Dual-tooth-head spiral zipper

A screw-type, tooth-head technology, applied in the field of zipper, can solve the problems of not having novel and fashionable appearance quality, difficult to change the zipper greatly, poor zipper pull strength, etc., to achieve excellent appearance quality, not easy to split, Strong pull effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

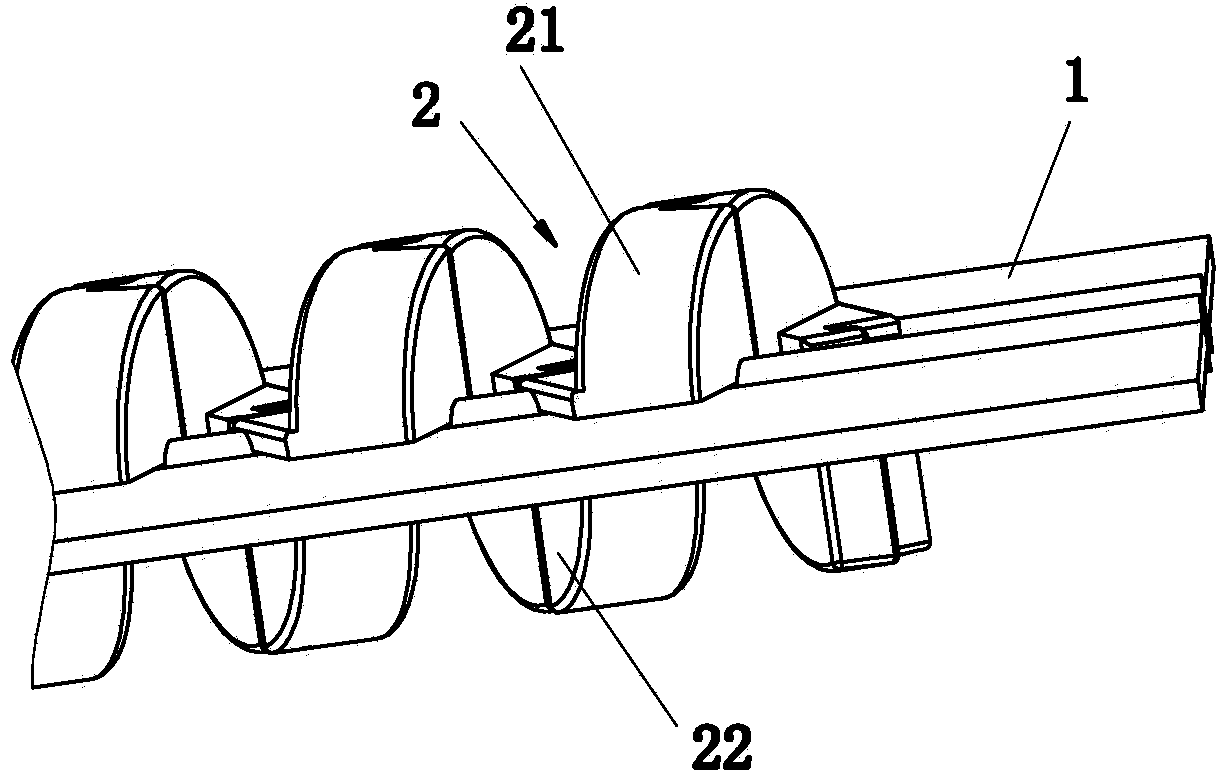

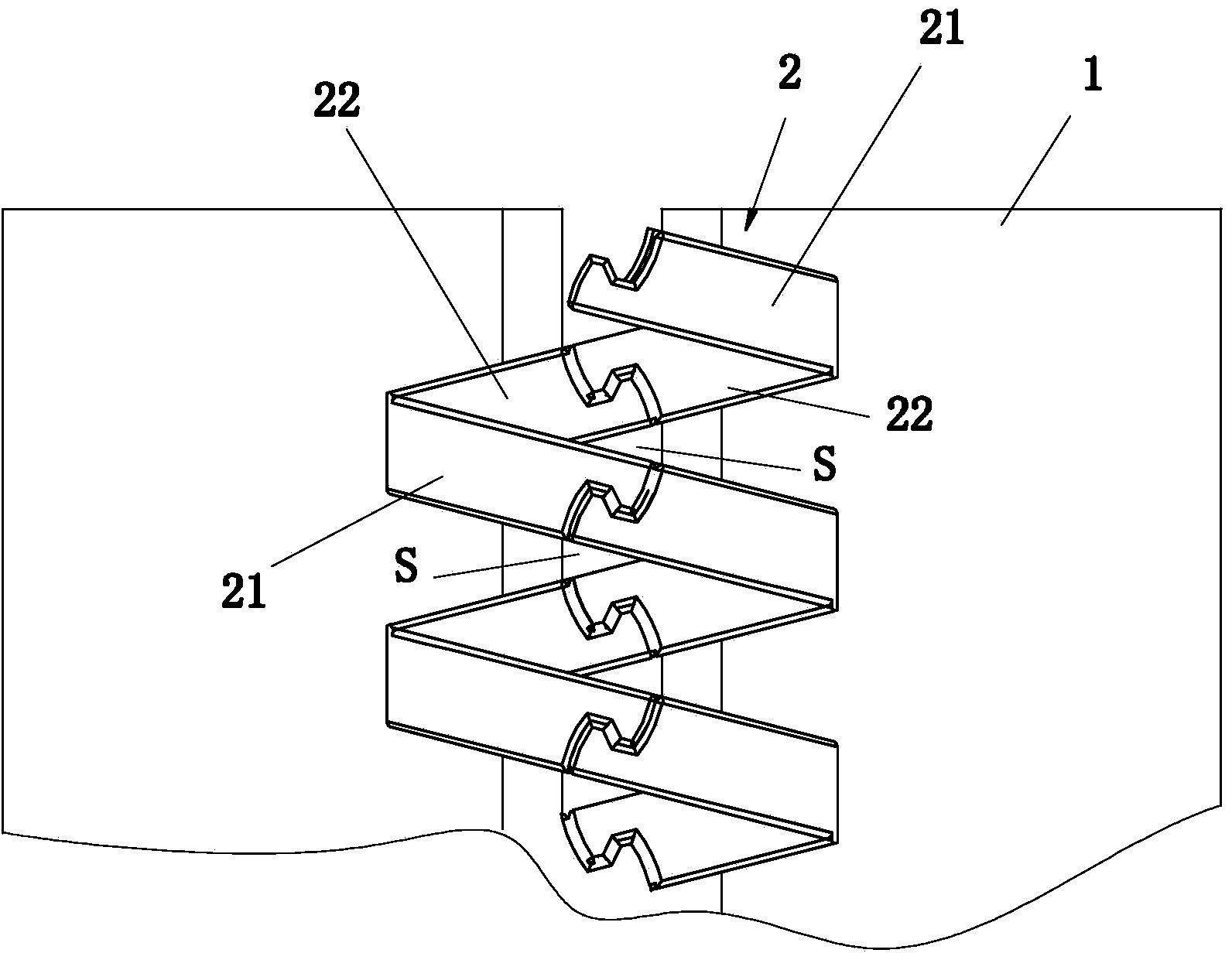

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. In the following description, the tape length direction of the fastener tape is described as the width direction of the fastener element, the two ends in the width direction of the fastener element are called the outer side, and the central part in the width direction of the fastener element is called the inner side; the width direction of the fastener tape is described as It is the length direction of the chain element, the tooth head end for the chain element meshing is the front end, and the tooth leg end for the chain element fixing is the rear end; Inside) is the up-down direction, that is, the height direction of the chain teeth.

