Production method of composite paper

A production method and technology of composite paper, which is applied in the field of papermaking, can solve the problems of weak adhesion, falling off, falling dust, etc., and achieve the effect of improving the adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] S1: The plant fiber is crushed in the pulper, the support concentration is 6% (plus or minus 0.5%), and finally the slurry enters the former of the double-cylinder forming wire through the slurry feed tank to obtain a plant fiber sheet, and then Add ES fiber on both sides of the plant fiber sheet, the addition of ES fiber is to add 0.5Kg for every 100Kg plant fiber, after adding ES fiber, make plant fiber paper, control the water content of plant fiber paper at 85%;

[0025] S2: Set a layer of viscose fiber on both sides of the planting fiber paper with a carding machine, and then perform hydroentanglement treatment on it with a hydroentanglement machine. The hydroentanglement needles are 3 to 6, and the hydroentanglement pressure is 6 to 14Mpa. , after the spunlace treatment is completed, a wood pulp cloth is obtained;

[0026] In S3, wood pulp cloth is dried in a drying cylinder at a temperature of 160°C and at a speed of 200 meters per minute.

[0027] In this embod...

Embodiment 2

[0031] The steps in this example are the same as those in Example 1, except that PE fibers are used instead of ES fibers in Example 1, and the drying temperature is reduced from 160°C to 120°C during drying, and the amount of PE fibers added is also Add 0.5Kg to 100Kg plant fiber.

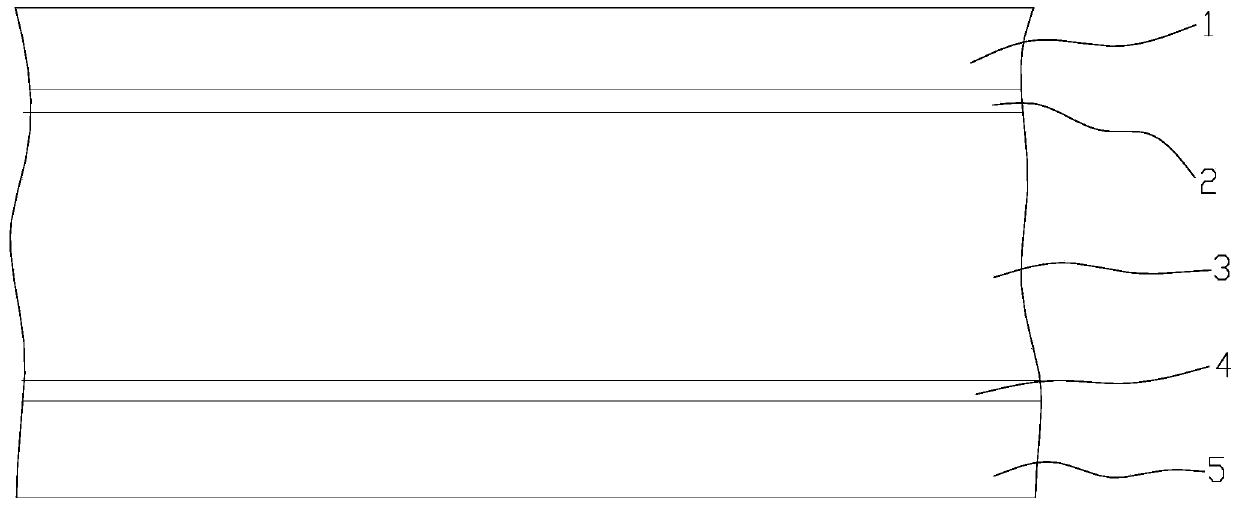

[0032] The compound paper that present embodiment present embodiment makes can be roughly divided into five layers, refer to attached figure 1 , the first layer 1 is a viscose fiber layer, the second layer 2 is a PE fiber layer, the third layer 3 is a plant fiber layer, the fourth layer 4 is a PE fiber layer, and the fifth layer 5 is a viscose fiber layer.

Embodiment 3

[0034] S1: The plant fiber is crushed in the pulper, the support concentration is 6% (plus or minus 0.5%), and finally the slurry enters the former of the double-cylinder forming wire through the slurry feed tank to obtain a plant fiber sheet, and then Add ES fiber on both sides of the plant fiber sheet, the addition of ES fiber is to add 0.5Kg for every 100Kg plant fiber, after adding ES fiber, make plant fiber paper, control the water content of plant fiber paper at 85%;

[0035] S2: Set up a layer of viscose fiber and PET fiber with a carding machine on both sides of the fiber planting paper, and then perform hydroentanglement treatment on it with a hydroentanglement machine. The hydroentanglement needles are 3 to 6, and the hydroentanglement pressure is 6. ~14Mpa, wood pulp cloth is made after spunlace treatment;

[0036] In S3, wood pulp cloth is dried in a drying cylinder at a temperature of 160°C and at a speed of 200 meters per minute.

[0037] In this embodiment, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com