Textile machine

A mechanical and fiber technology, applied in spinning machines, open-end spinning machines, spinning machines with continuous winding, etc., can solve the problems of inability to locate packages and difficulty in capturing yarn ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

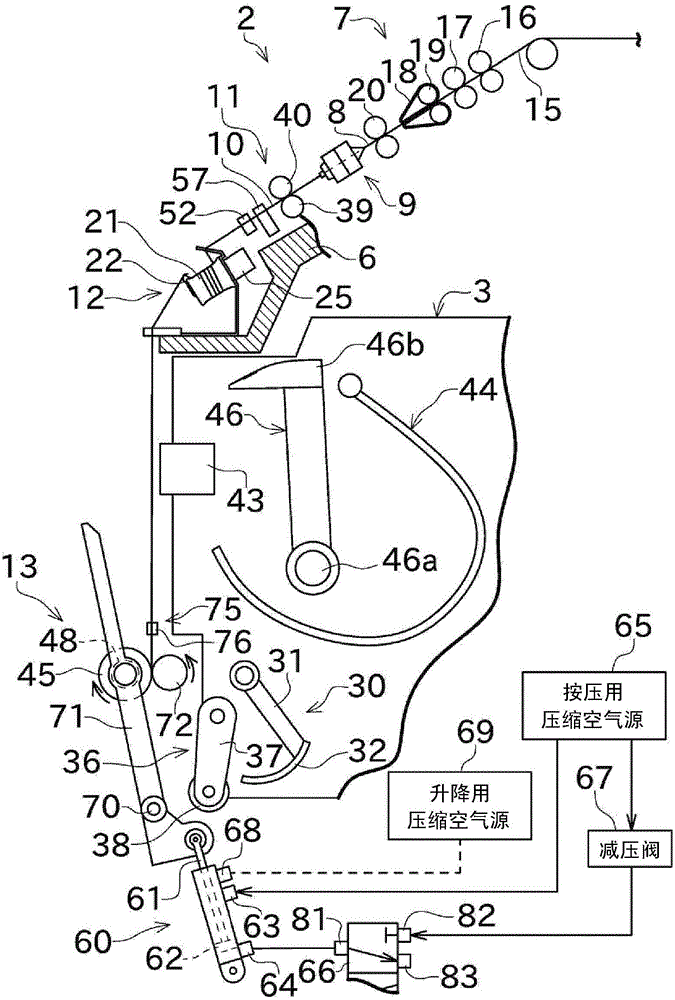

[0040] Next, a spinning frame (spinning machine) according to an embodiment of the present invention will be described with reference to the drawings. In addition, in this specification, "upstream" and "downstream" mean upstream and downstream in the traveling direction of the yarn during spinning.

