Patents

Literature

63results about How to "Full tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

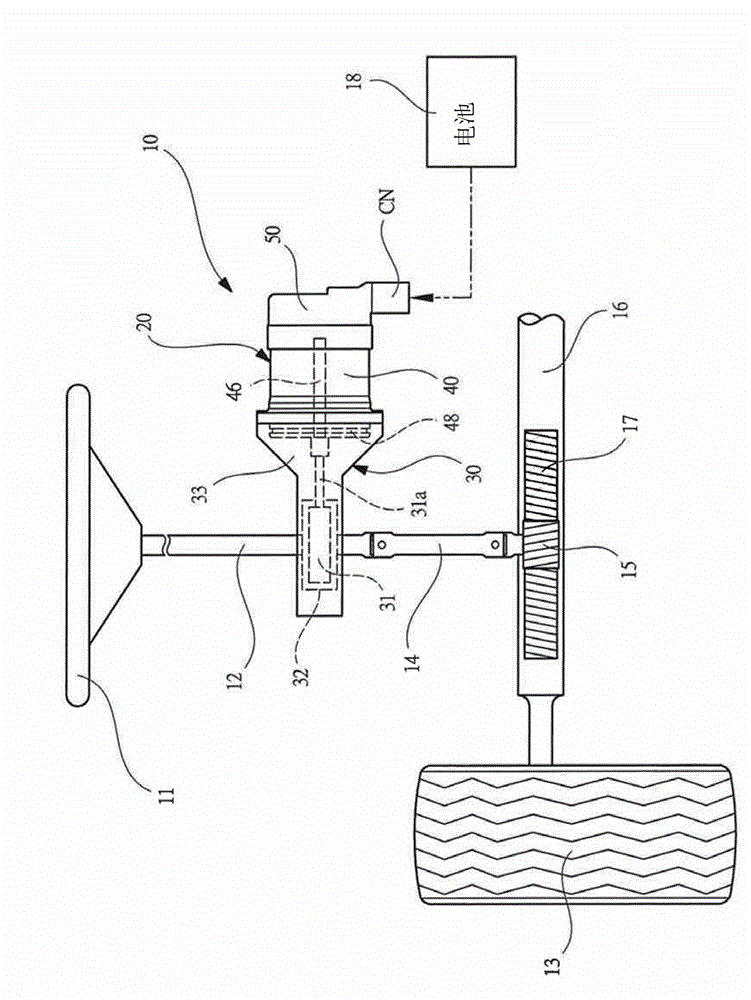

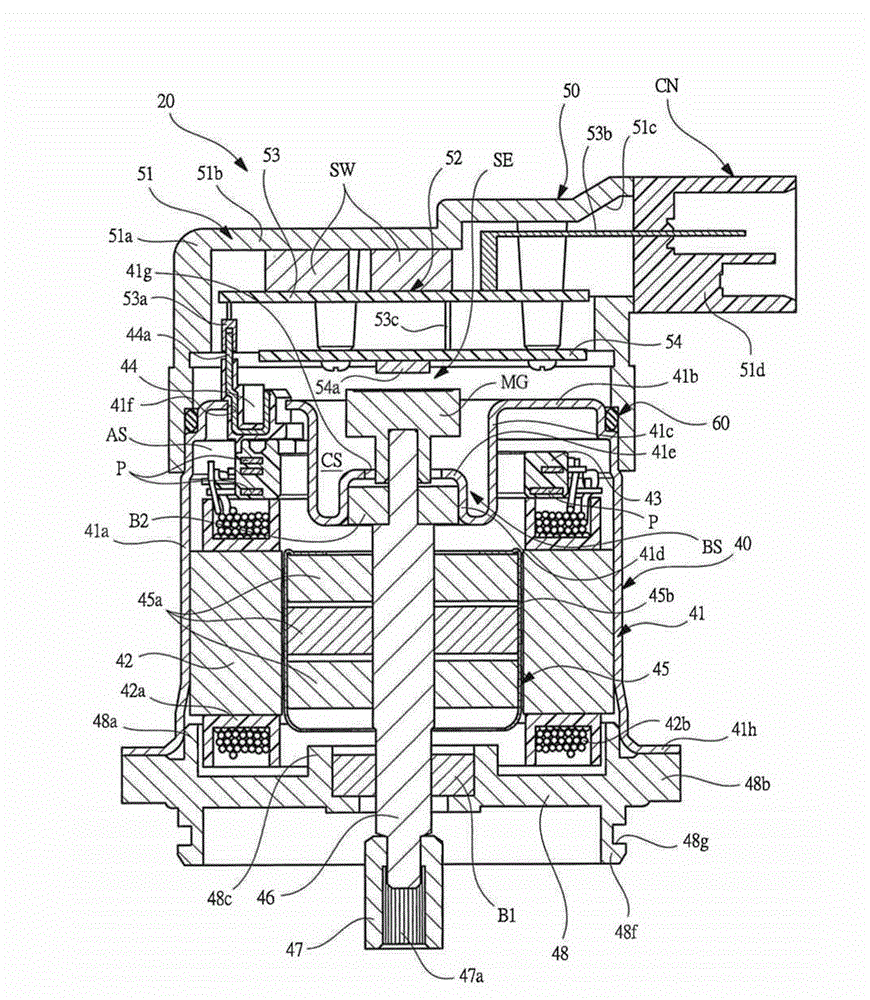

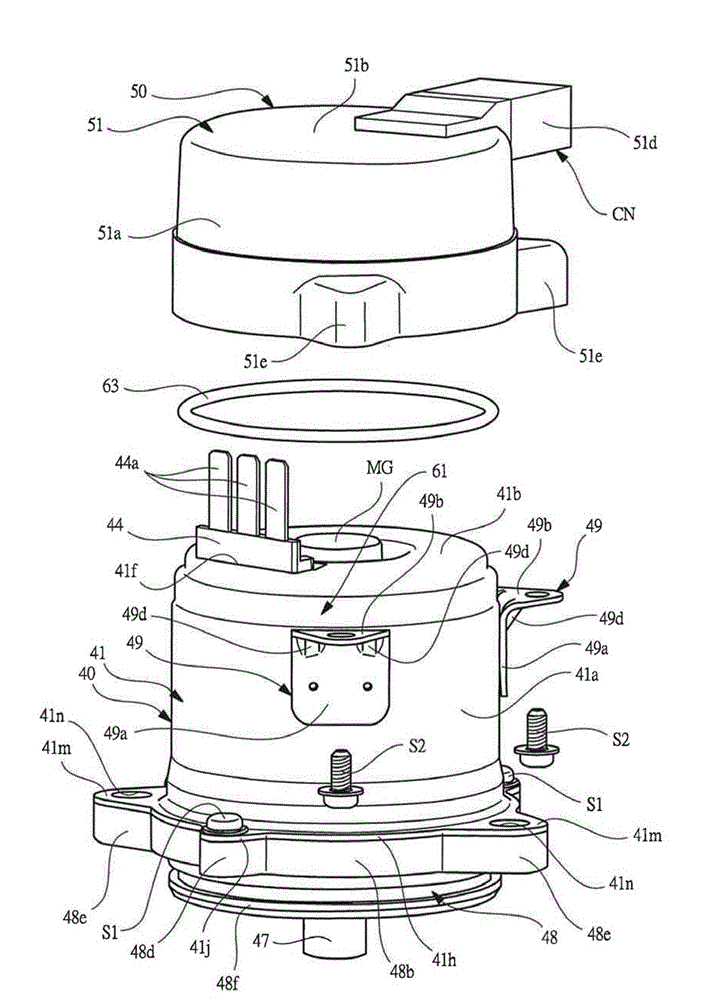

Brushless motor

InactiveCN103066787ASeek miniaturizationGuaranteed cooling effectAssociation with control/drive circuitsManufacturing dynamo-electric machinesBrushless motorsManufacturing cost reduction

The invention discloses a brushless motor which can ensure heat dissipation of a control device and meanwhile manufacturing process is simplified, manufacturing cost is reduced, and the brushless motor is minimized and has light weight. the brushless motor includes: a motor case 41 in which a cylindrical stator core 42 formed from steel plate by press molding is secured; a bracket 48 on one side in an axial direction of a motor case, a tip side of a rotary shaft 46 secured to a rotor 45 being rotatably supported by the bracket; and a housing member 51 on the other side in the axial direction of the motor case, a control device 52 for controlling the rotation of the rotor being accommodated in the housing member, the control device having a power-related circuit board 53 disposed on the side of a bottom 51b of the housing member and a control-related circuit board 54 disposed on the side of an opening of the housing member, semiconductor switching devices SW being disposed on the power-related circuit board in contact with the housing member.

Owner:MITSUBA CORP

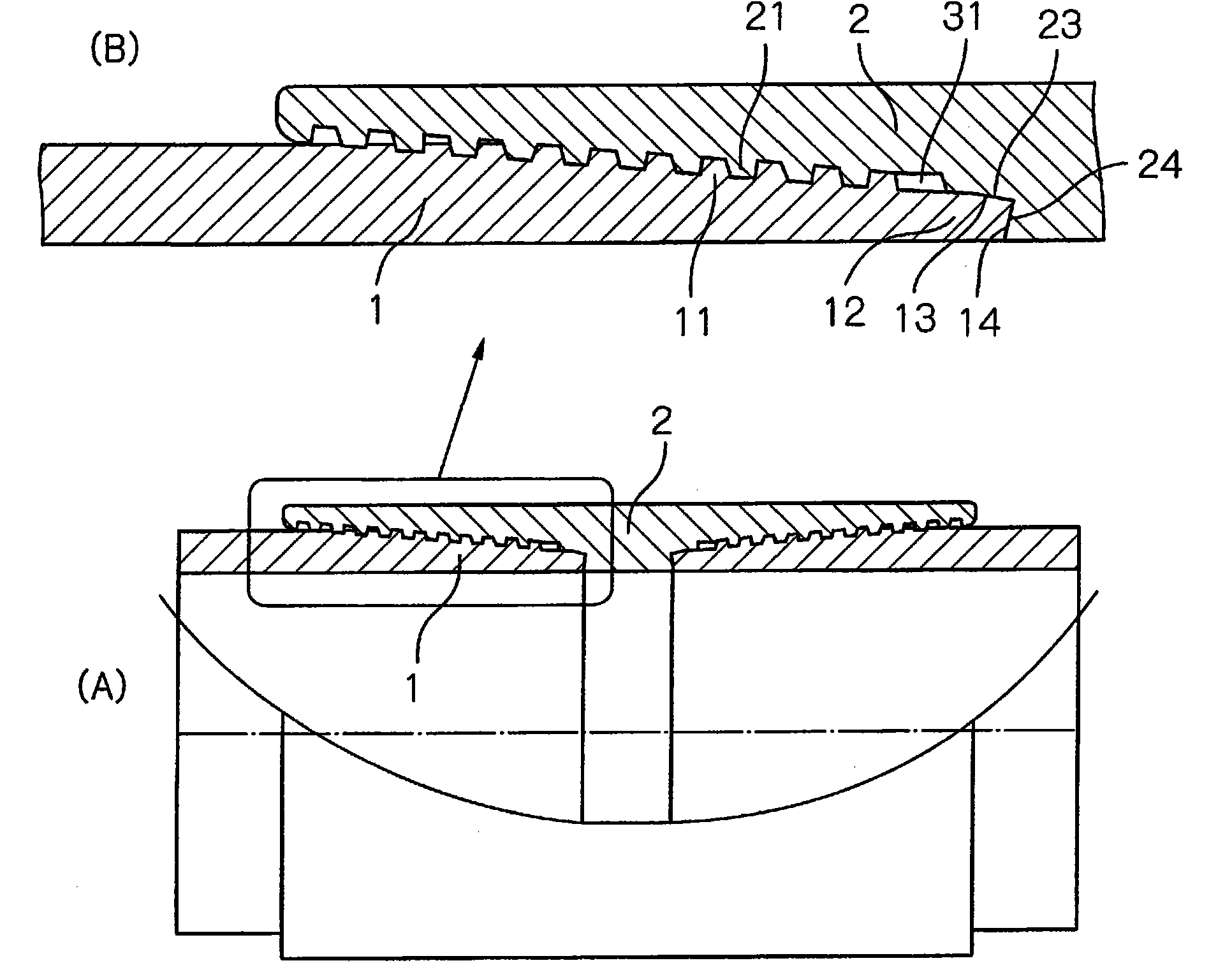

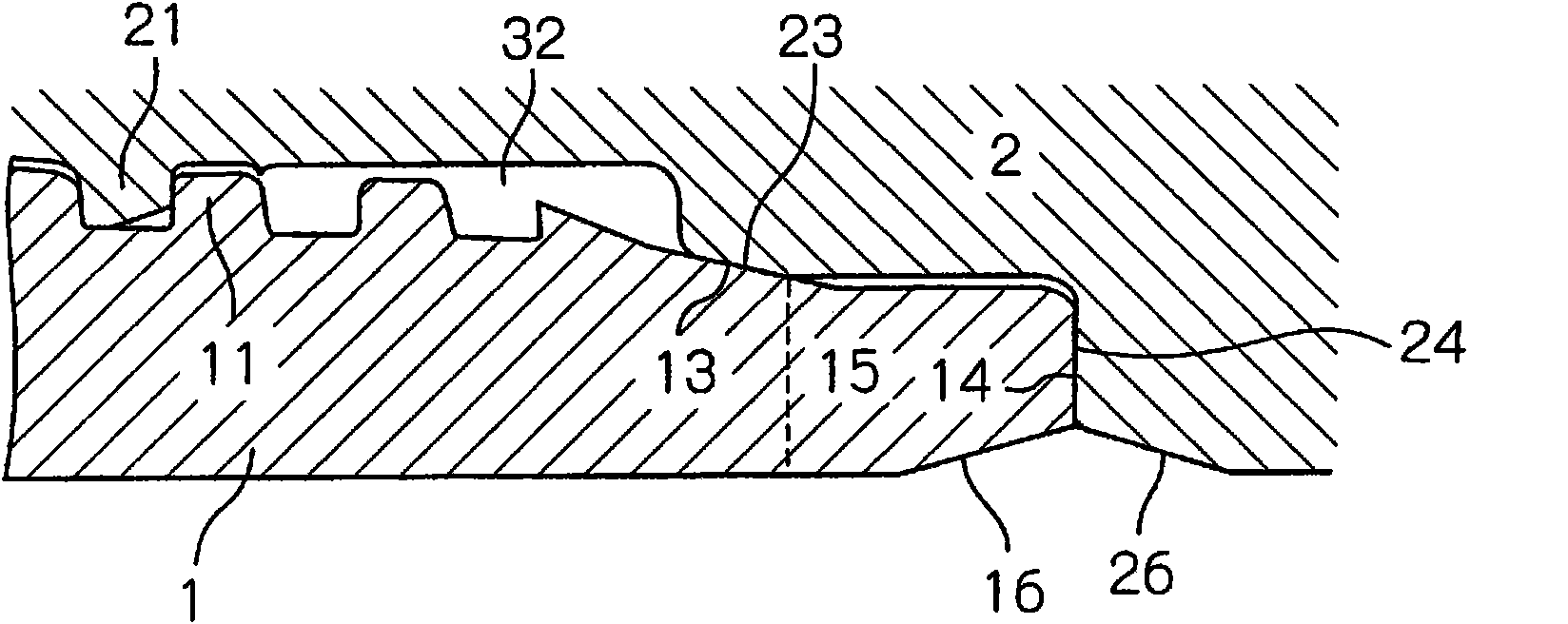

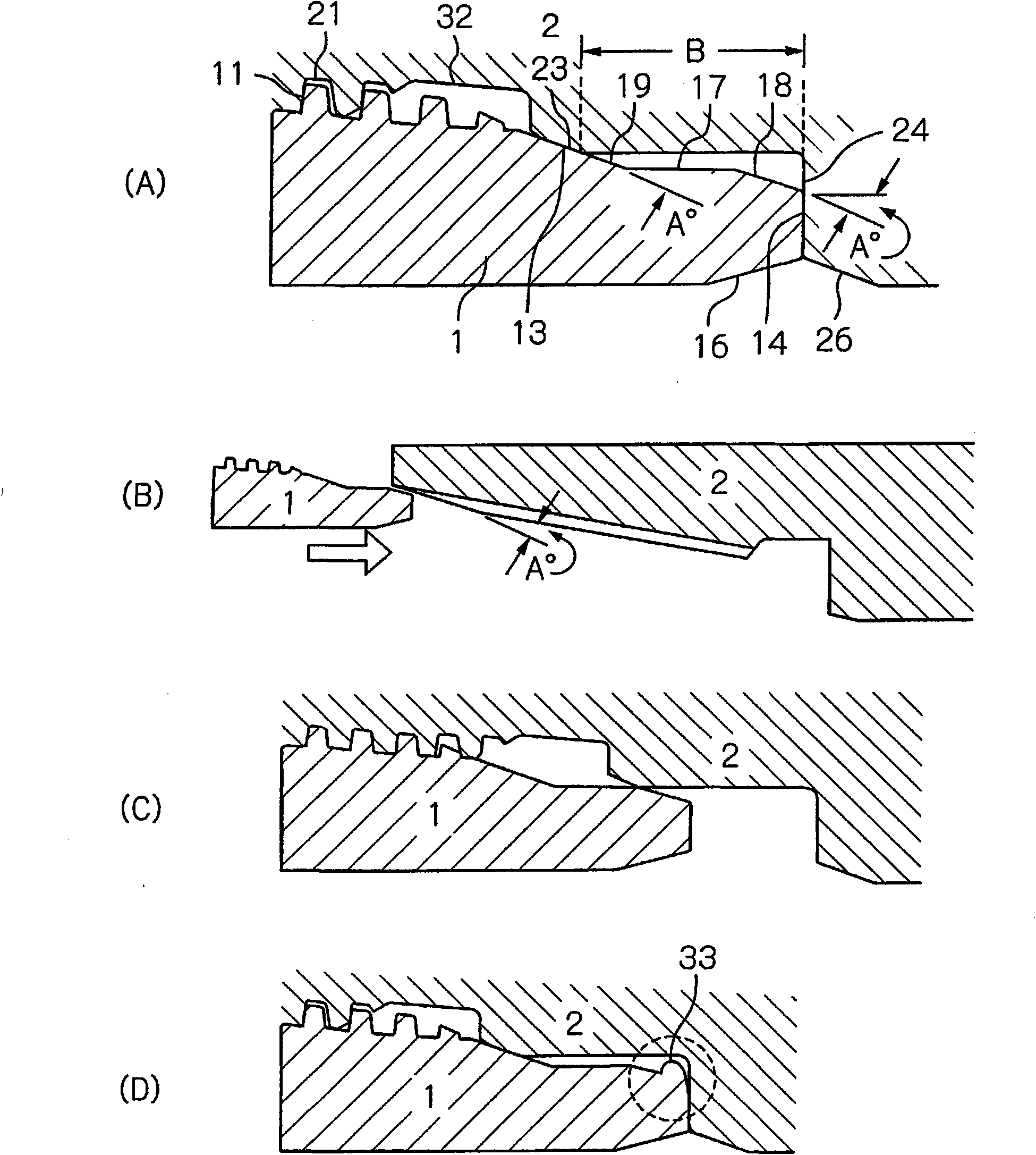

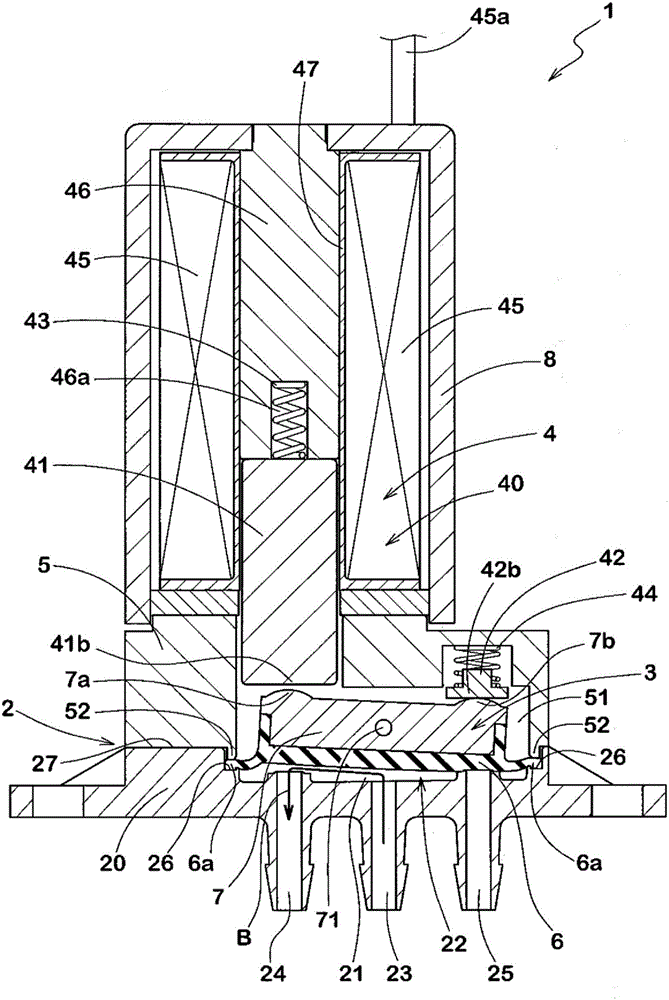

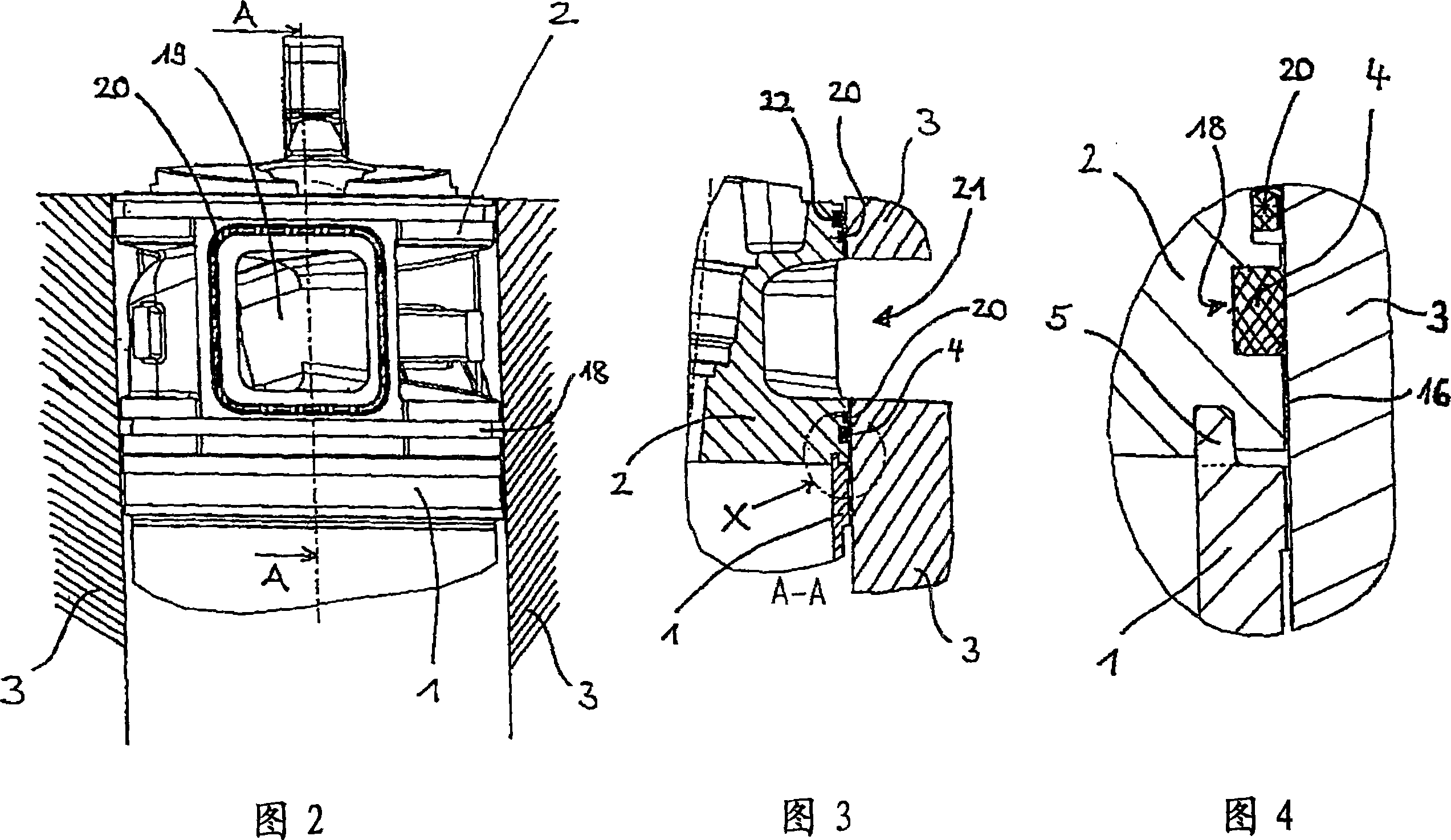

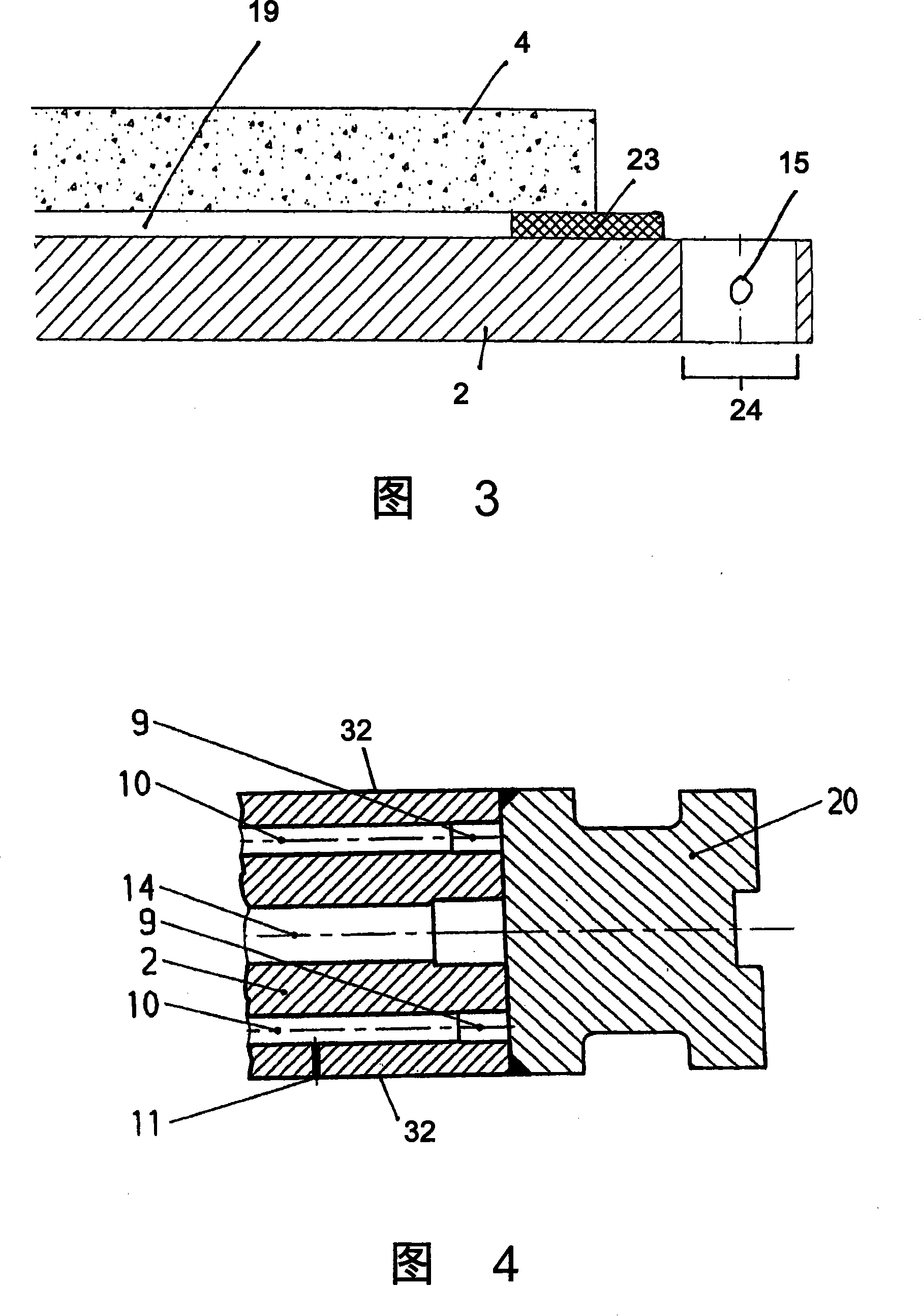

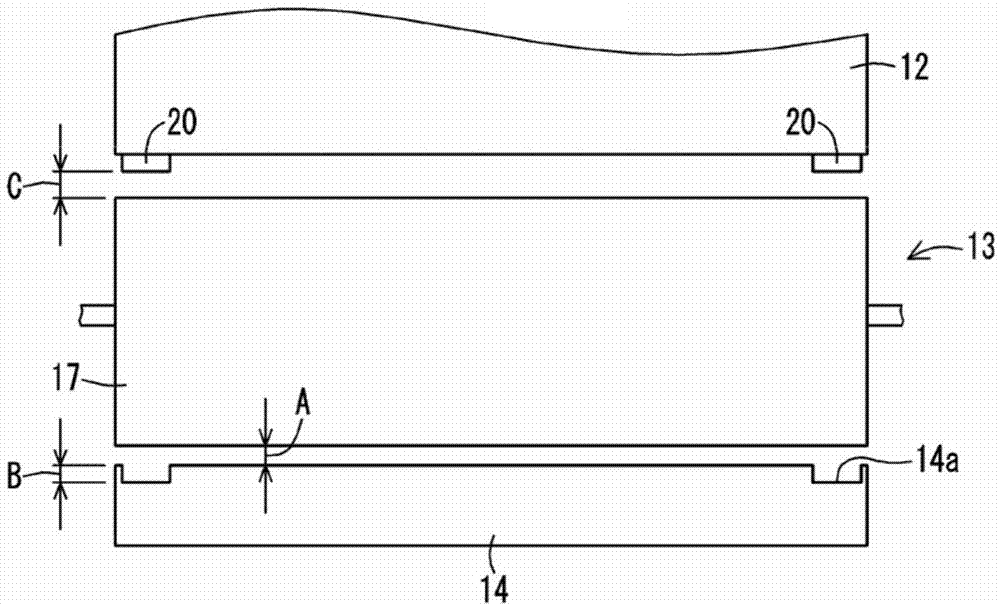

Screw-threaded joint for steel pipe

ActiveCN101883944AImprove rigidityImprove sealingDrilling rodsDrilling casingsEngineeringAir tightness

A screw-threaded joint for a steel pipe includes a pin (1) and a box (2). The pin (1) has a tapered male screw thread (11), a tapered seal surface (13), and an end shoulder surface (14), while the box (2) has, in a corresponding manner, a tapered female screw thread (21), a tapered seal surface (23), and a shoulder surface (24). The pin (1) and the box (2) can be easily fastened together, and the screw-threaded joint has improved tightness at seal surfaces. The pin and the box have a contactless region (B) between the seal surfaces (13, 23) and the shoulder surfaces (14, 24), and the peripheral surfaces of the pin and the box do not make contact with each other in the contactless region (B). At least that portion of pin which is in the contactless region and adjacent the front end of the pin is a tapered surface portion (18) having substantially the same inclination angle as the tapered seal surface (13). Also, that portion of the box which is in the contactless region is substantially a circular cylindrical surface.

