Stamping apparatus

A pressure chamber and chamber technology, applied in optics, opto-mechanical equipment, instruments, etc., can solve problems such as difficult separation, soft mold deformation or damage, and achieve the effects of easy separation, reduced size, and reduced space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

[0039] The following descriptions are within the scope of implementation by those skilled in the art.

[0040] Therefore, the embodiments of the present invention may have various modifications, and the protection scope thereof is not limited to the following embodiments.

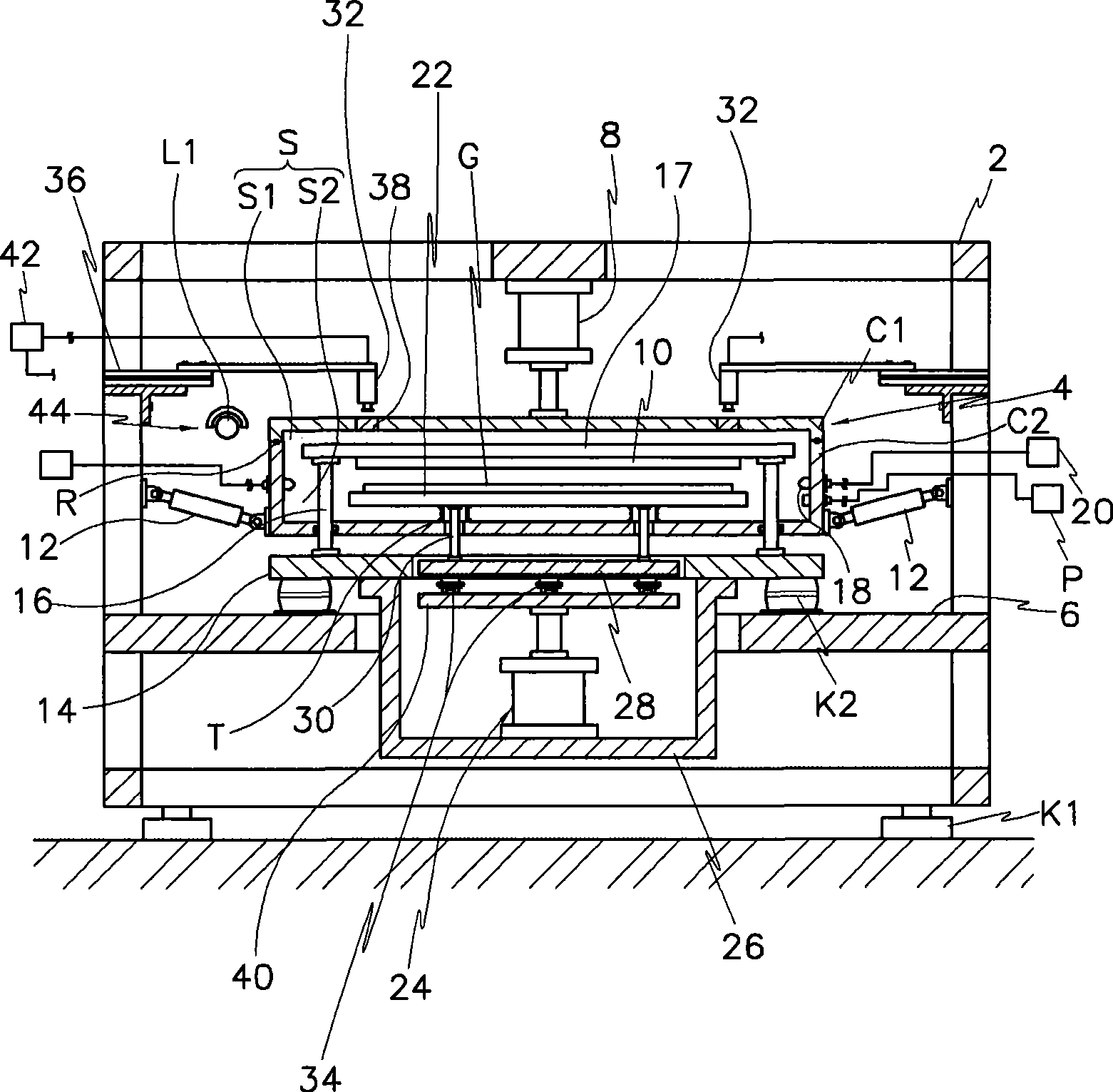

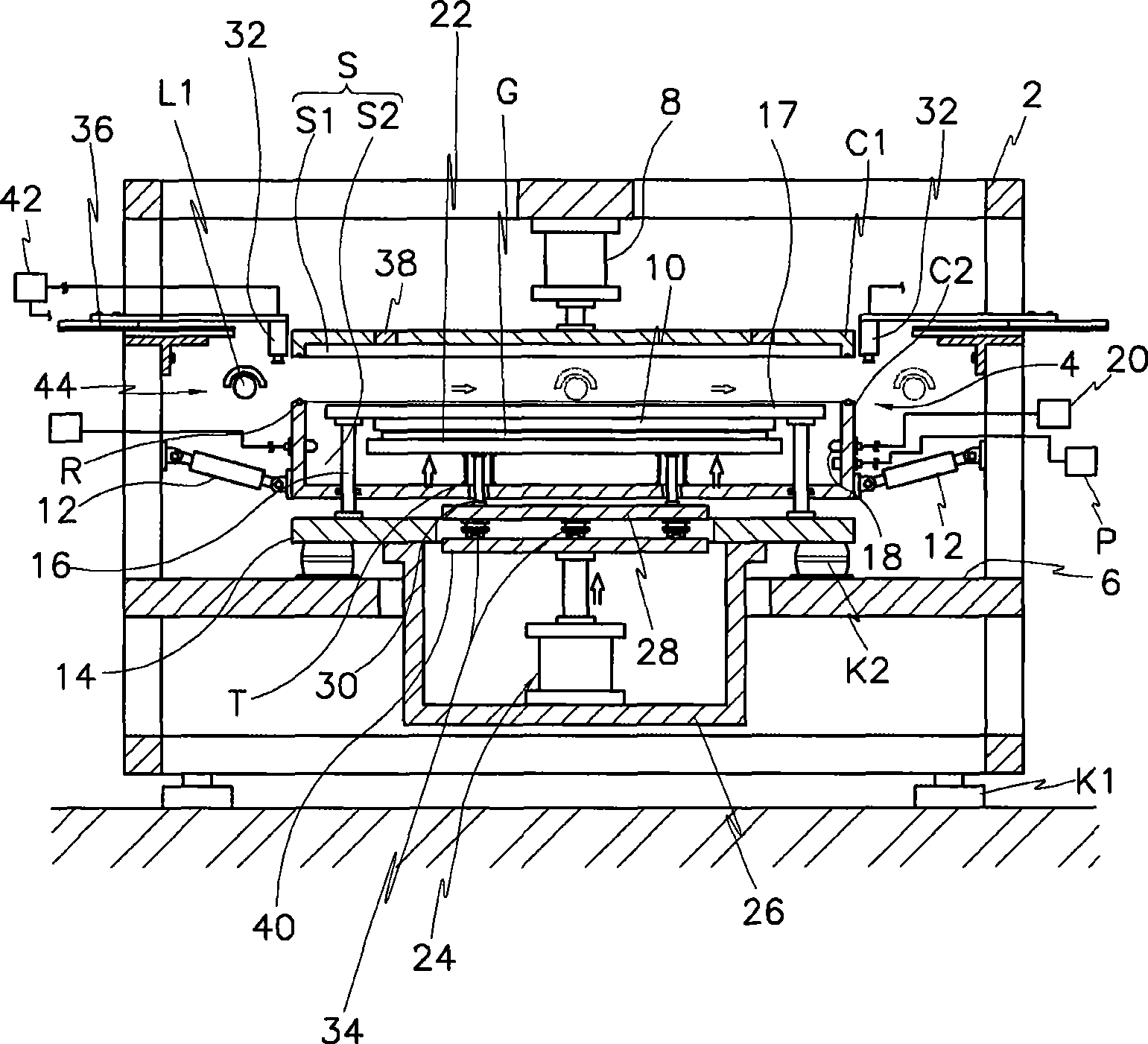

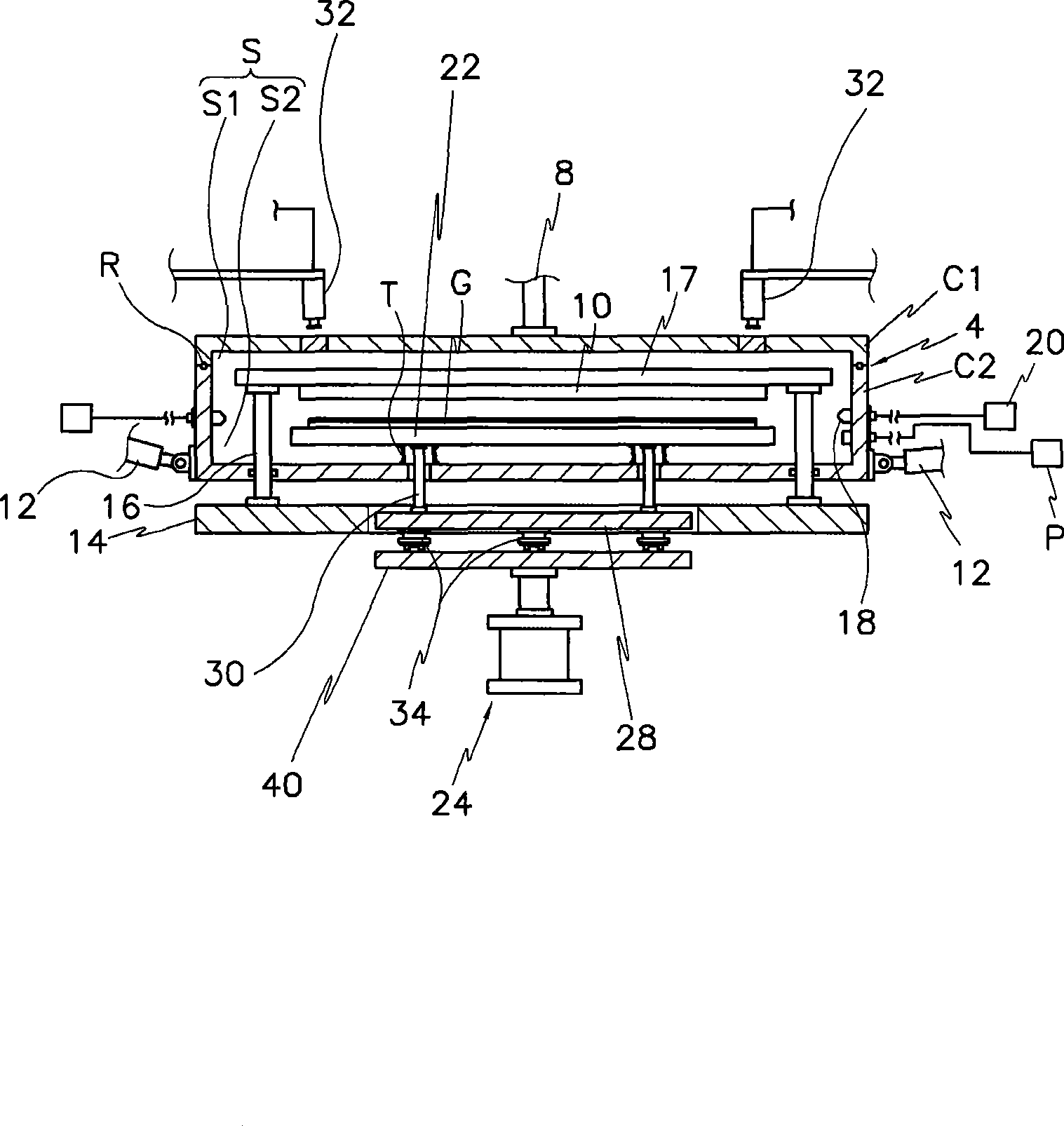

[0041] figure 1 It is a schematic diagram of the overall structure of an embodiment of an imprinting device for forming an etching region on a substrate according to the present invention, wherein reference numeral 2 denotes a frame.

[0042] The frame 2 is a rectangular frame formed by welding or screwing a plurality of metal pipes (or metal strips) by a conventional method, which is preferably supported on the ground by a backing plate K1 such as a rubber plate, so as to absorb the floor shock force.

[0043] Furthermore, a cavity 4 is provided on the inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com