Centring sleeve for bearing and centring a shaft end

A centering sleeve and centering shaft technology, applied in the field of centering sleeves, can solve problems such as high manufacturing cost, affecting manufacturing cost, and complexity, and achieve the effects of low manufacturing cost, sufficient sealing effect, and firm shape fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

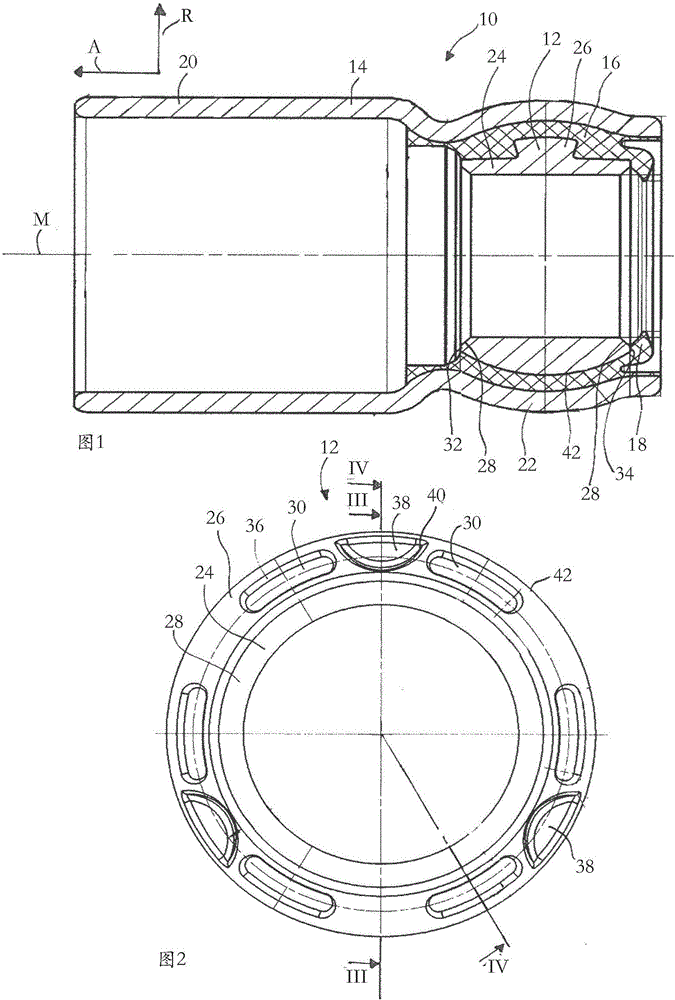

[0028] FIG. 1 shows a cross-sectional view of a centering sleeve 10 according to the invention for positioning and centering a shaft end (not shown).

[0029] The centering sleeve 10 has an inner bushing 12 and an outer bushing 14 surrounding the inner bushing 12 , wherein an elastic part 16 made of elastomer is arranged between the two bushings 12 , 14 . The elastic part 16 has a sealing lip 18 which protrudes from the elastic part 16 in the radial direction R in the direction of the central axis M of the centering sleeve 10 . The sealing lip 18 serves to seal the centering sleeve 10 in such a way that it bears against a shaft end, not shown, which is inserted into the inner sleeve 12 .

[0030] The outer sleeve is designed with an approximately cylindrical connecting section 20 and an adjoining spherical receiving section 22 . The inner sleeve 12 and the spring element 16 are placed or inserted in the receiving section 22 .