Owner:NIPPON STEEL CORP +1

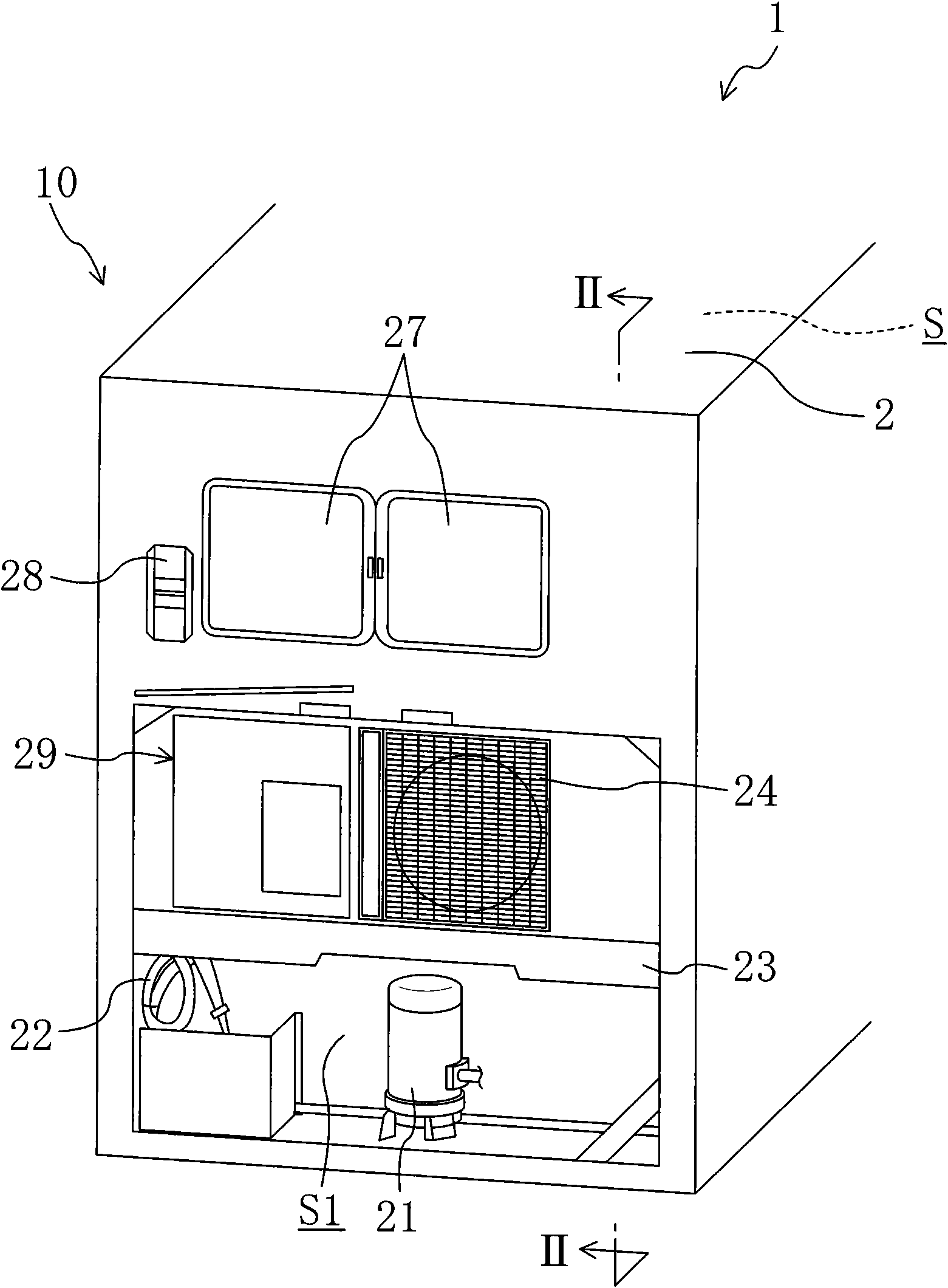

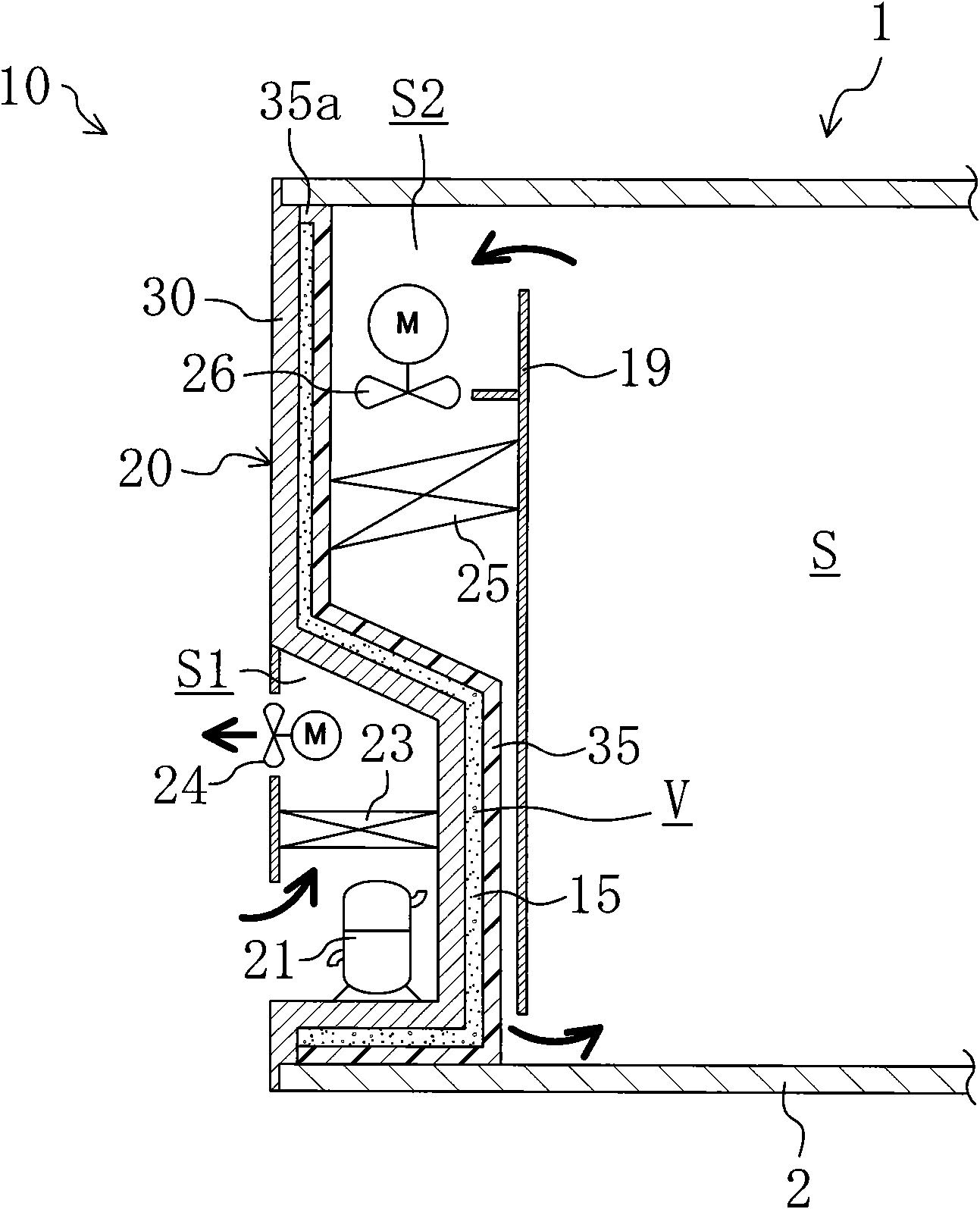

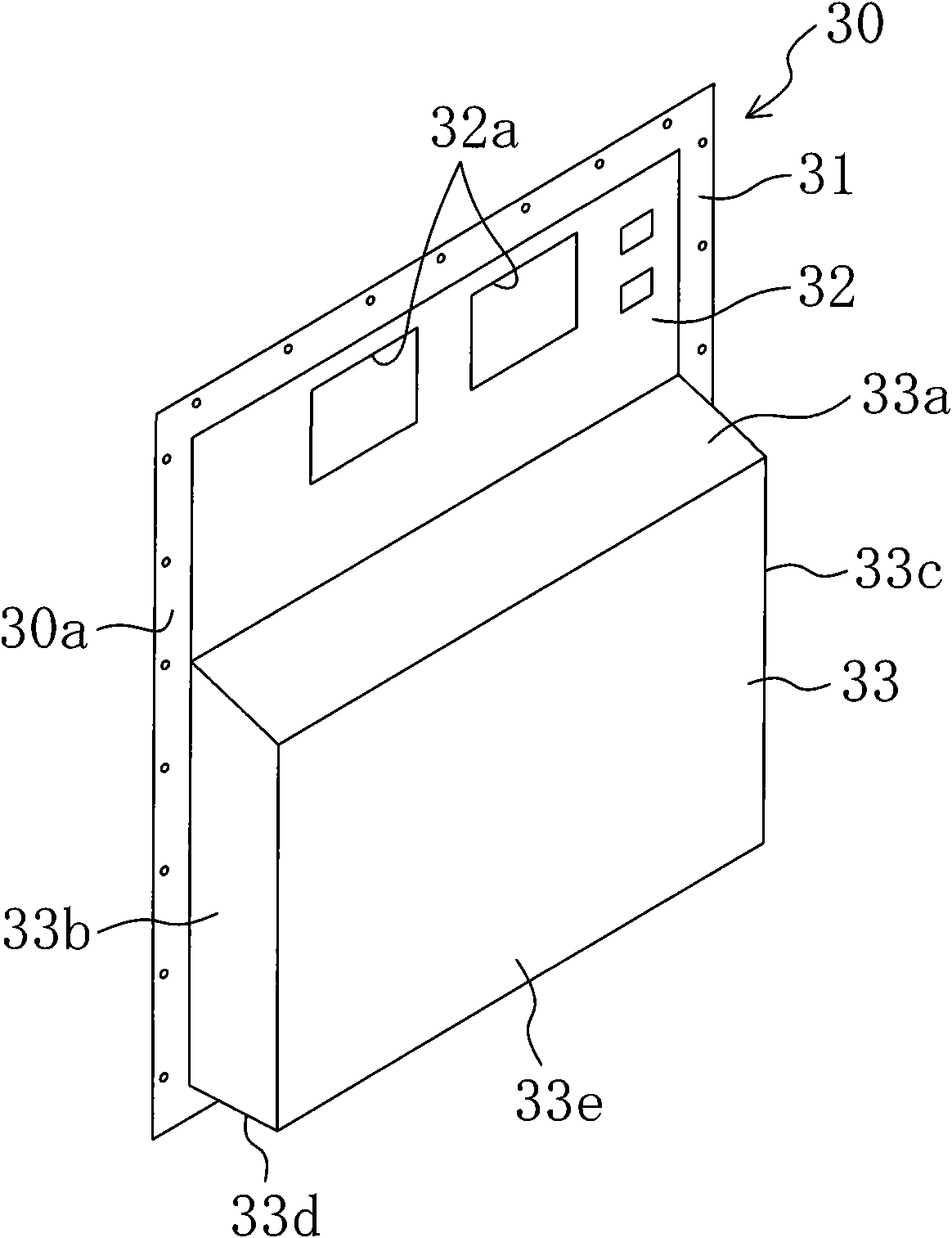

Casing structure of freezer for container and process for manufacturing the same

InactiveCN101669004AShorten working timeReduce manufacturing costLighting and heating apparatusRefrigerated goods vehicleManufacturing cost reductionFoaming agent

A casing structure of freezer for container having an outside casing and an inside casing provided therebetween with a heat insulating layer that while preventing any leakage of foaming agent at the formation of the heat insulating layer, realizes shortening of working time and reduction of manufacturing cost. The flange (34) of outside casing (30) on its inside surface (30a) is provided with rib(34c) so as to lock the peripheral edge (35b) of inside casing (35) at the time of foaming of foaming agent (38) in the foaming space (V) between the outside casing (30) and the inside casing (35). Atleast one of the interior of the interstice between the peripheral edge (35b) of the inside casing (35) and the inside surface (30a) of the outside casing (30) and the side of foaming space (V) of the interstice is provided with sealing medium (40).

Owner:DAIKIN IND LTD

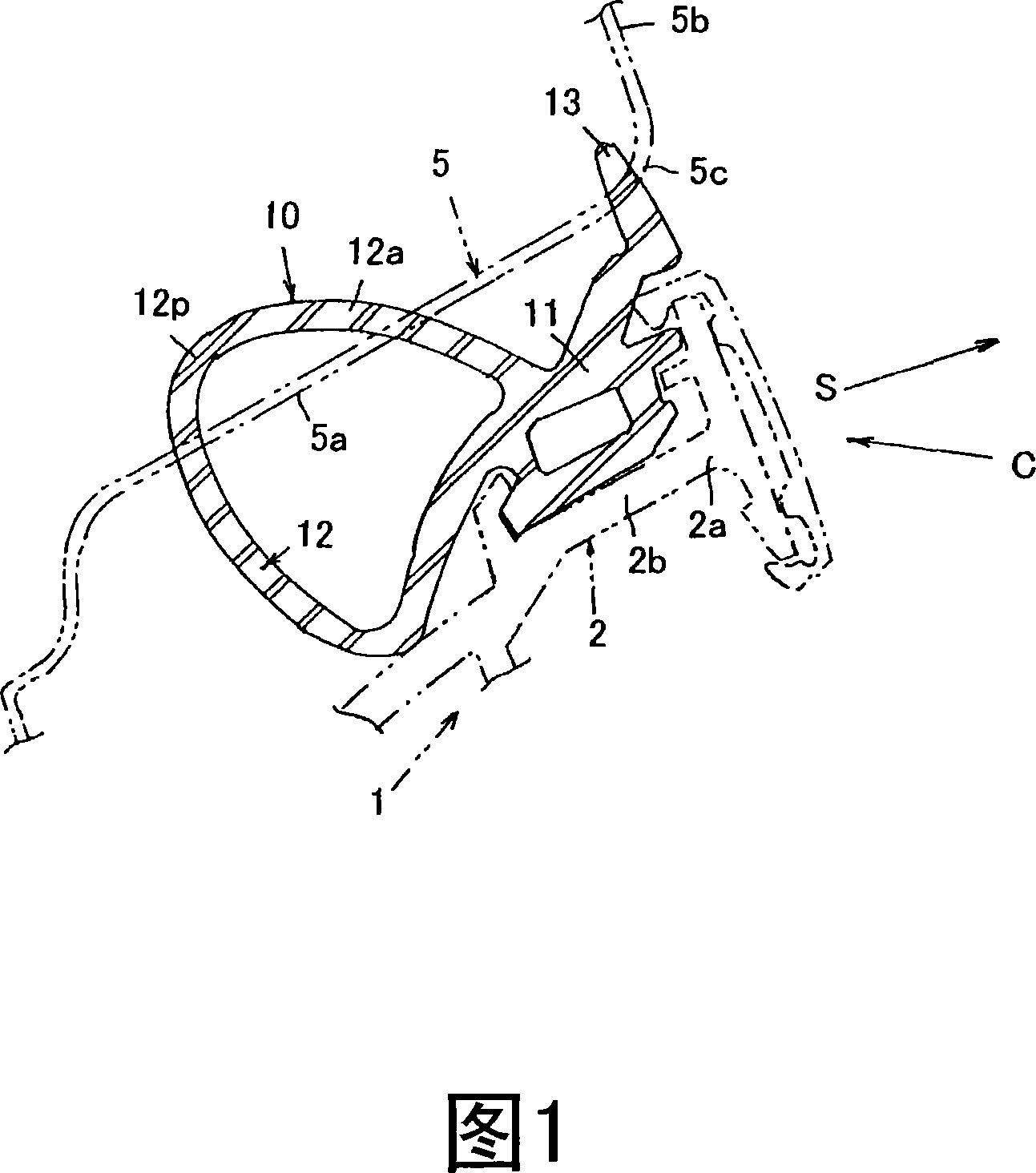

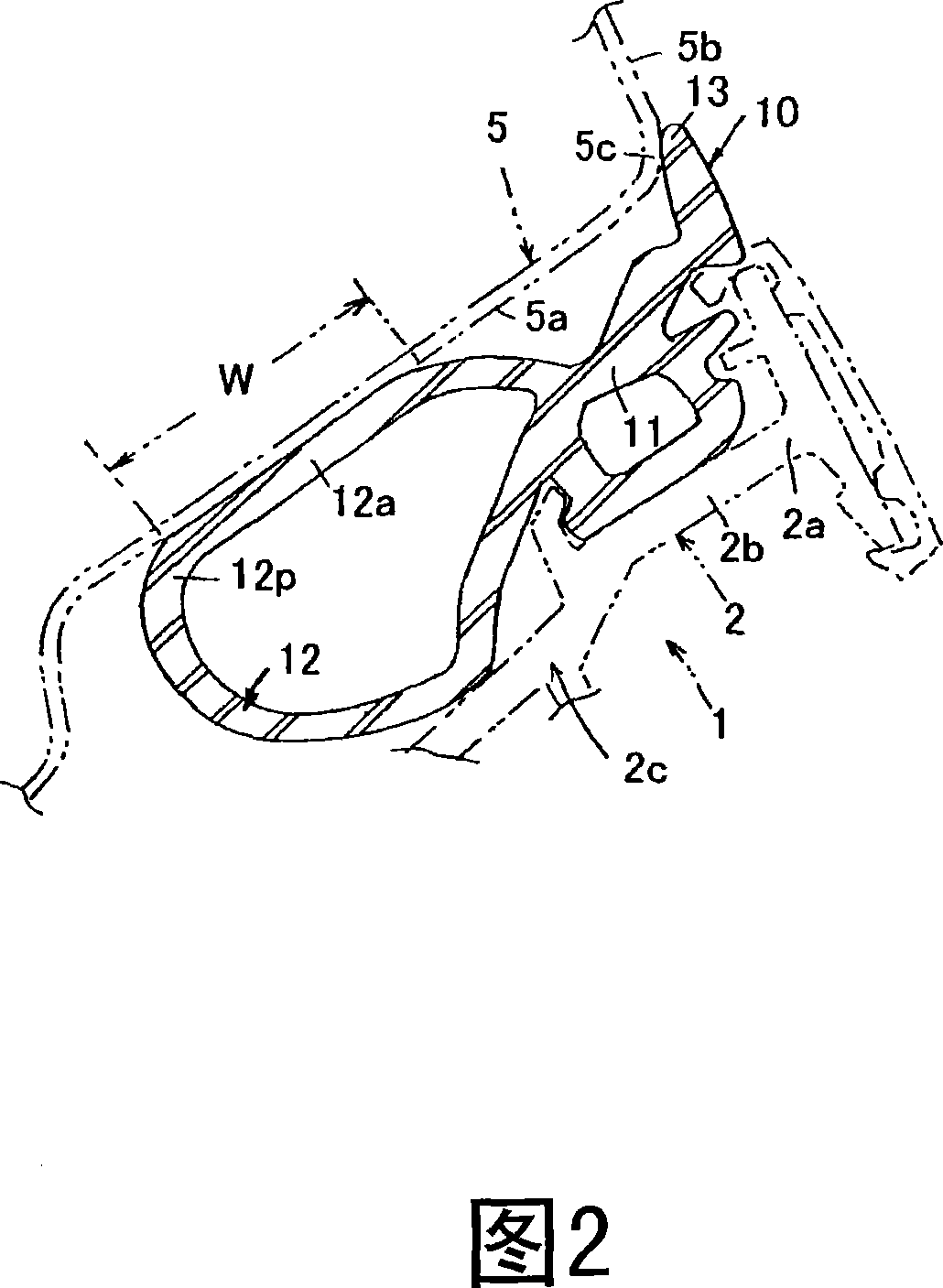

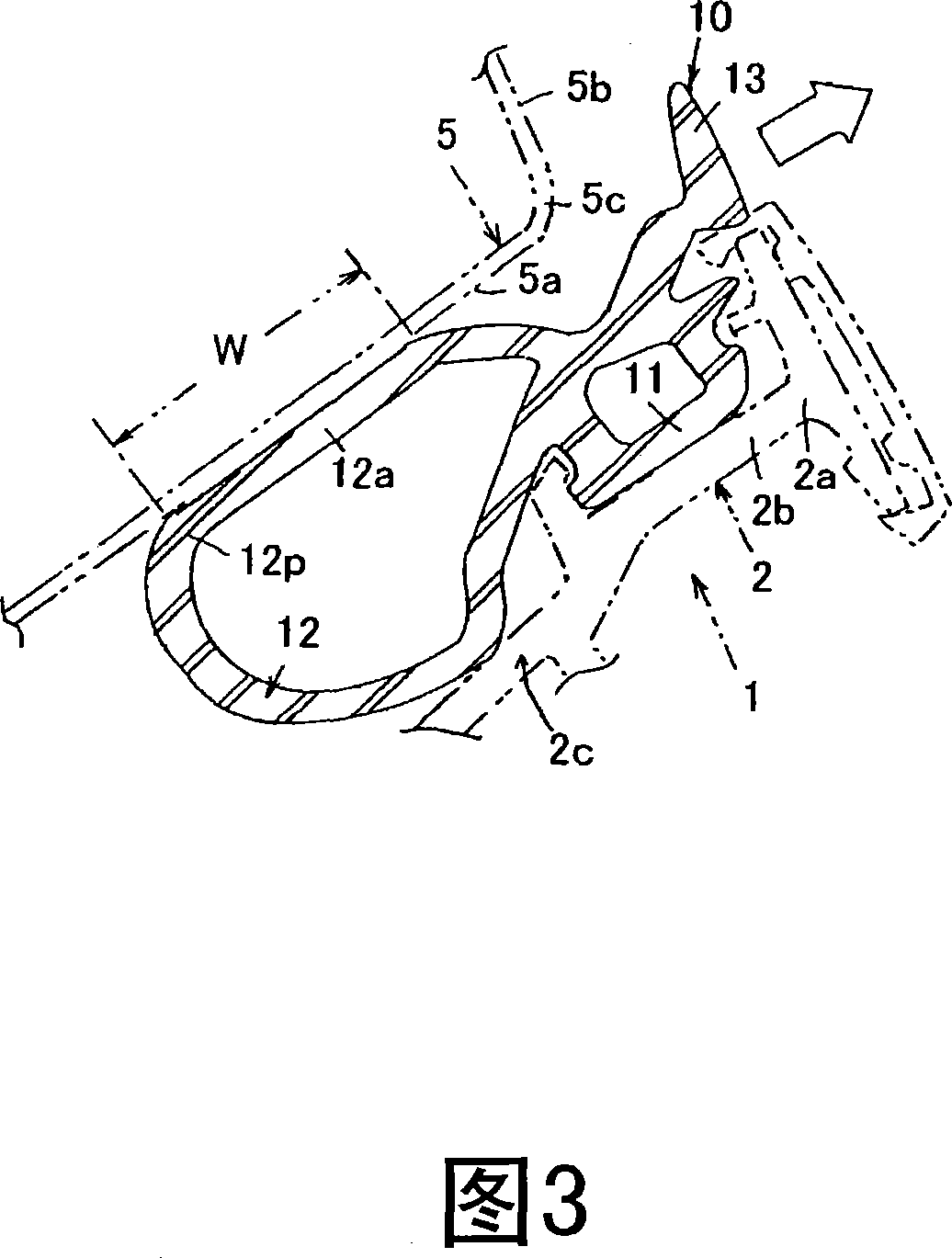

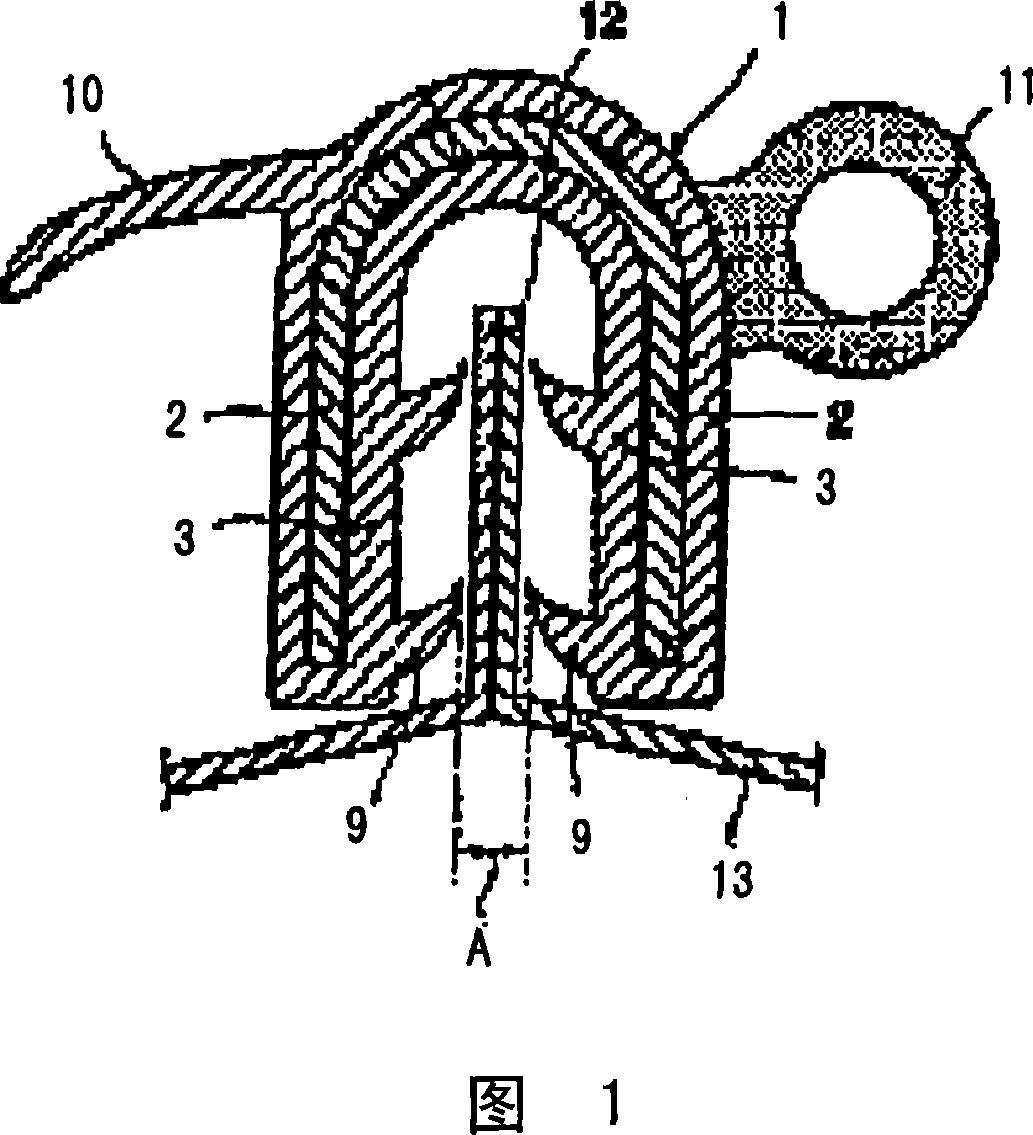

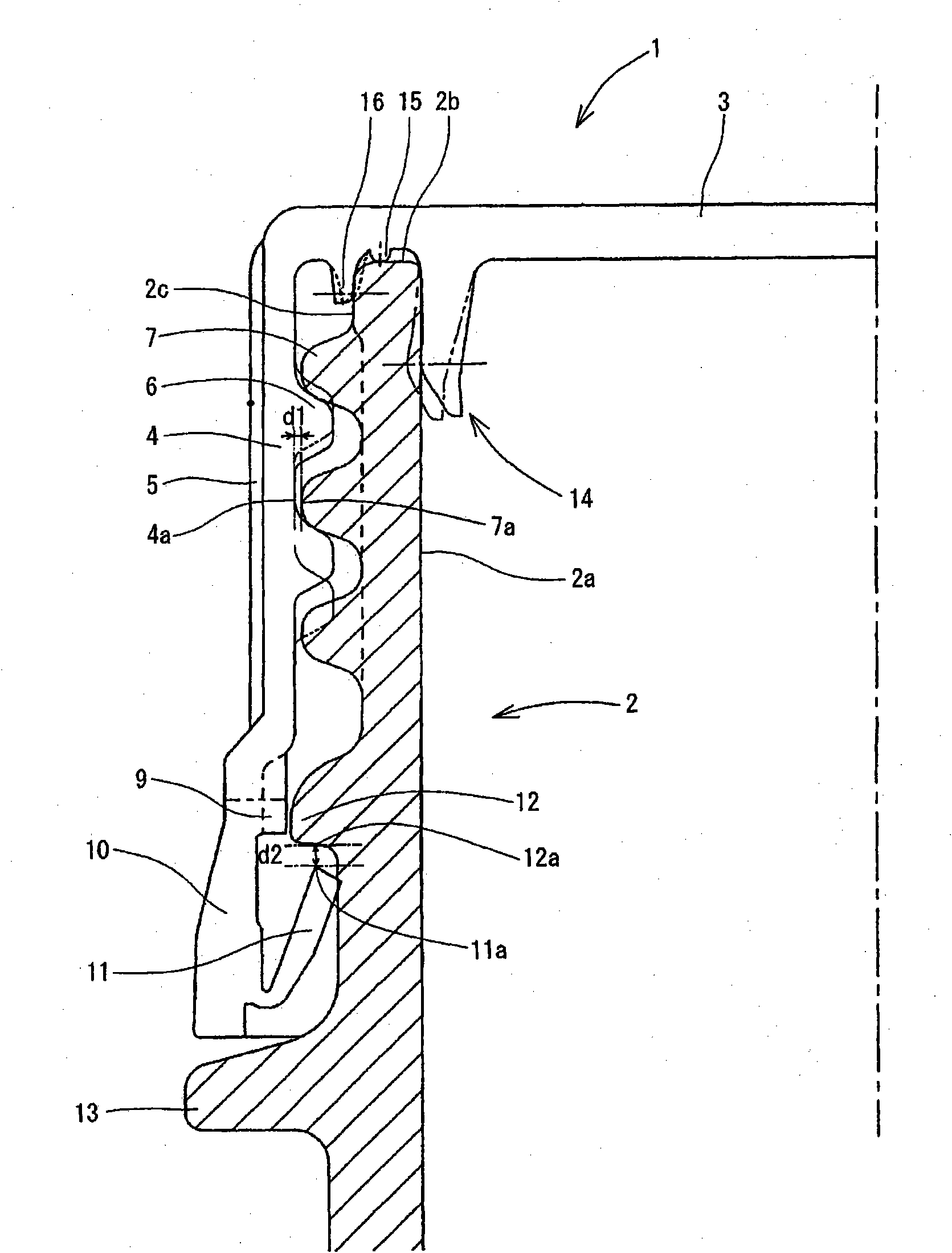

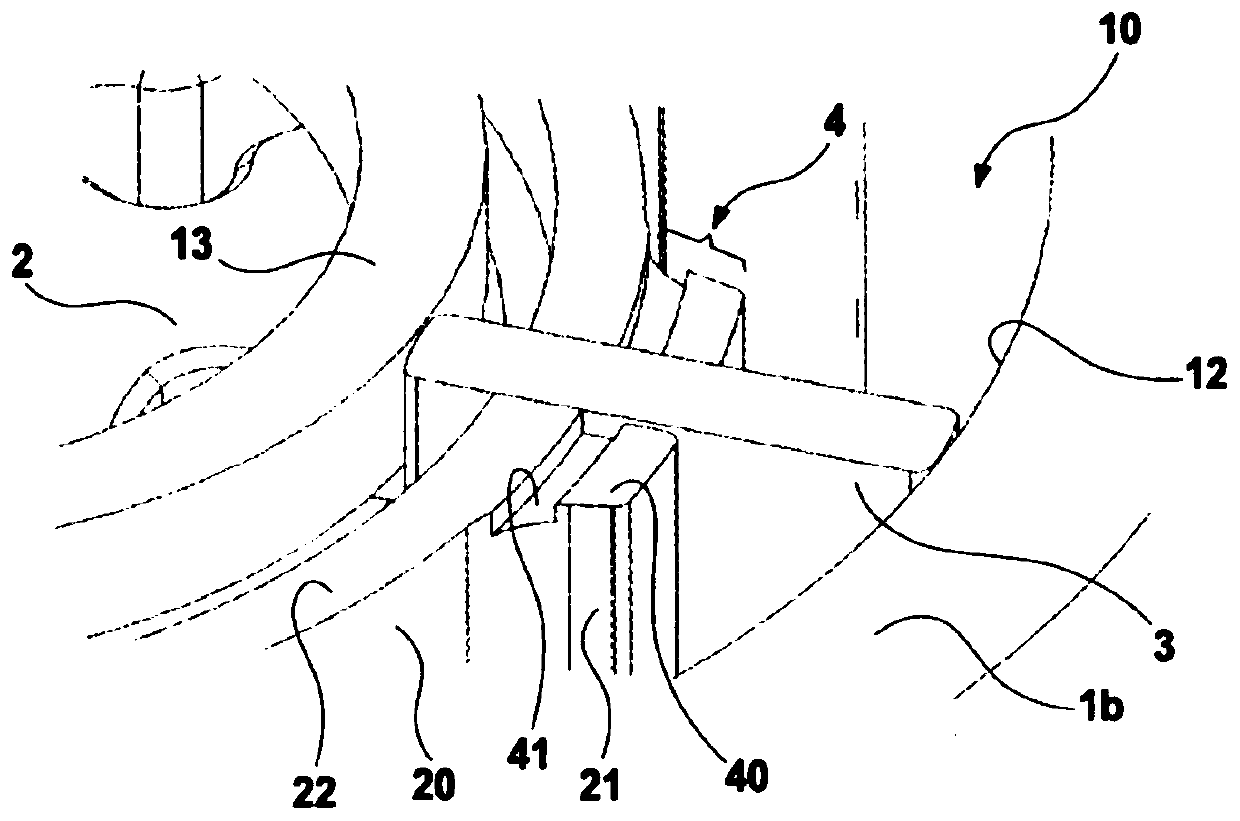

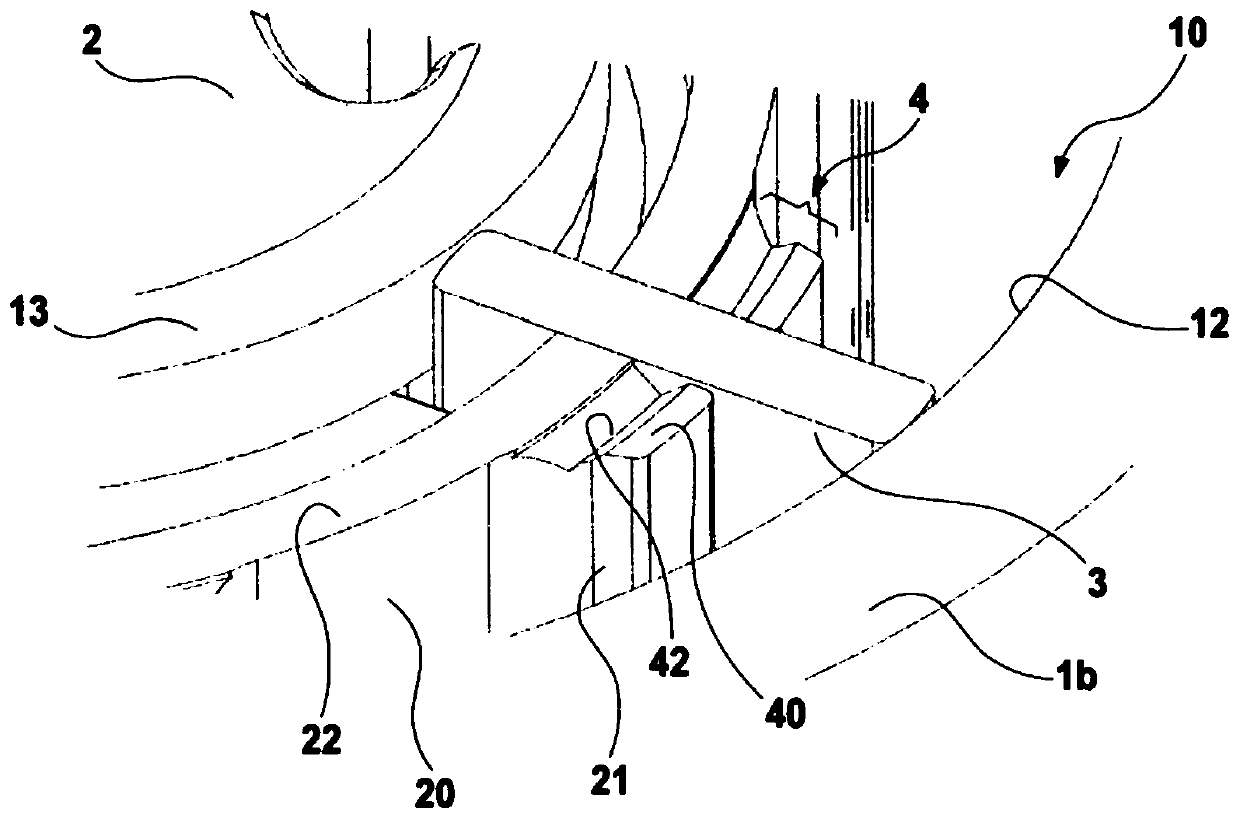

Attachment structure of door weather strip for vehicle

InactiveCN101062653AImprove sealingClosed retentionEngine sealsVehicle sealing arrangementsTravel modeEngineering

The invention provides a car door weather strip mounting structure capable of maintaining the high sealability even when a door is sucked outside a car when the car is traveling while maintaining the good door closability. The door weather strip 10 has a mounting base part 11 mounted on a retainer part 2a of a door sash 2, and a hollow seal part 12 which is integrated with the mounting base part 11 and elastically brought into contact with a body panel 5 when the door is closed. A part of the body panel 5 with the hollow seal part 12 elastically brought into contact therewith forms a flat parallel seal face 5a which is formed parallel or substantially parallel to the sucking direction S of a door 1 in a traveling mode.