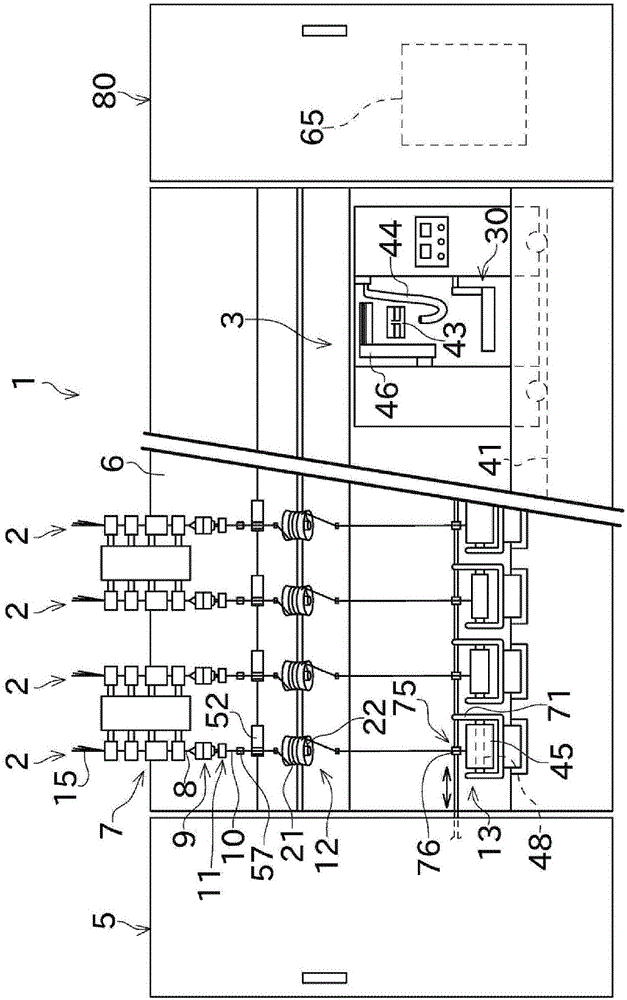

[0041] figure 1 The spinning frame 1 shown as an example of a textile machine includes a plurality of spinning units (winding units) 2 arranged in a row. The spinning frame 1 has a piecing cart (work cart) 3 , a blower box 80 and a power box 5 .

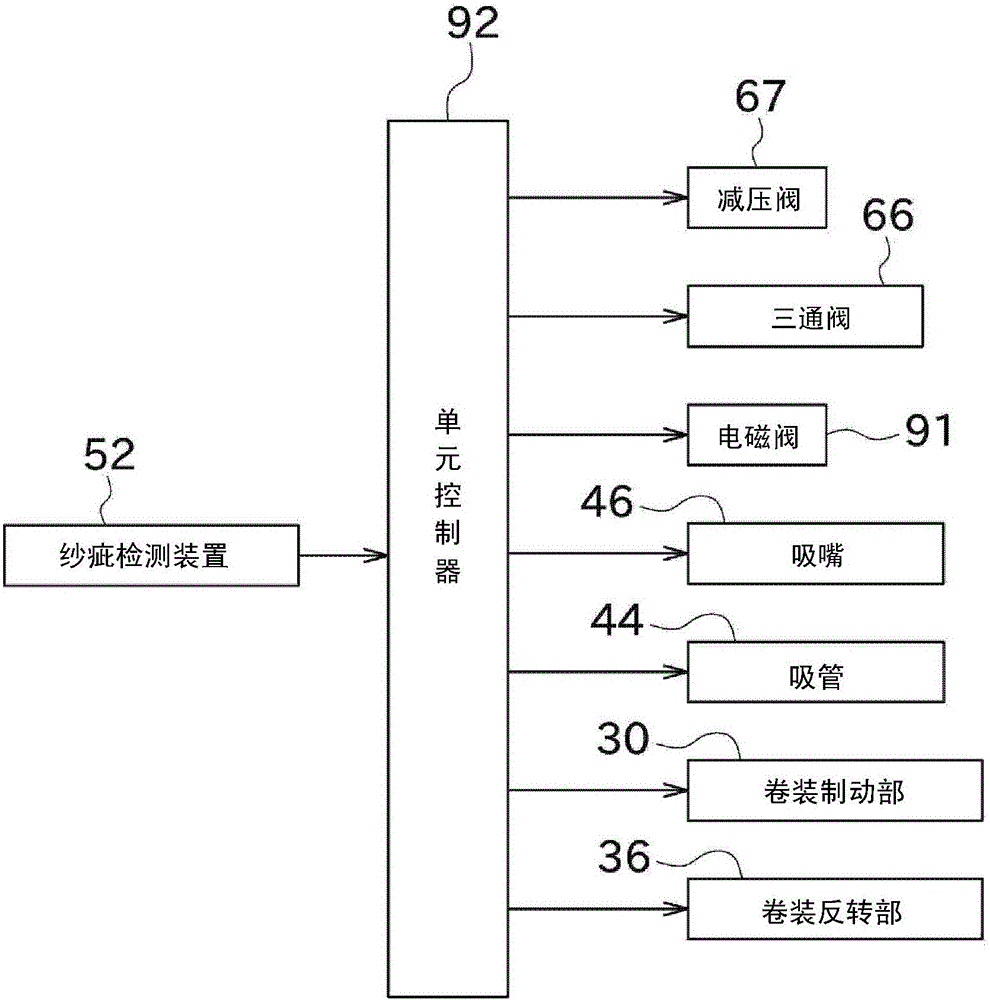

[0042] Such as figure 1 As shown, each spinning unit 2 includes a draft device 7, a spinning device (yarn supply section) 9, a yarn feeding device 11, a yarn slack removing device 12, and a winding device 13 as main structures in order from upstream to downstream.

[0043] The draft device 7 is provided near the upper end of the housing 6 included in the spinning frame 1 . The fiber bundle 8 sent from the drafting device 7 is spun by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com