Sealant film, multilayer film using same and packaging bag

一种密封剂、多层膜的技术,应用在包装袋,多层膜领域,能够解决透过多层膜透过率降低、内容物内容物质量劣化等问题,达到低吸附性优异、充分低温密封性和密封强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

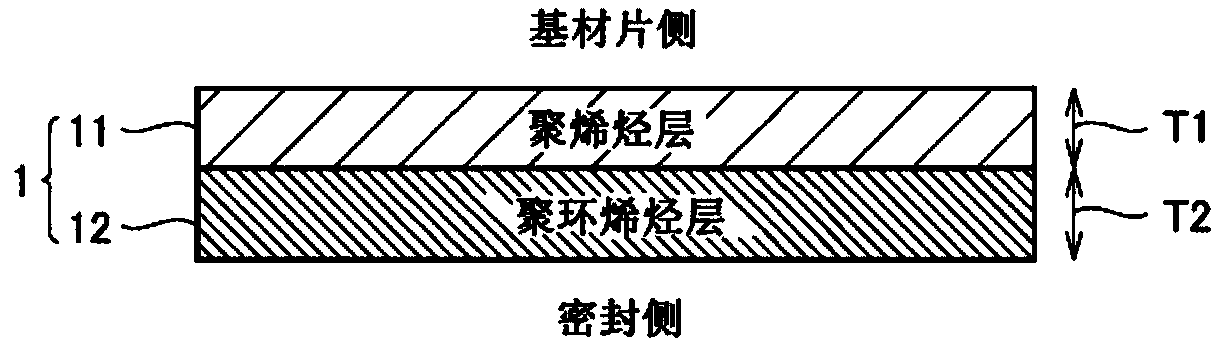

[0072] refer to figure 1, the sealant film 1 of the present embodiment is a sealant film made of two layers of a polyolefin layer 11 (on the substrate sheet side) and a polycycloolefin layer 12 (on the sealing side).

[0073] (polyolefin layer: on the substrate sheet side)

[0074] The polyolefin layer 11 contains polyolefin as a main component. The expression "contains as a main component" means, for example, that the content of polyolefin is more than 50% by mass with respect to the total amount of polyolefin layer 11, and the content of polyolefin is preferably 80% by mass or more, more preferably 90% by mass or more (same below).

[0075] As the polyolefin, polyethylene can be suitably used. As the polyethylene, for example, low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE) can be suitably used.

[0076] (Polycycloolefin layer: on the sealing side)

[0077] The polycycloolefin layer 12 contains polycycloolefin as a main component. Other polym...