Owner:NISHIKAWA RUBBER +1

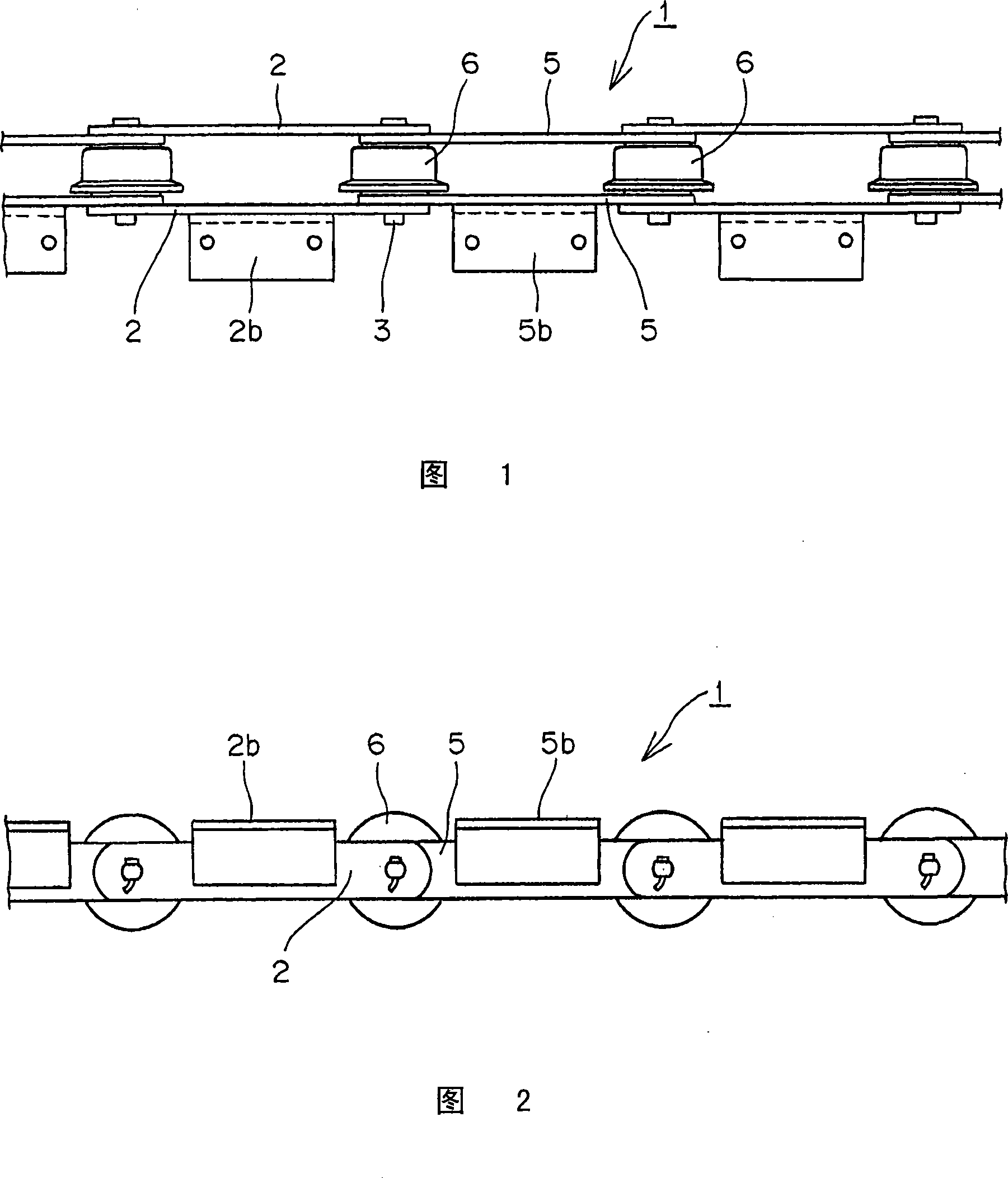

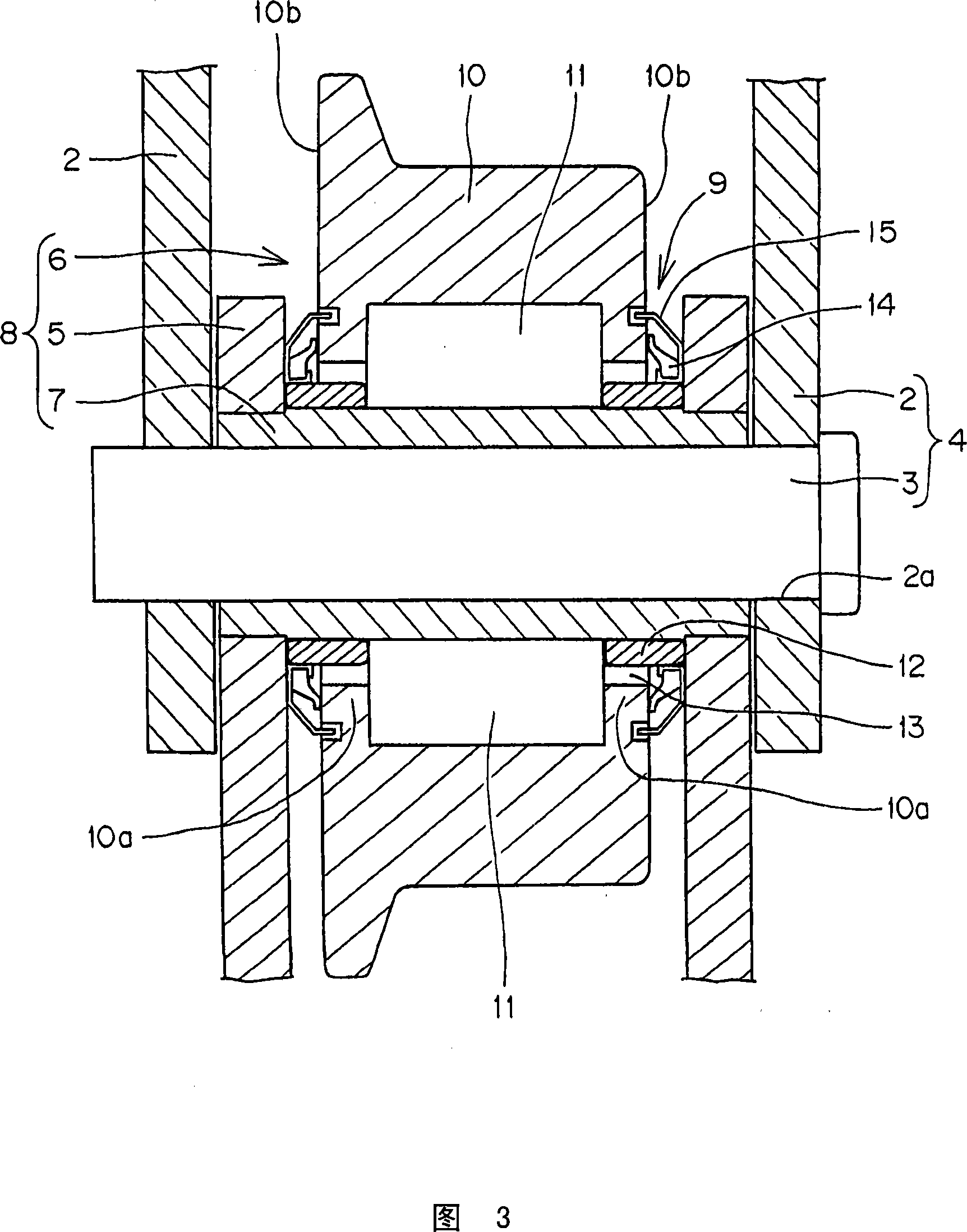

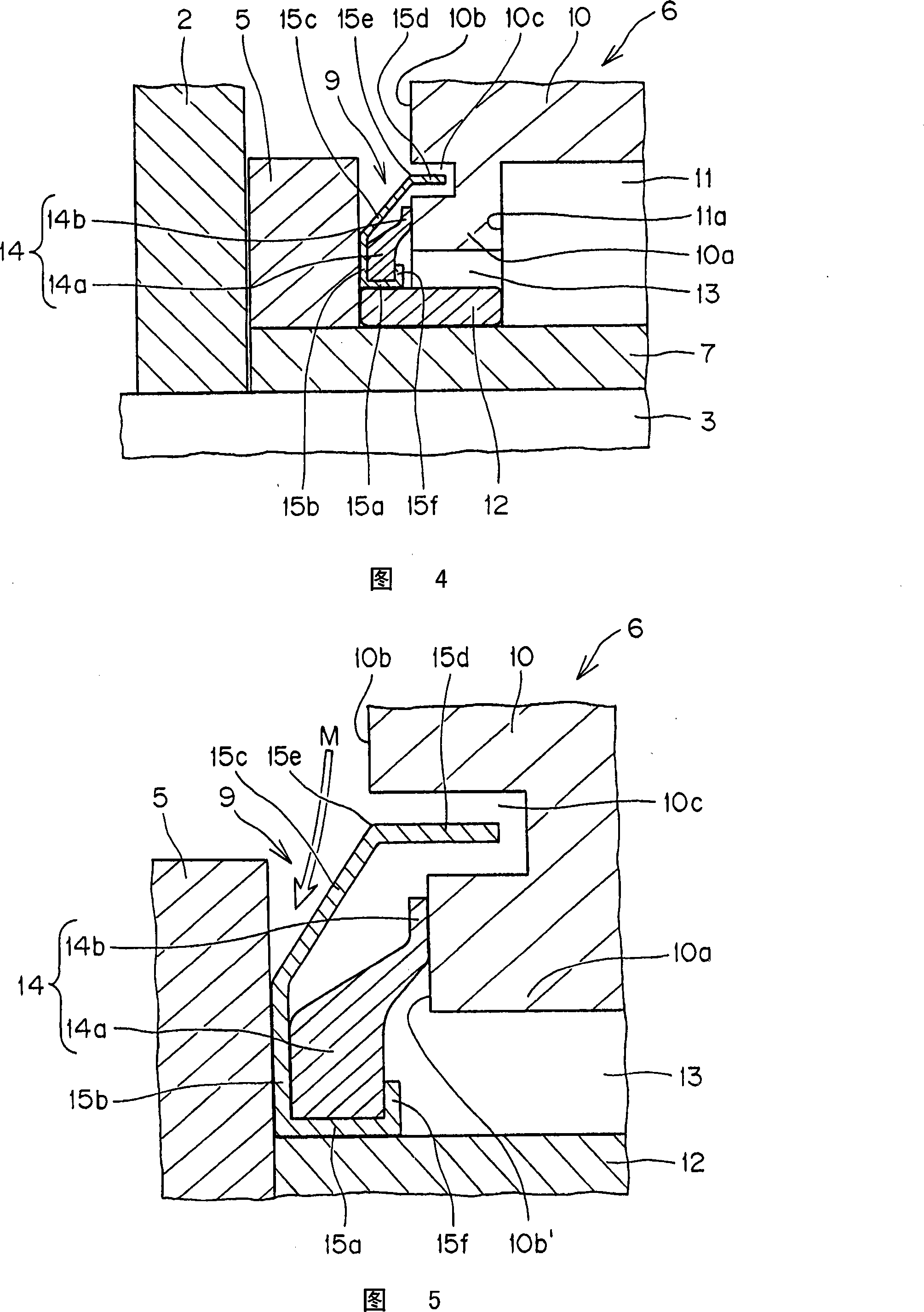

Bearing roller chain

InactiveCN101191527APrevent axis misalignmentAvoid direction shiftEngine sealsConveyorsRoller chainEngineering

A bearing roller chain having a seal mechanism preventing entry of foreign substance from the outside, and leaking of lubricating oil leakage to the outside and the like, thereby improving wear resistance of the bearing roller and reducing both the likelihood of rotation failure and the traveling resistance of the chain. The seal mechanism is provided between an inner link plate of the chain and the hollow bearing roller, which has a plurality of internal anti-friction rollers rotatable between the hollow bearing roller and a bush mounted between opposed inner link plates. The seal mechanism encloses the internal anti-friction rollers and comprises two parts, i.e a seal ring having an annular lip portion, which comes into close contact with an outer side surface of the bearing roller and an annular metallic seal member. The metallic seal member forms a labyrinth structure by providing a flange on an outer circumferential portion which loosely enters an annular concave groove in the outer side surface of the bearing roller. The seal mechanism provides a double sealing effect by virtue of the seal ring and the annular metallic seal member.

Owner:TSUBAKIMOTO CHAIN CO

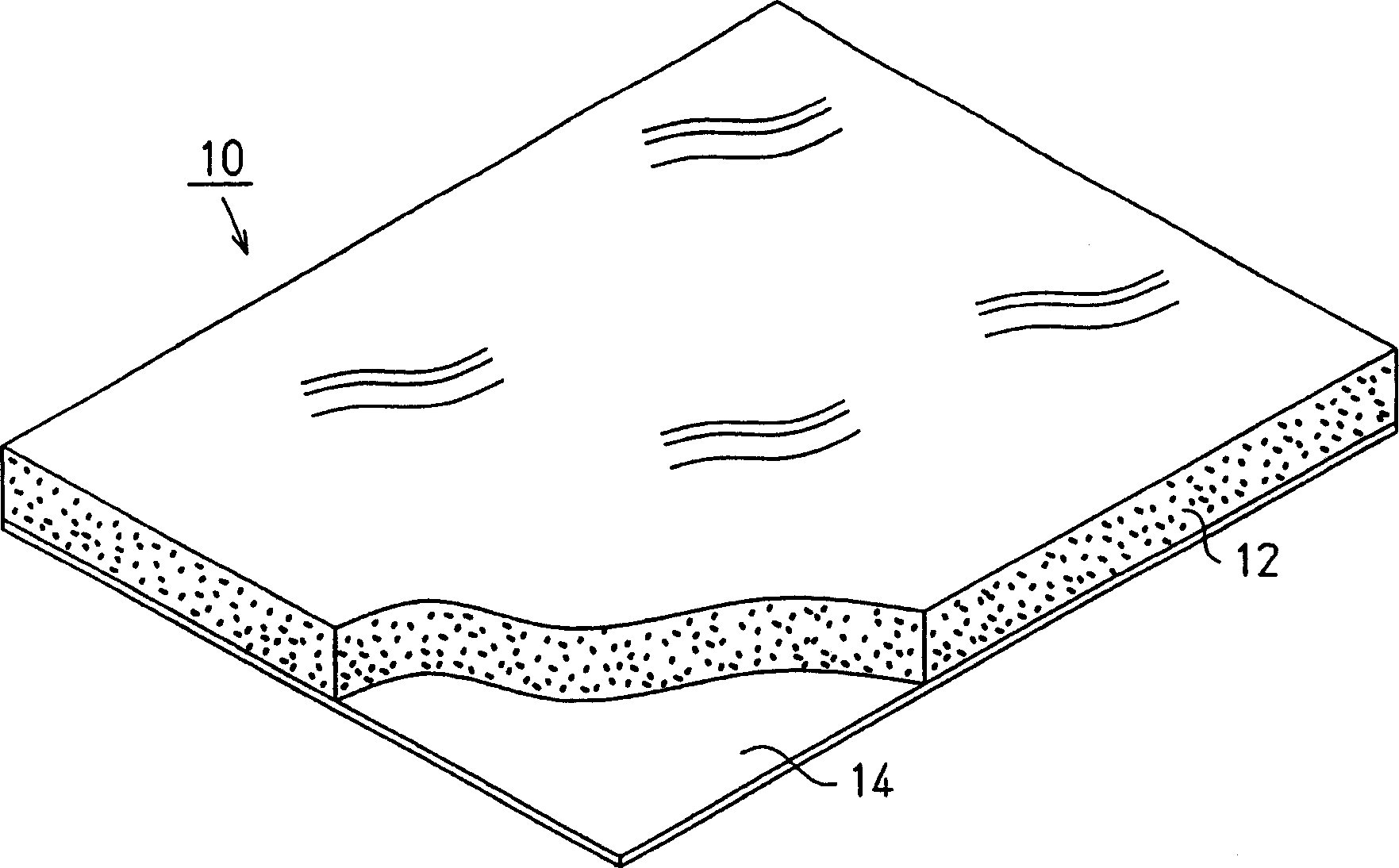

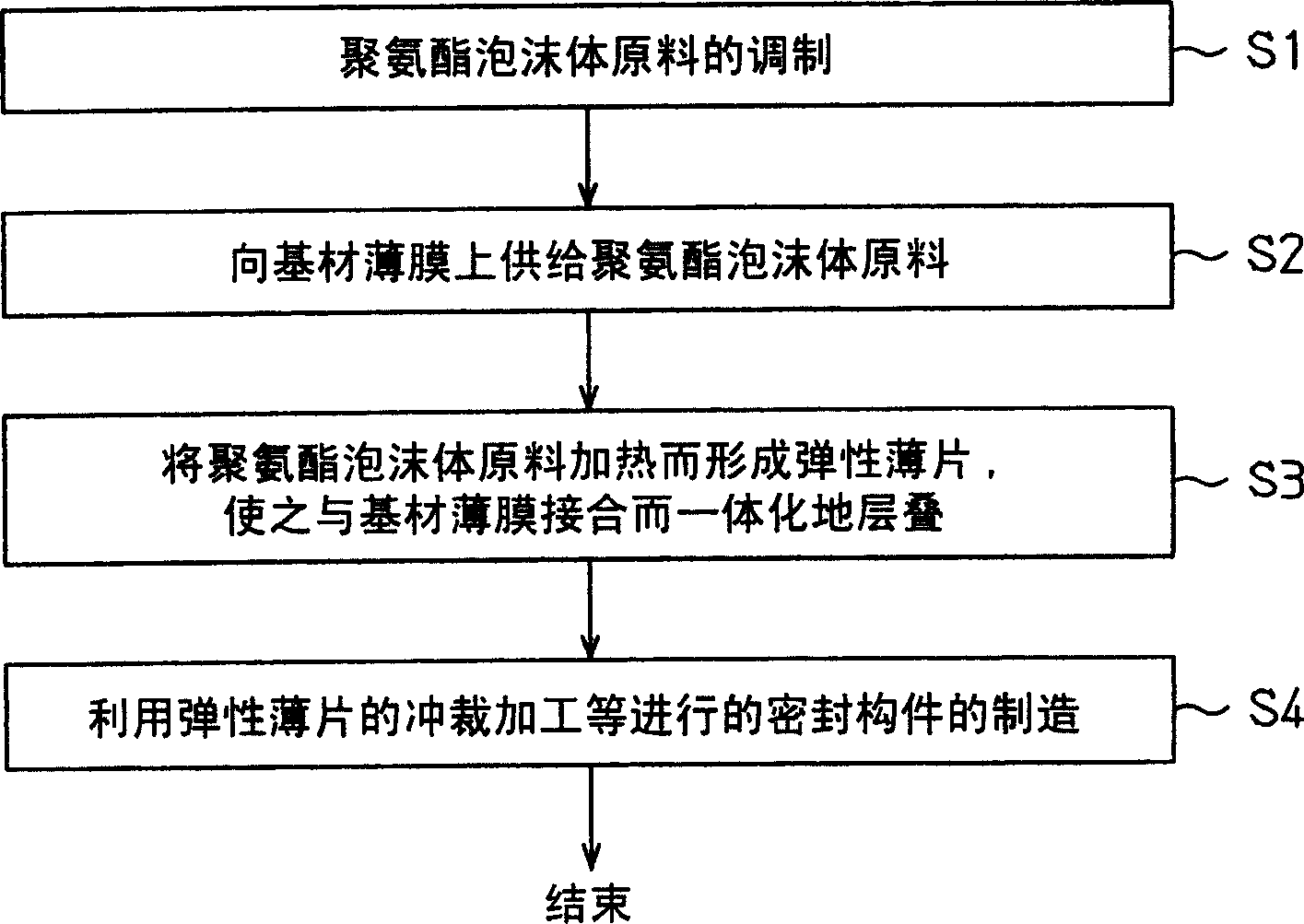

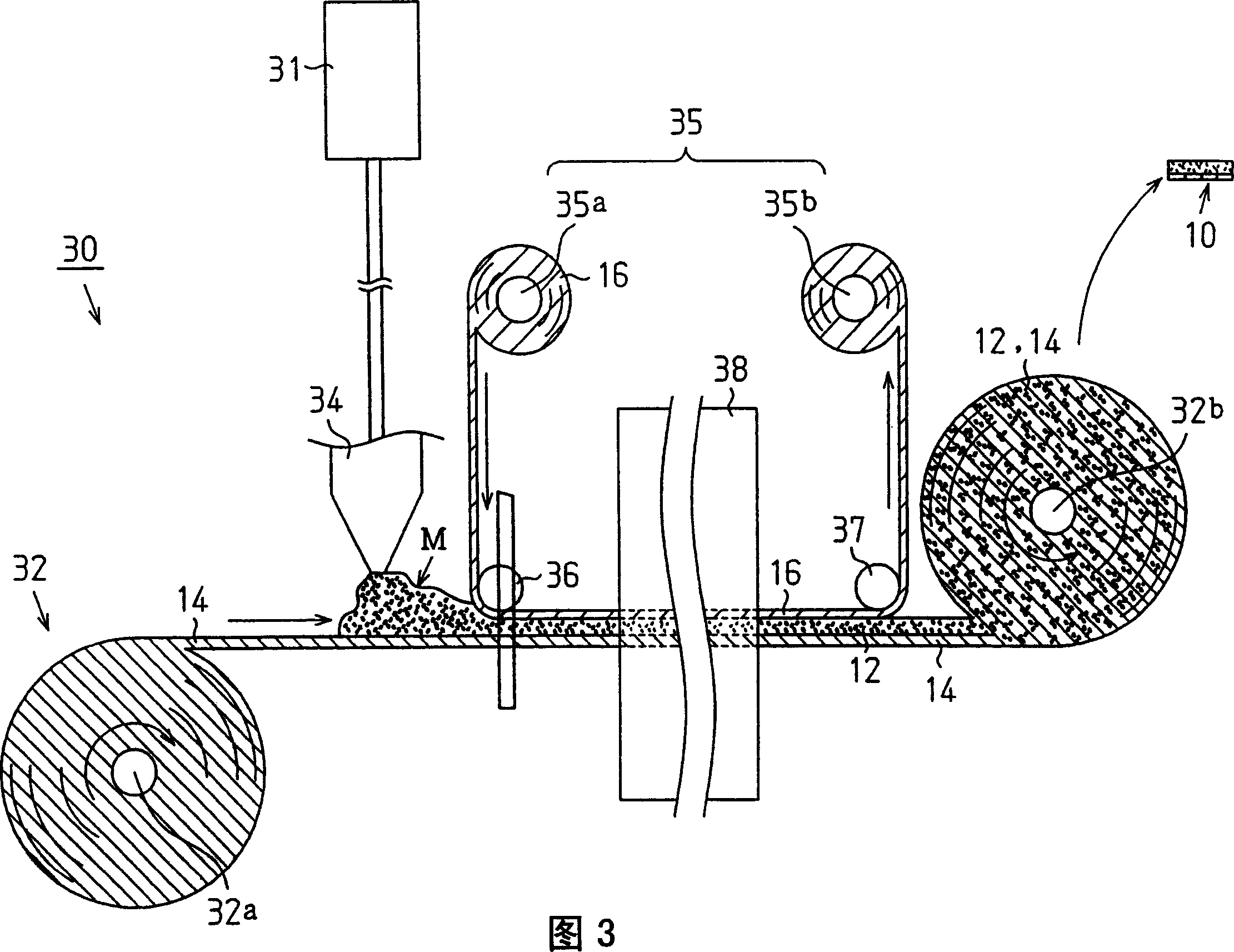

Sealing member and method of producing the same

ActiveCN1655034AFull tightnessReduce specific permittivityEngine sealsOther chemical processesForming gasPolyol

A sealing member comprising an elastic sheet having a density in the range of 100 to 250 kg / m<3>. The elastic sheet is obtained by reacting and curing a polyurethane-foam raw material which is provided by mixing 100% by volume of a resin raw material and 300% by volume or more of a foam-forming gas, in which the resin raw material includes polyol and isocyanate as a main raw material and a foam stabilizer as an auxiliary material, and the like. The compression load deflection at 50% of the elastic sheet is in the range of 0.003 to 0.025 MPa, and the compression load deflection at 75% thereof is in the range of 0.02 to 0.40 MPa.

Owner:INOAC CORP +1

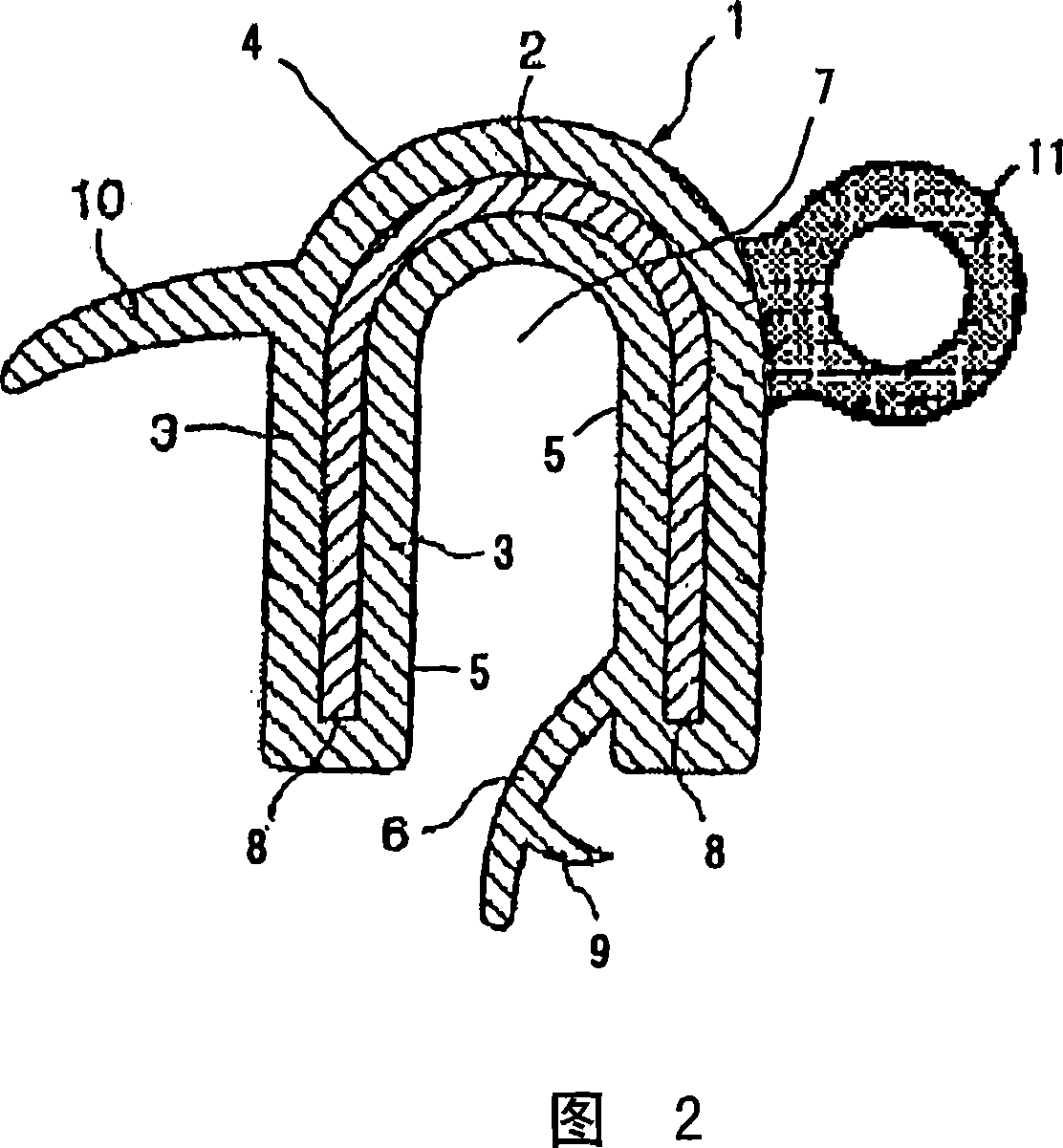

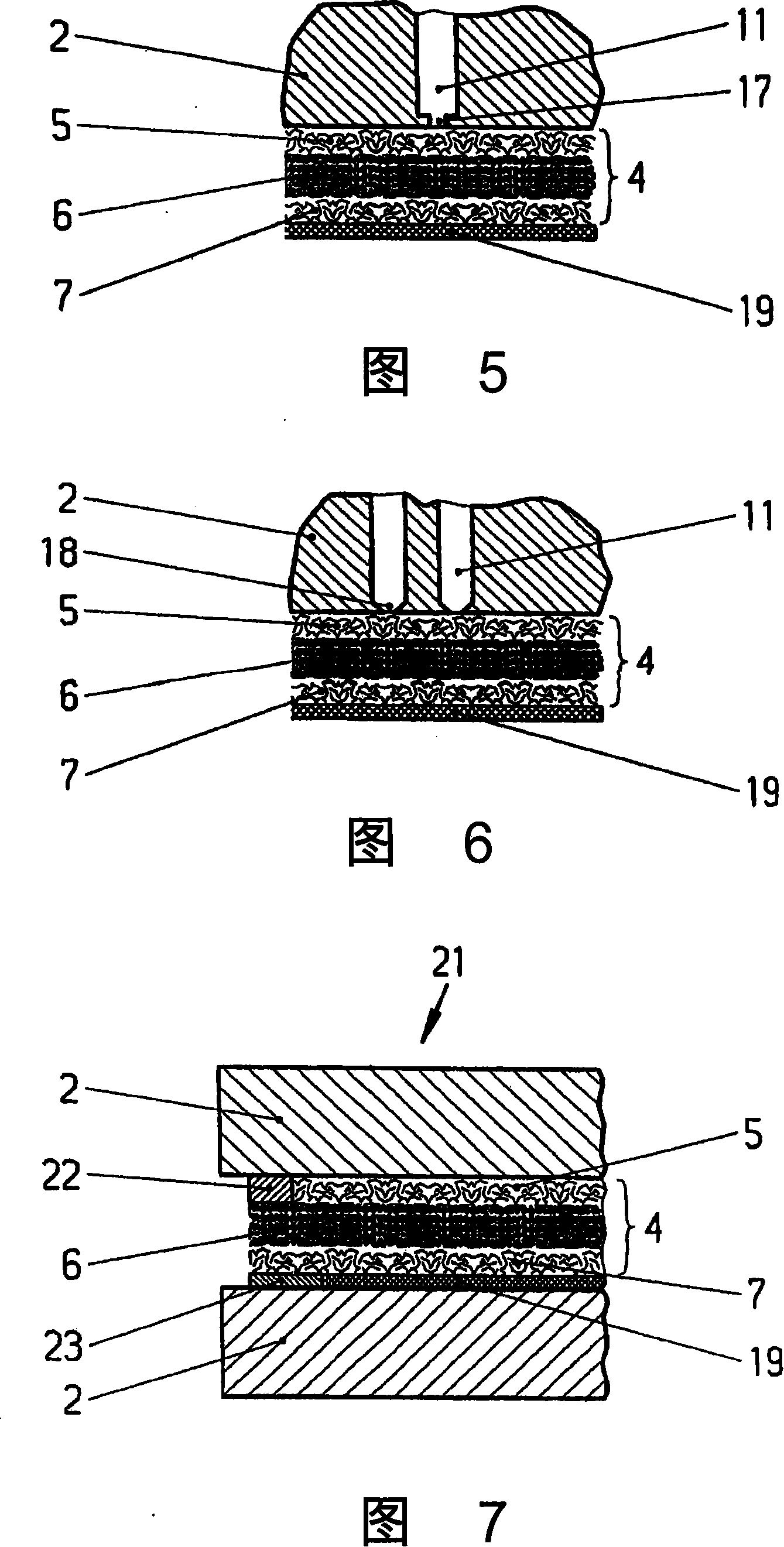

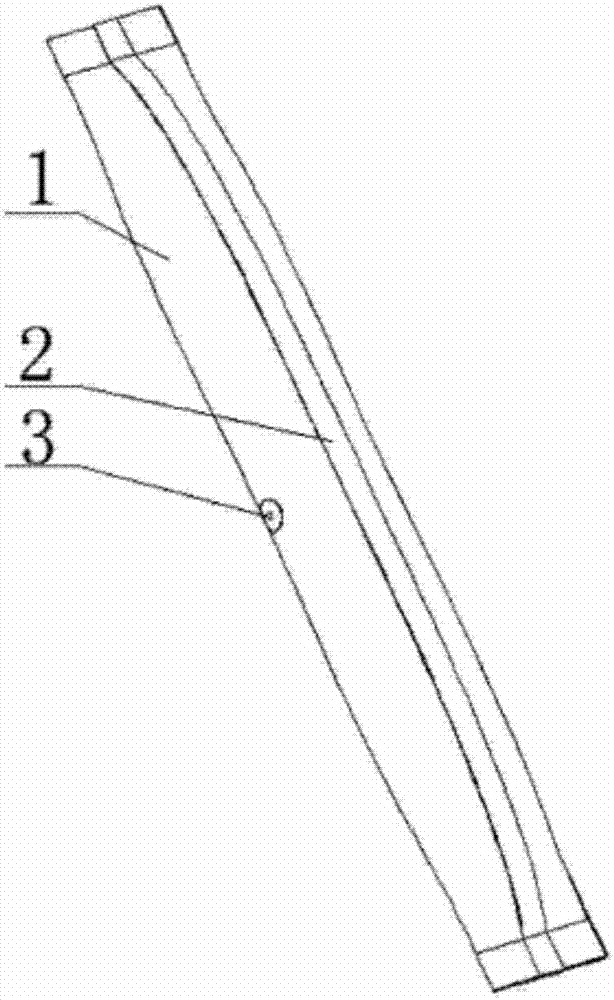

Extrusion molded article for automobiles

ActiveCN101049726AEasy to squeeze outFully flexibleEngine sealsVehicle sealing arrangementsThermoplastic elastomerEngineering

An extrusion molded article for automobiles, having a body portion (1) and a hollow sealing portion (11), where the body portion (1) comprises a core (2) made of a resin having a U-shaped cross-section extending in a longitudinal direction and a covering layer (3) surrounding and covering the core partly or entirely, and the hollow sealing portion (11) is bonded integrally with an outer surface (4) of the body portion, characterized in that the covering layer (3) is made of a thermoplastic elastomer composition having a tensile elongation at break of at least 350% , as determined according to JIS K6251, and a change in 100% modulus of at most 40%, wherein the change in 100% modulus = [(100% modulus at 23 DEG C - 100 % modulus at 80 DEG C) / 100 % modulus at 23 DEG C ] x 100, and the 100 % modulus is a stress at 100% elongation, as determined according to JIS K6251, and the hollow sealing portion (11) is made of a thermoplastic elastomer composition having a tensile elongation at break of at least 250%, as determined according to JIS K6251, and a compression set of 35% or less, as determined at 25% compression, 70 DEG C, 200 hours.

