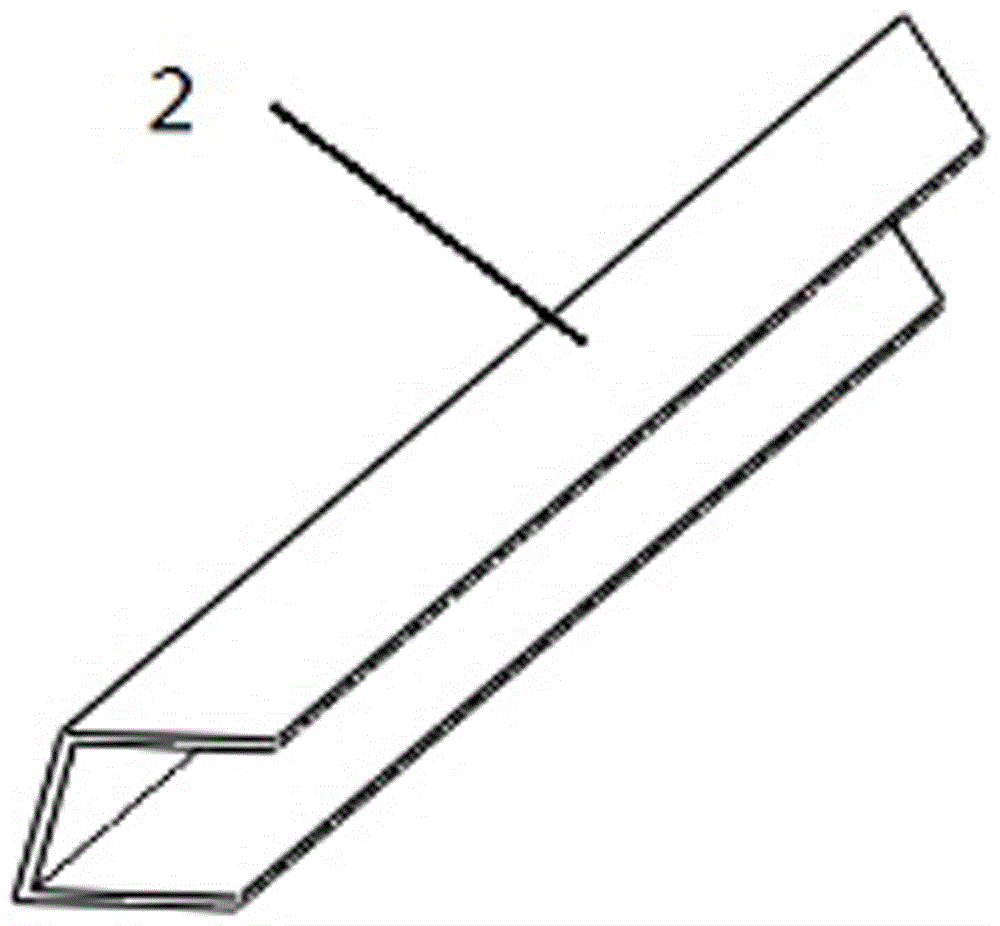

[0039] Such as Figure 1~9 As shown, an all-paper combined heavy-duty pallet with embedded feet includes a decking 1, a paper corner 2 and a footing 3. The decking 1 includes a top board 11, a core board 12, and a bottom board 13 stacked in sequence. The bottom board 13 includes The first flat bottom plate 131 and the slotted flat bottom plate 132 are stacked in sequence. The slotted flat bottom plate 132 is provided with a through groove 134 that is the same size as the cross section of the foot 3. The first flat cardboard and the slotted flat bottom plate 132 are superimposed on the through groove A groove 133 is formed at 134, the foot 3 is installed in the groove 133 and extends out of the slotted flat bottom plate 132, the paper corner 2 is cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com