Flow Optimized Vane Pumps

A vane pump and vane technology, applied in the field of flow-optimized vane pumps, can solve problems affecting the volumetric efficiency of the pump, achieve the effects of suppressing the decline in volumetric efficiency, reducing the generation of high-pressure peaks, and preventing hydraulic short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

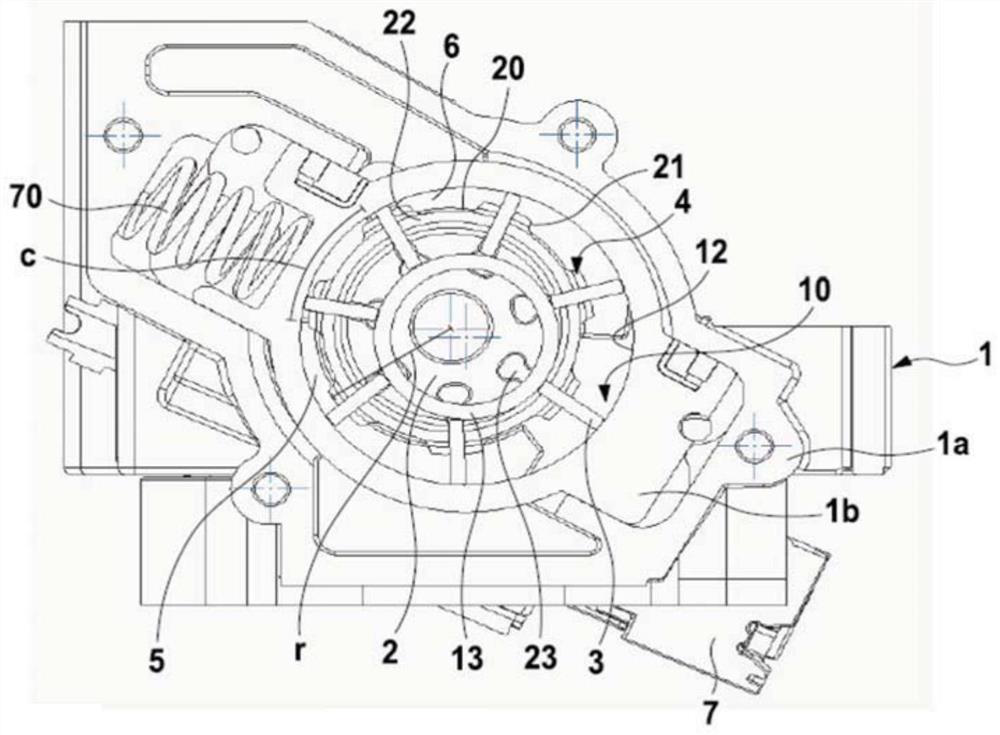

[0031] will be referred to below Figure 1 to Figure 3 The structure of the vane pump according to the present invention will be described.

[0032] figure 1 Shows a view of an open pump housing 1 of a variable volume vane pump from which the pump cover has been removed. In order to be able to set the delivered volumetric flow independently of the rotational speed of the pump, the pump has a variable pump geometry that is adjusted with the displacement between the two housing parts.

[0033] The housing part 1a constitutes the main part of the pump housing 1 and houses the inlet 5, the outlet 6 and the actuator 7 with the return spring 70 therein. Furthermore, the rotor 2 is rotatably mounted in the housing part 1a, whereby the rotor 2 and the housing part 1a define fixed parts with respect to the adjustment movement of the variable pump geometry. The lifting ring 1b comprising the pump chamber 10 is housed in the outer shell part 1a in a displaceable manner together with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com