Owner:RIKEN TECHNOS CORP

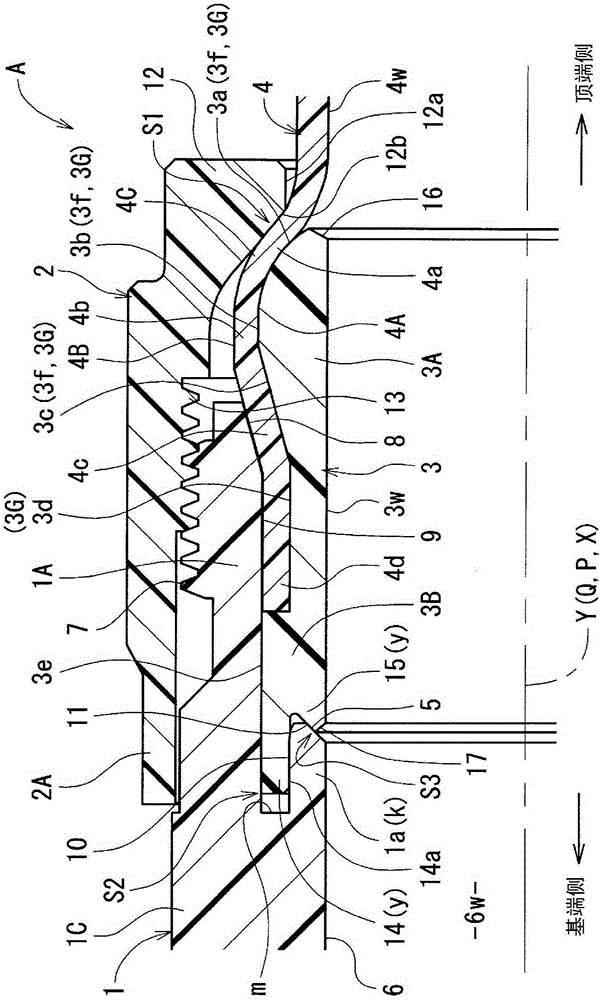

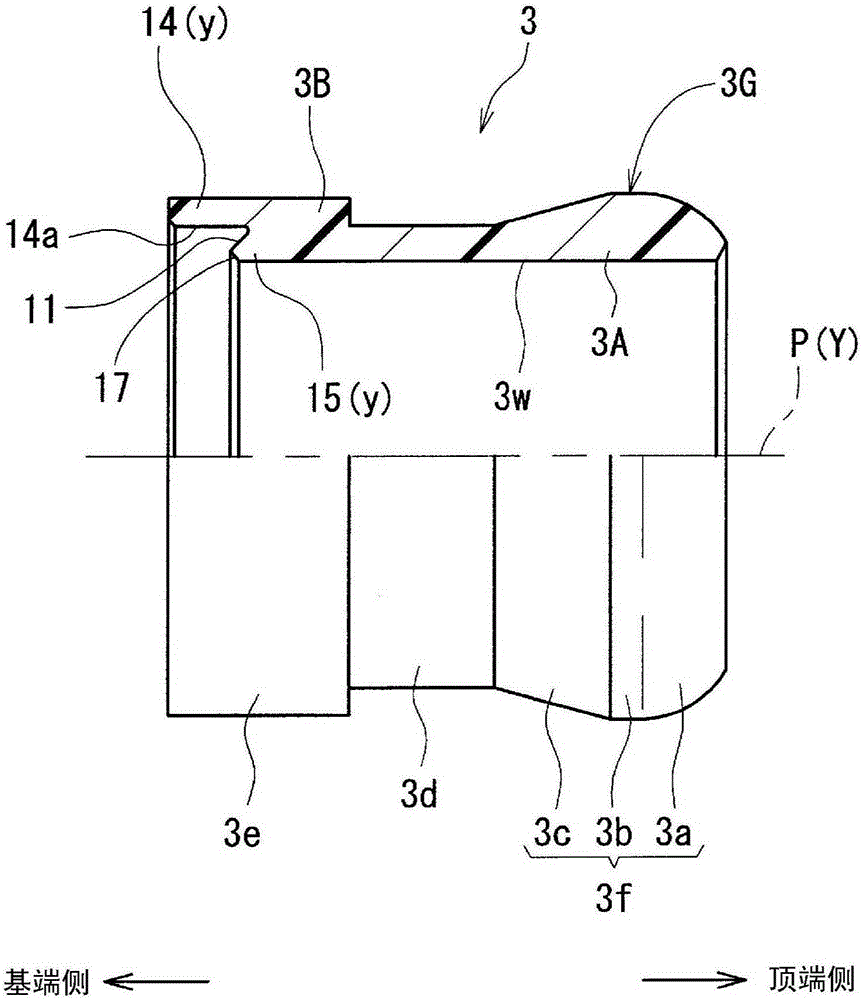

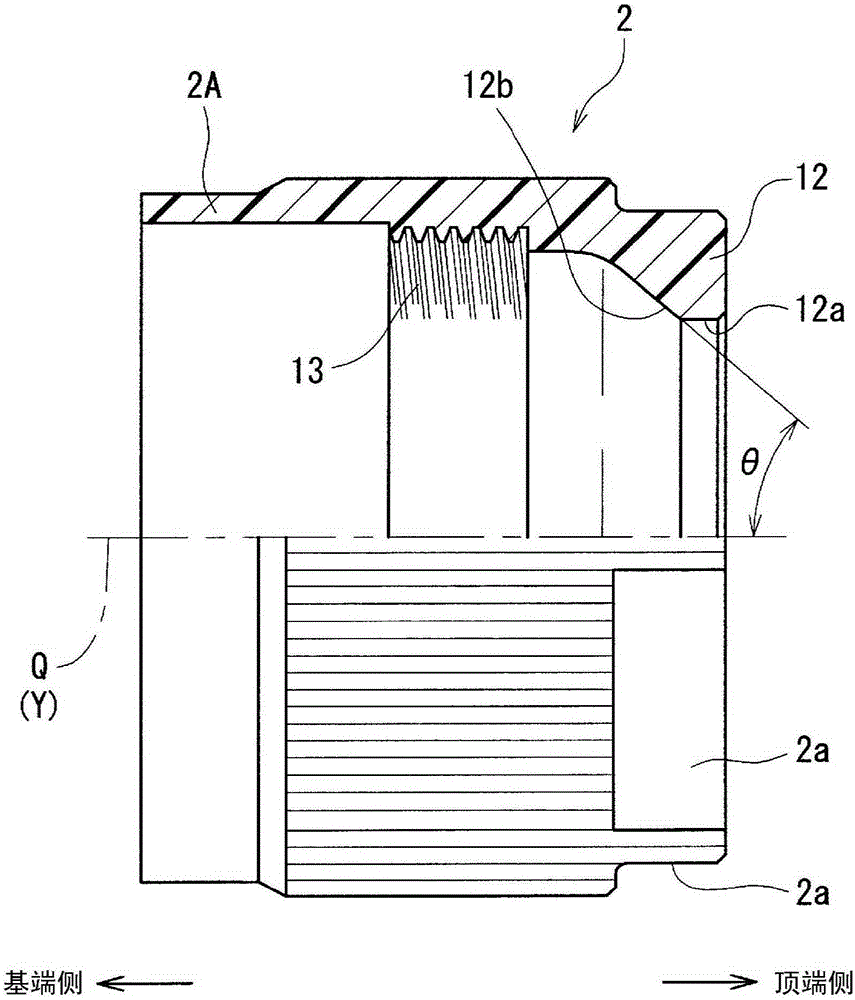

Pipe connecting device

ActiveCN105190148ARelieve pressureSmall creep phenomenonJoints with sealing surfacesHose connectionsPipe fittingEngineering

A pipe connecting device of the type using an inner ring is provided which, through further review of the structure, has been improved so as to allow more repeated use than conventionally possible even while maintaining good seal performance. This pipe connecting device is provided with: an inner ring (3) which has an inner ring (3) comprising an inner peripheral part (3w) and an outer peripheral part (3G) which has a tapered outer peripheral expanded surface (3a) which is press-fitted into and expands the end (4C) of a tube (4); a pipe fitting main body (1) which has a cylindrical screw part (1A) with a male screw (7) attached; and a union nut (2) having a female screw (13) that screws onto the male screw (7). The inner ring (3) provided with the tube (4) is inserted into the cylindrical screw part (1A), and the tapered outer peripheral expanded surface (3a) is pressed by a pressing portion (12b) of the union nut (2) with the tube (4) interposed therebetween, wherein the pressing portion (12b) of the union nut (2) that presses the tube (4) between the tapered outer peripheral expanded surface (3a) is formed as an inclined inner peripheral surface which, relative to the axis (Y) of the cylindrical screw part (1A), is inclined in the same direction as the tapered outer peripheral expanded surface (3a).

Owner:NIPPON PILLAR PACKING CO LTD

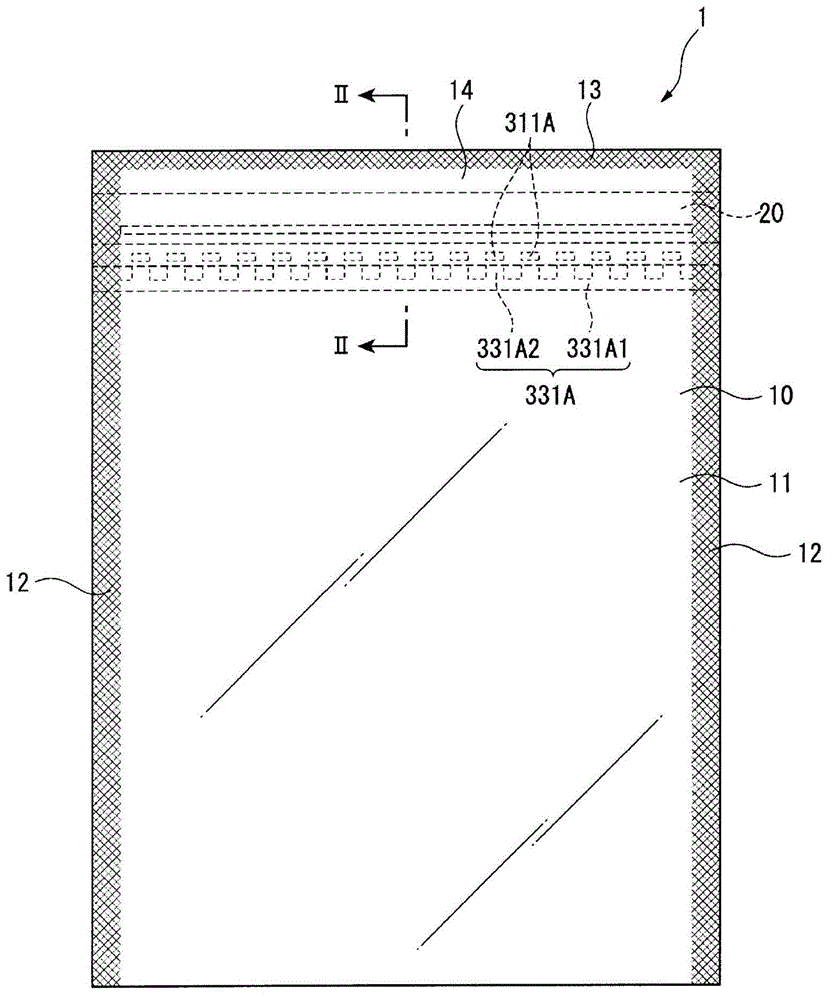

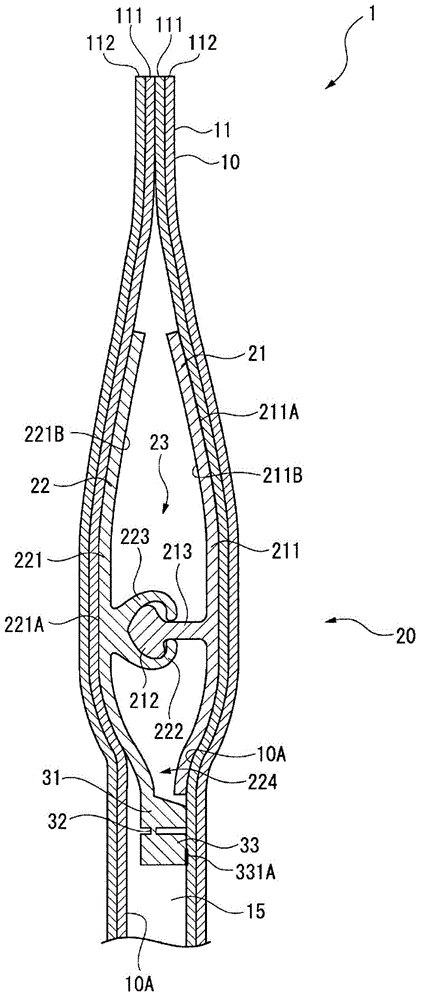

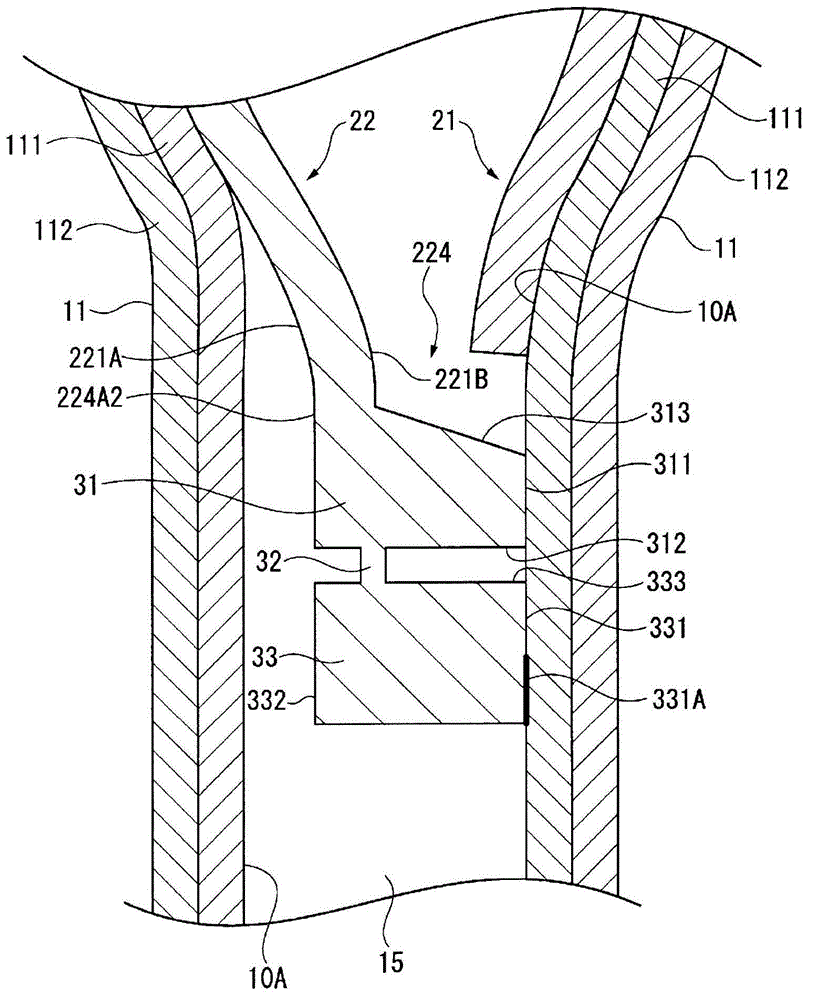

Zipper tape and packing bag with zipper tape

Owner:IDEMITSU UNITECH CO LTD

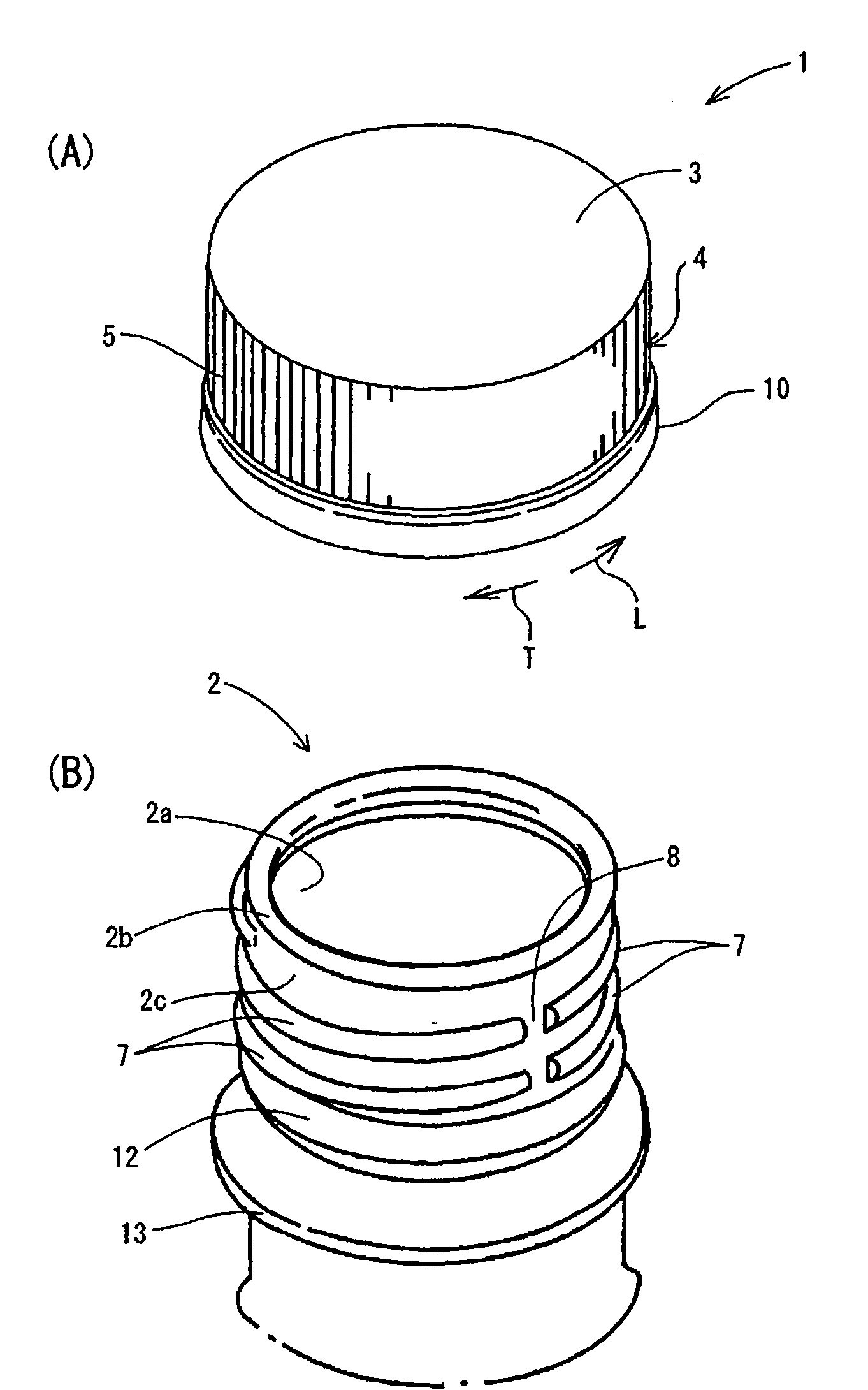

Synthetic resin cap

InactiveCN101910014AExcellent tamper evident performancePrevent leakageCapsClosure capsEngineeringSynthetic resin

A synthetic resin cap having excellent tamper evidence properties, simultaneously achieving both good sealing ability and easiness of opening of the cap, and capable of reliably preventing leakage of container contents before a bridge is cut. The synthetic resin cap has a top wall, a skirt wall, and a tamper evidence band connected to the skirt wall via the bridge. A middle leg, an annular protrusion, and an outer leg are formed integrally with the inner surface of the top wall. The thickness in lateral cross sections of an intermediate section of the middle leg is substantially constant in the vertical direction. The inner and outer peripheral surfaces of the intermediate section are circular arc curved surfaces protruding radially inward so as to have substantially the same curvature in a vertical cross section of intermediate section. A guide surface for guiding a container mouth section is provided on the outer peripheral surface of the tip of the middle leg. The intermediate section is tilted radially outward so that, when the middle leg is inserted into the container mouth section, the upper end of the guide surface moves radially inward by 0.1 - 0.6 mm.

Owner:NIHON YAMAMURA GLASS CO LTD

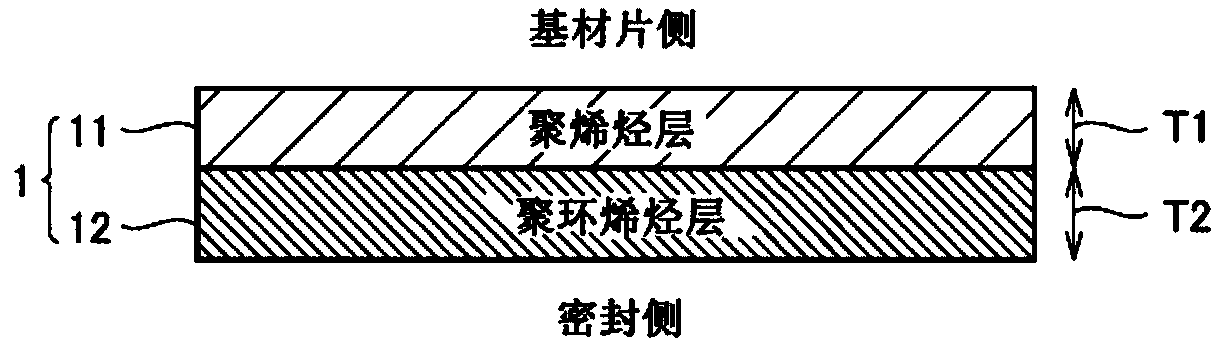

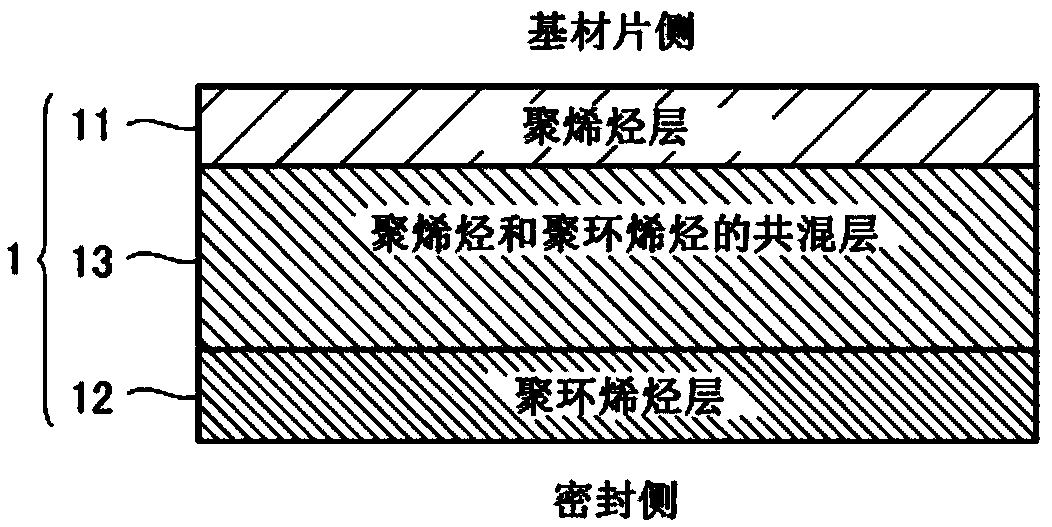

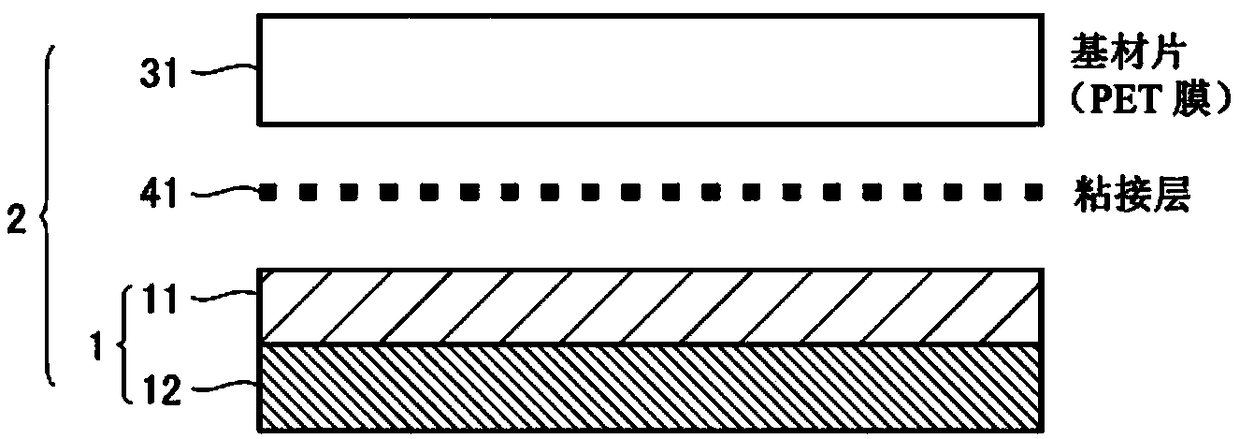

Sealant film, multilayer film using same and packaging bag

ActiveCN109476141AExcellent low adsorptionFull tightnessFlexible coversWrappersPolymer sciencePolyolefin

A sealant film which is provided with: a polyolefin layer that contains a polyolefin as a main component; and a polycycloolefin layer that serves as the outermost layer, while containing a polycycloolefin as a main component. The polycycloolefin comprises two or more structural units selected from among a structural unit (A) derived from a dicyclopentadiene compound, a structural unit (B) derivedfrom a tetracyclododecene compound and a structural unit (C) derived from a norbornene compound; and the polycycloolefin has a glass transition temperature of 80 DEG C or less.

