Separation and reunion nut and separation and reunion method thereof

A clutch nut and clutch screw technology, applied in the direction of nuts, bolts, threaded fasteners, etc., can solve the problem of reducing the applicability of the sliding screw drive engineering application field, unable to load the screw drive axial force between the nut and the screw, reducing sliding Screw drive applicability and other issues, to achieve stable and reliable meshing and separation state, compact size, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

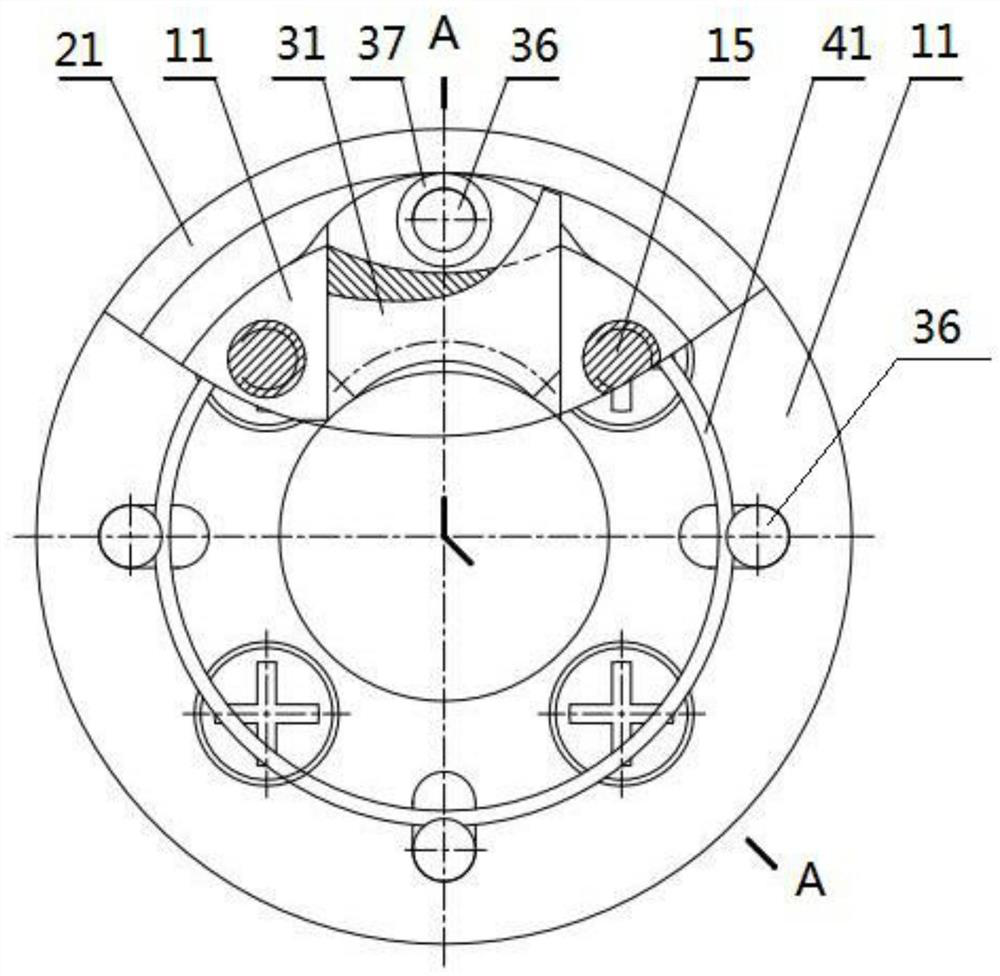

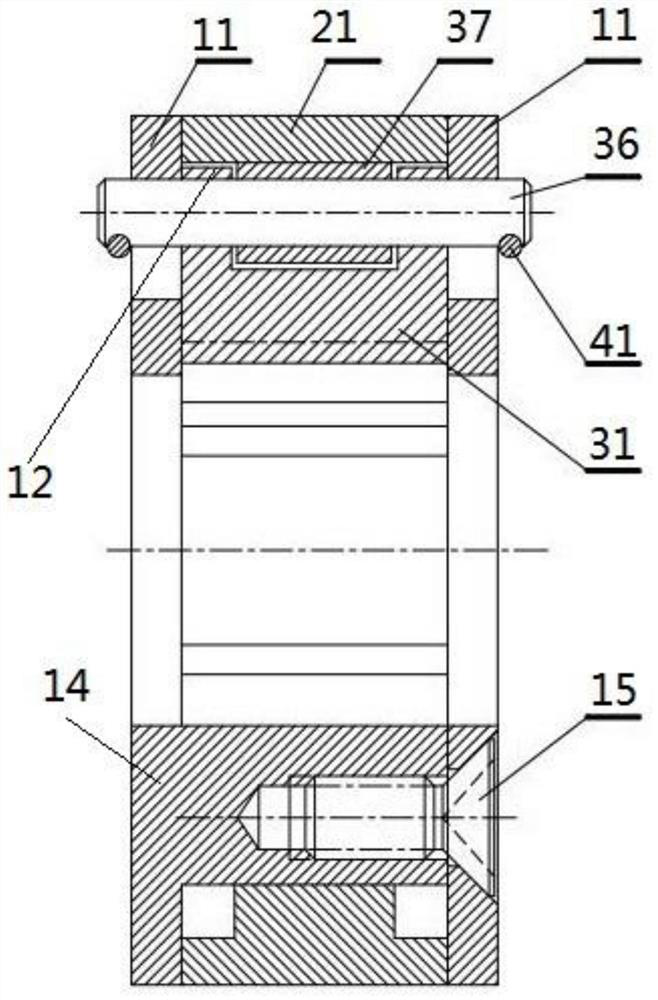

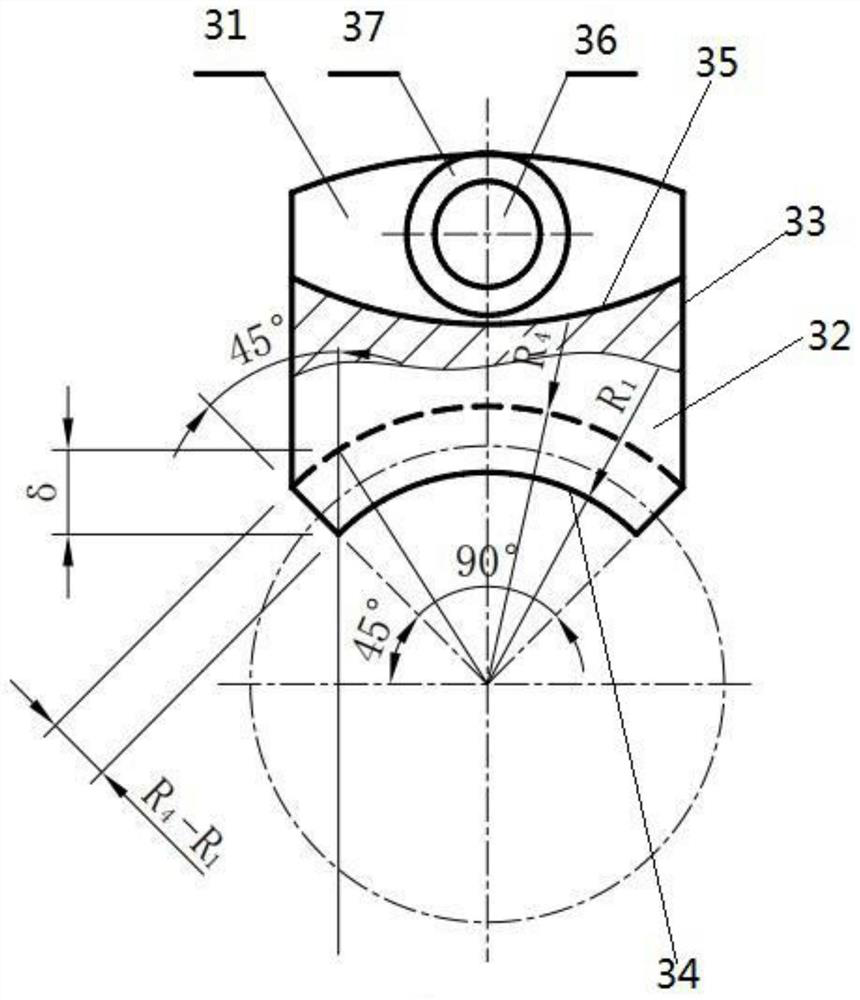

[0045] see Figure 1 to Figure 5 , as shown in the legend therein, a clutchable nut comprising:

[0046] The guide assembly includes two annular end plates 11 respectively sheathed on the radially outer side of the clutched screw at different positions in the axial direction, a rotating guide 12 arranged on at least one annular end plate 11 and at least one annular end plate The radial guide part 13 on the plate 11, and the two annular end plates 11 are relatively fixed;

[0047] The steering ring 21 is sheathed on the radially outer side of the clutched screw and is located between two annular end plates 11. The steering ring 21 is rotatably connected to the rotation guide 12 around the central axis of the clutched screw. The steering ring 21 The inner peripheral surface of the inner peripheral surface is provided with a plurality of first concave arc-shaped surfaces 22 uniformly distributed along the circumferential direction and a plurality of second concave arc-shaped sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com