Production equipment of anti-infective bone graft material and preparation method

A kind of production equipment and bone grafting technology, which is applied in the field of preparation of anti-infection bone grafting materials, can solve the problems of less granular gelatin content, excessive gelatin amount, and different sizes of bone particles, and achieve tight joints, large-scale, and bone grafting. Excellent repair ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

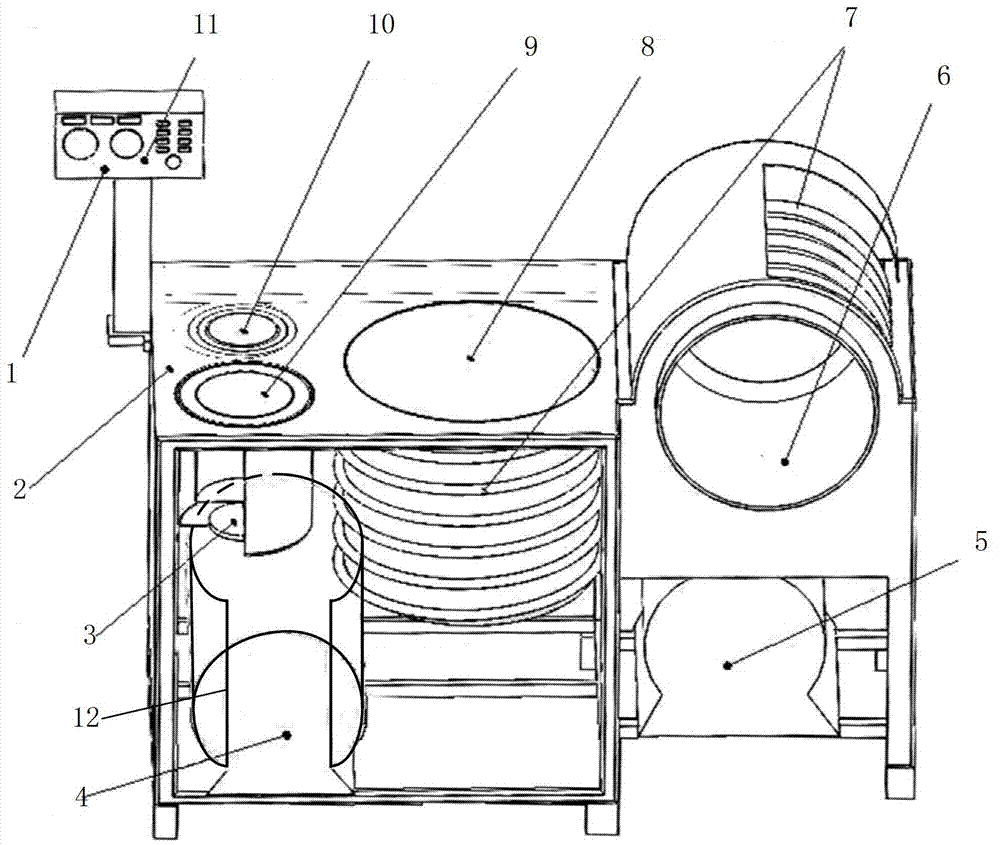

[0026] see figure 1 The production equipment of this kind of anti-infection bone graft material includes a frame 2 and an operation panel, the operation panel is installed on the side of the frame 2 through a support rod, and the upper part of the frame 2 is vertically installed with a bone particle preheating tank 10, The sol tank 9, the vacuum cold air drying chamber 6, and the cold water pool 8 provided with a dispersing device, and the bone particle preheating tank 10, the tank body of the sol tank 9 and the cold water pool 8, and the pool body are inserted into the inside of the frame 2, and the top inlet Set on the same level as the top of the frame 2; a vacuum wrapping tank 12 is connected below the sol tank 9, and a vacuum pump 4 is arranged below the vacuum wrapping tank 12; the vacuum cold air drying chamber 6 is horizontally embedded in the frame 2 above; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com