Owner:TOPPAN INC

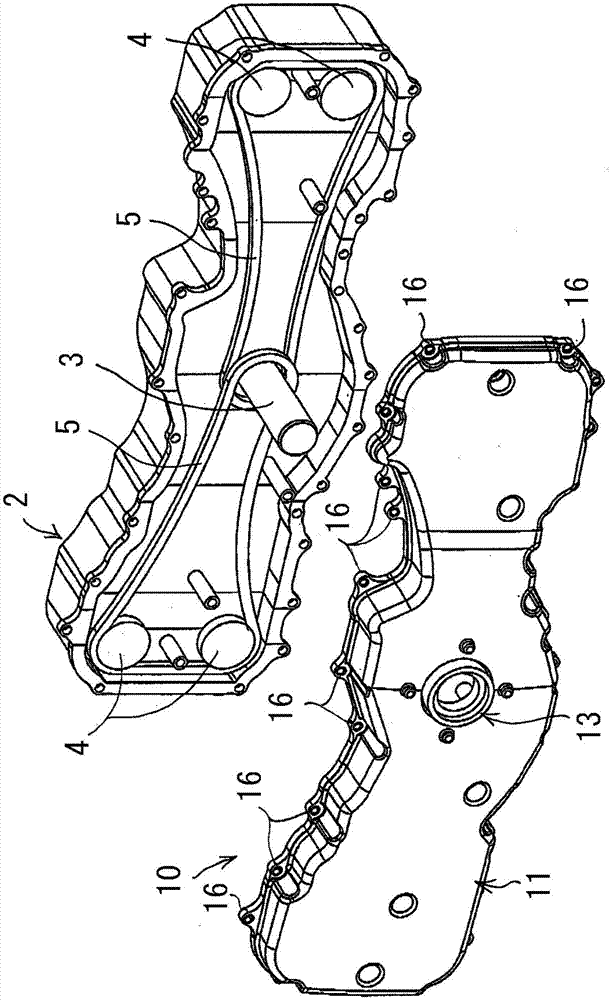

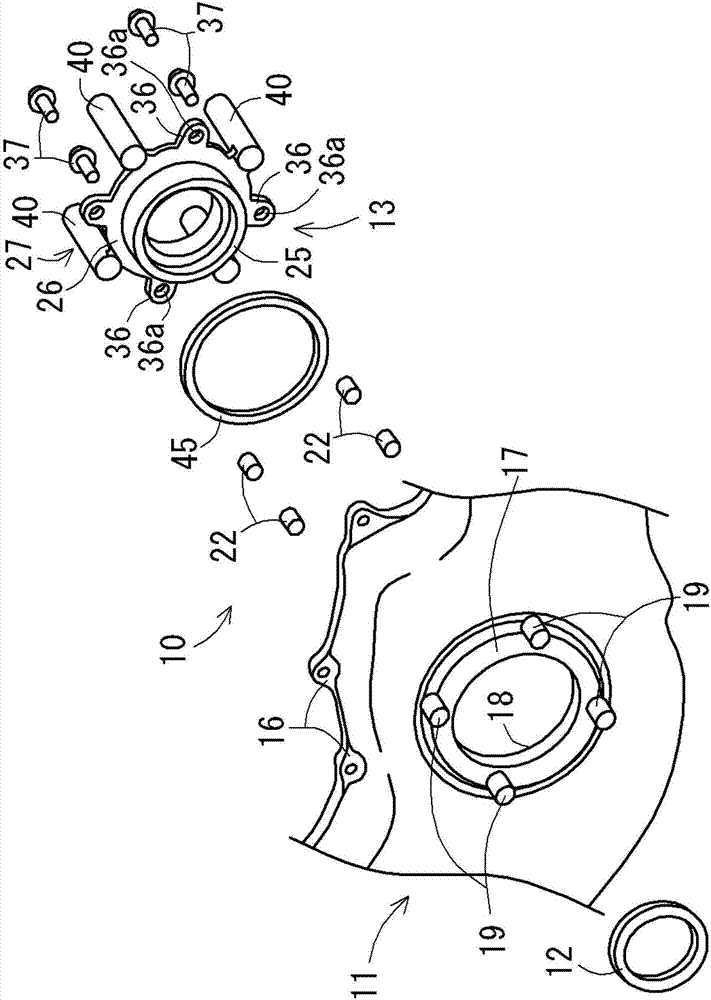

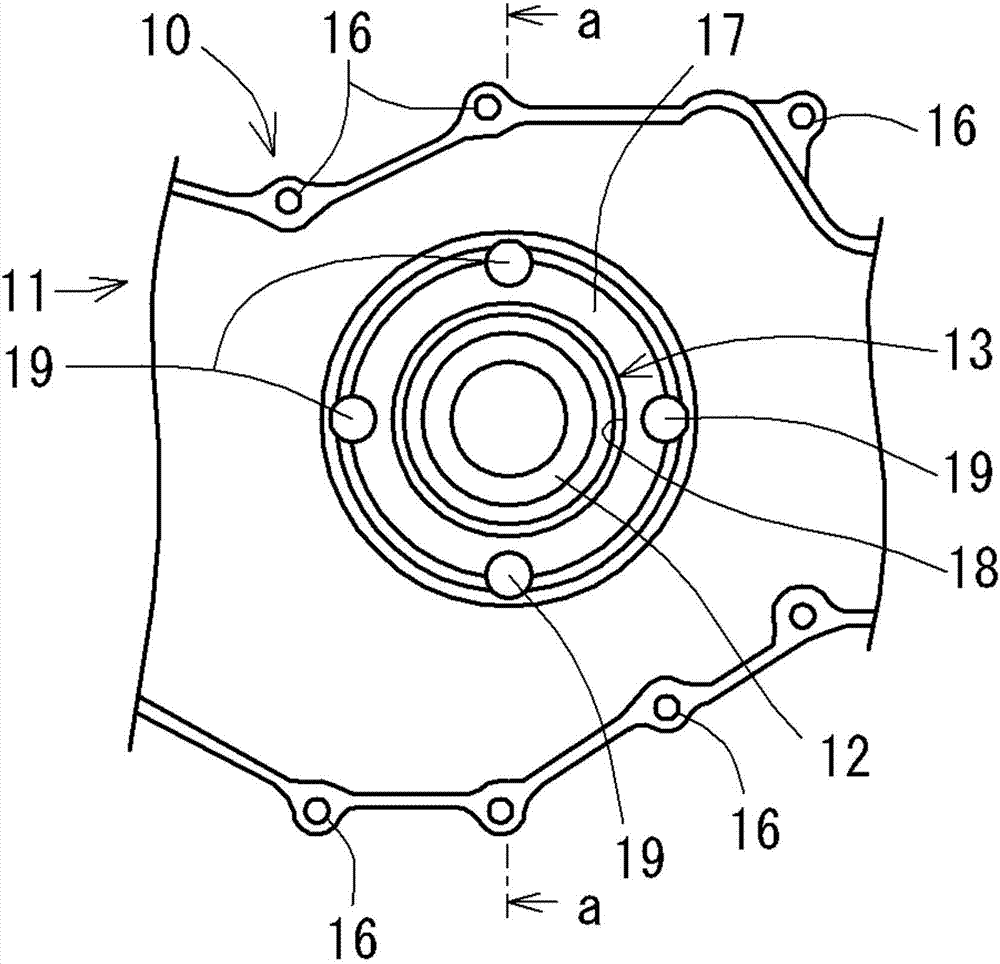

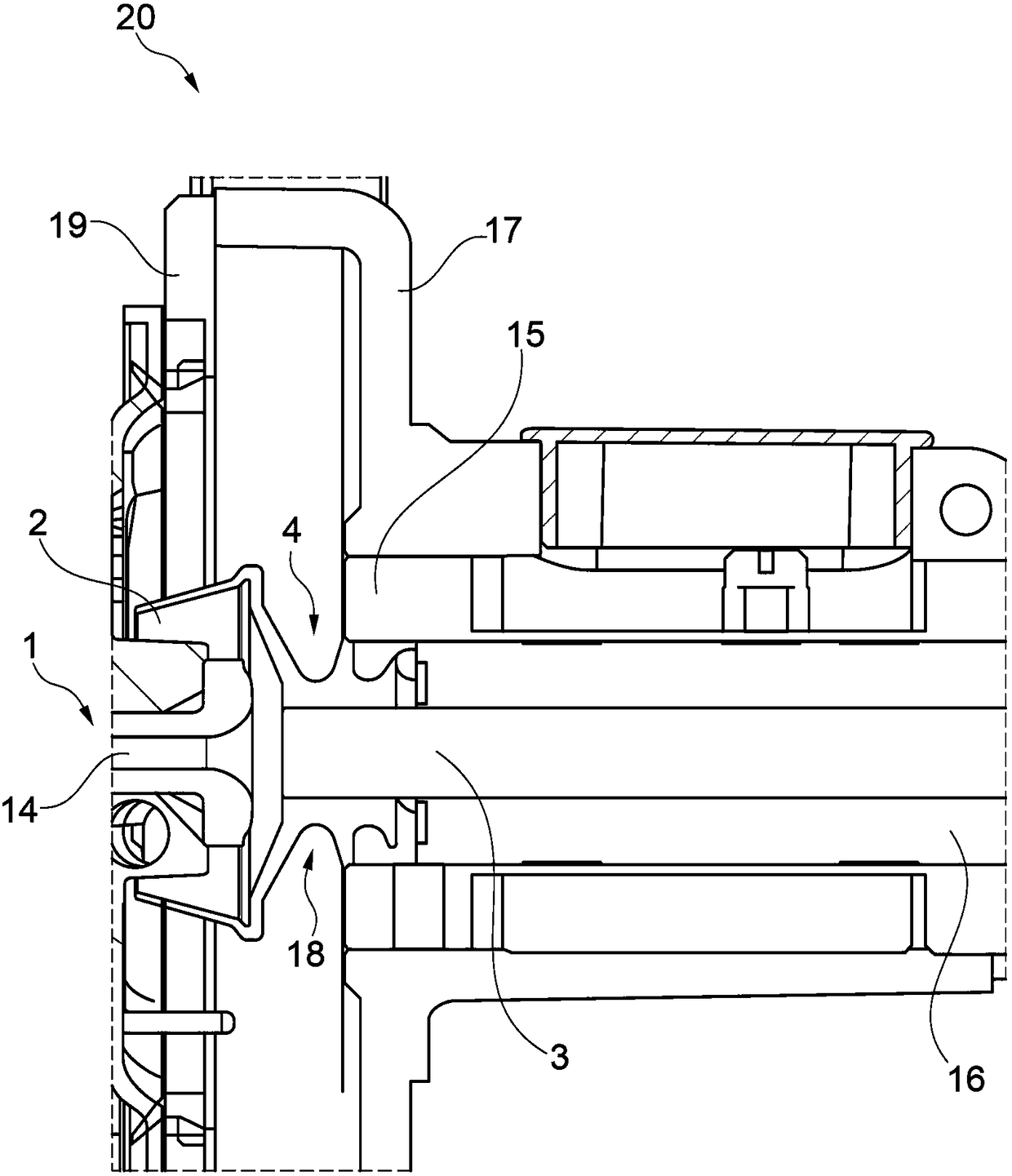

Shield structure for internal combustion engine

ActiveCN107023416AAvoid deformationFull tightnessCasingsValve drivesExternal combustion engineInternal combustion engine

The present invention provides a shield structure for an internal combustion engine. The shield structure of the internal combustion engine can be reduced in weight and can ensure sufficient sealing performance of the oil seal and the gasket.The shield structure of the internal combustion engine includes a shield member (11) which is made of resin and which can be attached to the main body (2) of the internal combustion engine in such a manner as to cover the power transmission portion (5); and a holding member (13) which is made of metal, and the holding member holds the oil seal (12) pressed against the outer peripheral surface of the crankshaft.Further, the holding member is engaged with the main body of the internal combustion engine so as to be able to be positioned in the axial direction of the crankshaft and in the plane direction orthogonal to the axial direction.Further, a gasket (45) sandwiched between the shroud member and the holding member so as to surround the crankshaft is fastened by the fastening bolt (37).

Owner:TOYOTA BOSHOKU KK

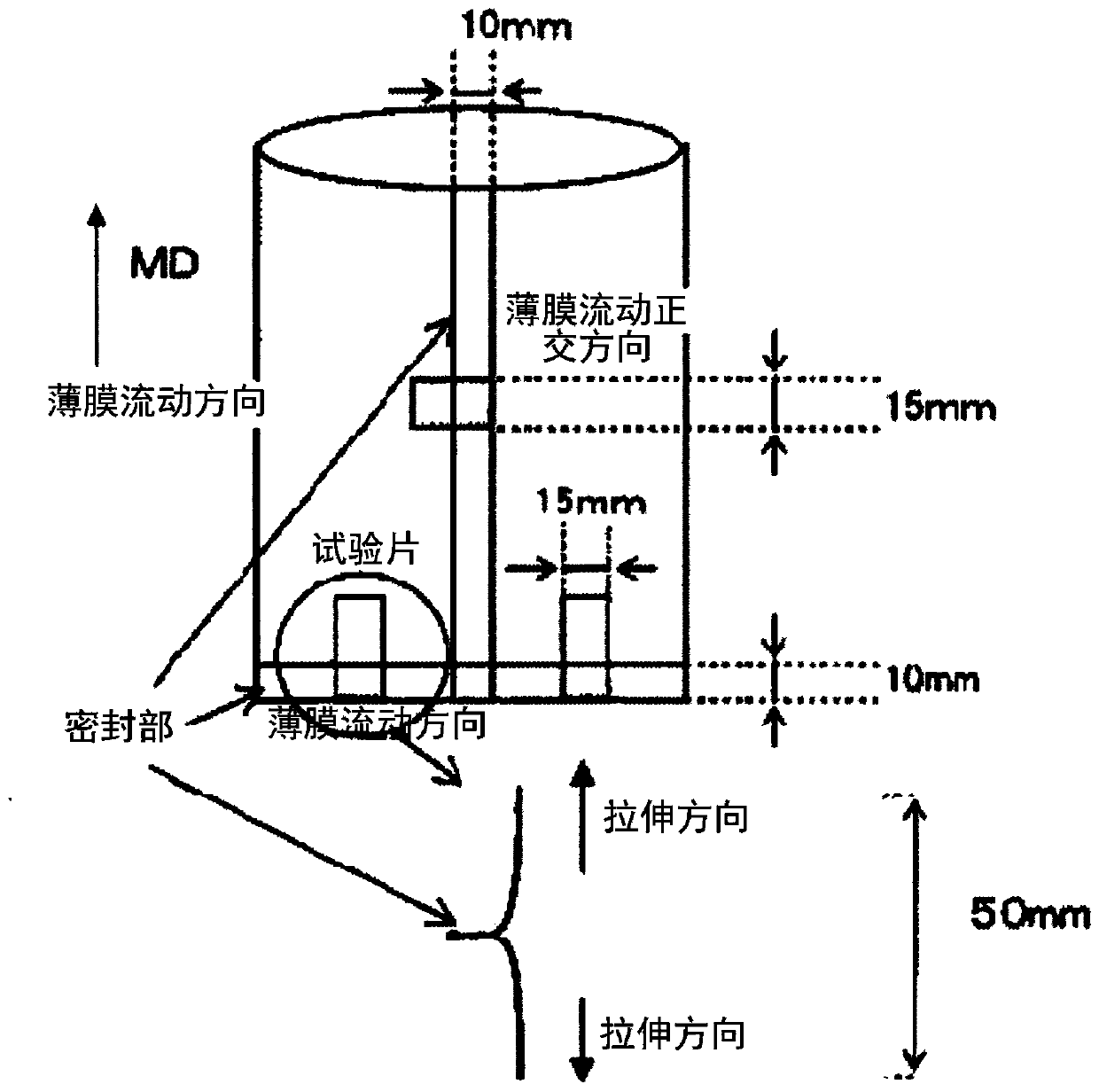

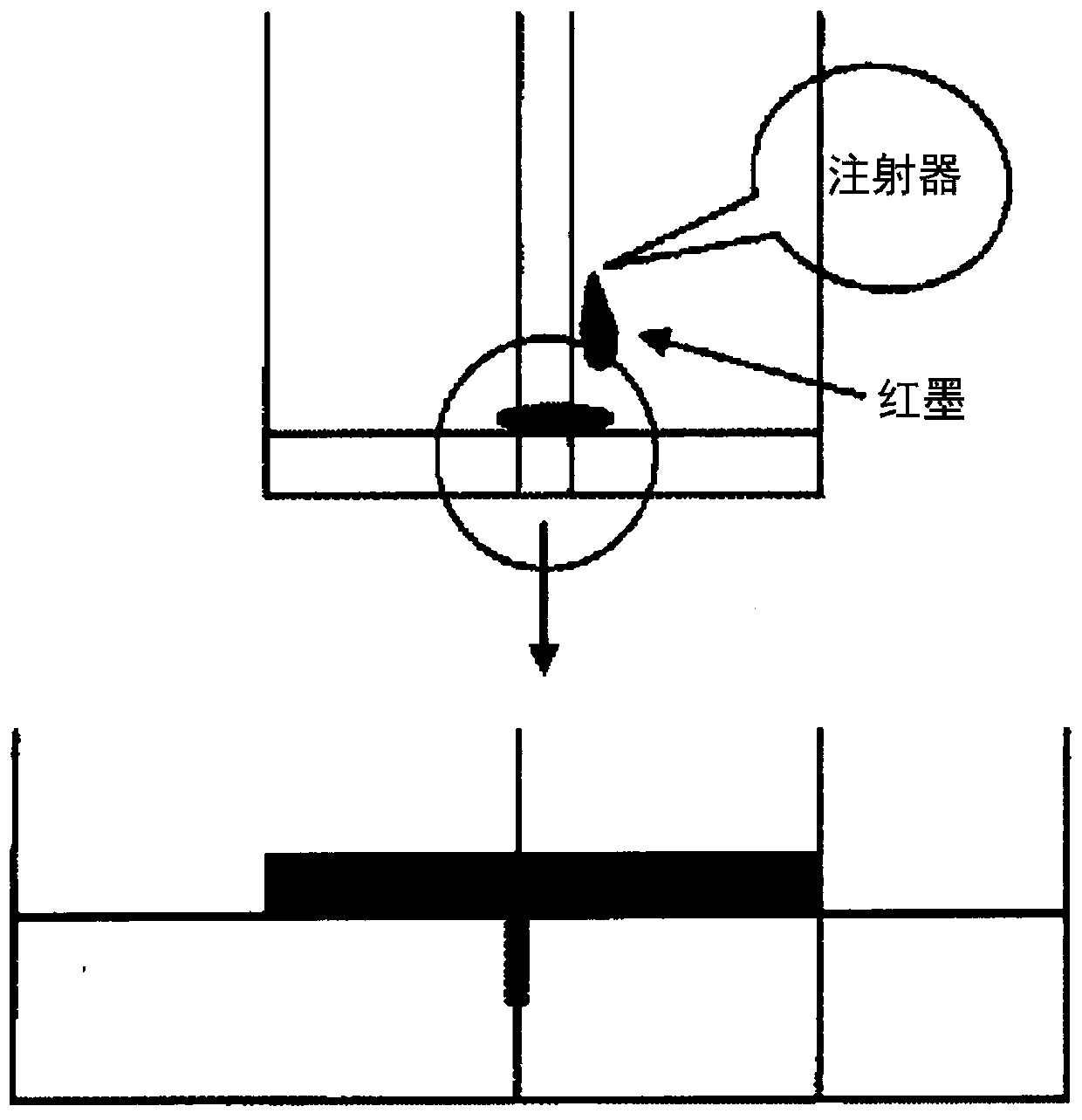

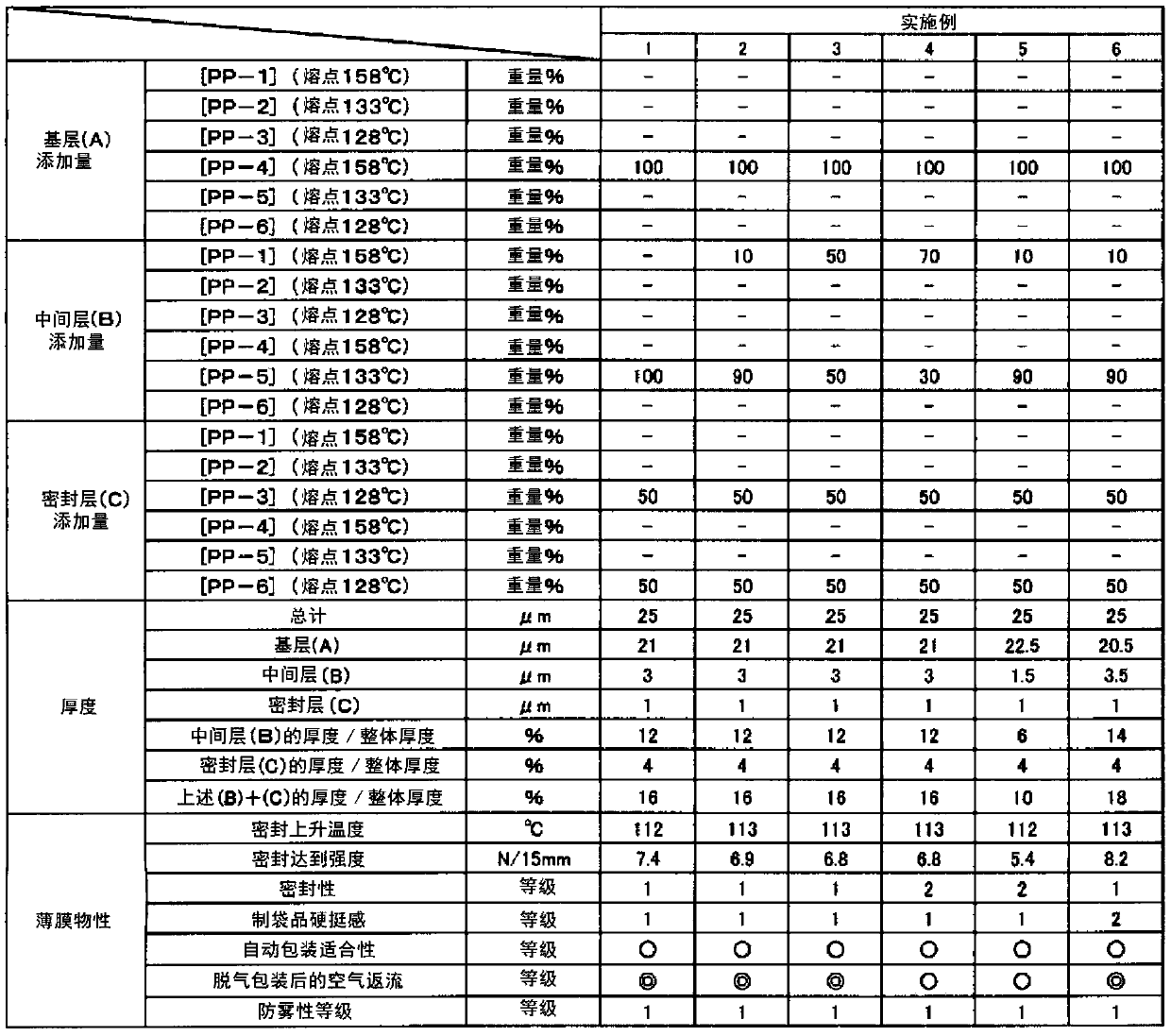

Biaxially oriented polypropylene resin film

ActiveCN110505960AReduce wrinklesLess air regurgitationFlexible coversWrappersPolypropyleneUltimate tensile strength

The present invention provides a polypropylene resin film that has heat seal strength and sealing properties adequate for packaging a heavy object and that is also suitable for automatic packaging. Abiaxially oriented polypropylene resin film comprising a substrate layer (A), an intermediate layer (B), and a seal layer (C), the melting point of a resin constituting part of the substrate layer (A)and the seal layer (C) being in a specific range, and the thickness of each of the intermediate layer (B) and the seal layer (C) furthermore being set so that the ratio thereof with respect to the thickness of all the layers is in a specific range.

Owner:TOYOBO CO LTD

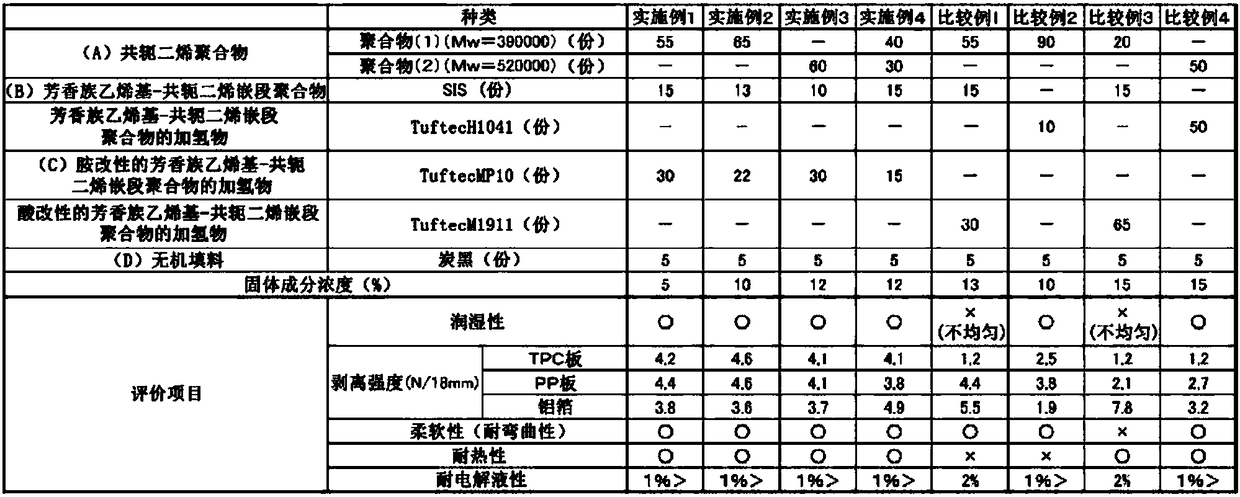

Sealing agent for electrochemical device in which nonaqueous electrolytic solution is used, and sealing agent composition for electrochemical device

ActiveCN108475740AFull tightnessOther chemical processesLi-accumulatorsElectrolytic agentEngineering

The objective of the present invention is to provide a sealing agent for an electrochemical device in which a nonaqueous electrolytic solution is used, the sealing agent having adequate sealing performance for a high-polarity resin. This sealing agent contains (A) a conjugated diene polymer, (B) an aromatic vinyl-conjugated diene block polymer, and (C) a hydrogenation product of an amine-modifiedaromatic vinyl-conjugated diene block polymer.

Owner:ZEON CORP

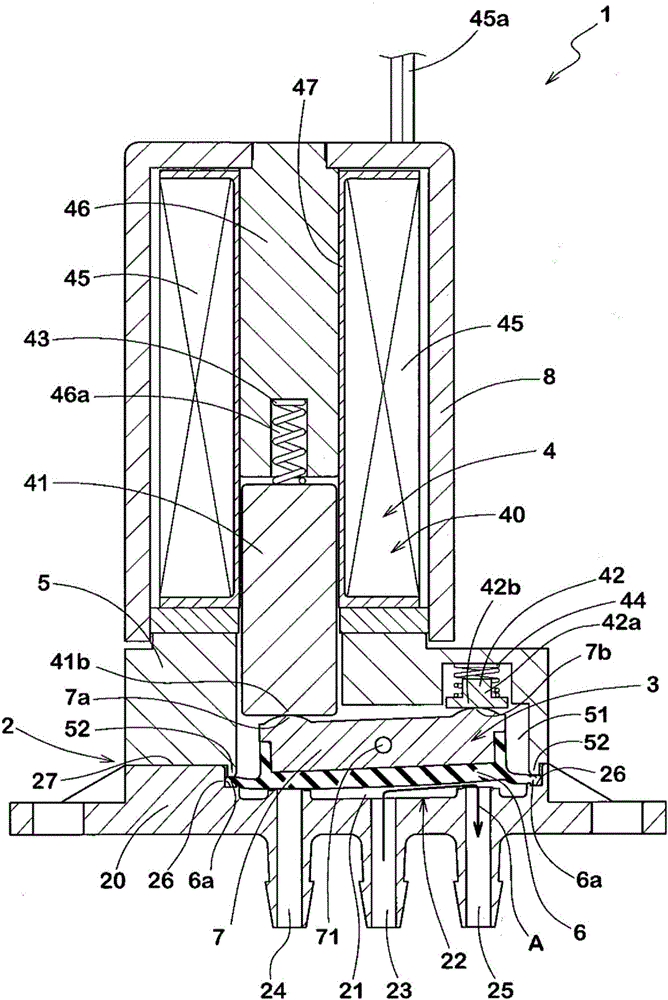

Valve device

InactiveCN105814348AHigh hardnessIncrease pressureDiaphragm valvesOperating means/releasing devices for valvesHardnessEngineering

This invention provides a valve device. The valve device (1) has: a valve main body (2) that compartmentalizes a valve chamber (21) provided with an NO outflow port (25) and NC outflow port (24) through which a fluid flows; and a valve body (3) that opens / closes the NC outflow port (24) and NO outflow port (25). The valve body (3) includes: a diaphragm (6) disposed in a manner so as to cover the valve chamber (21); and a drive means (4) that, by means of pressing the diaphragm (6), can open / close the NC outflow port (24) and NO outflow port (25). A first valve seat (24b) and second valve seat (25b) are formed at the periphery of the NC outflow port (24) and NO outflow port (25). The diaphragm (6) comprises an elastic material of which the JIS-K6253 durometer A hardness is A50-A85. The pressure of the seated diaphragm (6) to the first valve seat (24b) and second valve seat (25b) is 0.5-1.0 N / mm<2>.

Owner:SUMITOMO RUBBER IND LTD

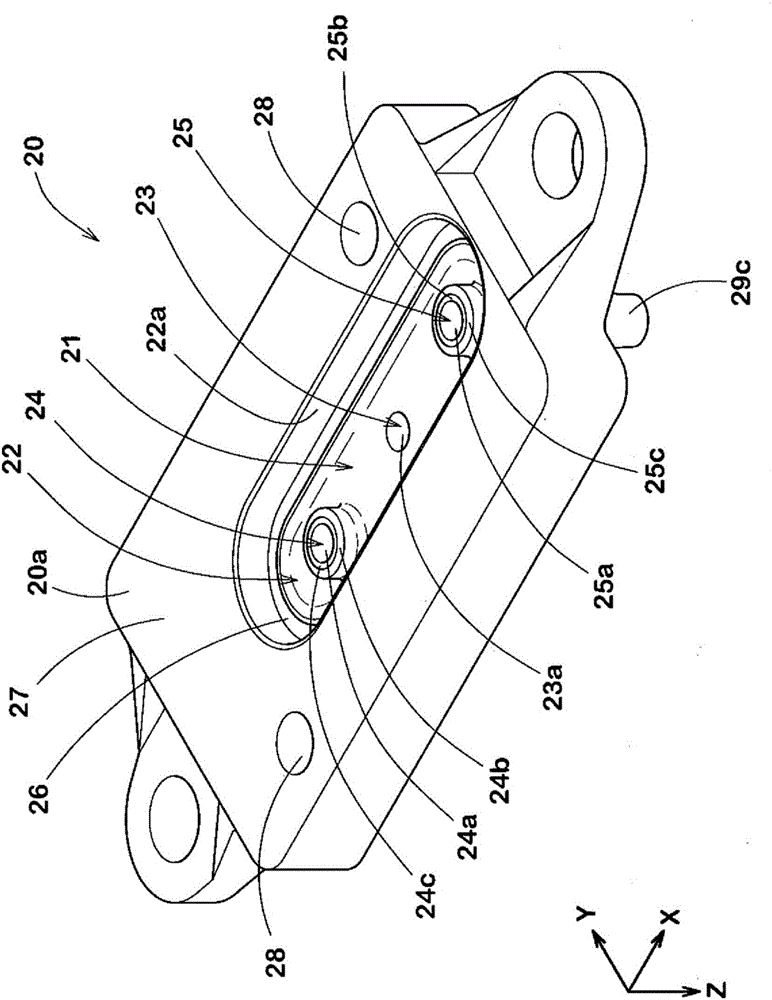

Sealing system for an internal combustion engine with a divided casting enclosure

InactiveCN1985111AImprove sealingSimple structureEngine sealsSealing arrangements for enginesCombustion chamberCylinder head

The invention relates to a sealing system for sealing a cylinder head (2) against a cylinder sleeve (1) of a single- or multi-cylinder internal combustion engine, notably a four-stroke diesel engine, with a divided cast iron crankcase consisting of two half-shells (3) connected to each other by screws, and wherein the joint plane runs in the direction of the crankshaft and the cylinder axis. The half-shells (3) comprise recesses for housing separate cylinder sleeves (1) and separate cylinder heads (2) are provided for each cylinder. The inventive sealing system comprises an annular sealing element. An annular groove (7), being open towards the combustion chamber, is provided in the cylinder head (2) and arranged in such a way that at least part of the prolongation of the cylinder sleeve (1) configured as sealing unit (5) is housed thereby forming a press fit. The annular sealing element is configured as a separate annular seal (4) which is supported on a sealing surface of the cylinder head (2) and radially supported on a sealing surface of the half-shells (3). Said annular seal thereby seals an annular gap (16) between the radially outer peripheral surface of the cylinder head (2) and the recesses of the half-shells.

