Method of producing thermoelectric conversion device

A manufacturing method and thermoelectric conversion technology, applied in the manufacture/processing of thermoelectric devices, electrical components, thermoelectric device parts, etc., can solve the problem of not being able to apply loads evenly, and achieve good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described based on the drawings.

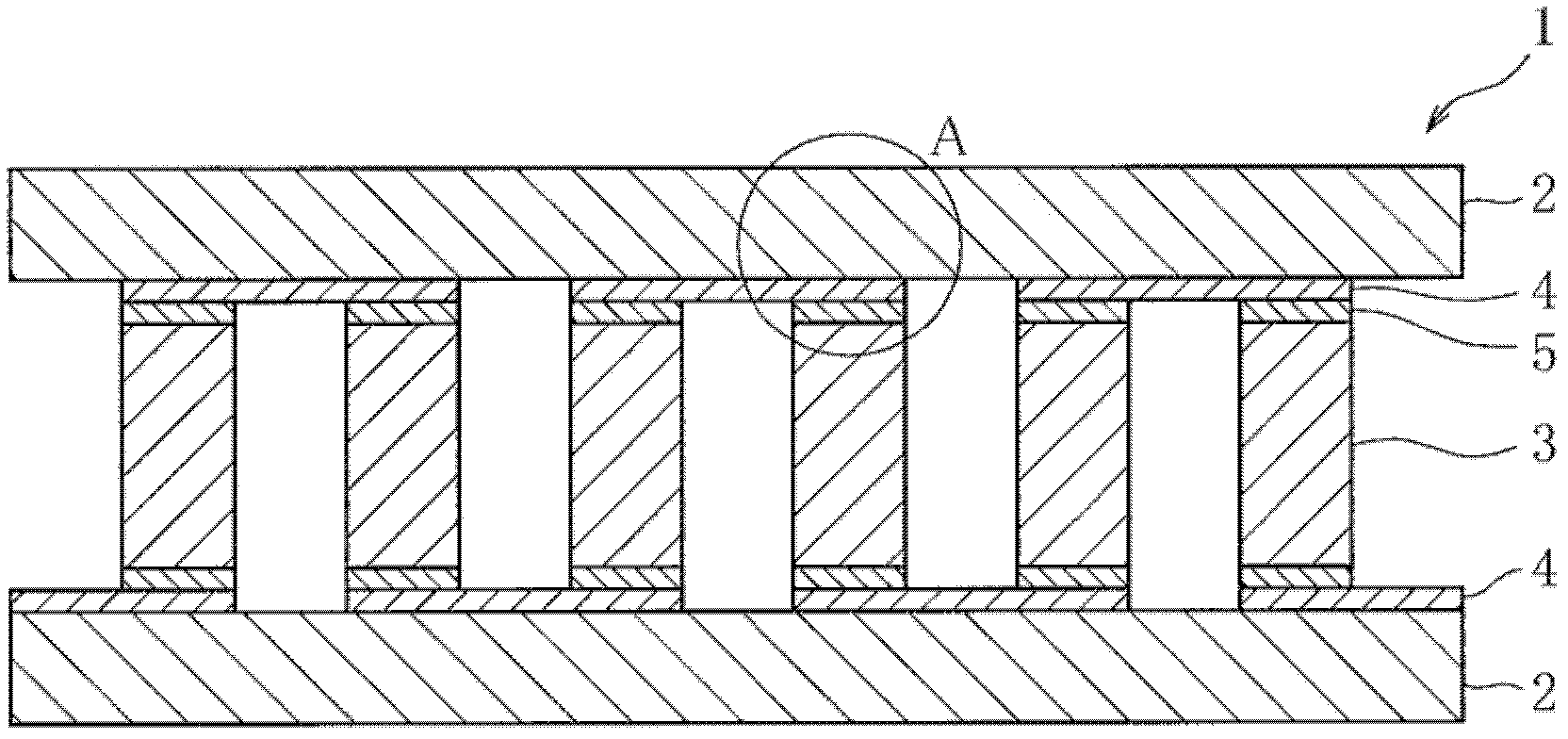

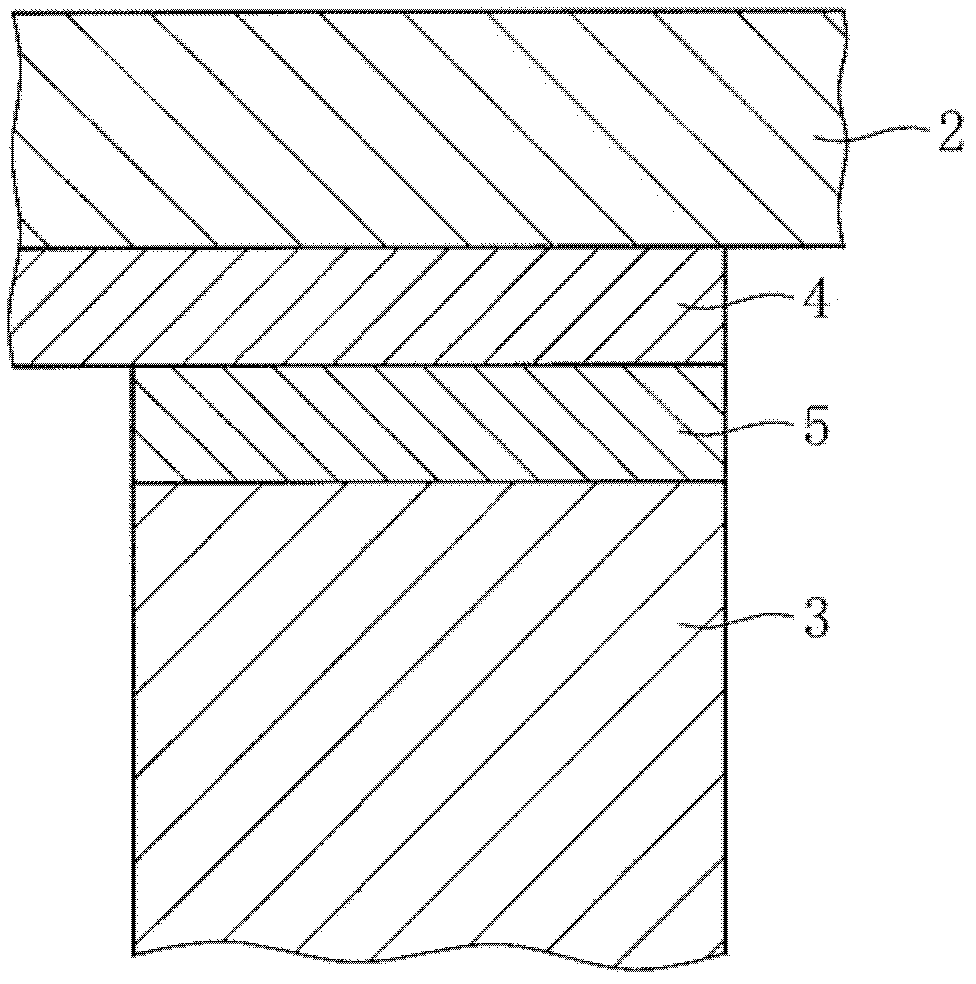