Embodiment approach 2

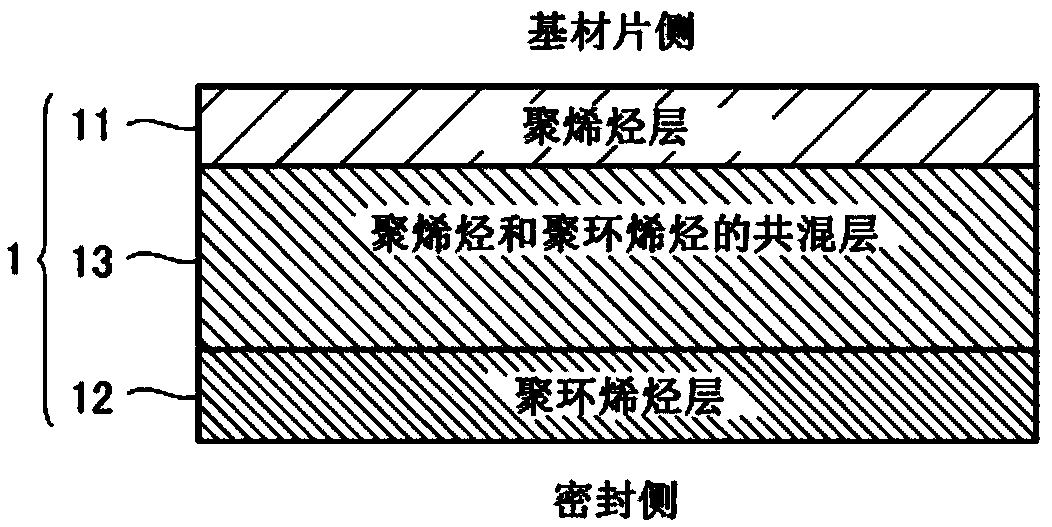

[0097] refer to figure 2 , the sealant film of this embodiment is the same as the sealant film of Embodiment 1, except that a polyolefin and polycycloolefin blend resin is provided between the polyolefin layer 11 and the polycycloolefin layer 12. The blended layer 13.

[0098] Preferably, the blend layer 13 is obtained by recycling the polycycloolefin material produced when both ends of the elongated polycycloolefin layer 12 are cut by trimming during production. In other words, the blend layer 13 is preferably composed of a blended resin of recycled polycycloolefin and polyolefin.

[0099] By providing such a blend layer 13 , even when the thickness of the polycycloolefin layer 12 becomes thinner, the same effect can be obtained compared with the case where there is no blend layer 13 . Therefore, the raw material cost of polycycloolefin which is a relatively expensive material can be reduced.

[0100]

Embodiment approach 3

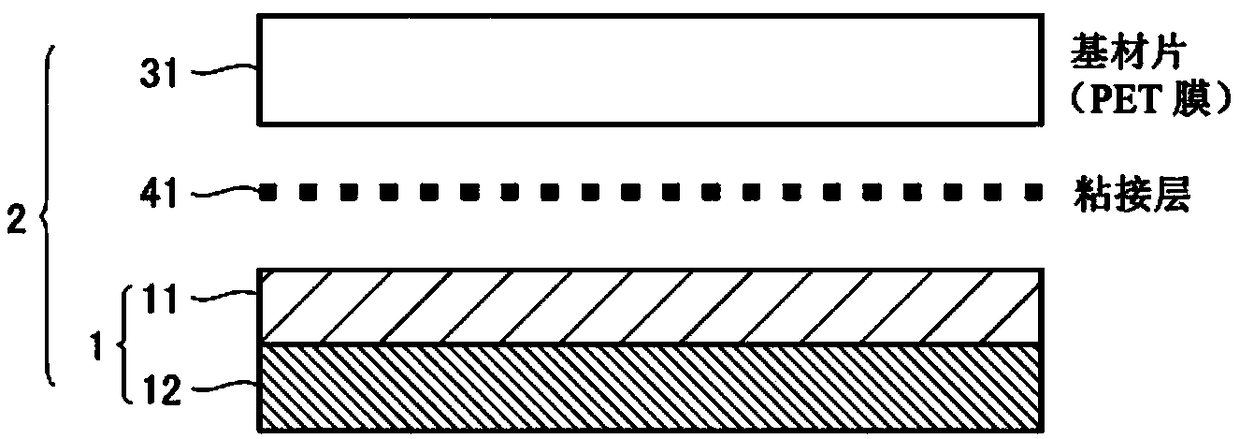

[0102] refer to image 3 , The multilayer film 2 (packaging material) of the present embodiment is a multilayer film obtained by sequentially laminating the sealant film 1 of Embodiment 1, the adhesive layer 41 and the base material sheet 31 .

[0103] As the base material sheet 31, the constituent material is not particularly limited, but a plastic film, paper, nonwoven fabric, etc. can be used as long as it has mechanical strength and dimensional stability. Examples of constituent materials of the plastic film include polyesters such as polyethylene terephthalate (PET) or polyethylene naphthalate, polyolefins such as polypropylene, polystyrene, such as 6- Polyamides such as nylon, polycarbonate, polyacrylonitrile and polyimide. The plastic film is preferably a biaxially stretched film. In the present embodiment, the base material sheet 31 is a PET film.

[0104] As the adhesive constituting the adhesive layer 41 , the constituent material is not particularly limited, but ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat seal strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com