CVT

A technology for transmissions and transmission housings, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., which can solve problems such as short life, high friction of CVT-transmissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

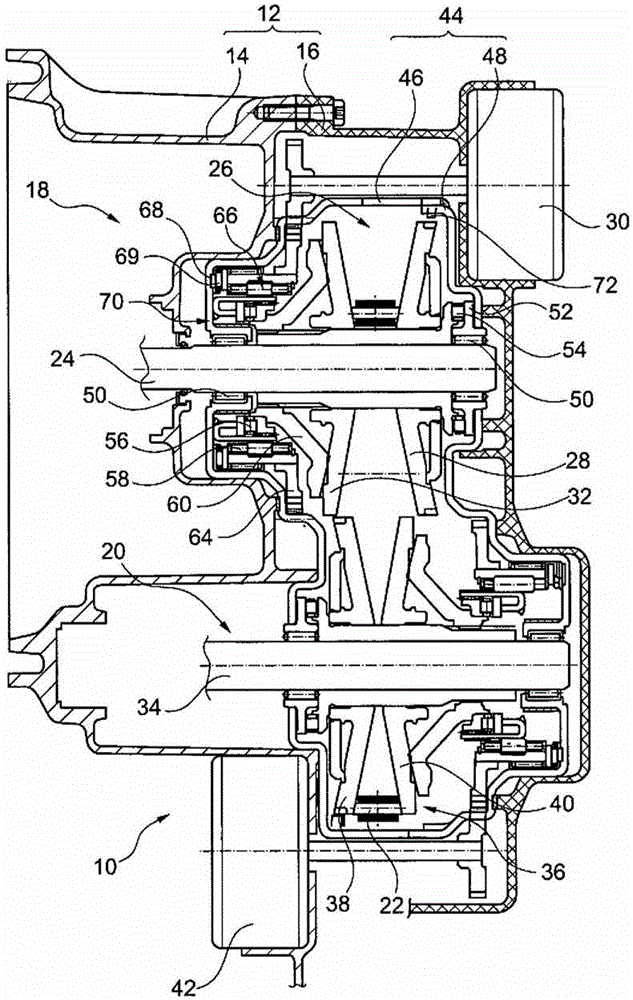

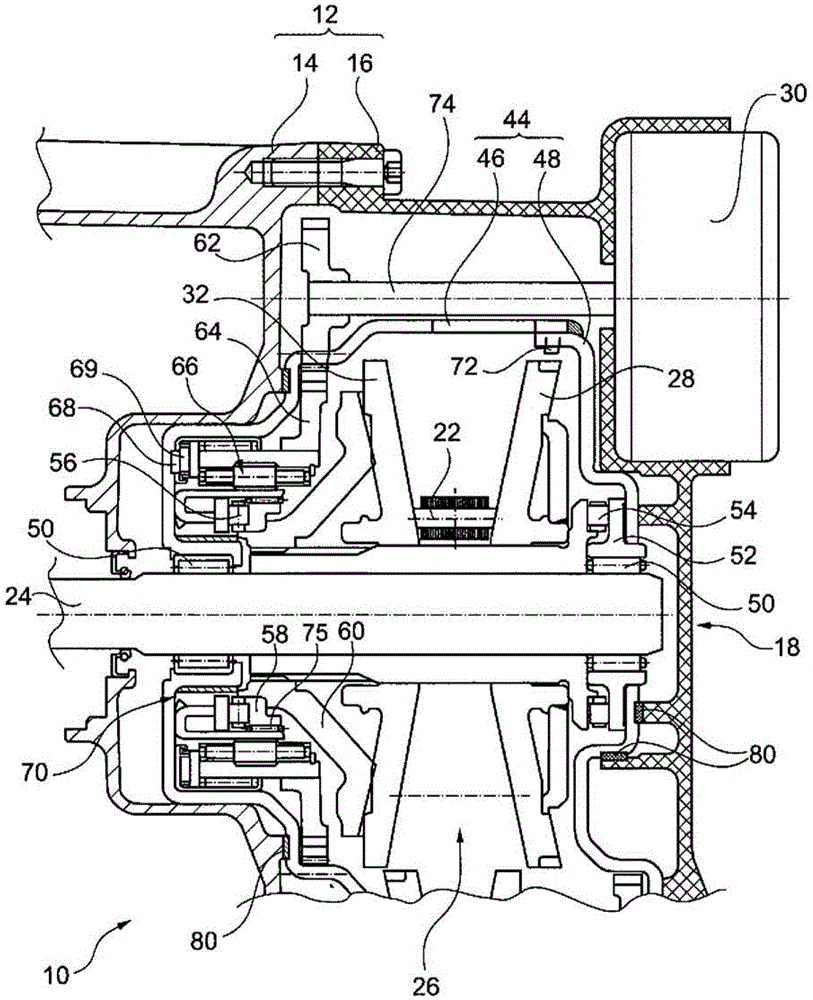

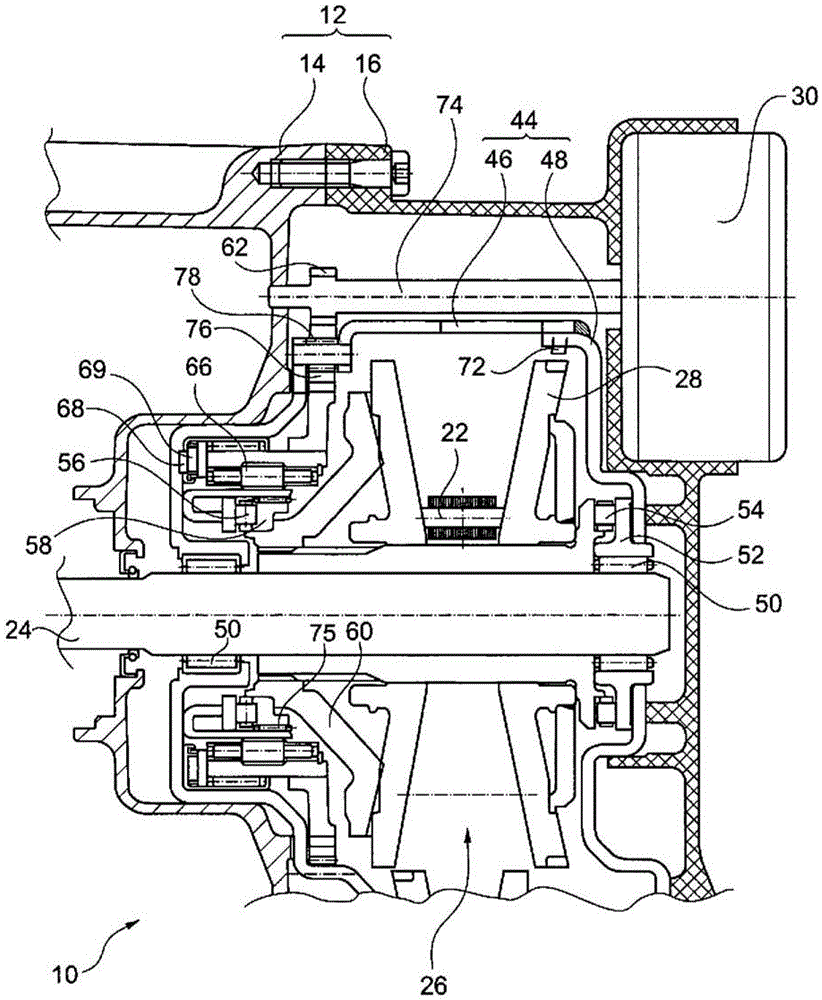

[0025] figure 1 The CVT transmission 10 shown in has a fluid-tight transmission housing 12, which in the illustrated embodiment consists of a first housing shell 14 and a second housing shell 16, which are screwed together . The first housing shell 14 and / or the second housing shell 16 can be produced from a plastic material. Inside the transmission housing 12 , a first variator 18 is arranged on the input side and a second variator 20 is arranged on the output side, which are coupled to one another via a flat-link chain 22 . The second variator 20 can be configured similarly to the first variator 18 , wherein the first variator 18 can be arranged in a mirror image relative to the second variator. The first variator 18 has an input shaft 24 which is connected to a first pair of cones 26 . The first conical disk pair 26 has a first counter disk 28 arranged immovably in the axial direction with respect to the input shaft 24, towards which a first adjusting disk 32 can be move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com