Welding method for electrical appliance display device

A technology of a display device and a welding method, which is applied to the welding field of electrical display devices, can solve the problems of different sizes of gaps, stress concentration, poor appearance, etc., and achieves the advantages of ensuring connection firmness, preventing gap overflow, and increasing the accommodating range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

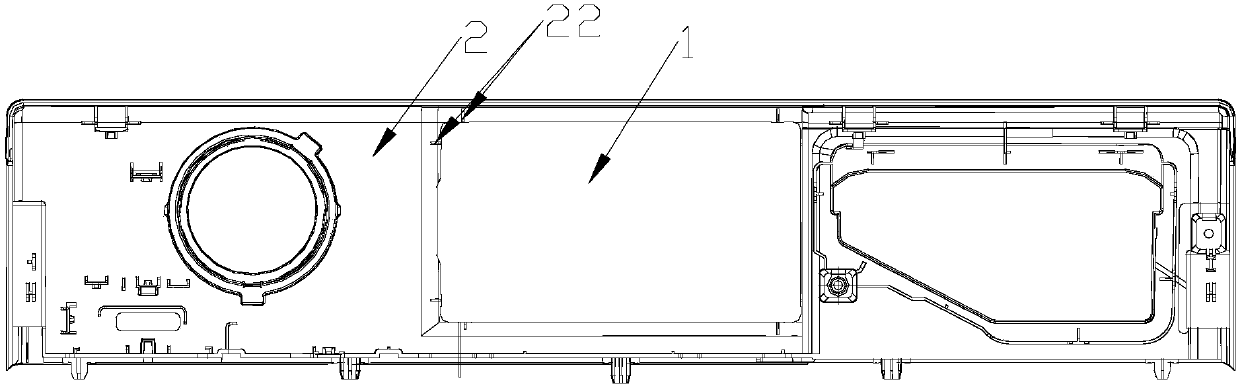

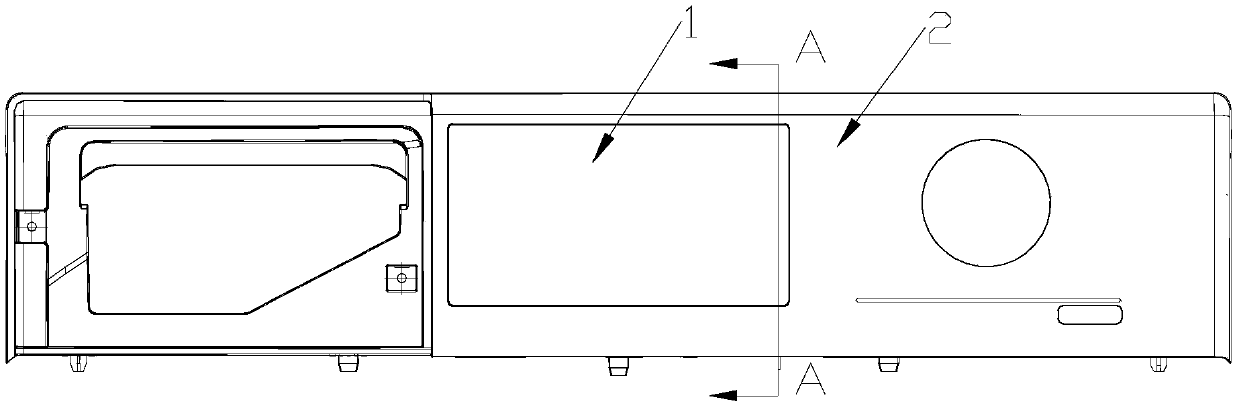

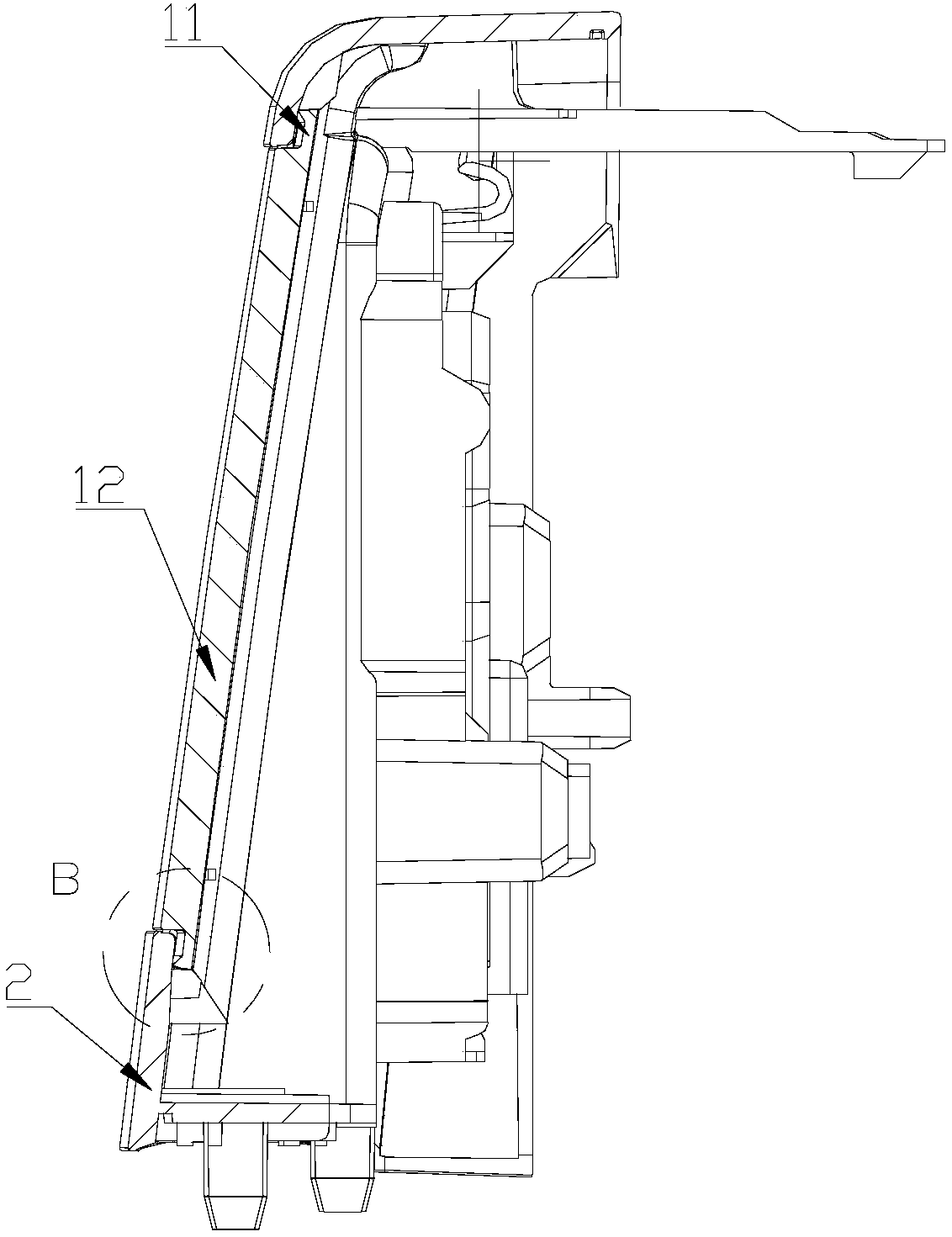

[0042] Such as Figure 1-Figure 6 As shown, a welding method for an electrical display device, the electrical display device includes a display structure 1 and a mounting structure 2, the display structure 1 is ultrasonically welded on the mounting structure 2, the mounting structure 2 includes a mounting hole, and the display structure 1 is at least partially fitted in the mounting hole, and the distance between the mounting hole on the front of the mounting structure 2 and the display structure 1 is smaller than the distance between the mounting hole on the back of the mounting structure 2 and the display structure 1.

[0043] In the above solution, the display structure 1 and the installation structure 2 of the electrical display device are connected and fixed by ultrasonic welding, which can not only ensure the firmness of the connection, but also ensure sufficient sealing, and protect the internal electrical components from water vapor, Damage from debris, etc. The insta...

Embodiment 2