Owner:赫驰动力公司

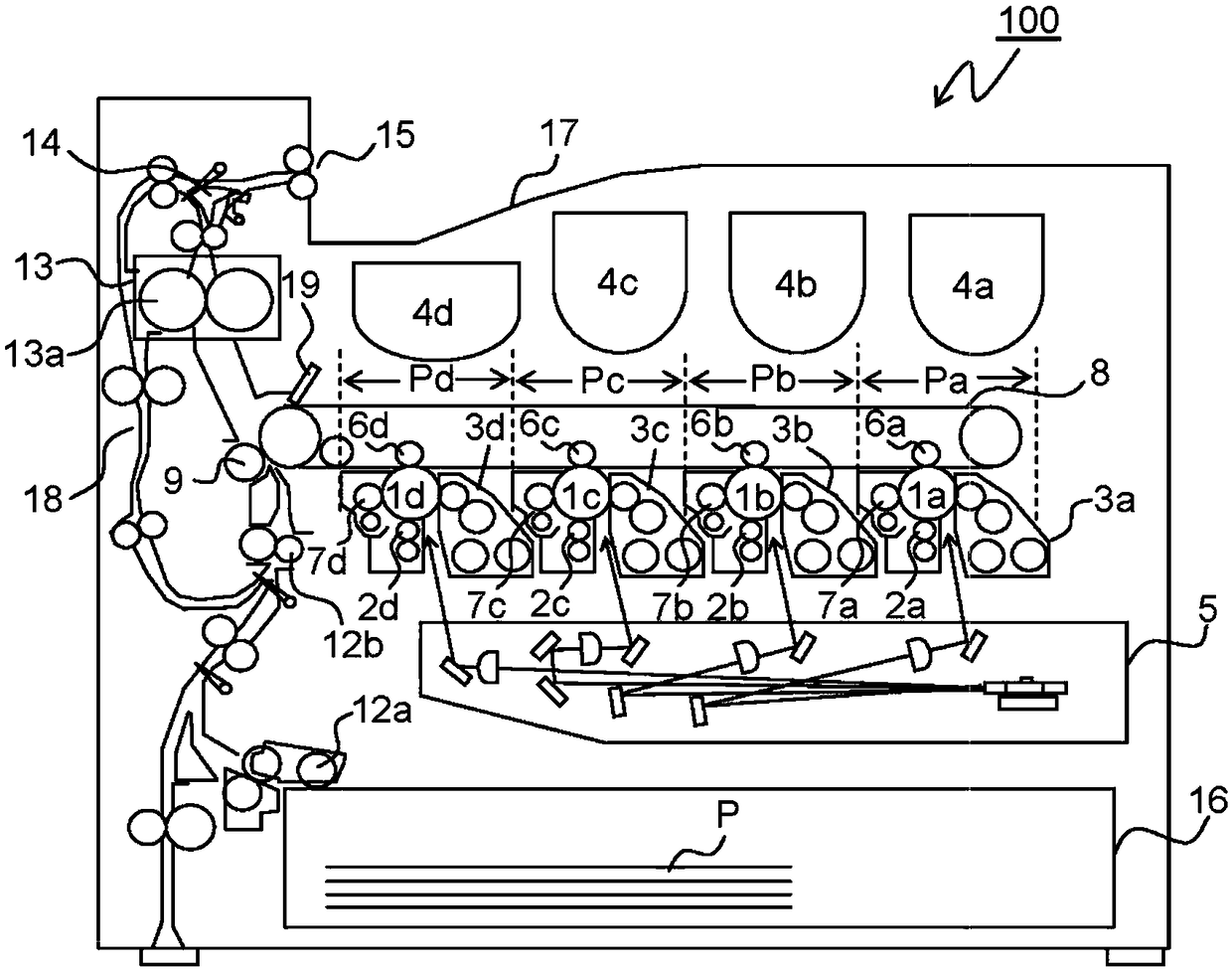

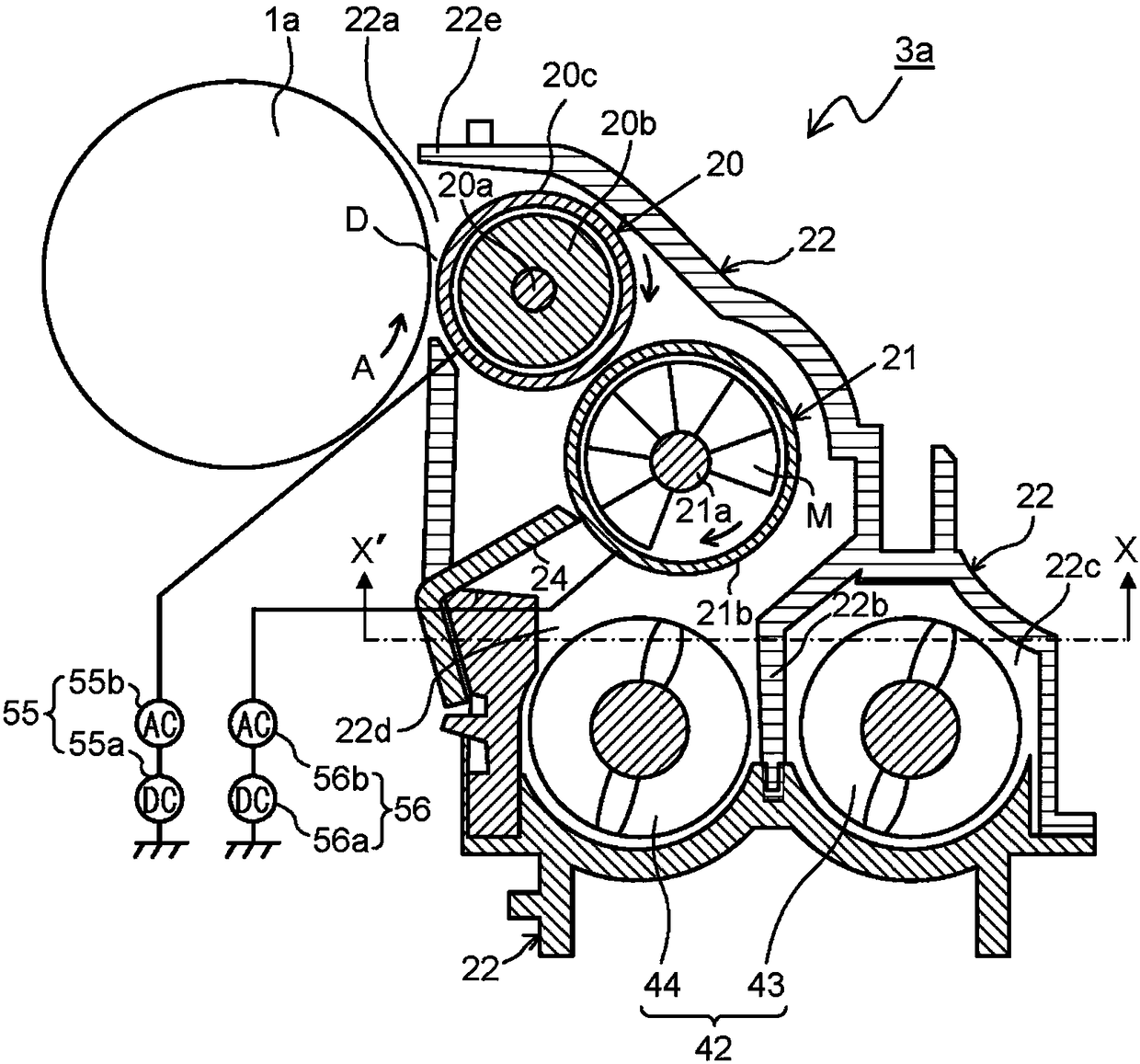

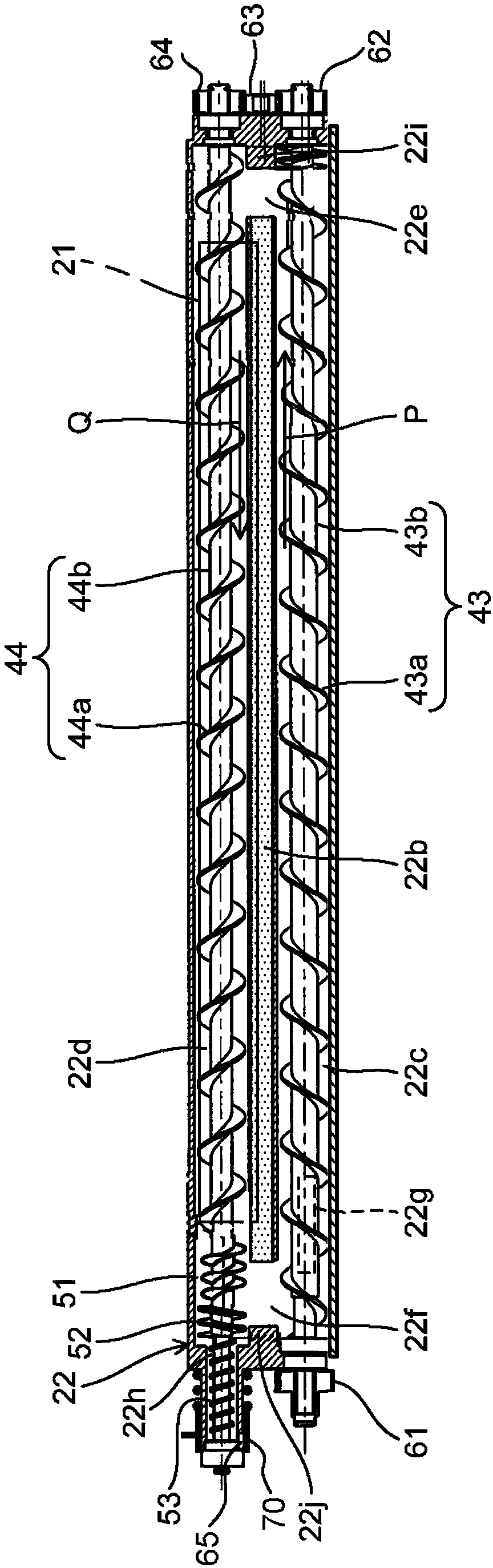

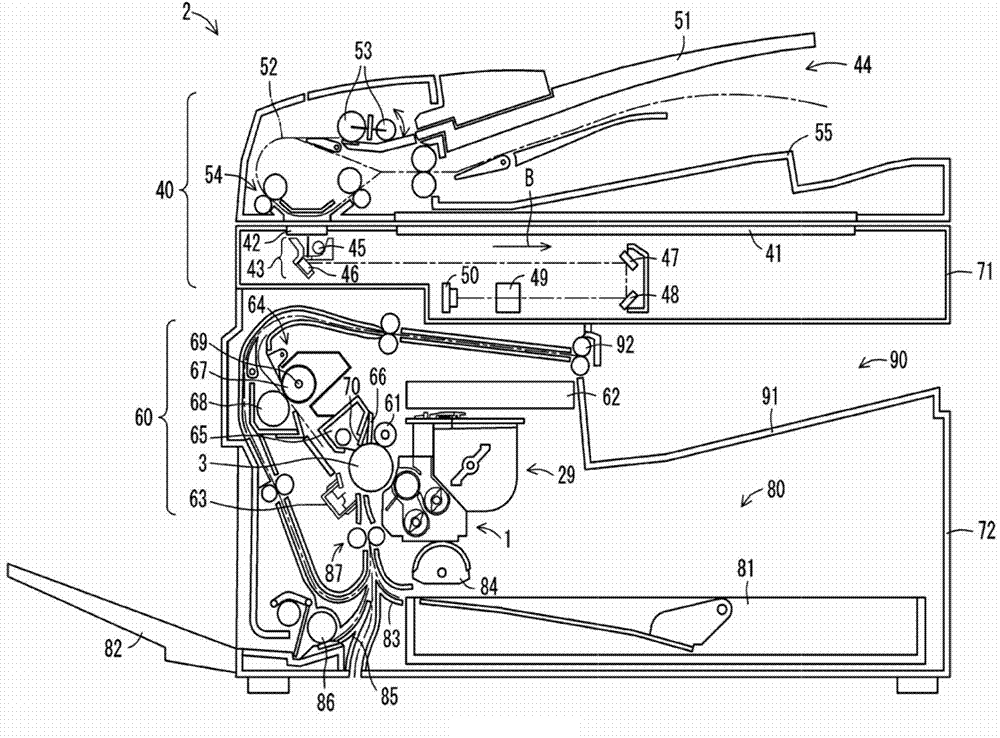

Developer conveying mechanism, and developing device and image forming apparatus therewith

InactiveCN108732891ASliding load reductionSmooth motionElectrographic process apparatusMechanical engineeringEngineering

The invention provides a developer conveying mechanism, and a developing device and an image forming apparatus therewith. The developer conveying mechanism has a pipe-shaped conveyance passage, a shutter, a sealing member, and a biasing member. Through the pipe-shaped conveyance passage, developer is conveyed, and a discharge port is formed in a part of a side surface of the pipe-shaped conveyancepassage. The shutter is arranged to be slidable along the outer circumferential surface of the pipe-shaped conveyance passage, and opens and closes the discharge port. The sealing member is fixed tothe inner circumferential surface of the shutter. The biasing member biases the shutter in a direction in which the discharge port is closed. The sealing member has a frame-shaped contact portion making contact with the pipe-shaped conveyance passage, and a non-contact portion in the contact portion.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

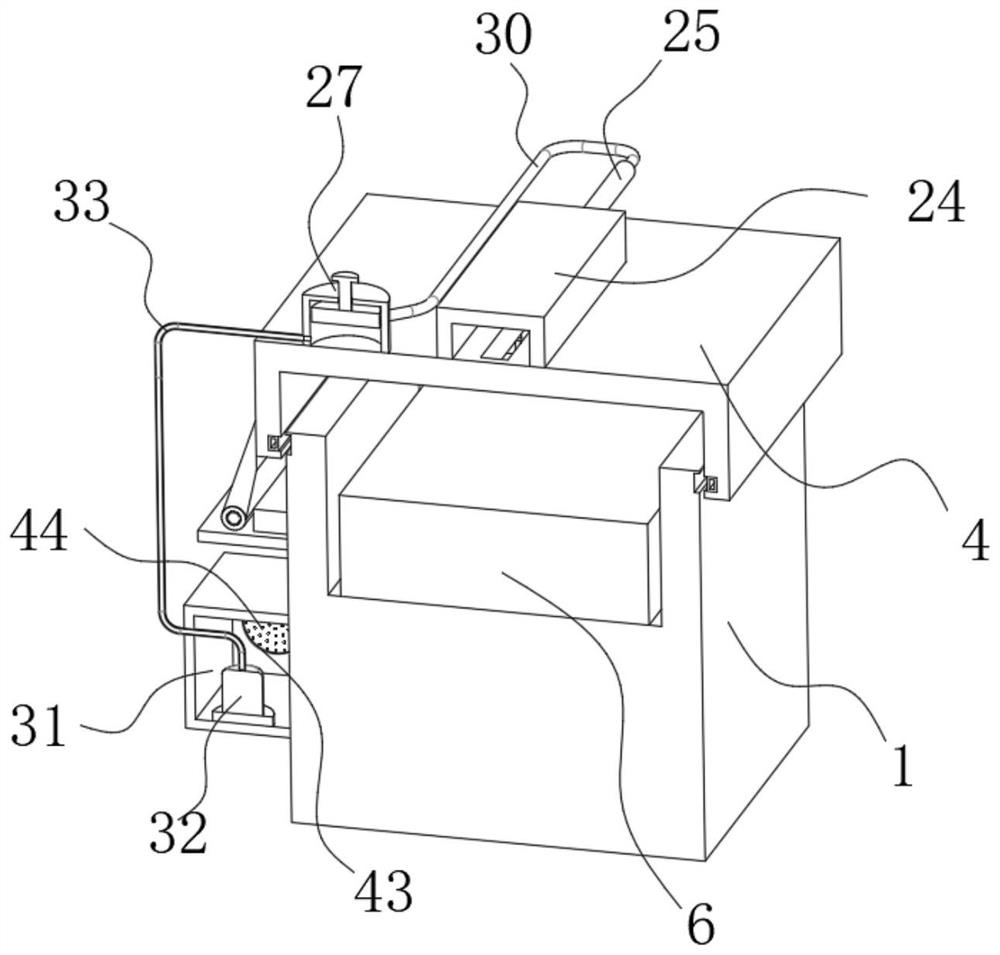

Electric power detection method

PendingCN114755517ARealize limitAchieve clampingWork holdersFault locationStructural engineeringMechanical engineering

The invention discloses an electric power detection method, and the method employs an electric power detection device, the device comprises a detection box and a sealing cover, the detection box is internally provided with an installation cavity, the inner surface of the installation cavity is fixedly provided with a device seat, and the inner surface of the sealing cover is fixedly connected with a separation plate. The sleeve rod is pushed to move, so that the top plate and the sliding plate push the movable seat to move, and the movable seat moves to pull the movable end of the detection line to move, so that the multiple groups of detection lines pull the detection line to slide along the partition plate, and automatic carding and arrangement of the multiple groups of detection lines are realized; in the next use process, the sealing cover is opened, and the sorted detection line is directly selected from the inner surface of the sealing cover, so that disordered arrangement of detection is effectively avoided, the target detection line is conveniently selected, the convenience in actual power detection is improved, the efficiency of emergency power detection is improved, power failure reasons are diagnosed in advance, and the use effect is good.

Owner:彭林辉

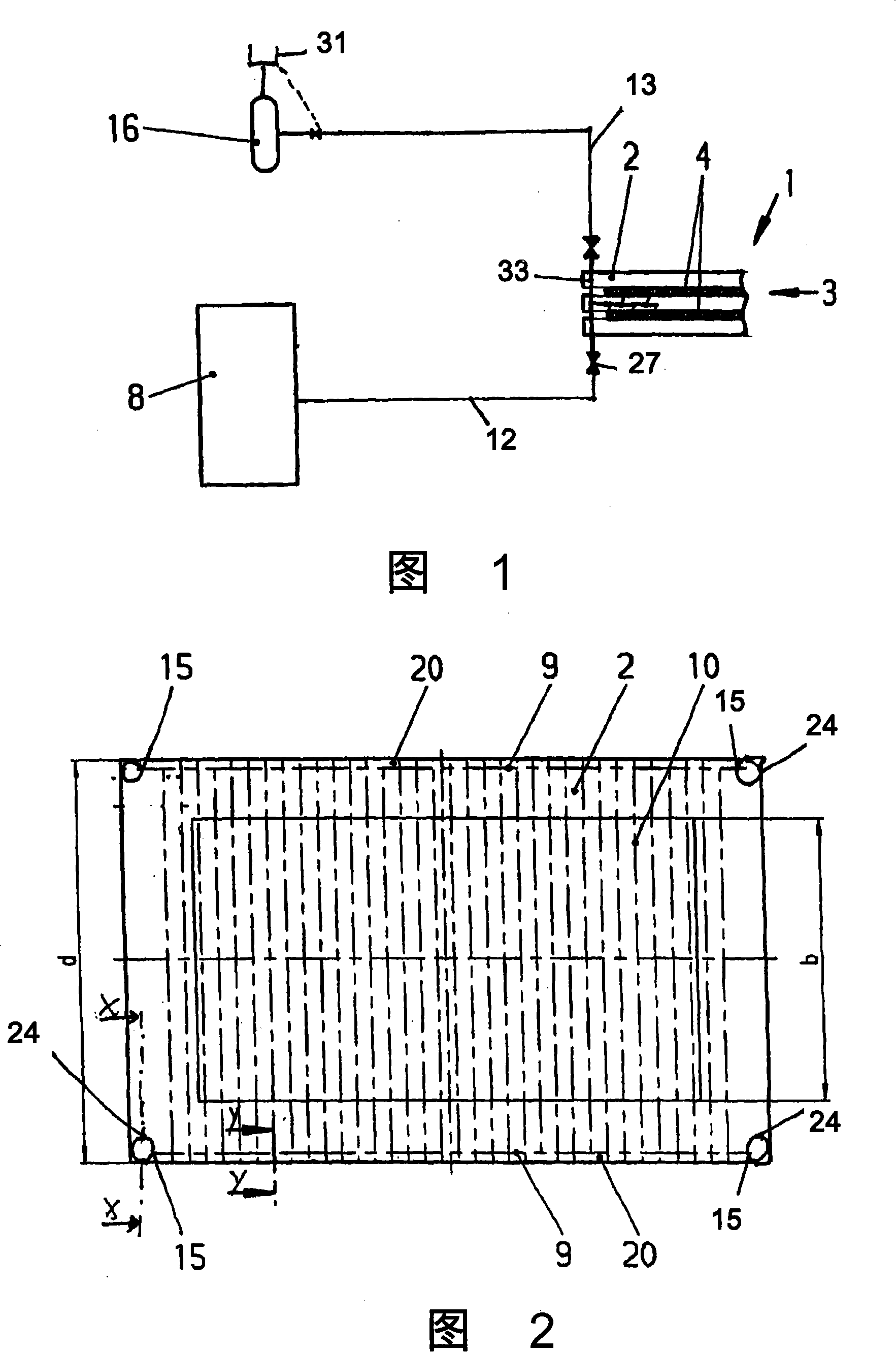

Single- or multi-tier press for manufacturing flake board

InactiveCN101108497AFull tightnessIncrease temperaturePlywood pressesVeneer pressesEngineeringFilter press

Owner:DIEFFENBACHER GMBH & CO KG

Inflatable electric power pipeline sealing device and production method

InactiveCN106992489APrevent intrusionProtection maintenanceCable installations in underground tubesCable installation apparatusSurface layerMolecular materials

The invention discloses an inflatable electric power pipeline sealing device and a production method. The sealing device is characterized by comprising an air type sealing bag body comprising a sealing bag body. The sealing bag body consists of a soft metal surface layer and multiple high-molecular material layers and is in shape of a flat ball body. A cavity is arranged in the sealing bag body. High temperature resisting waterproof films are integrated into the sealing bag body are recombined on two sides of the surface of the sealing bag body. An air charging opening is arranged in one end of the sealing bag body. The interior of the air charging opening contains self-filling colloid materials. A wear-resisting layer is arranged on the soft metal surface layer of the sealing bag body. A waterproof glue layer is coated on the inner wall of the sealing bag body. According to the invention, after air is charged by use of the inflatable electric power pipeline sealing device, cables in a pipeline can be sufficiently protected and sealed, and service lifetime is prolonged.

Owner:嘉兴之电高压电气有限公司

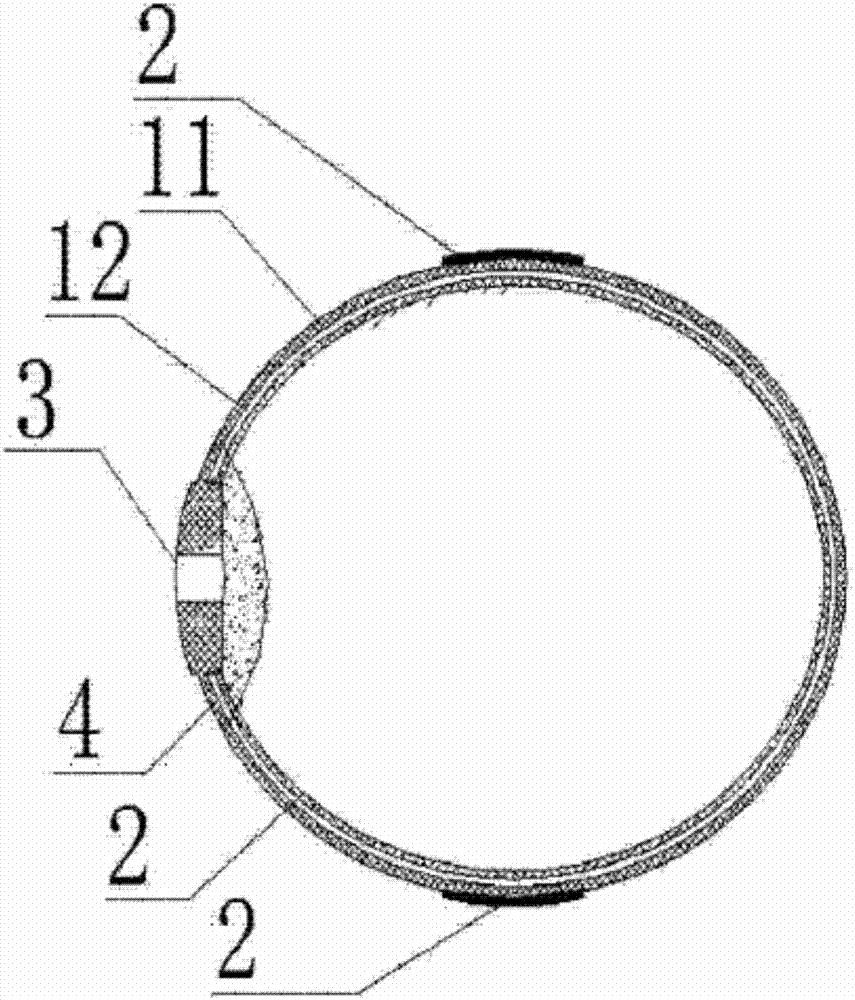

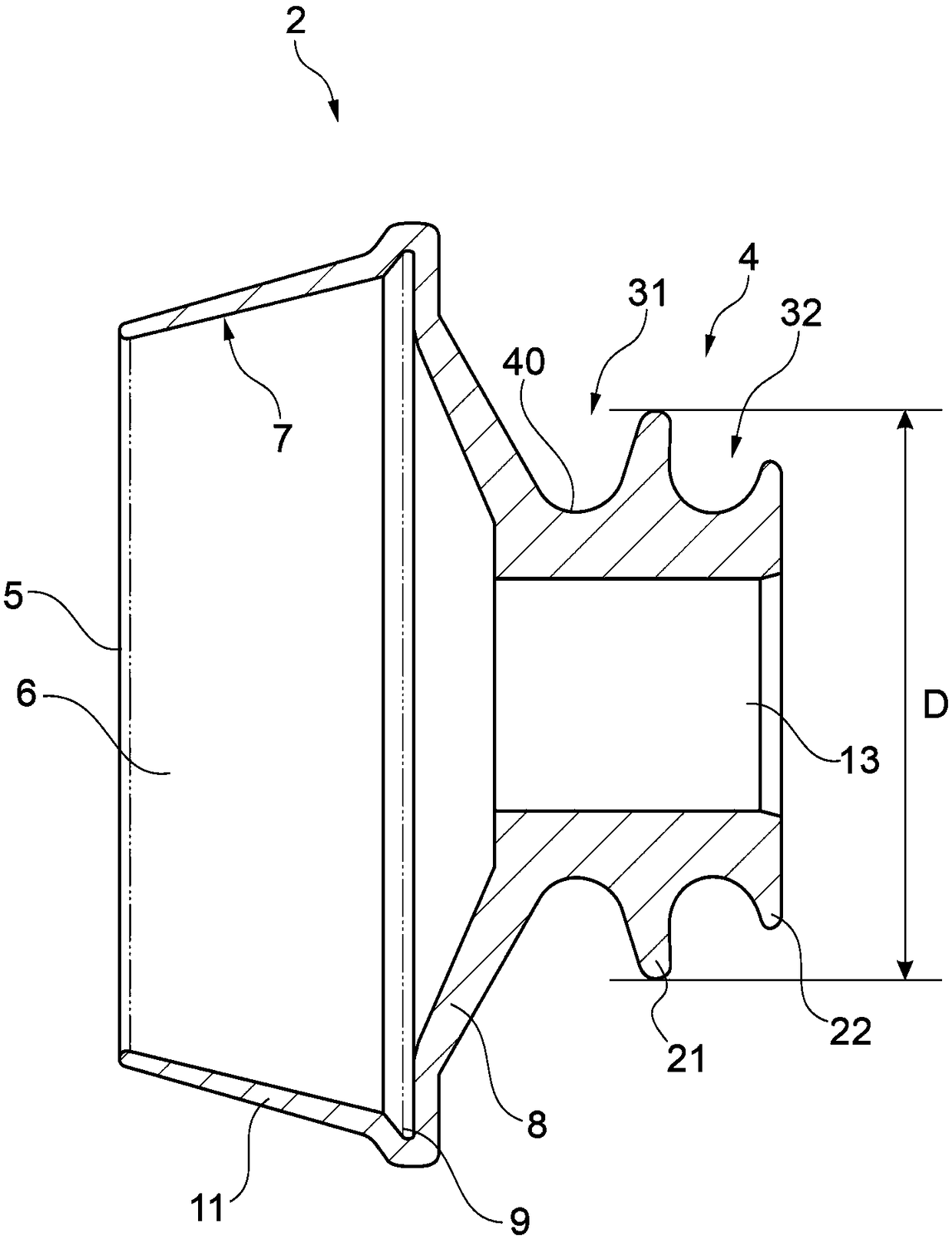

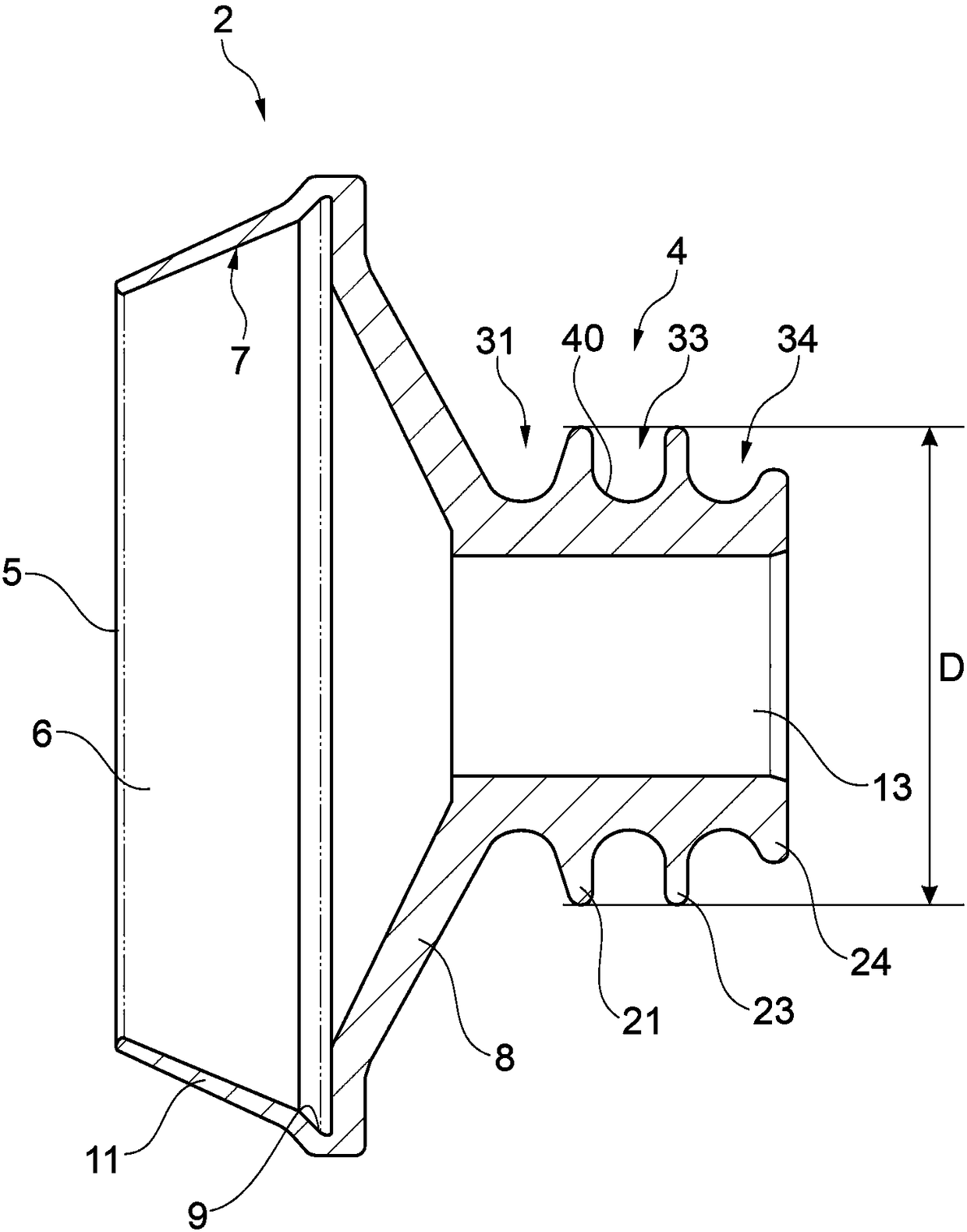

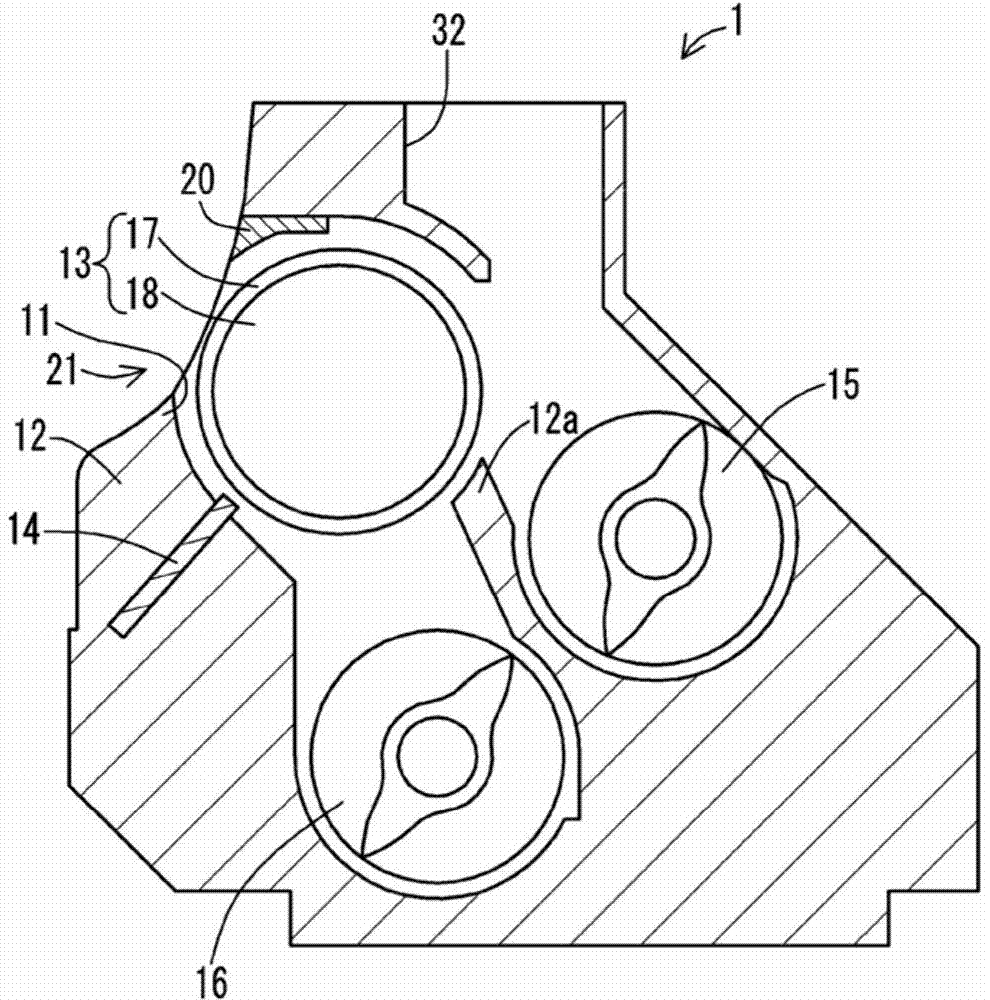

Open-end spinning device and spinning rotor for open-end spinning device

ActiveCN108166110AMeet all requirementsLight in massContinuous wound-up machinesOpen-end spinning machinesEngineeringAirflow

The present invention relates to an open-end spinning device and a spinning rotor (1) for the open-end spinning device (20). The spinning rotor comprises a rotor disk (2) and a rotor shaft (3). The rotor disk (3) has an annular wall section (11), a rotor base (8) and a collar (4). The collar (4) is connected to the rotor base (8) and has a bore (13) which accommodates the rotor shaft (3). According to the invention, the collar (4) has at least one annular web (21, 23) on its outer circumference, the outer diameter of which defines the outer diameter (D) of the collar (4), and the collar (4) has at least one circumferential depression (31, 32, 33, 34) for forming the at least one annular web (21,23).