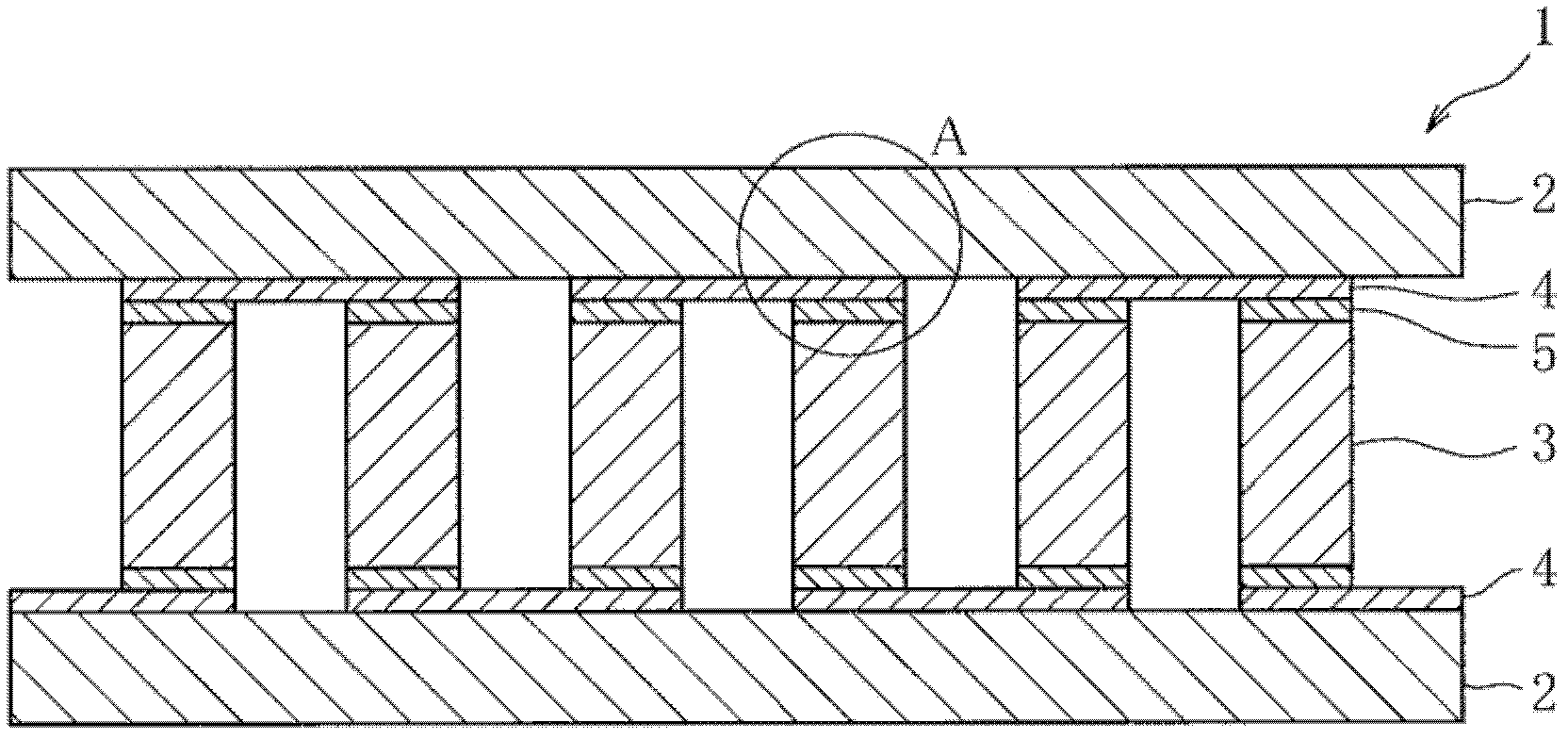

[0024] figure 1 It is a schematic diagram of the manufacturing apparatus of the thermoelectric conversion element used for the manufacturing method of the thermoelectric conversion element which concerns on one Embodiment of this invention. in addition, figure 2 yes figure 1 Enlarged view of part A.

[0025] As shown in the figure, a manufacturing apparatus 1 of a thermoelectric conversion element includes a pair of vertically arranged punches 2 that are energized and pressurized members arranged up and down. The punch 2 is made of a conductive material (for example, graphite). A plurality of thermoelectric conversion materials 3 (six thermoelectric conversion materials 3 in the figure) are arranged between these punches 2 .

[0026] At this time, the thermoelectric conversion materials 3 are arranged alternately in p-type and n-type. In addition, in the case of using a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com