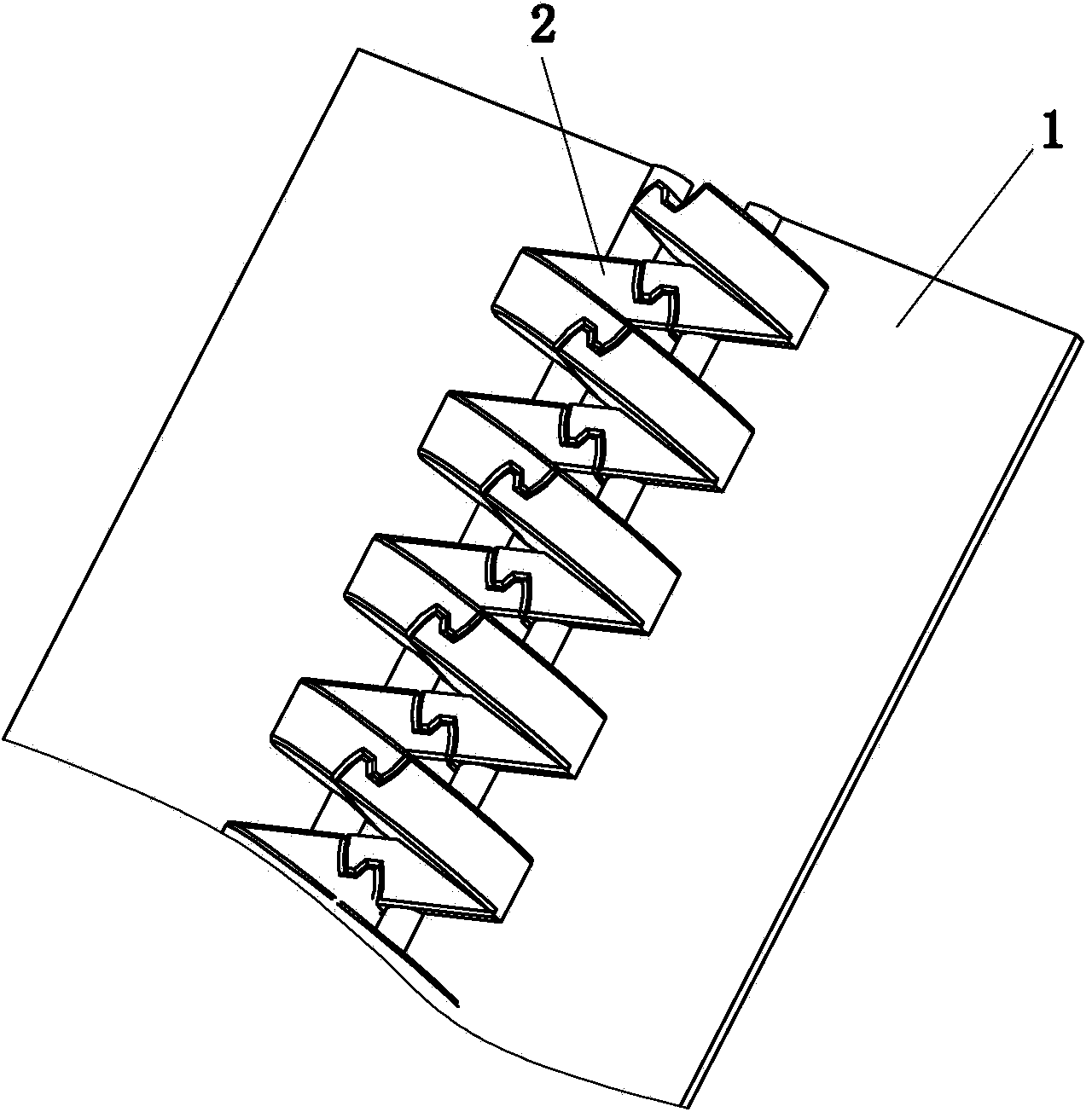

[0030] Such as Figure 1 to Figure 8 As shown, a double-head spiral zipper includes a pair of zipper tapes 1, and a plurality of chain elements 2 are fixed on the opposite side edges of the two zipper tapes 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com