Owner:SAURER GERMANY GMBH & CO KG

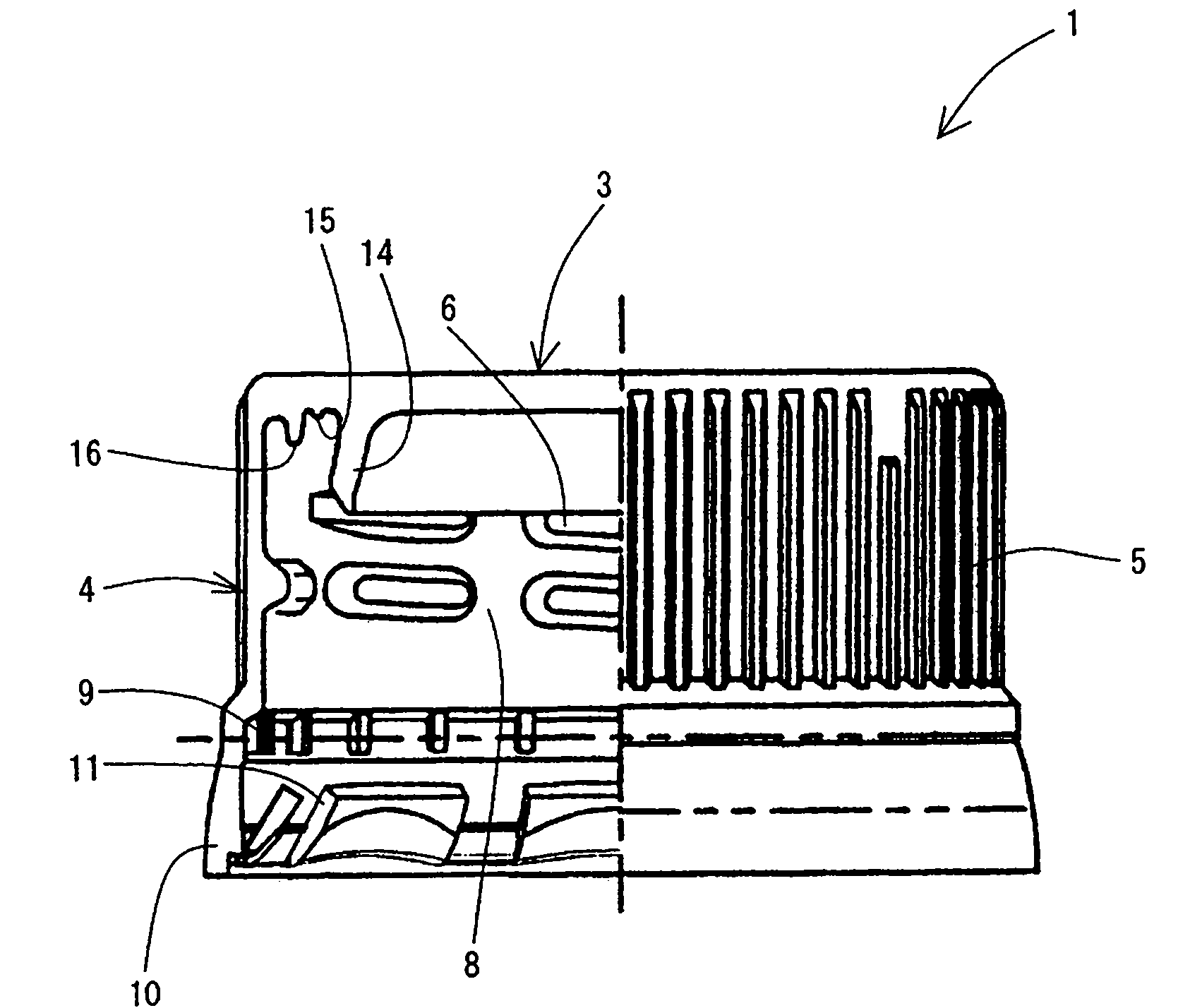

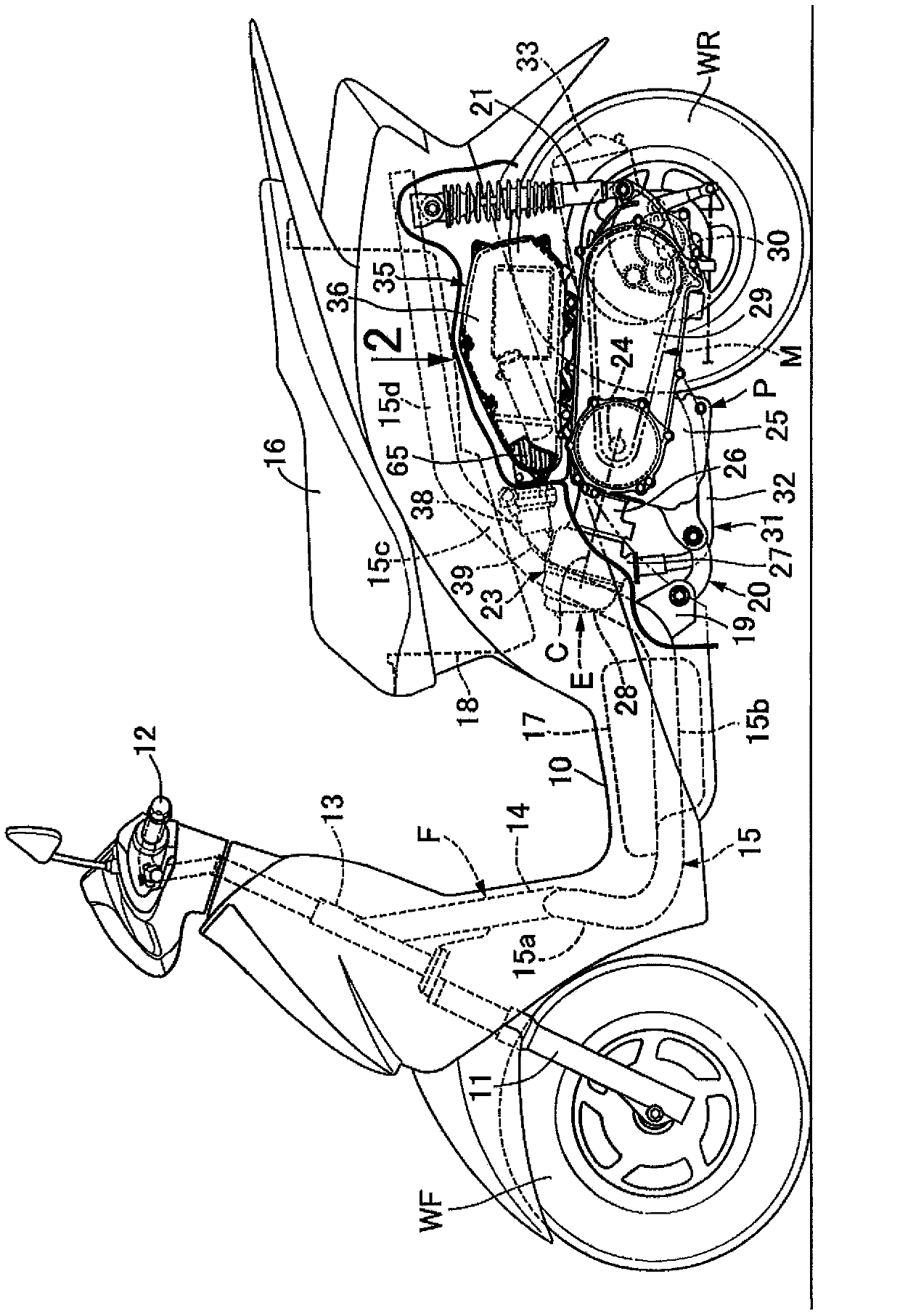

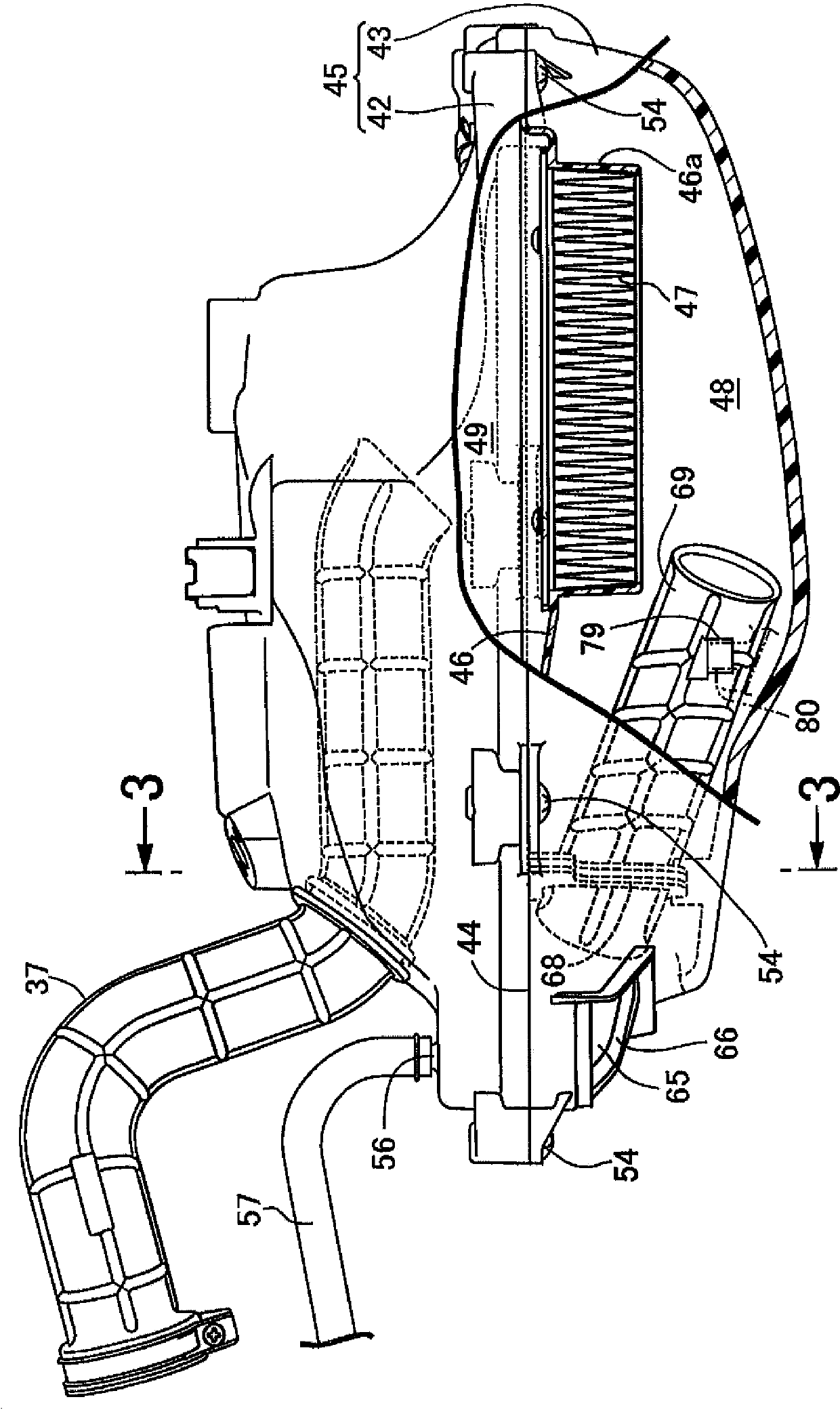

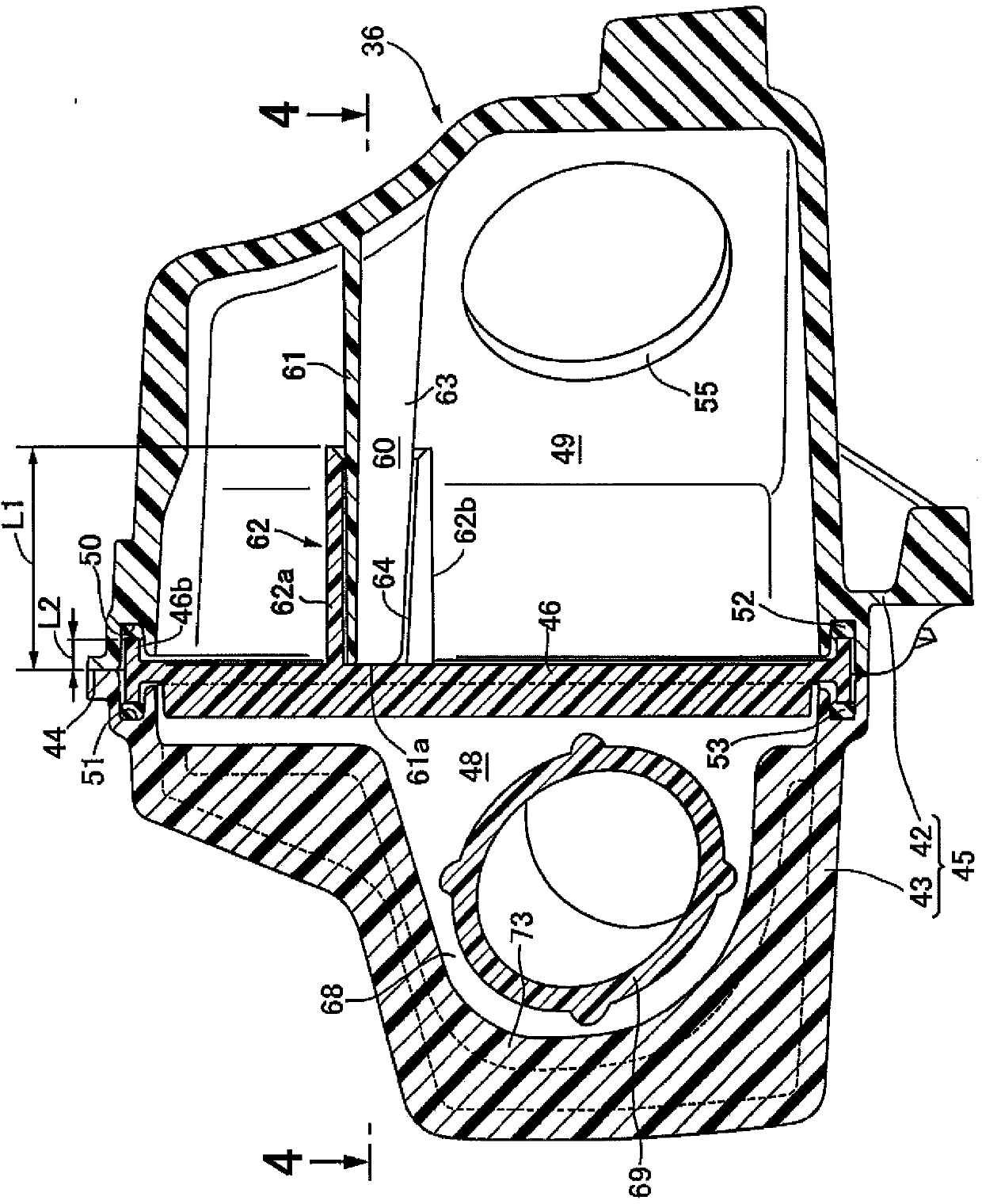

Air filter of internal combustion engine for saddle type vehicle

ActiveCN103967659AInhibit sheddingReduce in quantityCombustion-air/fuel-air treatmentMachines/enginesAir filterInternal combustion engine

An air filter of an internal combustion engine for a saddle type vehicle. A shell main body and a shell cover are bonded on a bonding surface extending along a vertical direction and a filter element bearing plate clamped between the shell main body and the shell cover is provided with a filter element of the filter, reduction of the number of components and simplification of the structure can be realized without affecting the appearance of the vehicle, and disengagement of the filter element bearing plate is prevented during maintenance. An inner wall of the shell main body (42) is provided with a first protruding wall (61), the first protruding wall (61) protrudes towards the filter element bearing plate (46) side, a tail end part (61a) of the first protruding wall (61) approaches or abuts against the filter element bearing plate (46), the filter element bearing plate (46) is provided with a second protruding wal (62) in a protruding manner, and the second protruding wall abuts against or approaches and coincides with the first protruding wall (61) at least from upper and lower sides.

Owner:HONDA MOTOR CO LTD

Developing apparatus and image forming apparatus

ActiveCN104730882AHigh densityAvoid flyingElectrographic process apparatusImage formationEngineering

A developing apparatus including a layer thickness adjustment member configured to regulate a layer thickness of a two-component developer carried on a surface of a developing sleeve of a developing roller is disposed so that one end portion in a width direction faces the surface of the developing sleeve at a predetermined interval. At two end portions in a longitudinal direction of the layer thickness adjustment member, a notch open to the one end side in the width direction is provided. Since an amount of conveyance of the developer locally increases at two end portions of the developing sleeve by providing such a notch in the layer thickness adjustment member, density of an ear of a magnetic brush to be formed increases, and it is possible to exhibit the sufficient seal performance and prevent the toner from being scattered.

Owner:SHARP KK

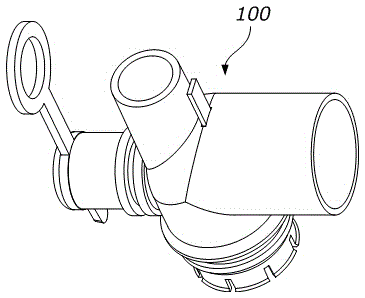

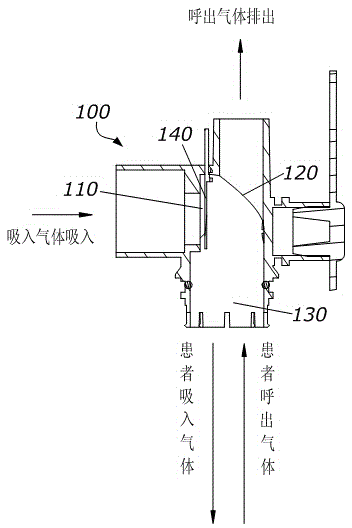

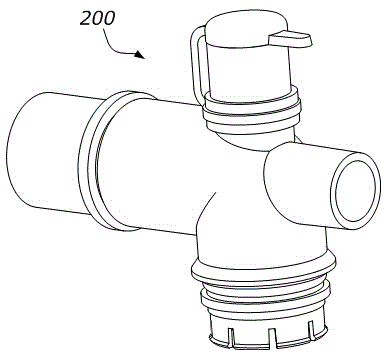

Breather valve and application method thereof

The invention discloses a breather valve and an application method thereof. The breather valve comprises a breather tube, a valve plate and a return spring; the valve plate is disposed within the breather tube; the return spring used for returning the valve plate is disposed within the breather tube. The return spring allows the valve plate to be returned in time when a patient breathes, sealing is insufficient, and no leakage occurs.

Owner:VINCENT MEDICAL (DONG GUAN) MFG CO LTD

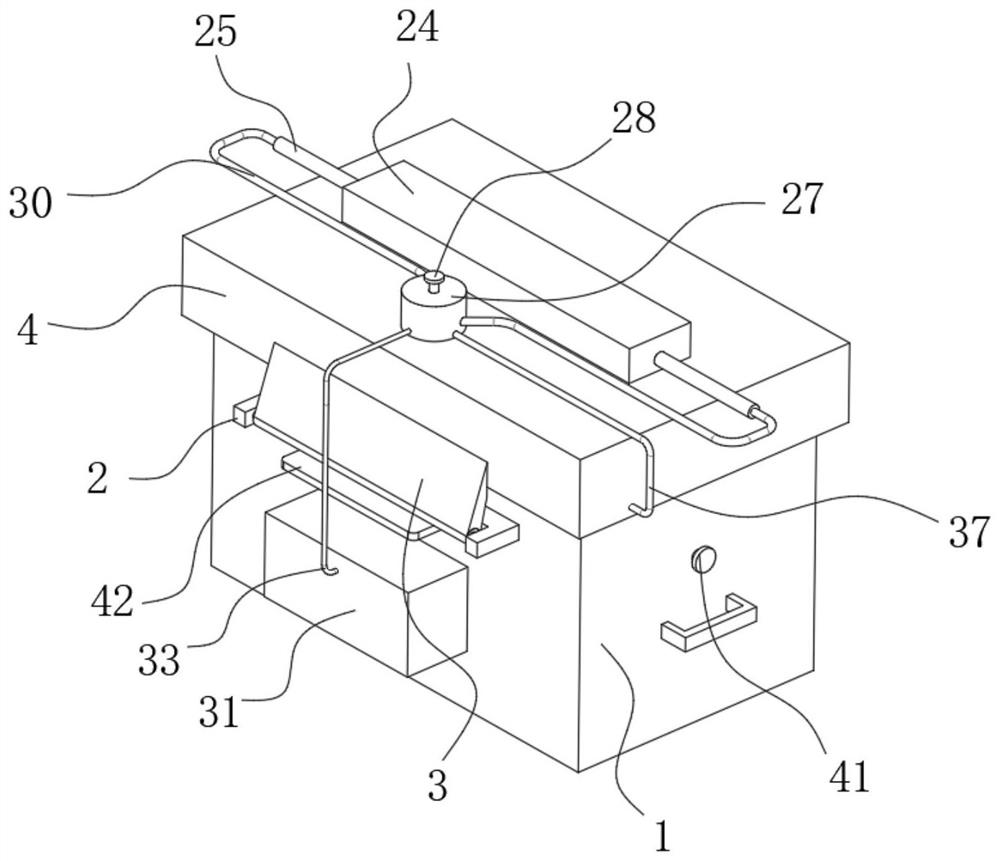

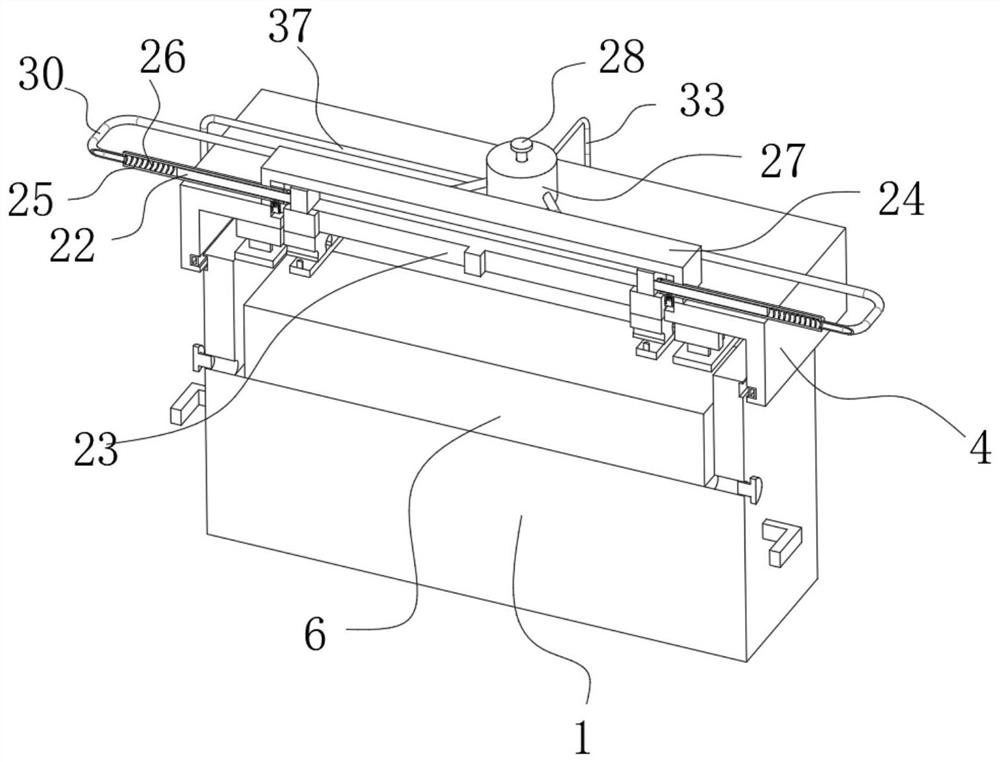

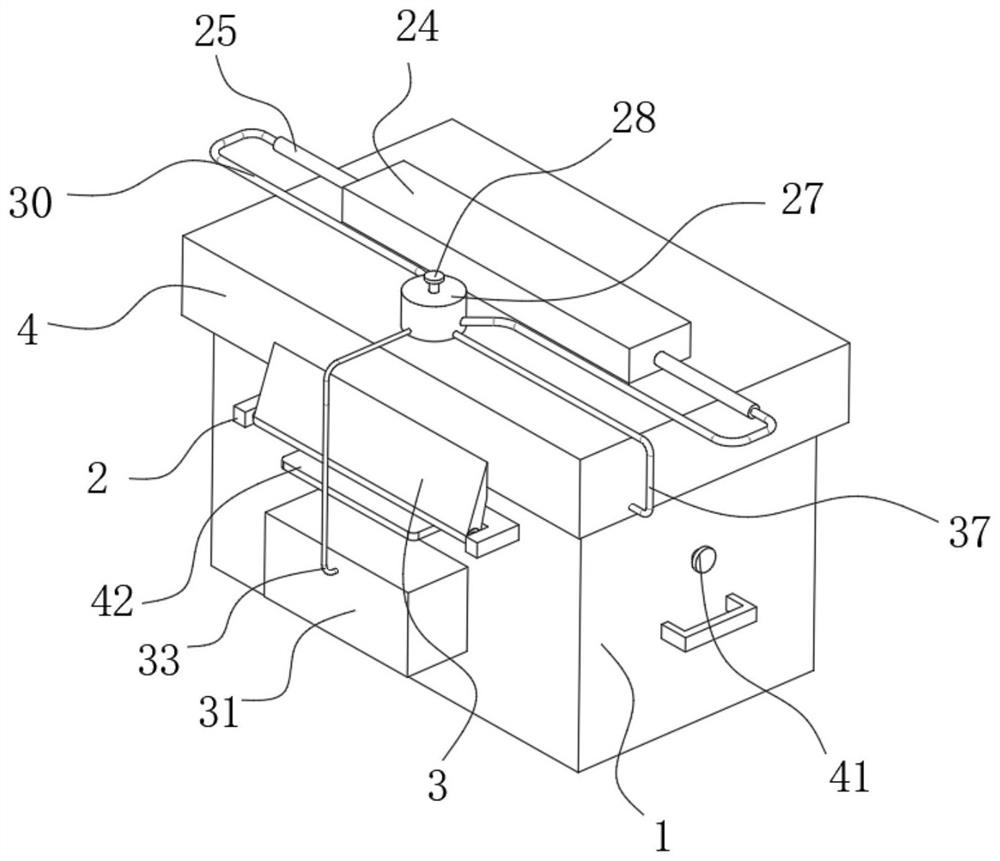

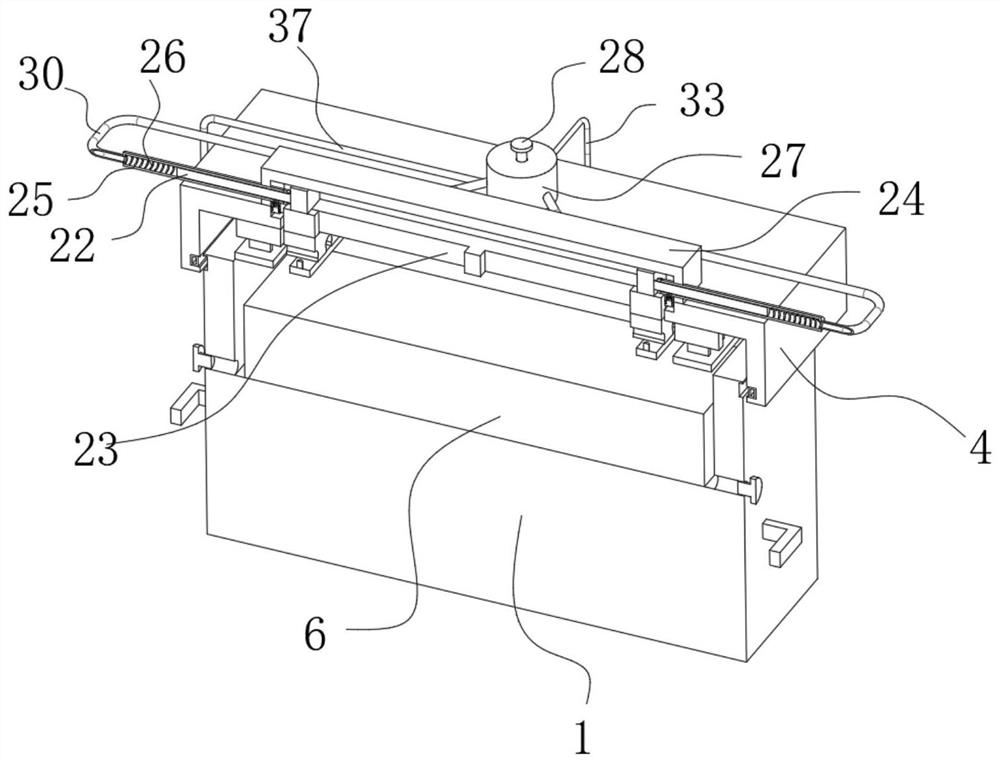

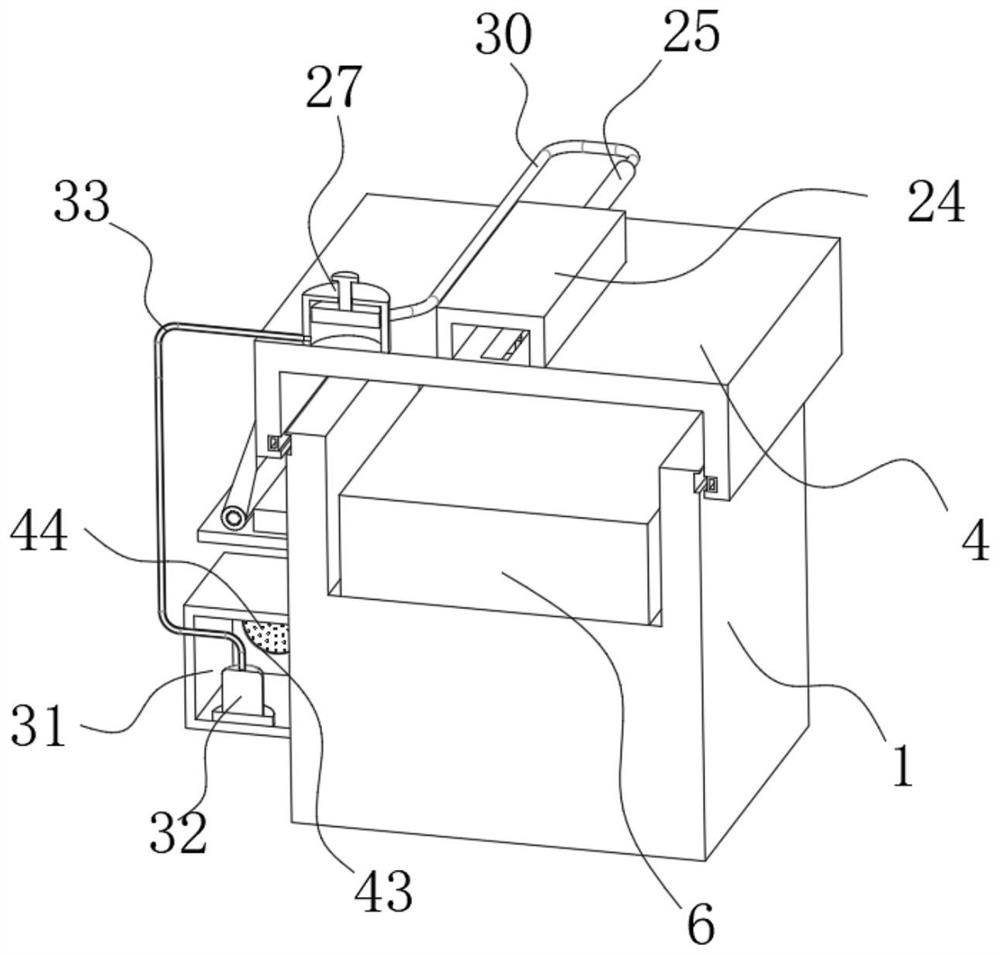

Electric power detection equipment convenient to use

PendingCN114755466ARealize limitAchieve clampingHermetically-sealed casingsMeasurement instrument housingStructural engineeringMechanical engineering

The invention belongs to the technical field of electric power detection equipment, and discloses electric power detection equipment convenient to use, which comprises a detection box and a sealing cover, a mounting cavity is formed in the detection box, an equipment seat is fixedly mounted on the inner surface of the mounting cavity, and a partition plate is fixedly connected to the inner surface of the sealing cover. The sleeve rod is pushed to move, so that the top plate and the sliding plate push the movable seat to move, and the movable seat moves to pull the movable end of the detection line to move, so that the multiple groups of detection lines pull the detection line to slide along the partition plate, and automatic carding and arrangement of the multiple groups of detection lines are realized; in the next use process, the sealing cover is opened, and the sorted detection line is directly selected from the inner surface of the sealing cover, so that disordered arrangement of detection is effectively avoided, the target detection line is conveniently selected, the convenience in actual power detection is improved, the efficiency of emergency power detection is improved, power failure reasons are diagnosed in advance, and the use effect is good.