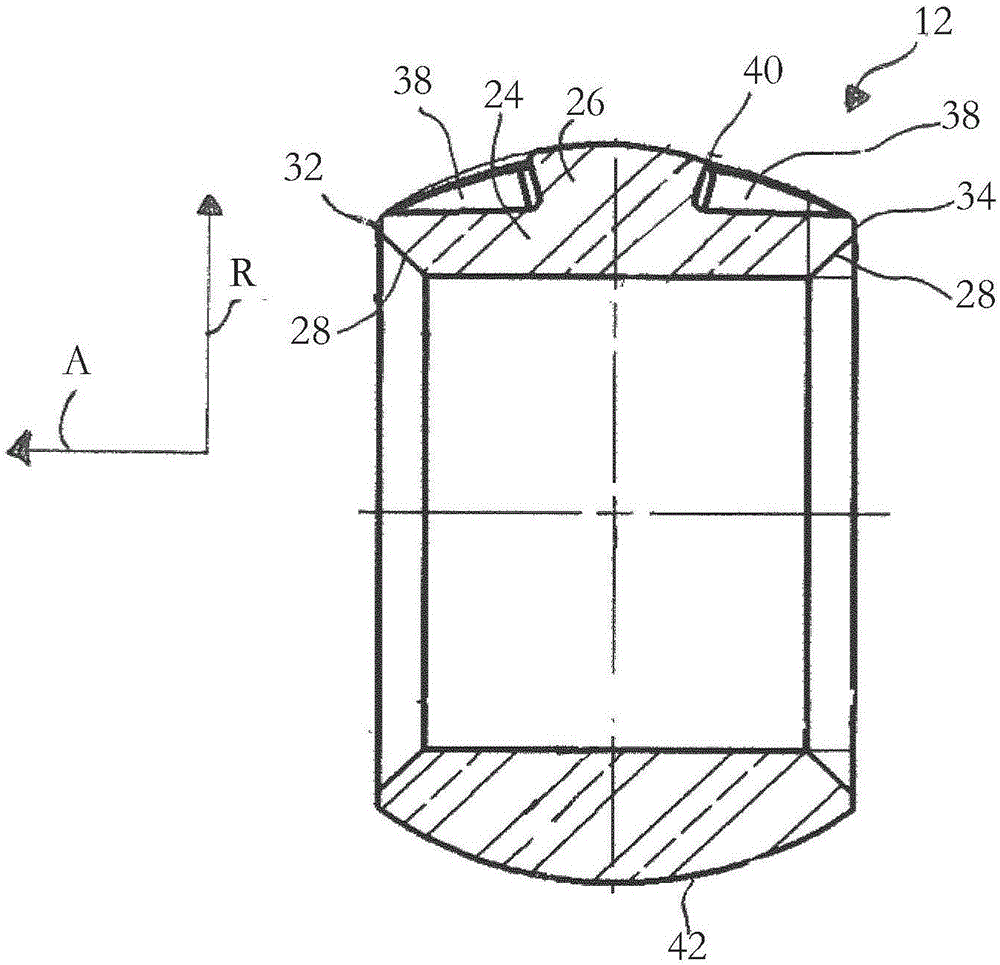

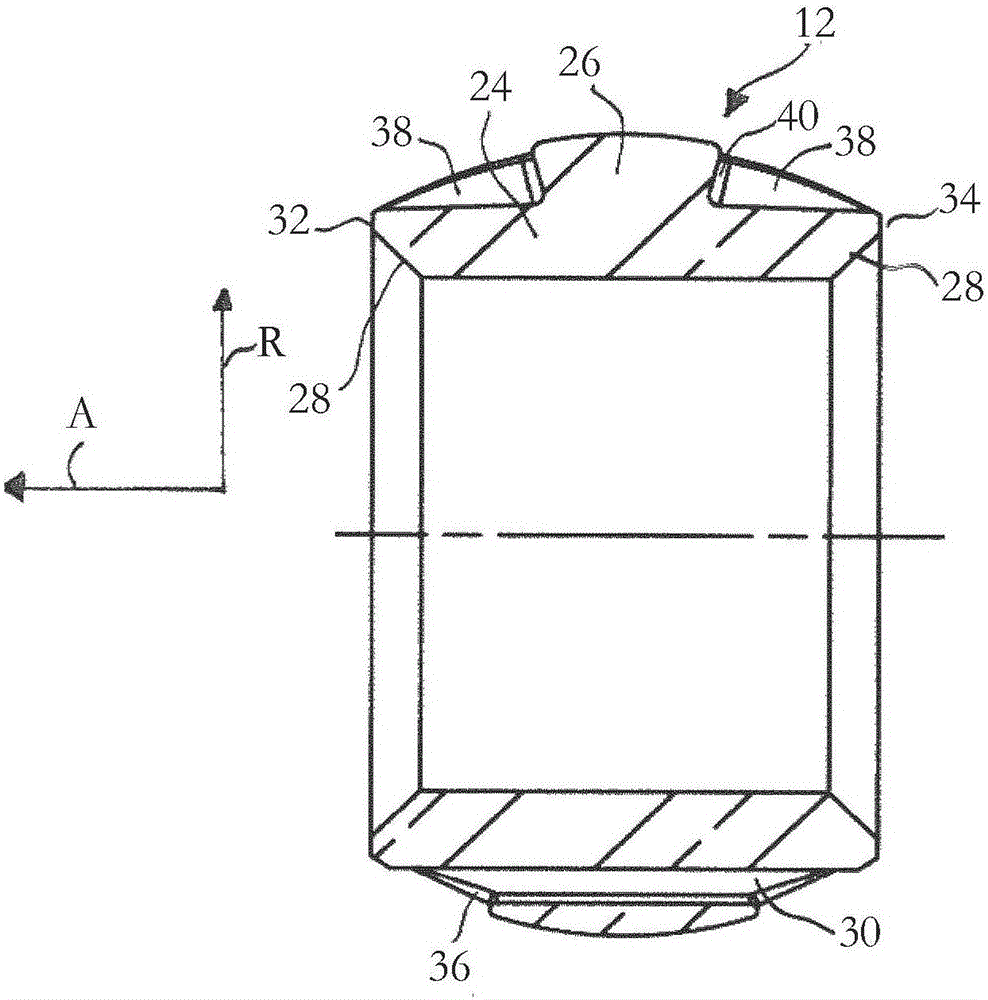

[0031] Especially as shown in Figure 2 to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com