[0056] In this embodiment, a welding method for an electrical display device, the electrical display device includes a display structure 1 and a mounting structure 2, the display structure 1 is ultrasonically welded on the mounting structure 2, the mounting structure 2 includes a mounting hole, the The display structure 1 is at least partially fitted in the installation hole, and the distance between the installation hole on the front of the installation structure 2 and the display structure 1 is smaller than the distance between the installation hole on the back of the installation structure 2 and the display structure 1 .

[0057] Compared with the first embodiment, the difference between the second side 24 and the display structure 1 extends farther toward the back of the installation structure 2 .

[0058] Further, the area of the second side 24 parallel to the display structure 1 is greater than or equal to the area of the first side 23 .

Embodiment 3

[0060] In this embodiment, a welding method for an electrical display device, the electrical display device includes a display structure 1 and a mounting structure 2, the display structure 1 is ultrasonically welded on the mounting structure 2, the mounting structure 2 includes a mounting hole, the The display structure 1 is at least partially fitted in the installation hole, and the distance between the installation hole on the front of the installation structure 2 and the display structure 1 is smaller than the distance between the installation hole on the back of the installation structure 2 and the display structure 1 .

[0061] Compared with Embodiments 1 and 2, the difference is that the distance between the side of the installation hole corresponding to the display structure 1 and the display structure 1 gradually increases from the front of the installation structure 2 to its back.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com