Owner:彭林辉

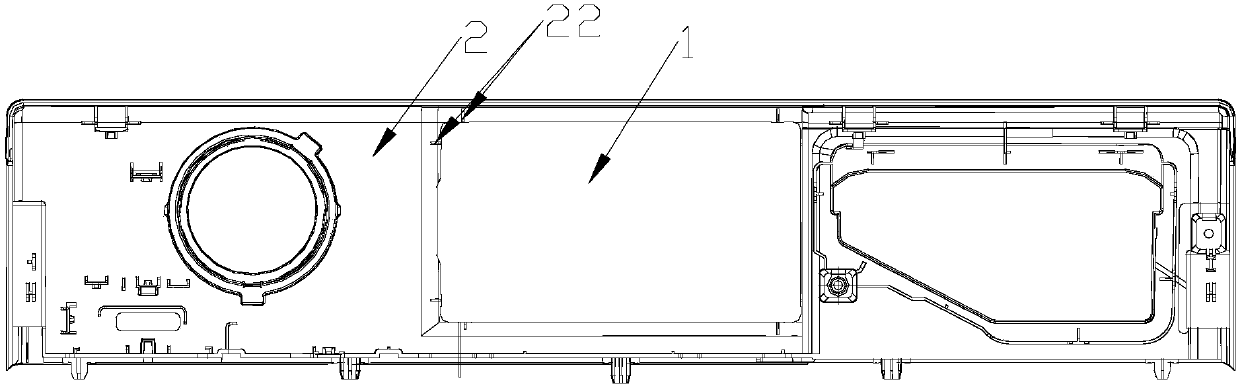

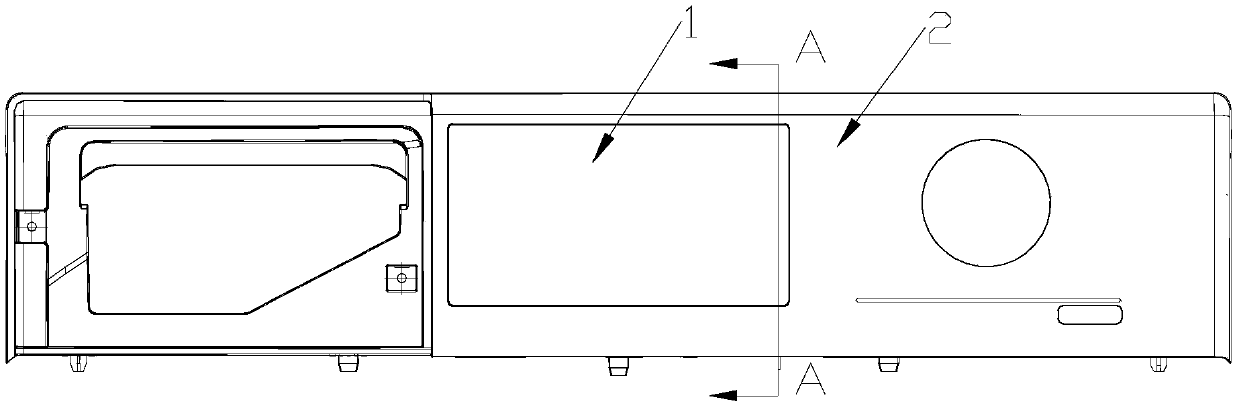

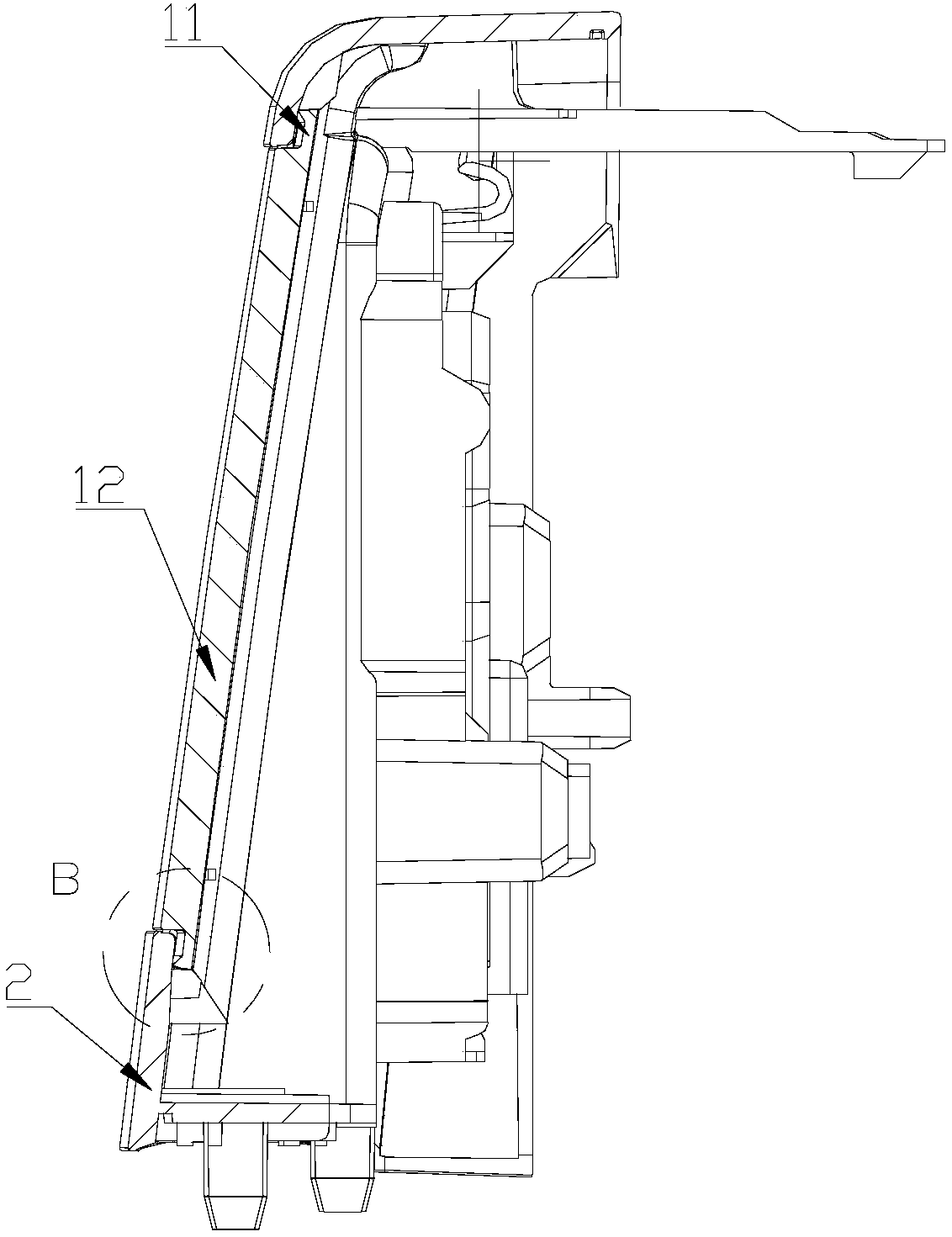

Welding method for electrical appliance display device

The invention discloses a welding method for an electrical appliance display device. The electrical appliance display device comprises a display structure and a mounting structure, wherein the displaystructure is ultrasonically welded on the mounting structure; the mounting structure comprises a mounting hole; the display structure is at least partially arranged in the mounting hole in a sleevedmode; and a distance between the mounting hole in the front surface of the mounting structure and the display structure is smaller than that between a mounting hole in the back surface of the mountingstructure and the display structure. The welding method solves the problem that poor visual effect of a user is caused as a gap, seen from appearance, between the mounting structure and the display structure is great if a pattern withdrawing angle is gradually increased from the back surface of the mounting structure to the front surface of the mounting structure.

Owner:HEFEI HAIER DRUM WASHING MASCH CO LTD +1

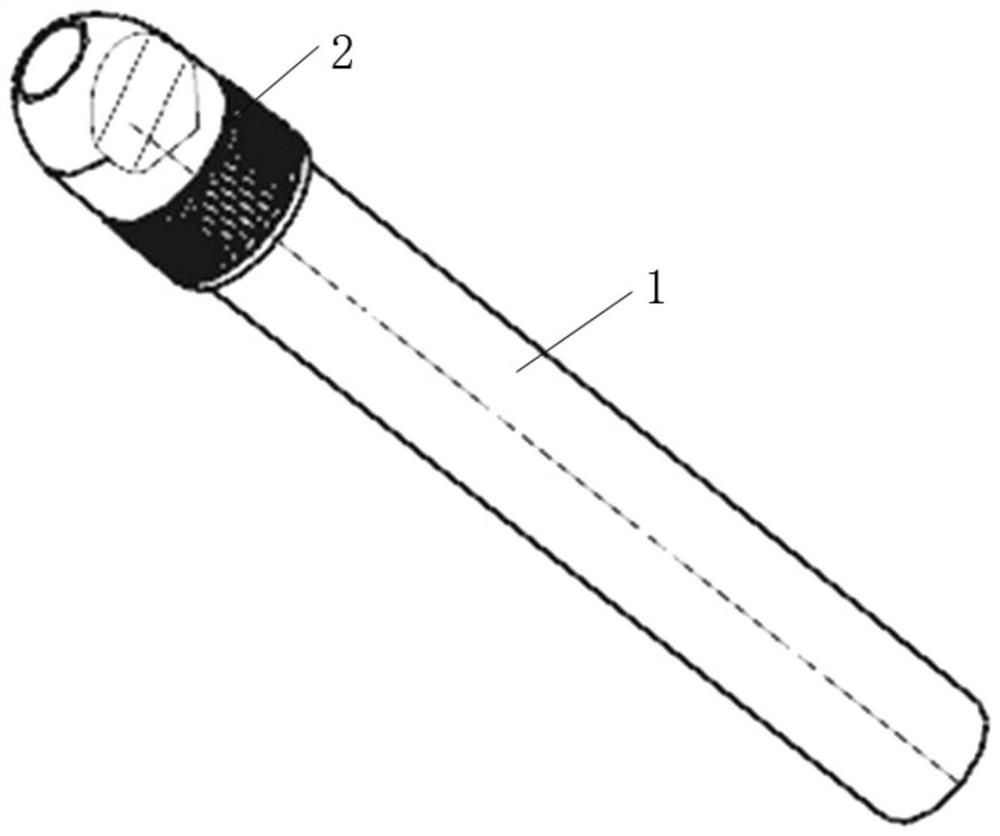

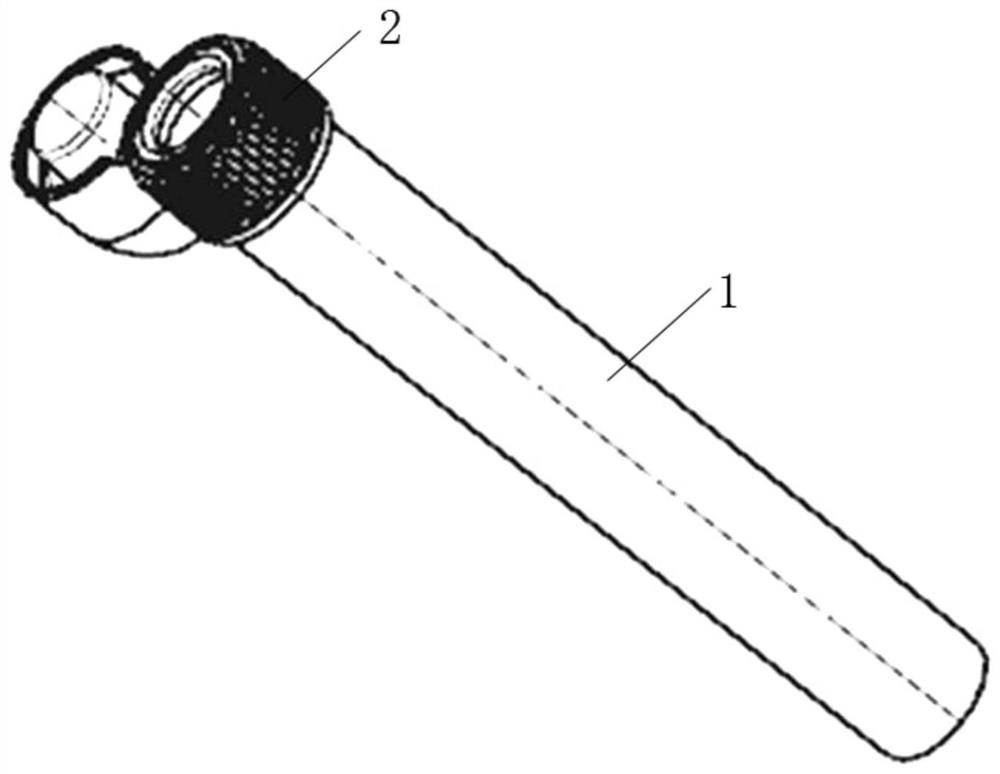

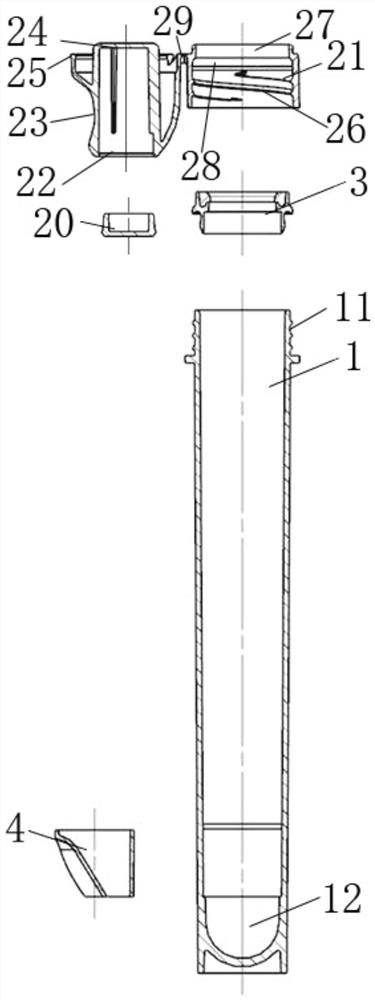

Combined sealed test tube cover and sealed test tube

PendingCN111808733AGuaranteed accuracyMeet the collection requirementsBioreactor/fermenter combinationsBiological substance pretreatmentsInterference fitFluid Leak

The invention provides a combined sealed test tube cover. The combined sealed test tube cover comprises an upper cover, a lower cover and a sealing part, wherein the upper cover can be buckled above the lower cover; the lower cover is provided with internal threads matched with external threads at the opening of a test tube body; the lower cover is fixedly installed on the tube body through threads; the lower cover, the upper cover and the sealing part are coaxially arranged; the sealing part is fixedly installed on the inner side of the lower cover; the lower end of the sealing part is in interference fit with the inner side of the tube body; and the upper end of the sealing part is in interference fit with an annular protrusion at the middle part of the upper cover. In the using processof the combined sealed test tube cover and the sealed test tube, single-hand operation is achieved, and force application is easy and convenient; and through the arrangement of the sealing part, the lower cover and the tube body as well as the upper cover and the lower cover are fully sealed, the possibility of air leakage and liquid leakage is eradicated, and therefore, the accuracy and precisionof an experiment can be fully guaranteed.

Owner:北京奥博星生物科技有限公司

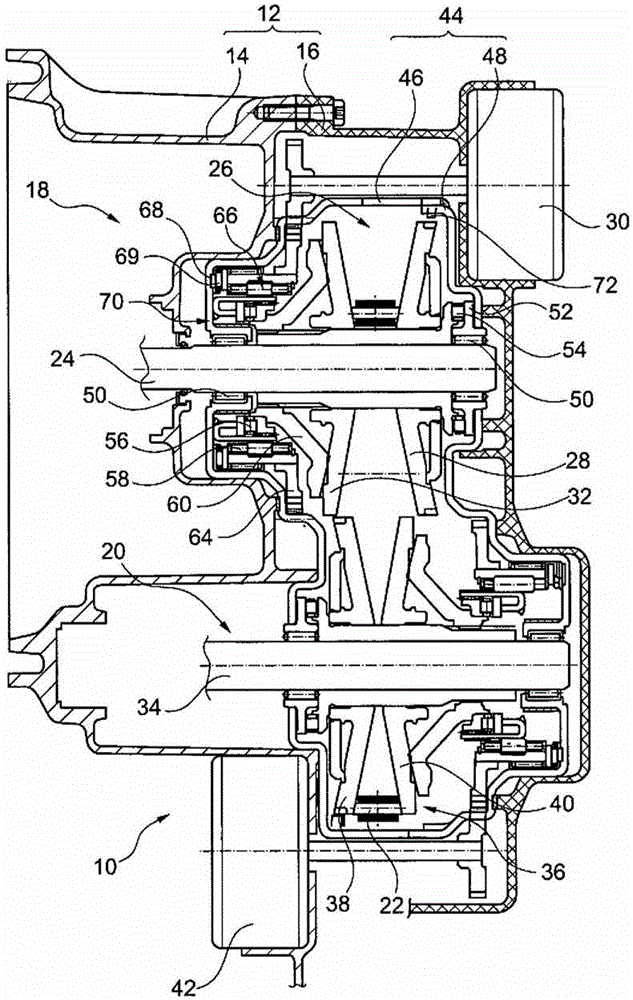

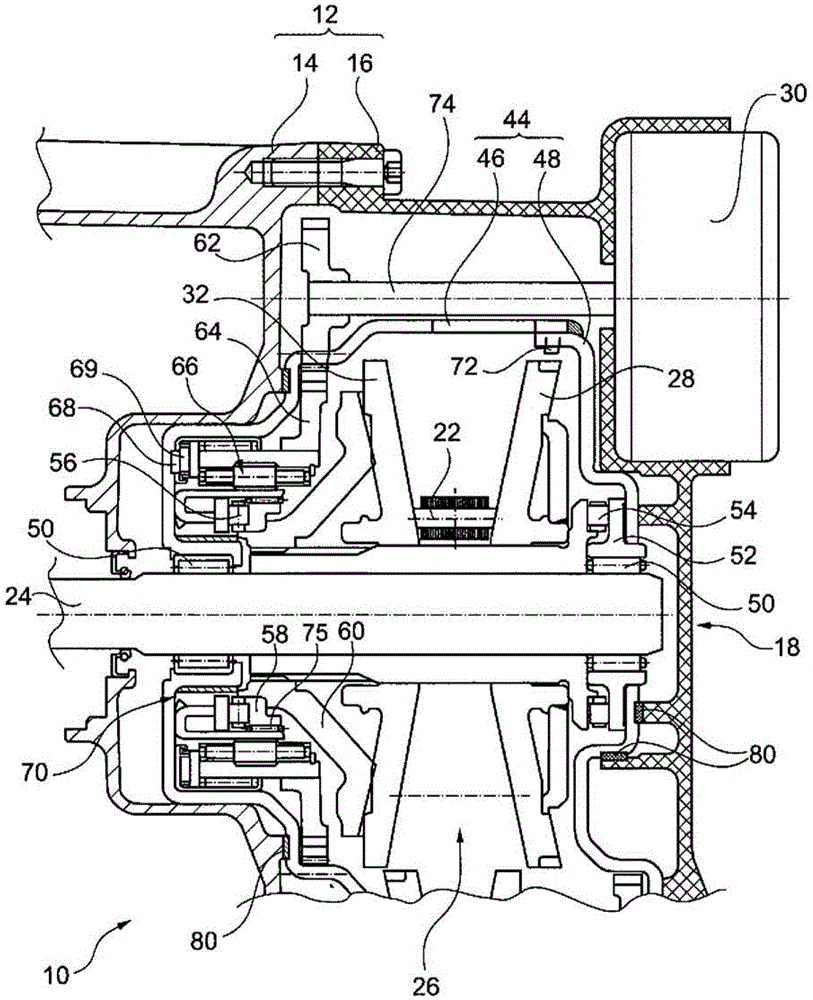

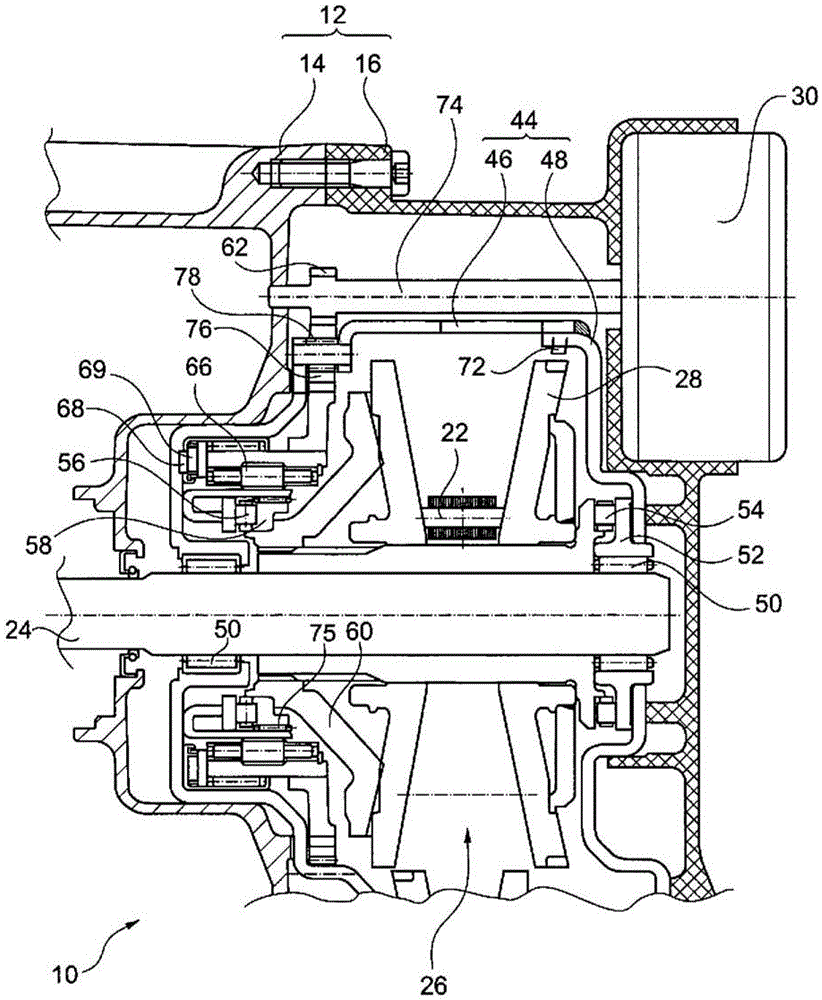

CVT

The invention relates to a CVT transmission for an essentially continuously variable transmission of a torque, comprising a first conical disk pair on the input side having a first adjusting disk moving in the axial direction relative to a first counter disk, a second conical disk pair on the output side having a second adjusting disk moving in the axial direction relative to a second counter disk, and further comprising a belt means which is received by the first and the second conical disk pair for transmitting the torque from the first conical disk pair to the second conical disk pair, an essentially electrically driven first adjustment device for pressing the belt means between the first counter disk and the first adjusting disk and an essentially electrically driven second adjustment device for pressing the belt means between the second counter disk and the second adjusting disk. According to the invention, the second adjustment device can be actuated independently from the first adjustment device for varying the pretension of the belt means. As a result, the CVT transmission is characterized by little wear over a high torque range.

Owner:SCHAEFFLER TECH AG & CO KG

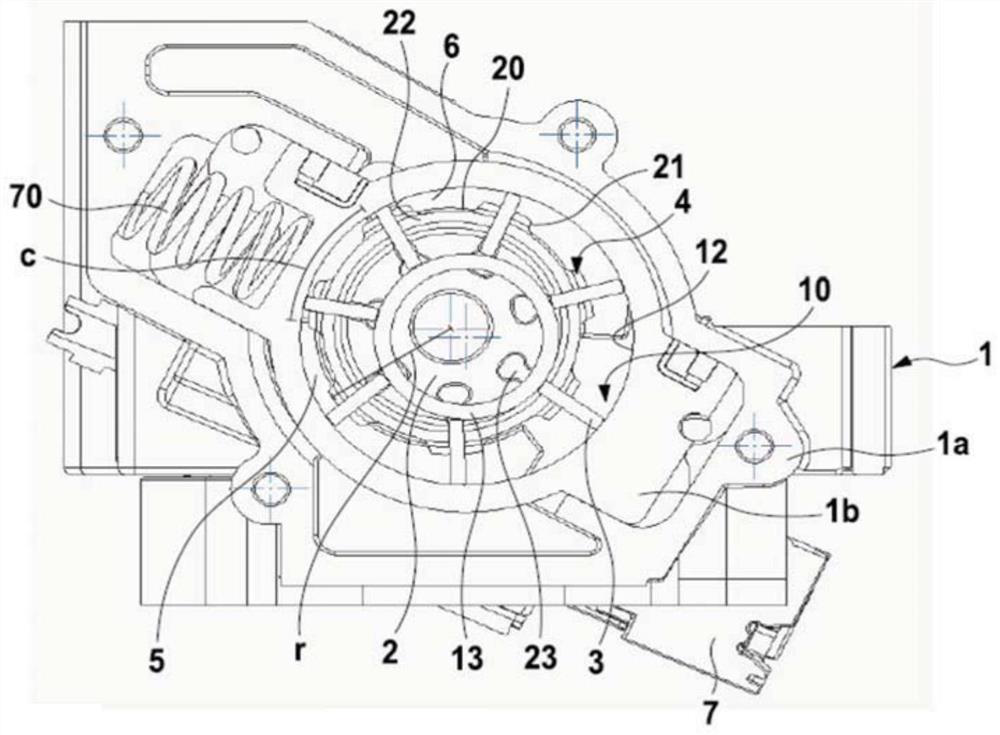

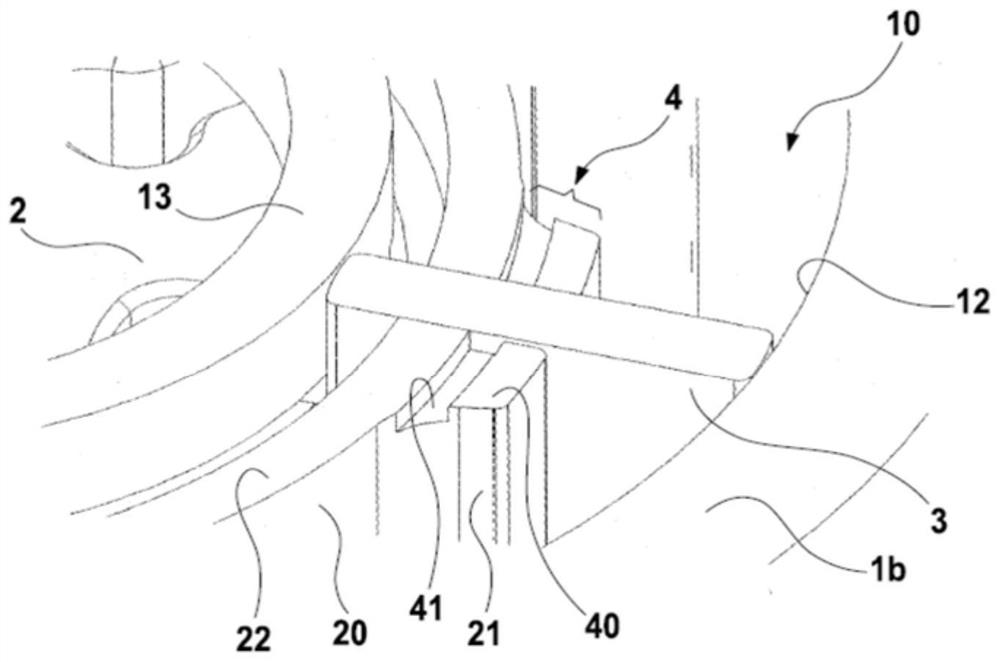

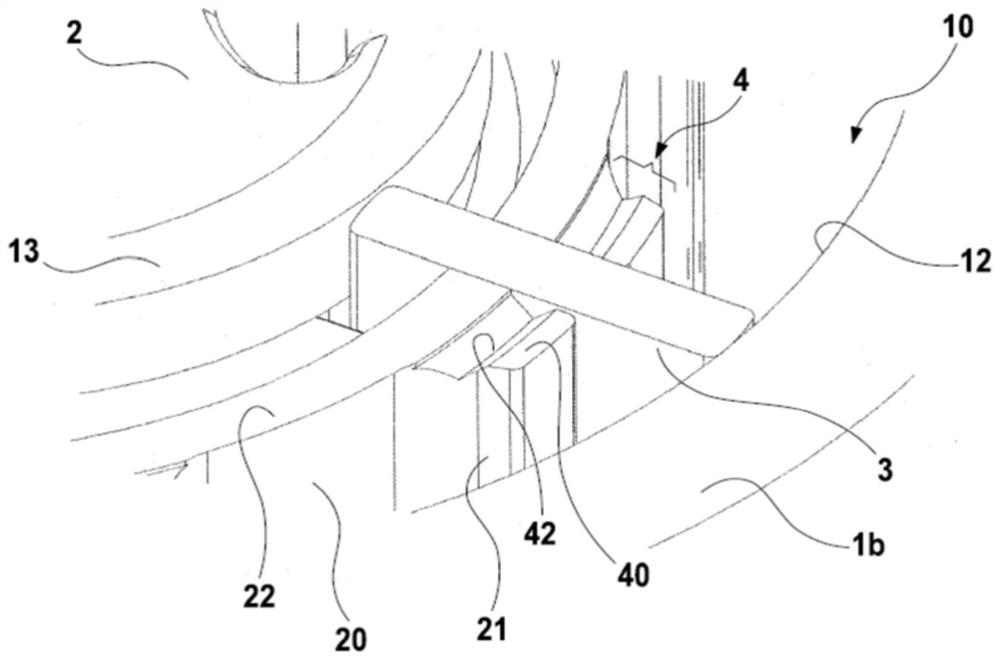

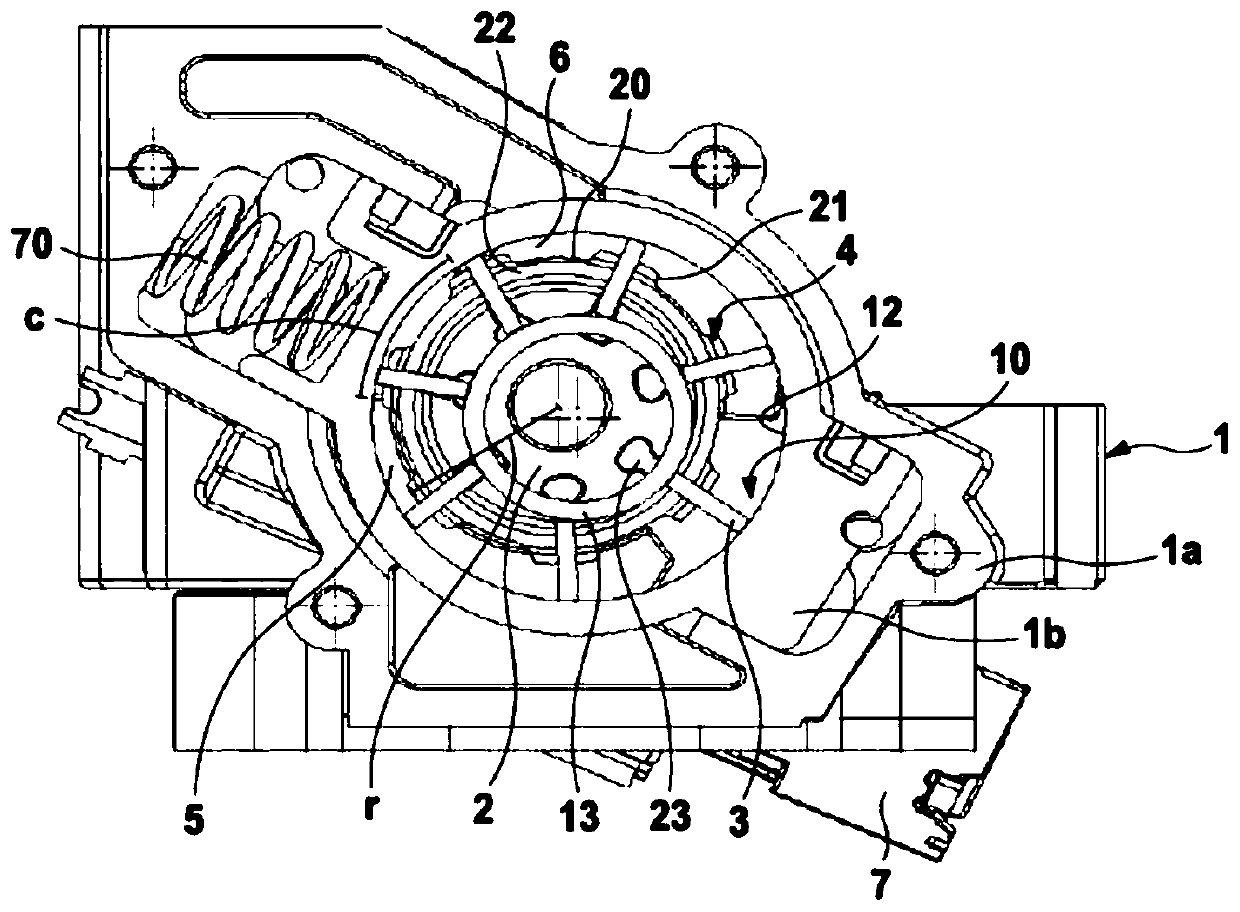

Flow Optimized Vane Pumps

ActiveCN111556928BReduce short-term high pressure peaksEffective distance minimizationRotary piston pumpsRotary piston liquid enginesPump chamberViscous oil

The invention relates to a vane pump for conveying liquid (especially viscous oil), comprising: a rotor (2) having a sliding groove (23) in which a slidable vane (3) is accommodated and which can be moved relative to the radius of the rotor ( r) indentation; the pump housing (1) with the pump chamber (10) housing the rotor (2); and the inlet (5) and outlet (6) towards at least The end side of the rotor (2) is open into the pump chamber (10); wherein around the circumference of the rotor (2) radial elevations (21) protruding towards the sliding slots (23) form the recesses to the retractable vanes (3) The rotor radius (r) on either side, and at the radially raised portion (21), the radially recessed portion (20) is recessed relative to the rotor radius (r). In the radial elevation (21), on at least one end side of the rotor (2) to which the inlet (5) and the outlet (6) are open, a recess (4) is formed which provides a Rotary servo control geometry for pressure peaks in the small vane chamber.

Owner:尼得科GPM有限公司

Flow-optimised vane pump

ActiveCN111556928AReduce short-term high pressure peaksEffective distance minimizationRotary piston pumpsRotary piston liquid enginesViscous oilPump chamber

The invention relates to a vane pump for conveying liquids, in particular viscous oils, which vane pump comprises: a rotor (2) having sliding slots (23) in which movable vanes (3) are held and can becountersunk in relation to a rotor radius (r); a pump housing (1) comprising a pump chamber (10), which encloses the rotor (2); and an inlet (5) and an outlet (6), which open into the pump chamber (10) at at least one end face of the rotor (2); radial elevations (21) protruding, with respect to the sliding slots (23), over the circumference of the rotor (2), which elevations form a rotor radius (r) on either side of the vanes (3) that can be countersunk, and radial pockets (20) being recessed, relative to the rotor radius (r), between the radial elevations (21). Within the radial elevations (21), recesses (4) are formed on the at least one end face of the rotor (2) at which the inlet (5) and the outlet (6) open, which recesses provide rotating anticipatory control geometry for reducing pressure spikes in the vane cells.

Owner:尼得科GPM有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com